Given up on tremec 5 speed--advice on another idea

#41

Drifting

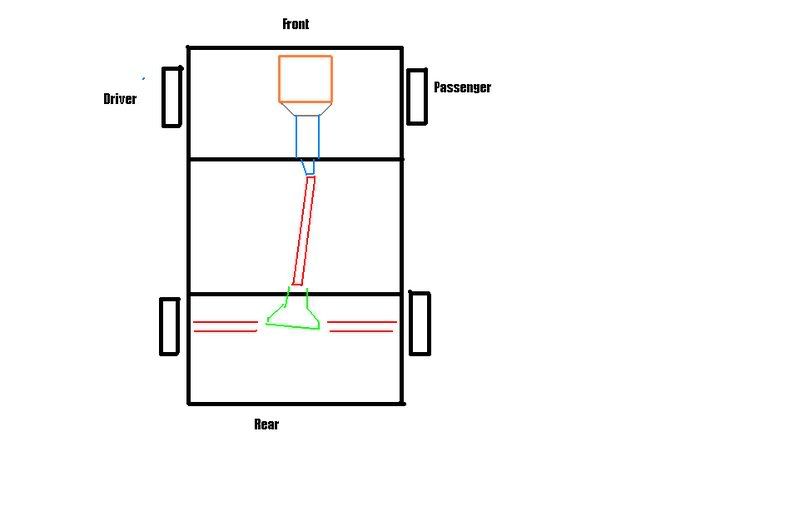

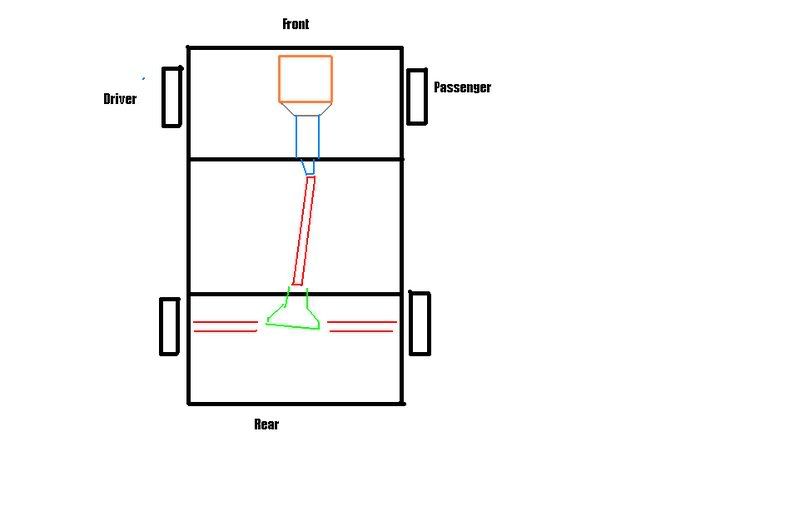

I remember reading a post a long time ago about the driveline angles and setup. I thought the engine was designed so it was not centered in the car from driver frame rail to passenger frame rail for better driveline geometry. I thought the Engine/trans was offset against the differential because under load the engine would torque to the driverside at which point the engine would line-up with the differential.

I could be off my rocker. I beleive TT had a diagram and explaination for this.

The transmission tail shaft could also be a little cocked towards the passenger side to help with the engine and driveline torque. We use bushings so there is flex when under torque load, I've never seen a solid tranmission mount. I beleive Norval bypassed the whole offset by reworking his engine mounts to center the engine and trans in the engine bay. Again, I could be smoking some good stuff and my memory is just messing with me.

It makes no sense to me why the differential would be crooked though. If the diff is crooked the the half shafts won't line up with the TA's and wheels and put major stress on the half shaft u-joints. Unless the differential tongue is also designed with a little slant to the front passenger side. I'm pretty sure the differential is centered between the drive and passenger frame rails. Whether or not the diff tongue is designed to point a little towards the passenger front tire to help with the driveshaft geometry until the engine is under load and centers itself.

I haven't spent enough time reading about driveline geometry on these cars to comment rock solid knowledge, these are just my opinon and what possiblities are running through my head.

Here's a shoty diagram, but it describes what ProSouth posted above.

I really don't think the diff was designed to be crooked.

Make sure your half shafts are parallel with the frame crossmember and your half shaft u-joints are not binded in any way.

I didn't study my 68's driveline geometry but I beleive to the naked eye my engine is pretty centered as well as my muncie, driveshaft and diff. I don't remember seeing my driveshaft at any wacky angles and I don't have any vibrations. Then again, I don't have a lift and anyway you crawl under the car on your back will give you a bias view of your driveline.

I could be off my rocker. I beleive TT had a diagram and explaination for this.

The transmission tail shaft could also be a little cocked towards the passenger side to help with the engine and driveline torque. We use bushings so there is flex when under torque load, I've never seen a solid tranmission mount. I beleive Norval bypassed the whole offset by reworking his engine mounts to center the engine and trans in the engine bay. Again, I could be smoking some good stuff and my memory is just messing with me.

It makes no sense to me why the differential would be crooked though. If the diff is crooked the the half shafts won't line up with the TA's and wheels and put major stress on the half shaft u-joints. Unless the differential tongue is also designed with a little slant to the front passenger side. I'm pretty sure the differential is centered between the drive and passenger frame rails. Whether or not the diff tongue is designed to point a little towards the passenger front tire to help with the driveshaft geometry until the engine is under load and centers itself.

I haven't spent enough time reading about driveline geometry on these cars to comment rock solid knowledge, these are just my opinon and what possiblities are running through my head.

Here's a shoty diagram, but it describes what ProSouth posted above.

I really don't think the diff was designed to be crooked.

Make sure your half shafts are parallel with the frame crossmember and your half shaft u-joints are not binded in any way.

I didn't study my 68's driveline geometry but I beleive to the naked eye my engine is pretty centered as well as my muncie, driveshaft and diff. I don't remember seeing my driveshaft at any wacky angles and I don't have any vibrations. Then again, I don't have a lift and anyway you crawl under the car on your back will give you a bias view of your driveline.

68NJ Conv454........If the driveshaft by design is supposed to be at an angle for proper U-Joint rotation to keep the needles uniformly moving, why wouldn't the same thing hold true for the half shafts?? They have U-joints at either end. Wonder if it's supposed to be offset as you show. ???

Also, if someone does the test as Clutchdust just described it would be interesting to see if there's any difference in the vibratioin by raising and lowering the angle of the trailing arms so that the halfshaft angles were different.

#43

Drifting

True for sure, just a thought. On a long trip on the highway they don't move much.

I have the same stuff going on with mine but not as severe. Mine seems more RPM related.............it starts to vibrate at 3500. It did it with my old L-48 and with this new motor as well. Everything from the radiator to the taillights has been replaced or rebuilt and it hasen't changed one bit! Did it with the Muncie and does it with the TKO500.

I have the same stuff going on with mine but not as severe. Mine seems more RPM related.............it starts to vibrate at 3500. It did it with my old L-48 and with this new motor as well. Everything from the radiator to the taillights has been replaced or rebuilt and it hasen't changed one bit! Did it with the Muncie and does it with the TKO500.

#44

Racer

Member Since: Dec 2004

Location: Wichita Kansas

Posts: 410

Likes: 0

Received 0 Likes

on

0 Posts

I've been watching this with interest. You might try reading this article see if it helps;

http://www.clubfte.com/users/jniolon...nephasing.html

http://www.clubfte.com/users/jniolon...nephasing.html

#45

Burning Brakes

I've been watching this with interest. You might try reading this article see if it helps;

http://www.clubfte.com/users/jniolon...nephasing.html

http://www.clubfte.com/users/jniolon...nephasing.html

I definitely have an issue with my angles, as the trans points down(towards rear) and my diff points down (towards front)

I haven't got much space left to raise the trans. The diff is pointing down by about 2 degrees ....

If I raise the front of diff to reduce the difference between the trans and diff vertical angle, I have been told that it affects rear traction.

I can visualise the problem of torque twist under accelleration on a fixed rear axle vehicle, but as our diffs are fixed in position... is this really a big issue? When compared to level ground, what is the ideal vertical angle for the diff.... and what would be the limit before it becomes an issue for a street car?

cheers

tom

#46

I first tried the Tremec 5 years ago in my 63 which was dead smooth with the muncie and 3.36 rear. After 3 winter months could not get the vibration out, back in goes the muncie and dead smooth.

Next winter buy another new Tremec (figure i just got a bad one) in and out a few times study and learn all I can about drive line vibration. Adjust everything. Same vibrations.

Put muncie back in smooth as silk. Have the Tremec factory rep take trans and go through it and check everything. Put back in and more vibration.

Son buys new Tremec puts it behind zz383 in his 73, We get it up higher in the tunnel so u joints and driveline is same as factory, what was a smooth car now vibrates but he is young and lives with it.

I put T5 in my 63 for 300 bucks and is smooth as silk and quiet from 0 to 135. I drive my 63 coast to coast and if it isn't smooth I wont drive it to the Sonic.

Just my 2 cents worth Jeff

Next winter buy another new Tremec (figure i just got a bad one) in and out a few times study and learn all I can about drive line vibration. Adjust everything. Same vibrations.

Put muncie back in smooth as silk. Have the Tremec factory rep take trans and go through it and check everything. Put back in and more vibration.

Son buys new Tremec puts it behind zz383 in his 73, We get it up higher in the tunnel so u joints and driveline is same as factory, what was a smooth car now vibrates but he is young and lives with it.

I put T5 in my 63 for 300 bucks and is smooth as silk and quiet from 0 to 135. I drive my 63 coast to coast and if it isn't smooth I wont drive it to the Sonic.

Just my 2 cents worth Jeff

#47

Burning Brakes

Well Jeff...

I think you've established a very strong case against the Tremec.

I wish I'd known about your experience before I undertook this project.

Then again, two fellow club members with original 4sp C3's (69 and 71) have just installed TKO-600's without any issues at all.

On his first lengthy run through the countryside, one the guys had to stop and get a toothbrush....... to get the bugs out of his teeth due to grinning so much!

I think you've established a very strong case against the Tremec.

I wish I'd known about your experience before I undertook this project.

Then again, two fellow club members with original 4sp C3's (69 and 71) have just installed TKO-600's without any issues at all.

On his first lengthy run through the countryside, one the guys had to stop and get a toothbrush....... to get the bugs out of his teeth due to grinning so much!

#48

Tom I am not against the Tremec, all I am saying is they just aren't as smooth as a muncie or borg warner. It pains me to see so many people go through all the same things I have gone through trying to smooth that transmission out.

I contend that the guys that are happy with the tremec tko, 500 or 600 either have loud side pipes, convertibles or the car was not smooth in the first place. My sons 73 is ok if you don't go far, it also has side pipes and is a convertible.

I contend that the guys that are happy with the tremec tko, 500 or 600 either have loud side pipes, convertibles or the car was not smooth in the first place. My sons 73 is ok if you don't go far, it also has side pipes and is a convertible.

#49

Drifting

Member Since: Feb 2002

Location: Manchester, Dead Center in the Middle of TN 25 miles to Jack Daniels,10 miles to Geo Dickle, and .8 mile from the Liquor Store at I-24 Exit 114

Posts: 1,987

Likes: 0

Received 2 Likes

on

2 Posts

St. Jude Donor '05

My point on the drive line angles being off in two directions was that it further complicates the zone of vibration. If it is down in the front and up in the rear and then to the left in the front and to the right in the rear even a little it ain't got a chance to be anything but a vibration nightmare.

I'm sure this is a worse case scenario but even with reasonable degrees in the up and down range, it would still be compromised by a minor left and right degree added to that.

I realize that this was not meant to be a smooth transmission and that it is somewhat a rock crusher style and yes I've driven a real rock crusher before. But I still feel that the trans can be tamed if the right combination of placement and angles are found.

It was a priority to me to run the car without the drive shaft to see if it had the vibration when contained to just the motor and transmission with out the rear half of the system and then attend to it if it wasn't.

I wouldn't expect the rear end system to have vibration if nothing else had been altered except for installing a new transmission. But the drive shaft can be changed drastically by the change of a couple of degrees due to the design differences and size of the unit by altering where the output shaft comes out in relation to the rear mount, hence changing the relationship to the rear chunk and compromising drive line angles.

It's gotta work, I have to much invested to go back now. I will mount the trans and string it in every direction if I have to and then cut the floor pan to fit it to get the body back on.

I'm sure this is a worse case scenario but even with reasonable degrees in the up and down range, it would still be compromised by a minor left and right degree added to that.

I realize that this was not meant to be a smooth transmission and that it is somewhat a rock crusher style and yes I've driven a real rock crusher before. But I still feel that the trans can be tamed if the right combination of placement and angles are found.

It was a priority to me to run the car without the drive shaft to see if it had the vibration when contained to just the motor and transmission with out the rear half of the system and then attend to it if it wasn't.

I wouldn't expect the rear end system to have vibration if nothing else had been altered except for installing a new transmission. But the drive shaft can be changed drastically by the change of a couple of degrees due to the design differences and size of the unit by altering where the output shaft comes out in relation to the rear mount, hence changing the relationship to the rear chunk and compromising drive line angles.

It's gotta work, I have to much invested to go back now. I will mount the trans and string it in every direction if I have to and then cut the floor pan to fit it to get the body back on.

#50

Team Owner

Member Since: Oct 2004

Location: Springfield MO

Posts: 23,831

Likes: 0

Received 6 Likes

on

6 Posts

St. Jude Donor '07

Tom I am not against the Tremec, all I am saying is they just aren't as smooth as a muncie or borg warner. It pains me to see so many people go through all the same things I have gone through trying to smooth that transmission out.

I contend that the guys that are happy with the tremec tko, 500 or 600 either have loud side pipes, convertibles or the car was not smooth in the first place. My sons 73 is ok if you don't go far, it also has side pipes and is a convertible.

I contend that the guys that are happy with the tremec tko, 500 or 600 either have loud side pipes, convertibles or the car was not smooth in the first place. My sons 73 is ok if you don't go far, it also has side pipes and is a convertible.

#51

#53

Silverslash, where did you get your T5? I've got side pipes and the vibration and rythmic hum I'm talking about is heard above the noise. I, too, have driven to the coast and back twice with mine and the trouble is just beyond me and the three shops I've been to.

#54

CFOT Attention Whore

i still say for those of us with higher rear gears (numerically lower), the richmond is a better selection. it would almost be pointless for someone to put together a kit to install this tranny. it uses the TH400 output yoke and requires relocation of the trans mount. other than that, only a small notch may or may not be required on the transmission tunnel to clear the shifter linkage.

i'm very happy with mine. and since it's just an evolution of the munchy/B-W, it's pretty solid.

again, since this is not an OD tranny i'd only recommend it for cars with 3.23:1 or lower gear.

i'm very happy with mine. and since it's just an evolution of the munchy/B-W, it's pretty solid.

again, since this is not an OD tranny i'd only recommend it for cars with 3.23:1 or lower gear.

#56

Burning Brakes

Jim, good article and it correlates with other info I've read.

I definitely have an issue with my angles, as the trans points down(towards rear) and my diff points down (towards front)

I haven't got much space left to raise the trans. The diff is pointing down by about 2 degrees ....

If I raise the front of diff to reduce the difference between the trans and diff vertical angle, I have been told that it affects rear traction.

I can visualise the problem of torque twist under accelleration on a fixed rear axle vehicle, but as our diffs are fixed in position... is this really a big issue? When compared to level ground, what is the ideal vertical angle for the diff.... and what would be the limit before it becomes an issue for a street car?

cheers

tom

I definitely have an issue with my angles, as the trans points down(towards rear) and my diff points down (towards front)

I haven't got much space left to raise the trans. The diff is pointing down by about 2 degrees ....

If I raise the front of diff to reduce the difference between the trans and diff vertical angle, I have been told that it affects rear traction.

I can visualise the problem of torque twist under accelleration on a fixed rear axle vehicle, but as our diffs are fixed in position... is this really a big issue? When compared to level ground, what is the ideal vertical angle for the diff.... and what would be the limit before it becomes an issue for a street car?

cheers

tom

Can anyone enlighten me on the optimal angles the diff should be set at... and if raised at the connection with the tailshaft, what effects would be noticed.

Mine is currently lower at the front of the diff, by about 2 degrees.

If I was to use a 20mm spacer on the front diff mount, it should rotate diff through about 4 degrees, and bring it closer to parallel with the transmission output shaft.

The diff would then be pointing 2degrees down towards the rear.....

Anyone have any advice on this?

tom

#57

CFOT Attention Whore

as i understand it, richmond has released a version using the same case (dimensions) that is an OD tranny for those of you who need it. may be something worth checking into.

#58

Melting Slicks

I have been watching this thread with great interest. I have also been working closely with the original poster to try and get the vibrations solved. Sorry to hear he is giving up on it but I guess you can only take so much...

To answer your question ozzytom....

In a perfect world, the tail should be at or above 0 and the pinion should be equal to the tail but oppositie. In other words, if you have a +2* on the tail housing, you need a -2* on the pinion.

When I do angles here at the shop, I check it in 3 places. 1. at the bottom of the tail housing near the end of it. 2. in the center of the driveshaft and 3. on the rear end pinion flange. None of those reading should exceed 5* and the difference between any of the readings cannot vary by more than 3*.

Setting driveline angles is probably the hardest, most time consuming part of a transmission install. What I like to do when doing a swap is take a measurement from the center of the output shaft up to the tunnel on the original transmission before removing it and then once the new transmission is installed, refer back to that measurement and try to duplicate it as close as possible. The only hitch is in my suggestion is the Muncie is about 2.250" shorter than the TKO but you can certainly get really close as 2.250" isn't that much of a difference.

I hope this helps answer your question ozzytom....I will continue to follw this thread and chime in if I can think I can add something worthwhile.

gavonm....I hope you decide to continue to work through it and remember, I am still here and still willing to help you on it. You have my number, call me if you'd like. I am still willing to have you send it to me and let me spin it up on our tranny dyno. If there is something inside the gearbox causing the vibration, it will find it.

Richard

Tech Support

Keisler Engineering

#59

Thanks, Richard, for chiming in. Will keep you advised how we come out. As you already read, the 3" driveshaft did not solve the problem. May take you up on the in-house testing offer. Are you anywhere close to the Jack Daniels distillery? I'm not much of a drinking man, but this project is starting to make that sound pretty good...

#60

Burning Brakes

Thanks for the info Richard..... wish I was closer to take up your offer too of the tranny dyno. I haven't given up hope yet .....

You didn't answer my question though.....

These are the angles from horizontal plane, going from front to rear....

I have -2.5* at trans,

-0.5* at tailshaft

+1.5 degrees at diff.

trans and diff are NOT even close to parallel ... 4* difference!!!

What I want to do is improve alignment of the diff with the trans (make parallel) possibly achieve about -1.5* by lifting the diff at the front diff mount by ~20~25mm.

this might then provide the following results (hopefully)

-2.5* at trans,

0.5* at tailshaft

-1.5* at diff

This would improve trans~diff alignment to within 1*.

In doing this though, I want to know if there is any compromise to handling / traction .... that is, raising the front of the diff by ~25mm ?

Some posters have stated traction would be affected by this procedure ???? not sure about this?

Are there any other issues with raising the front of the diff?

any responses would be appreciated.

You didn't answer my question though.....

These are the angles from horizontal plane, going from front to rear....

I have -2.5* at trans,

-0.5* at tailshaft

+1.5 degrees at diff.

trans and diff are NOT even close to parallel ... 4* difference!!!

What I want to do is improve alignment of the diff with the trans (make parallel) possibly achieve about -1.5* by lifting the diff at the front diff mount by ~20~25mm.

this might then provide the following results (hopefully)

-2.5* at trans,

0.5* at tailshaft

-1.5* at diff

This would improve trans~diff alignment to within 1*.

In doing this though, I want to know if there is any compromise to handling / traction .... that is, raising the front of the diff by ~25mm ?

Some posters have stated traction would be affected by this procedure ???? not sure about this?

Are there any other issues with raising the front of the diff?

any responses would be appreciated.

Last edited by OzzyTom; 01-14-2008 at 04:46 PM.