Can you help with 383ci engine build?

#21

Team Owner

That is why you buy a matched rotating set. You have nice pistons and a cheap crank. I would just put a few more $100 dollars into a 4340 forged crank made for 6 inch rods.

Those shorty non performace headers wer $695. You could have bought Coated Hooker Super Comps for the same price or even those 1 7/8the stainless headers

Those shorty non performace headers wer $695. You could have bought Coated Hooker Super Comps for the same price or even those 1 7/8the stainless headers

#22

Burning Brakes

Thread Starter

That is why you buy a matched rotating set. You have nice pistons and a cheap crank. I would just put a few more $100 dollars into a 4340 forged crank made for 6 inch rods.

Last edited by C3Paul; 05-09-2011 at 08:54 AM.

#23

Team Owner

You said that you have the UK Scat rep. Exchange your cast crank for a internally balanced 4340 Scat crank made for 6 inch rods.

I've got to run for the day. Off to pick up some cars returning by ship from the races leading up to the Australian F1 event.

I've got to run for the day. Off to pick up some cars returning by ship from the races leading up to the Australian F1 event.

#24

Burning Brakes

Thread Starter

Just checked with Scat UK and was told that ALL 1pc rear cranks, even the 4340 FORGED staff is balanced the same way as my existing 935060L crank.

That is Internal front/External rear.

Please look at this catalogue: http://www.scatcrankshafts.com/catalogs/2011/24-45.pdf

I think I need to stress that this is going to be 1pc rear Roller block, not the 2pc pre 87 block.

Paul

That is Internal front/External rear.

Please look at this catalogue: http://www.scatcrankshafts.com/catalogs/2011/24-45.pdf

I think I need to stress that this is going to be 1pc rear Roller block, not the 2pc pre 87 block.

Paul

#25

Drifting

[IMG]

[/IMG]

[/IMG]

#26

Team Owner

Member Since: Oct 2004

Location: altered state

Posts: 81,242

Received 3,043 Likes

on

2,602 Posts

St. Jude Donor '05

Polished a number of them myself, really its not necessary. (sure looks bitchin though lol) The oil will drain down fine and only pool up so far before it hits the return holes. Oil pump shoots the same amount up no matter what. The rear oil return hole on the head if it appears smallish might work that a slight bit thats all .Those shavings get everywhere, clean clean and clean again. And again.

Last one I left alone plugged the holes by the cam, screened and epoxied the rest. To each their own.

The team G is a pretty decent manifold with very little diff if any in tq to the performer rpm. It will take off from about 5k or so on a stroker.

Either way they will both work very well. If you need more tq down low get a used one off ebay. Should be lots of fun.

Last one I left alone plugged the holes by the cam, screened and epoxied the rest. To each their own.

The team G is a pretty decent manifold with very little diff if any in tq to the performer rpm. It will take off from about 5k or so on a stroker.

Either way they will both work very well. If you need more tq down low get a used one off ebay. Should be lots of fun.

#27

lol you guys are pretty funny about all the smoothing and polishing as if its some 10000 rpm motor that needs a dry sump and has serious oiling demands. COME on really???? his engine with that tiny cam wont see 6000 rpm. waste of time in my opinion.

#28

nice work! but very unnessary. I dont think any engine builder would get away with charging 25 hours @ $75-90 per to polish up a stock 350 block in a street motor.

#29

Drifting

Hi, I really need your help on this one.

I spoke to Scat Dealer here in the UK and he is happy to take my crank and exchange it for the 935050L crank.

BUT,

He is saying that it will be lot more difficult to balance the 935050L crank with the 6” rod, because the counter weights in this crank are smaller and he is advising against adding weight to balance the crank.

Apparently I will be better off to keep my existing crank and take away weight to internally balance the crank.

Something to do with BOB weight?

This 935060L crank is asking for INTERNAL front balancer and EXTERNAL Flywheel

This is link to the Scat catalogue PAGE 2 : http://www.scatcrankshafts.com/catalogs/2011/24-45.pdf

935050L *Balances at 1830 to 1850 grams with std weighted flywheel , neutral std balancer & one piece mallary in counterweight 1

Help

I spoke to Scat Dealer here in the UK and he is happy to take my crank and exchange it for the 935050L crank.

BUT,

He is saying that it will be lot more difficult to balance the 935050L crank with the 6” rod, because the counter weights in this crank are smaller and he is advising against adding weight to balance the crank.

Apparently I will be better off to keep my existing crank and take away weight to internally balance the crank.

Something to do with BOB weight?

This 935060L crank is asking for INTERNAL front balancer and EXTERNAL Flywheel

This is link to the Scat catalogue PAGE 2 : http://www.scatcrankshafts.com/catalogs/2011/24-45.pdf

935050L *Balances at 1830 to 1850 grams with std weighted flywheel , neutral std balancer & one piece mallary in counterweight 1

Help

I am pretty sure your bob weight will be under 1800 grams.

#30

Burning Brakes

Thread Starter

Hi,

Forgive me for being ignorant, but I am still confused about this crank.

The 935050L is 1pc rear crank, but to Internally balance this crank I will have to add weight to the #1 counterweight, right?

935060L crank (The one I have) is 1 pc rear crank but to balance this crank I will need Internal front balancer and External flywheel.

BTW: All 4340 Forged 1 pc cranks have to be balanced with Internal front and External rear!!!!

Scat catalogue page #3 http://www.scatcrankshafts.com/catalogs/2011/24-45.pdf

What would happen if I was going to use Internally balanced flywheel on the 935060L crank?

Surely the counterweights are much larger in the 935060L crank so it should have enough of weight to Internally balance this assembly?

Paul

Forgive me for being ignorant, but I am still confused about this crank.

The 935050L is 1pc rear crank, but to Internally balance this crank I will have to add weight to the #1 counterweight, right?

935060L crank (The one I have) is 1 pc rear crank but to balance this crank I will need Internal front balancer and External flywheel.

BTW: All 4340 Forged 1 pc cranks have to be balanced with Internal front and External rear!!!!

Scat catalogue page #3 http://www.scatcrankshafts.com/catalogs/2011/24-45.pdf

What would happen if I was going to use Internally balanced flywheel on the 935060L crank?

Surely the counterweights are much larger in the 935060L crank so it should have enough of weight to Internally balance this assembly?

Paul

Last edited by C3Paul; 05-10-2011 at 05:52 AM.

#31

Drifting

Hi,

Forgive me for being ignorant, but I am still confused about this crank.

The 935050L is 1pc rear crank, but to Internally balance this crank I will have to add weight to the #1 counterweight, right?

935060L crank (The one I have) is 1 pc rear crank but to balance this crank I will need Internal front balancer and External flywheel.

BTW: All 4340 Forged 1 pc cranks have to be balanced with Internal front and External rear!!!!

Scat catalogue page #3 http://www.scatcrankshafts.com/catalogs/2011/24-45.pdf

What would happen if I was going to use Internally balanced flywheel on the 935060L crank?

Surely the counterweights are much larger in the 935060L crank so it should have enough of weight to Internally balance this assembly?

Paul

Forgive me for being ignorant, but I am still confused about this crank.

The 935050L is 1pc rear crank, but to Internally balance this crank I will have to add weight to the #1 counterweight, right?

935060L crank (The one I have) is 1 pc rear crank but to balance this crank I will need Internal front balancer and External flywheel.

BTW: All 4340 Forged 1 pc cranks have to be balanced with Internal front and External rear!!!!

Scat catalogue page #3 http://www.scatcrankshafts.com/catalogs/2011/24-45.pdf

What would happen if I was going to use Internally balanced flywheel on the 935060L crank?

Surely the counterweights are much larger in the 935060L crank so it should have enough of weight to Internally balance this assembly?

Paul

If you want an internally balanced assembley buy a 2 piece rear seal crank and buy the seal adaptor for your pan and you should be fine.

P.S.

We use alot of the one peice seal blocks with 2 peice rear seal cranks over the years with no problems.

#32

Drifting

When you pick the opinions you want to listen to, Take a harder look toward the opinions that include detail.

The machinist that does your balance will help you with the details. You'll be fine, you seem to be overly concerned. Enjoy your build. As far as the polishing goes. It is enjoyable to owners to put their mark and efforts into the little extra things with their engines. If you like it polished go for it.

It does reduce the total surface area, but not enough to be an issue about anything. The oil will drain faster, but it will spend less time absorbing heat in the process.

Still it's a street motor so not an issue.

You have your parts that are in your price range so enjoy and learn from your build. Everybody would like to be dropping in a Dart Little M with a set of Oliver rods and on and on and on, but that isn't the case for most folks.

You can build an engine that can remove the pleasure from your Vette, don't do that unless it's your thing, and speed and power are your goal.

Like Blockman said, it's the bob weight that will tell you where you are. It's not the end of the world if it would be external either.

If you think the polishing above is a lot, checkout a lightened Dart little circle track block. The exterior has maybe 29 to 30 pounds ground off.

The machinist that does your balance will help you with the details. You'll be fine, you seem to be overly concerned. Enjoy your build. As far as the polishing goes. It is enjoyable to owners to put their mark and efforts into the little extra things with their engines. If you like it polished go for it.

It does reduce the total surface area, but not enough to be an issue about anything. The oil will drain faster, but it will spend less time absorbing heat in the process.

Still it's a street motor so not an issue.

You have your parts that are in your price range so enjoy and learn from your build. Everybody would like to be dropping in a Dart Little M with a set of Oliver rods and on and on and on, but that isn't the case for most folks.

You can build an engine that can remove the pleasure from your Vette, don't do that unless it's your thing, and speed and power are your goal.

Like Blockman said, it's the bob weight that will tell you where you are. It's not the end of the world if it would be external either.

If you think the polishing above is a lot, checkout a lightened Dart little circle track block. The exterior has maybe 29 to 30 pounds ground off.

#33

Drifting

When you pick the opinions you want to listen to, Take a harder look toward the opinions that include detail.

The machinist that does your balance will help you with the details. You'll be fine, you seem to be overly concerned. Enjoy your build. As far as the polishing goes. It is enjoyable to owners to put their mark and efforts into the little extra things with their engines. If you like it polished go for it.

It does reduce the total surface area, but not enough to be an issue about anything. The oil will drain faster, but it will spend less time absorbing heat in the process.

Still it's a street motor so not an issue.

You have your parts that are in your price range so enjoy and learn from your build. Everybody would like to be dropping in a Dart Little M with a set of Oliver rods and on and on and on, but that isn't the case for most folks.

You can build an engine that can remove the pleasure from your Vette, don't do that unless it's your thing, and speed and power are your goal.

Like Blockman said, it's the bob weight that will tell you where you are. It's not the end of the world if it would be external either.

If you think the polishing above is a lot, checkout a lightened Dart little circle track block. The exterior has maybe 29 to 30 pounds ground off.

The machinist that does your balance will help you with the details. You'll be fine, you seem to be overly concerned. Enjoy your build. As far as the polishing goes. It is enjoyable to owners to put their mark and efforts into the little extra things with their engines. If you like it polished go for it.

It does reduce the total surface area, but not enough to be an issue about anything. The oil will drain faster, but it will spend less time absorbing heat in the process.

Still it's a street motor so not an issue.

You have your parts that are in your price range so enjoy and learn from your build. Everybody would like to be dropping in a Dart Little M with a set of Oliver rods and on and on and on, but that isn't the case for most folks.

You can build an engine that can remove the pleasure from your Vette, don't do that unless it's your thing, and speed and power are your goal.

Like Blockman said, it's the bob weight that will tell you where you are. It's not the end of the world if it would be external either.

If you think the polishing above is a lot, checkout a lightened Dart little circle track block. The exterior has maybe 29 to 30 pounds ground off.

checkout a lightened Dart little circle track block. The exterior has maybe 29 to 30 pounds ground off

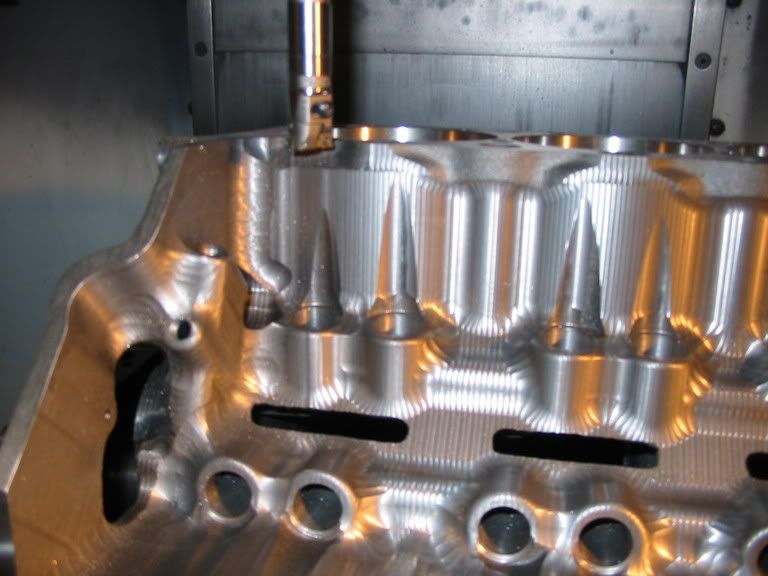

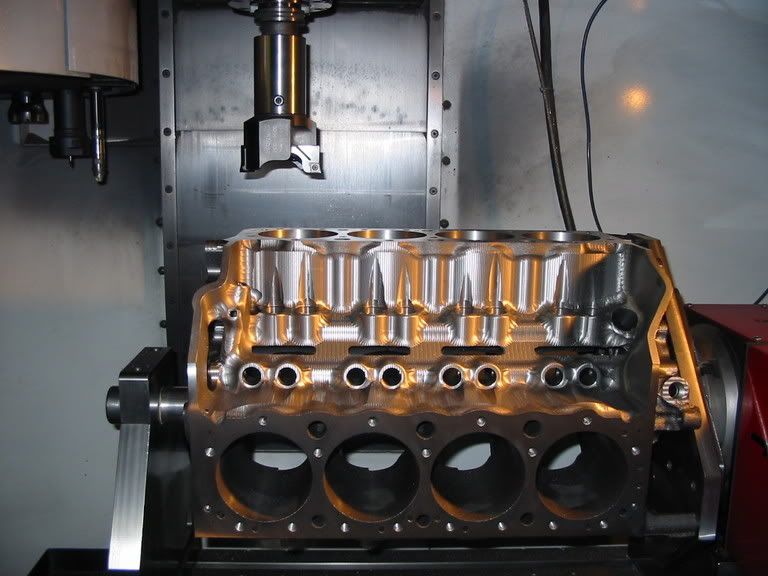

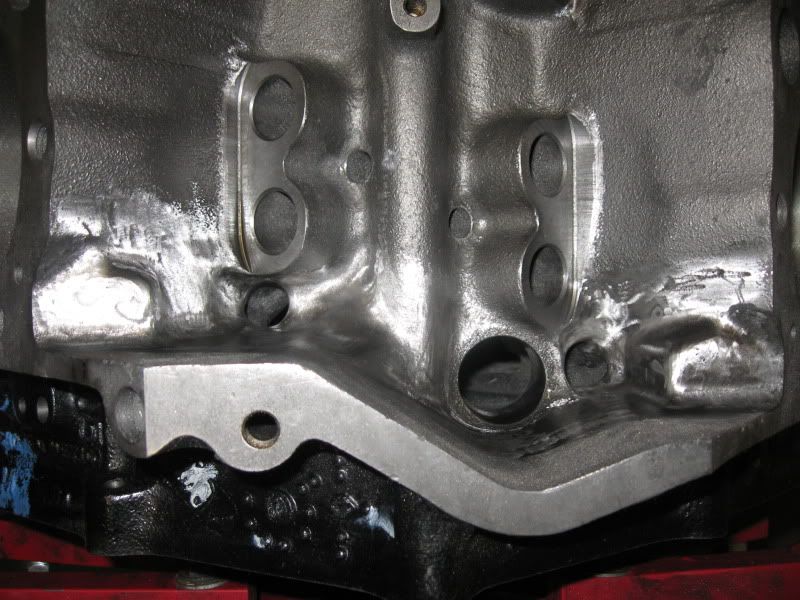

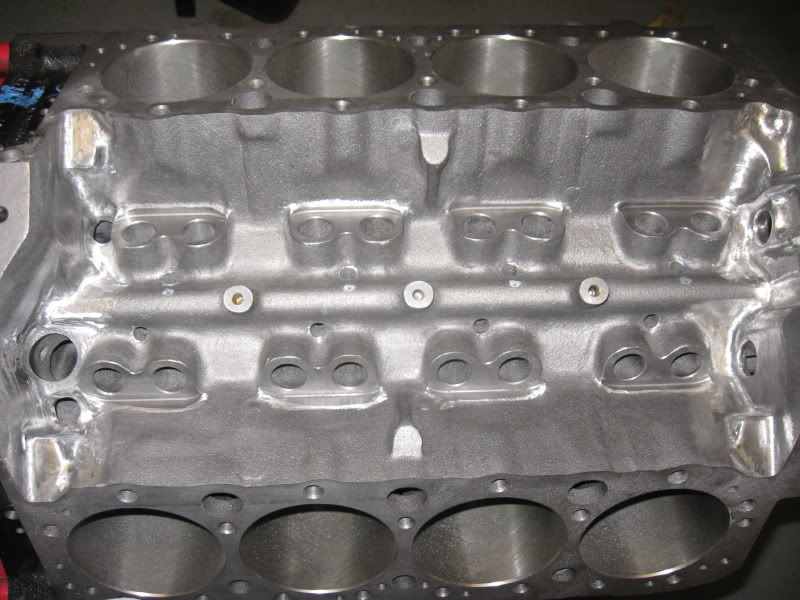

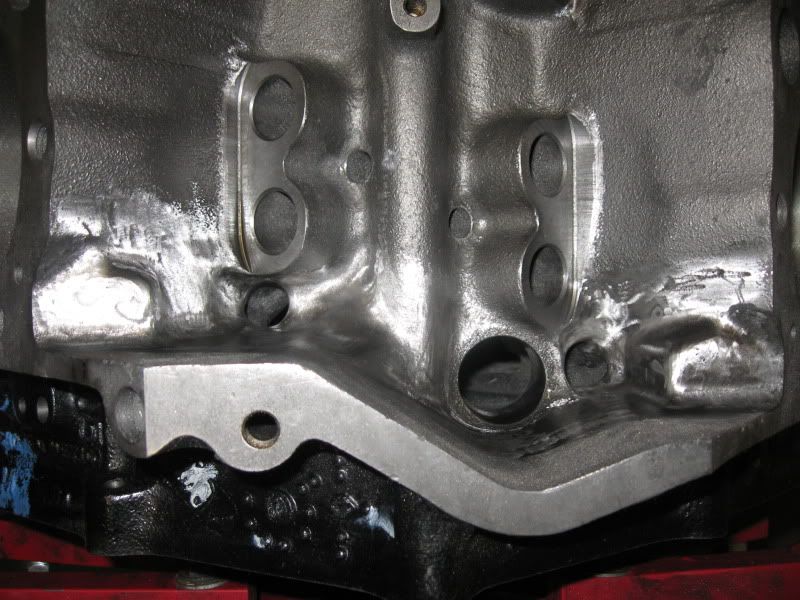

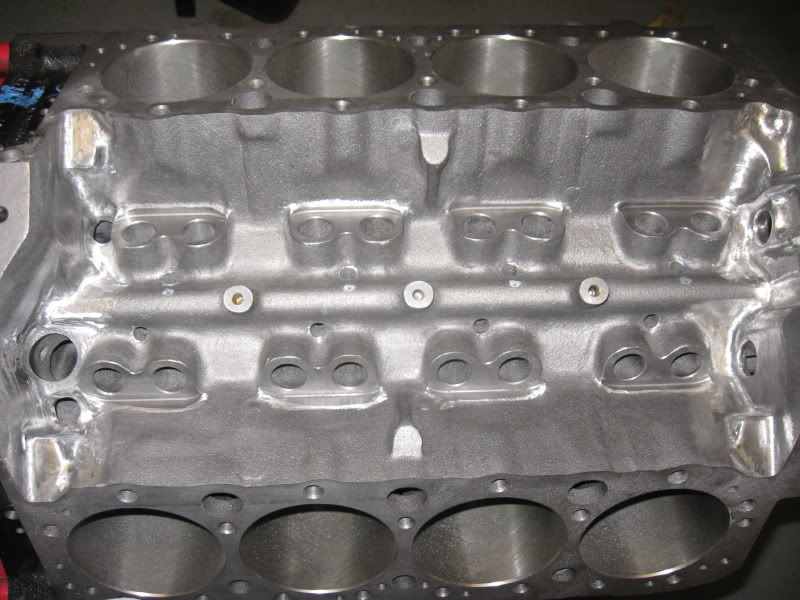

Here are some pics of a lightened Dart block.

Lifter galley

FRONT

REAR

#34

Race Director

Since you seem to have a Scat rep on hook over there, get him to put together a package that is going to cause you the least grief. I'm not quite understanding the external flywheel, external crank internal this or that.

You want to avoid adding mallory to the crank, that is the last thing you want. Maybe take advice from blockman and use the part that allows you to use a 2 piece rms crank.

I have built a few engines and as you are finding out without even turning a wrench you are not even getting the correct parts. It is not your fault but I would find someone who has a shop and works on chevy motors and pick his brains.

I am lucky I have a friend who has been building racing engines for 30 years so he helps steer me right especially when it comes to parts.

Basically you can't really buy all the parts and put the motor together without a machine shop being involved. I had all brand new parts and things still needed to be machined to fit correctly.

You have to get it balanced at a shop so now is the time to try and find someone to help you. It is not as easy as many think nor as hard as others think.

You need to buy some tools you may only use once or twice

You want to avoid adding mallory to the crank, that is the last thing you want. Maybe take advice from blockman and use the part that allows you to use a 2 piece rms crank.

I have built a few engines and as you are finding out without even turning a wrench you are not even getting the correct parts. It is not your fault but I would find someone who has a shop and works on chevy motors and pick his brains.

I am lucky I have a friend who has been building racing engines for 30 years so he helps steer me right especially when it comes to parts.

Basically you can't really buy all the parts and put the motor together without a machine shop being involved. I had all brand new parts and things still needed to be machined to fit correctly.

You have to get it balanced at a shop so now is the time to try and find someone to help you. It is not as easy as many think nor as hard as others think.

You need to buy some tools you may only use once or twice

#35

Burning Brakes

Thread Starter

Hi,

All of the rotating assembly will be balanced before final assembly and am sure it will be fine.

(Just out of interest. Spoke to Scat US and the matter of fact is that the crank I have and All 4340 forged 1 pc rear are balanced as follows: Not internal, Not external BUT Internal Front and External rear.)

Anyway,

Had a best day for a while in the garage!!!!! Love it!!

Have a look:

Next stop: Timing gear valley YEY!!!

BTW, Thank you for all of your help so far and keep it coming!!!

THANK YOU

All of the rotating assembly will be balanced before final assembly and am sure it will be fine.

(Just out of interest. Spoke to Scat US and the matter of fact is that the crank I have and All 4340 forged 1 pc rear are balanced as follows: Not internal, Not external BUT Internal Front and External rear.)

Anyway,

Had a best day for a while in the garage!!!!! Love it!!

Have a look:

Next stop: Timing gear valley YEY!!!

BTW, Thank you for all of your help so far and keep it coming!!!

THANK YOU

#36

Race Director

I believe the crank you have can be internally balanced with your piston rod setup. You can also swap for the internally balanced 2 piece rear seal crank and use the rear seal adapter. If you don't go internally balanced you will need to buy a flywheel anyway so I would put the money in internally balancing it.

#37

Burning Brakes

Thread Starter

Hi,

Just out of interest.

If I had the urge to buy 4340 forged crank, which one would you recommend for my build?

This is just an idea at this moment, nothing else

Paul

Just out of interest.

If I had the urge to buy 4340 forged crank, which one would you recommend for my build?

This is just an idea at this moment, nothing else

Paul

Last edited by C3Paul; 05-11-2011 at 07:27 AM.

#38

Drifting

#39

Drifting

That depends on how much cash you'd like to spend. Parts are sort of in classes. A $2,000 crank and a set of $200 rods can reduce the value, (effectively) to the quality of the lesser quality part. They all work in harmony with each other, so all as good as the weakest link.

Scat, Eagle, Pro Comp. Work well. Oliver, Crower, Cola, Callies, better. All will work, just pick your buget and go with it. Just understand there are different grades of parts. I check for size, weight and true all parts regardless of grade of part. I check Crower just like Eagle.

Don't feel like because you don't have Oliver rods, that your's will fall apart. You've spent a fair amount of cash, spend a little more and get a 2" to 3" mic and check your stuff. Crank sizes, rod width while doing that look for spots that you might be able to smooth. Casting flash that you can remove.

There is a ton of little things you can check before you start. Get a dial indicator from someone or get a harbor frieght cheap one. Put #1 and #5 main bearing (oiled and spare ones if you have them) in your block while upside down put the dial indicator on #3 turn your crank and see how straight your crank is. Use the indicator to check your end play also. Use it to find TDC any number of things. Plastigage the rods and mains. If you have some simple issue and post it here, You'll be asked these questions and you'll have answers for the, bearing clearance, end play, crank run out, rod clearance and on and on and on.

It looks like you enjoy the building process, dig in and do the checking that a good shop would do if building it for you. I think you would enjoy that also.

You'll be less likely to be surprised.

Scat, Eagle, Pro Comp. Work well. Oliver, Crower, Cola, Callies, better. All will work, just pick your buget and go with it. Just understand there are different grades of parts. I check for size, weight and true all parts regardless of grade of part. I check Crower just like Eagle.

Don't feel like because you don't have Oliver rods, that your's will fall apart. You've spent a fair amount of cash, spend a little more and get a 2" to 3" mic and check your stuff. Crank sizes, rod width while doing that look for spots that you might be able to smooth. Casting flash that you can remove.

There is a ton of little things you can check before you start. Get a dial indicator from someone or get a harbor frieght cheap one. Put #1 and #5 main bearing (oiled and spare ones if you have them) in your block while upside down put the dial indicator on #3 turn your crank and see how straight your crank is. Use the indicator to check your end play also. Use it to find TDC any number of things. Plastigage the rods and mains. If you have some simple issue and post it here, You'll be asked these questions and you'll have answers for the, bearing clearance, end play, crank run out, rod clearance and on and on and on.

It looks like you enjoy the building process, dig in and do the checking that a good shop would do if building it for you. I think you would enjoy that also.

You'll be less likely to be surprised.

#40

Team Owner

If you want to be improving the block for hp cansider tapping the block holes in the cam vally and installing vet tubes

If you want to be improving the block for hp cansider tapping the block holes in the cam vally and installing vet tubes