598 cid and 4-link Stingray Build

#22

Advanced

Thread Starter

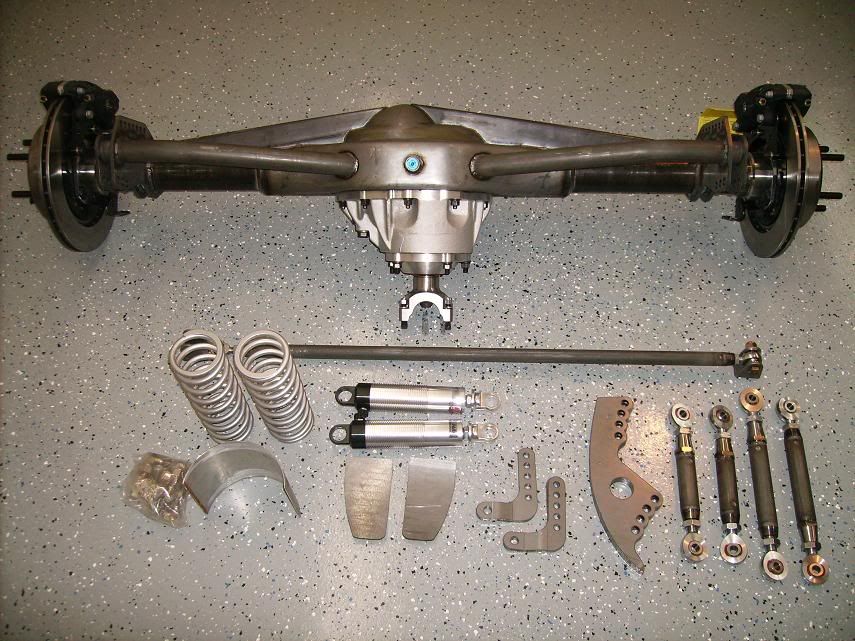

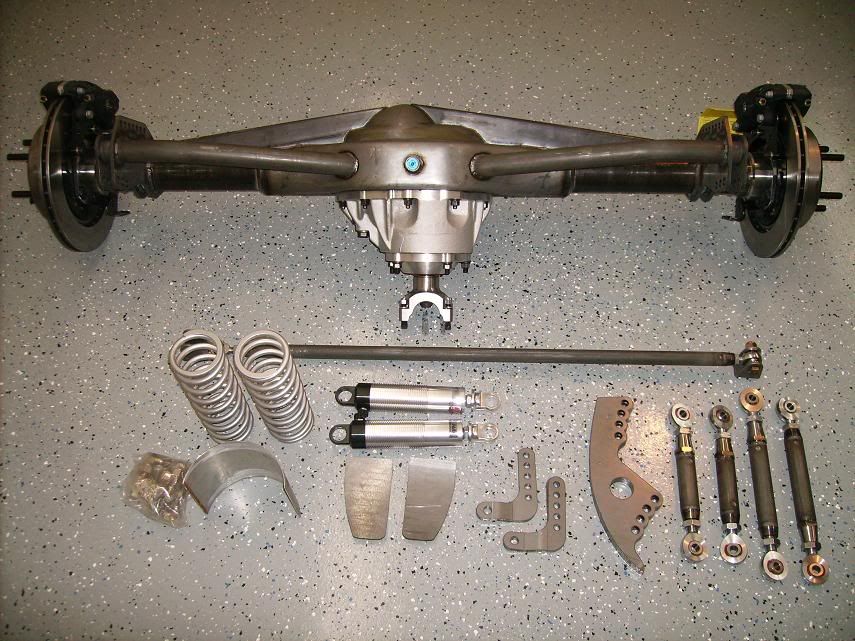

Pics of the Autofab parts.....

The only two problems are that we are missing one of the heim joint spacers and one of the link bar welds is cracking out. Neither are a big deal. We'll just call Josh for the missing spacer and run another pass over the cracked weld.

The only two problems are that we are missing one of the heim joint spacers and one of the link bar welds is cracking out. Neither are a big deal. We'll just call Josh for the missing spacer and run another pass over the cracked weld.

#23

Advanced

Thread Starter

Specs on the axle....

- 3.50 Gearset with EDM backcut to lighten the ring gear

- Aluminum center section

- Aluminum pinion support

- 1350 series yolk

- 35 spline gun-drilled axles with lightening holes driled in the faces

- Wave Track Posi

- Back brace

- 3" long, 1/2" diameter studs

Let the shenanigans begin!

- 3.50 Gearset with EDM backcut to lighten the ring gear

- Aluminum center section

- Aluminum pinion support

- 1350 series yolk

- 35 spline gun-drilled axles with lightening holes driled in the faces

- Wave Track Posi

- Back brace

- 3" long, 1/2" diameter studs

Let the shenanigans begin!

#24

Advanced

Thread Starter

Hope that doesn't happen to us! Regardless, I'm seeing a roll bar in the very near future.....

#25

Pro

What's the flange to flange width on that rear end? Also what are your plans for the stock rear end? I'm contemplating starting this swap and it would be nice to offset some of the expense by selling the stock rear. Do you think that would bring the most return by selling it complete or parting out?

#27

Advanced

Thread Starter

Well, goings were slow today, but we got some good work done. The control arm holes are plated and the 4-link brackets are in. Hopefully tomorrow we'll get the axle in place and the shock mounts welded in.

#28

Advanced

Thread Starter

What's the flange to flange width on that rear end? Also what are your plans for the stock rear end? I'm contemplating starting this swap and it would be nice to offset some of the expense by selling the stock rear. Do you think that would bring the most return by selling it complete or parting out?

#29

Advanced

Thread Starter

The Nova actually has a rotary engine....bring on the flames!

http://www.youtube.com/watch?v=-SBpIwKfjps

http://www.youtube.com/watch?v=-SBpIwKfjps

#33

Advanced

Thread Starter

#34

Melting Slicks

Member Since: Feb 2006

Location: Mo

Posts: 2,209

Likes: 0

Received 0 Likes

on

0 Posts

The Nova actually has a rotary engine....bring on the flames!

http://www.youtube.com/watch?v=-SBpIwKfjps

http://www.youtube.com/watch?v=-SBpIwKfjps

#36

Advanced

Thread Starter

Well, we made some more progress today. We got the axle mocked in place and cut the fiberglass to accomodate the center section. It needs to be trimmed a little higher, but the way we are cutting it is very sanitary looking and should be very easy to create a template to fiberglass it back in. One thing we couldn't find were the shock mount tabs. We'll ask Josh at Autofab about it tomorrow. We decided not to relieve the center crossmember the way the instructions said. We cut a section out of the crossmember and are going to create our own loop instead. TIG welding in their piece would have been a nightmare and would have resulted in some welds I wouldn't be proud of.

#38

Burning Brakes

And your welds look great!

-Patrick

#39

Race Director

Member Since: Jan 2000

Location: Corsicana, Tx

Posts: 12,607

Received 1,875 Likes

on

913 Posts

2020 C2 of the Year - Modified Winner

2020 Corvette of the Year (performance mods)

C2 of Year Winner (performance mods) 2019

2017 C2 of Year Finalist

I have a 2-3/4" x .134" wall driveshaft in mine. With 1350's on both ends.

And yes....your welding is definitely nice stuff!

JIM

And yes....your welding is definitely nice stuff!

JIM