350 block 10066036, is this a high nickel block?

#41

Burning Brakes

Member Since: Aug 2005

Location: Europe, France

Posts: 1,164

Likes: 0

Received 0 Likes

on

0 Posts

cast iron : 1% tin / 2% nickel.

Even stainless steel doesn't contain 20% nickel, only about 10% nickel and 18% chrome.

About the purpose of the tin, here's an interesting article :

http://www.springerlink.com/content/k58407663733k5h5/

Last edited by 73StreetRace; 05-07-2010 at 05:10 AM.

#42

Drifting

"The single message I'm trying to get across is that the presence of high tin/nickel is not 100% connected to the presence of the 010 020 markings."

If that's true, a lot of folks have shelled out extra money just to have one.

I quit looking for the 010/020 blocks a long time ago, I'd much rather find one with the 2482 caps

If that's true, a lot of folks have shelled out extra money just to have one.

I quit looking for the 010/020 blocks a long time ago, I'd much rather find one with the 2482 caps

#45

Cruising

Member Since: Oct 2003

Location: Chatsworth California

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

Hello all. Just thought I'd donate my 2 cent to the thread.

To Mike Ward. In all due respect, I'd have to disagree with you regarding the hard seats vs. std. seats. GM induction hardend the seats on the late model heads because of the unleaded fuel & leaner air/fuel ratios. And I can tell you from 35 years of personal experience, every motor I've taken apart that had std seats in it with stainless or hard valves ended up with leaking seats. Some performance engines even ended up with metal transfer if it was a feedback car with a closed loop system (since they run right at stoichiometric). A 383 I just took apart had 15K hard miles on it & all the exhaust seats were leaking. Its simple metallurgy. When you have a hard material & a soft one, the soft one usually gives up & transfers onto the hard one. Especially under heat, combustion & other elements.

As far as blocks go, again....I can tell you from working in machine shops since I was a kid (my dads was an aerospace machinist) that those early blocks are a ****** to machine vs. the later blocks. You can break off an ear of the two blocks & actually see how the metal was foundried. The later ones are much more pourous. I'm sure if you were to rockewell test the two, you'd find that the earlier blocks are much harder. I know they're heavier & you can see the oil pan rails & main webbings are much more thicker. When it comes to blocks, it just boils down to how much abuse you're going to put it though.

Case in point....

I build a blown 5.0 mustang for a guy once. This thing made a lot of power for just being a stock block 5.0. One day we were driving along doing some tuning when he got on it, the motor backfired & then shut off. We pulled over & saw a coolant leak at the front of the motor. It didn't want to turn over. Once we got it back to the shop & tore down the motor, we found the block had given way & the crank tried to errupt from the front of the engine. The block was split right down the center. I think we found the outer limits of that Ford block. Haha! But my point is (to the O.P.), the early vs. late, high nickle vs. lower is all relative. It really only matters on what you're doing with it. For a mild street motor up to 400 HP or so, the late model block will be just fine if thats all you got to work with. What much more important is to make sure you bore & hone it with a torque plate. Make sure the main saddles are straight. Make sure the blocks been magged well & you might even want to sonic check it just to make sure you don't have a bad core shift or a thin wall spot. But otherwise, just good machine work (round, no barrel shaping or taper) & checking all your tolerances will net you a good piece that will last you a long time.

To Mike Ward. In all due respect, I'd have to disagree with you regarding the hard seats vs. std. seats. GM induction hardend the seats on the late model heads because of the unleaded fuel & leaner air/fuel ratios. And I can tell you from 35 years of personal experience, every motor I've taken apart that had std seats in it with stainless or hard valves ended up with leaking seats. Some performance engines even ended up with metal transfer if it was a feedback car with a closed loop system (since they run right at stoichiometric). A 383 I just took apart had 15K hard miles on it & all the exhaust seats were leaking. Its simple metallurgy. When you have a hard material & a soft one, the soft one usually gives up & transfers onto the hard one. Especially under heat, combustion & other elements.

As far as blocks go, again....I can tell you from working in machine shops since I was a kid (my dads was an aerospace machinist) that those early blocks are a ****** to machine vs. the later blocks. You can break off an ear of the two blocks & actually see how the metal was foundried. The later ones are much more pourous. I'm sure if you were to rockewell test the two, you'd find that the earlier blocks are much harder. I know they're heavier & you can see the oil pan rails & main webbings are much more thicker. When it comes to blocks, it just boils down to how much abuse you're going to put it though.

Case in point....

I build a blown 5.0 mustang for a guy once. This thing made a lot of power for just being a stock block 5.0. One day we were driving along doing some tuning when he got on it, the motor backfired & then shut off. We pulled over & saw a coolant leak at the front of the motor. It didn't want to turn over. Once we got it back to the shop & tore down the motor, we found the block had given way & the crank tried to errupt from the front of the engine. The block was split right down the center. I think we found the outer limits of that Ford block. Haha! But my point is (to the O.P.), the early vs. late, high nickle vs. lower is all relative. It really only matters on what you're doing with it. For a mild street motor up to 400 HP or so, the late model block will be just fine if thats all you got to work with. What much more important is to make sure you bore & hone it with a torque plate. Make sure the main saddles are straight. Make sure the blocks been magged well & you might even want to sonic check it just to make sure you don't have a bad core shift or a thin wall spot. But otherwise, just good machine work (round, no barrel shaping or taper) & checking all your tolerances will net you a good piece that will last you a long time.

Last edited by JSAautomotive; 12-30-2010 at 01:20 PM.

#46

Drifting

Member Since: Jul 2000

Location: Melbourne Australia

Posts: 1,347

Likes: 0

Received 0 Likes

on

0 Posts

#48

#50

Drifting

Blocks are not one big cast. Each pair of cyls. are a cast as are the front and back. They are then cast together as a unit. That is why the lip around the cam bearing holes are not always exact, and can be different as the cyl. pairs go through the block. Often thought to br core shift. If not within spec the block is scrapped. I have photos that, if I can still find them, I could post.

It makes sence that the parts be identified by the 010 so to get the correct parts cast together.

Those holes in the sides, commomly called freeze out plugs or holes are really casting holes and are to get the sand out of the sand casting.

As far as the high nickel blocks go, until I see someone with the lab results I can only go by what I've seen. While boring the 010 block it sounds like any other block as the cutter goes through the cyl. The cyl. walls look like any other block.

The 509 blocks, both the 350 and 400, have a higher pitch as the cutter goes through the cyl. The finished fresh cut cylinder walls have a brighter look.

There are 010 blocks that also have 509 cast into them but most do not. Therefore I'd suspect the 509 has some importance.

The Ford mexico small blocks, also thought to be high nickel, have a similar sound and luster as the Chev. 509 blocks.

Therefore my opinion, until prooven incorrect, is the Chev. blocks 010 are so the correct parts are cast into the final assembly and that the 509 casting indicates a different formula of metal that I suspect as being the high nickel.

It makes sence that the parts be identified by the 010 so to get the correct parts cast together.

Those holes in the sides, commomly called freeze out plugs or holes are really casting holes and are to get the sand out of the sand casting.

As far as the high nickel blocks go, until I see someone with the lab results I can only go by what I've seen. While boring the 010 block it sounds like any other block as the cutter goes through the cyl. The cyl. walls look like any other block.

The 509 blocks, both the 350 and 400, have a higher pitch as the cutter goes through the cyl. The finished fresh cut cylinder walls have a brighter look.

There are 010 blocks that also have 509 cast into them but most do not. Therefore I'd suspect the 509 has some importance.

The Ford mexico small blocks, also thought to be high nickel, have a similar sound and luster as the Chev. 509 blocks.

Therefore my opinion, until prooven incorrect, is the Chev. blocks 010 are so the correct parts are cast into the final assembly and that the 509 casting indicates a different formula of metal that I suspect as being the high nickel.

#51

The story related by Brain Berry mirrors what I was told verbally.

#52

Drifting

Anyone interested in the 010 blocks under the impression they are high nickel, there are 50 or 60 in my core building. I'd sell anyone one of them, not machined, for $300. Just not the 010 with the 509 also. I'd guess there are more 010 blocks than any other cast number in 350/4" bore. Not that I'm trying to sell them, as they are worth more to me as builds than bare blocks, just that they are plentiful. Therefore I don't think they are special.

#53

Advanced

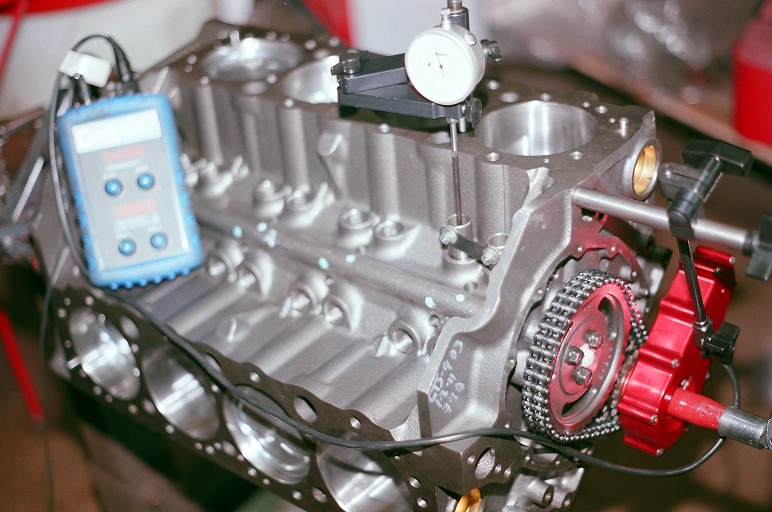

It appears to me to be every bit as stout as any factory production car block and perhaps even a bit better. I'd go so far as to suggest that a modern casting facility and modern machining probably produce better overall quality than what we could obtain in the 60s and 70s regardless of locality where produced.

Considering the remainder of the content found in replies to this thread, there are no 010 or 020 (either/or) found under the timing cover. There is a '10' but I couldn't say what it means, if anything.

The oil galleys above the cam were, as received, slightly misaligned. I've seen much worse on production engines, but overall, I'd say that the part is every bit as worthy of a high performance project as any decent condition production car block; possibly more so.

I have absolutely no fear using it for my ~430 HP street/strip use.

MxB

#54

I have two blocks with 010, 020 in the bell housing area with a 10 over the top of 20 in the timing chain one of them has 2482 caps. A third block without 10,20

Where is this 509 mentioned located at ?

Where is this 509 mentioned located at ?

Last edited by Little Mouse; 05-20-2012 at 05:59 PM.

#55

Drifting

In the tining cover area. The majority of 350 blocks are 010 blocks. The 509s are fewer. They seem to be in demand. They do look and sound different when being bored than do most of the rest.

There is a 400 sbc that has a casting number ending in 509. Not same issue.

There is a 400 sbc that has a casting number ending in 509. Not same issue.

#56

Advanced

...my 72yo machinist and engine builder tells me that he "likes" this block...and we searched through probably a dozen factory "seasoned" blocks before deciding on this PN: 10066036 one that is made in Mexico.

MxB

#57

Team Owner

Member Since: Oct 2004

Location: altered state

Posts: 81,242

Received 3,043 Likes

on

2,602 Posts

St. Jude Donor '05

NO. Im using one in a higher hp build that sees plenty of rpm and had no issues. As said the whole "high nickel" thing is so overrated its not even funny. The car will run and last the same.

PLUS you get a new block without worn out lifter bores threads that are old and weak, etc. Nothing like brand spankin new!!

Who wants to build on something thats seen god how many miles, machining, fubars, etc. I dont. "seasoned block" to me means really damn old and worn out lol .

[QUOTE]CF Senior Member

Garage is empty, add now

My Corvette Photos

Member Since: Apr 2003

Location: Castle Hills Texas

Default

Because people like to sound like they got something cool and rare. It means nothing really.

Ill take a block from modern tooling/casting any day over something from 30+ yrs ago.

PLUS you get a new block without worn out lifter bores threads that are old and weak, etc. Nothing like brand spankin new!!

Who wants to build on something thats seen god how many miles, machining, fubars, etc. I dont. "seasoned block" to me means really damn old and worn out lol .

[QUOTE]CF Senior Member

Garage is empty, add now

My Corvette Photos

Member Since: Apr 2003

Location: Castle Hills Texas

Default

Why is a high nickel count block so coveted, out of curiosity

Ill take a block from modern tooling/casting any day over something from 30+ yrs ago.

Last edited by cv67; 08-05-2012 at 09:10 PM.

#59

Again with the chip on your shoulder.

A former GM employee who worked at the foundry came forward and confirmed that the 010 020 numbers had no connection to a high nickel or tin content. No connection. Another GM employee came forward and offered that while these blocks do exist, the extra % of nickel and tin is in the 1/10s of a percent- and was done to address high field warranty costs. The program ended with no positive results being shown.

Please show me GM documents to prove me wrong and I will retract my post. Same goes for the burnt valves seats myth.

A former GM employee who worked at the foundry came forward and confirmed that the 010 020 numbers had no connection to a high nickel or tin content. No connection. Another GM employee came forward and offered that while these blocks do exist, the extra % of nickel and tin is in the 1/10s of a percent- and was done to address high field warranty costs. The program ended with no positive results being shown.

Please show me GM documents to prove me wrong and I will retract my post. Same goes for the burnt valves seats myth.

#60

Le Mans Master