Can you help with 383ci engine build?

#1

Burning Brakes

Thread Starter

Hello

Well, finally I am in the position to build my new 383ci engine for my 1980 but, unfortunately to have the space to build this engine I had to send my Z on holiday to a lonely industrial storage place.

I have never built an engine before, but I am sure that I can do it and hope that you will be able to point me in the right direction.

Here is the parts list:

SHORT BLOCK:

Block: http://www.summitracing.com/parts/NAL-10105123/

Crank: http://www.summitracing.com/parts/SCA-435050L/

Balancer: Pro Street 6.75” Internal

Fly Wheel: http://www.summitracing.com/parts/MCL-460260/

Rods: http://www.summitracing.com/parts/SCA-26000716/

Piston: http://www.cnc-motorsports.com/produ...99&CtgID=16047

Cam: Comp Cams. Billet Custom grind 282/288 advertised duration, 230/236 duration @ .050 with lift of .591 intake, .593 exhaust with 1.52 rockers on a 111 LSA.

Timing Chain: http://www.summitracing.com/parts/CLO-9-3145A/

Timing cover: http://www.summitracing.com/parts/CLO-9-225/

Oil Pan: http://www.summitracing.com/parts/NAL-12557558/

Pan Gasket: http://www.summitracing.com/parts/FPP-1886/

Oil Pump: http://www.summitracing.com/parts/MEL-10552/

Lifters: http://www.summitracing.com/parts/CCA-850-16/

Instalation kit: http://www.summitracing.com/parts/CCA-08-1000/

Main bearings:http://www.summitracing.com/parts/CLE-MS909H/

Rod Bearing:http://www.summitracing.com/parts/CLE-CB663HN/

Flywheel bolts: not yet

Balancer bolt: got ARP one

Clutch:http://www.summitracing.com/parts/MCL-6911-07/

TOP END:

Head Studs: http://www.summitracing.com/parts/ARP-134-4001/

Heads: http://www.summitracing.com/parts/RHS-12024/

Head Gasket http://www.summitracing.com/parts/FEL-1010/

In. Valve: http://www.summitracing.com/parts/CCA-6009-8/

Ex. Valve: http://www.summitracing.com/parts/CCA-6012-8/

Valve seal: http://www.summitracing.com/parts/CCA-529-16/

Installation tool: http://www.summitracing.com/parts/CCA-5334/

Spring locator: http://www.summitracing.com/parts/CCA-4696-16/

Spring Shims: http://www.summitracing.com/parts/CCA-4757/

Springs: http://www.summitracing.com/parts/CCA-26120-16/

Spring retainer: http://www.summitracing.com/parts/CCA-795-16/

Valve locks: http://www.summitracing.com/parts/CCA-613-16/

Guide plates: http://www.summitracing.com/parts/CCA-4808-8/

Rocker studs: http://www.summitracing.com/parts/ARP-100-7101/

Rockers: http://www.summitracing.com/parts/CCA-1604-16/

Intake Manifold: http://www.summitracing.com/parts/EDL-71041/

Intake manifold gasket: http://www.summitracing.com/parts/FEL-1206/

MSD Ignition: http://www.summitracing.com/parts/MSD-8362/

Distributor Dyna Module: http://www.ecklers.com/product.asp?p...1&dept_id=1785

Fuel pump: http://www.summitracing.com/parts/ACF-41240/

Fuel pump push rod: http://www.summitracing.com/parts/CCA-4607/

Well, finally I am in the position to build my new 383ci engine for my 1980 but, unfortunately to have the space to build this engine I had to send my Z on holiday to a lonely industrial storage place.

I have never built an engine before, but I am sure that I can do it and hope that you will be able to point me in the right direction.

Here is the parts list:

SHORT BLOCK:

Block: http://www.summitracing.com/parts/NAL-10105123/

Crank: http://www.summitracing.com/parts/SCA-435050L/

Balancer: Pro Street 6.75” Internal

Fly Wheel: http://www.summitracing.com/parts/MCL-460260/

Rods: http://www.summitracing.com/parts/SCA-26000716/

Piston: http://www.cnc-motorsports.com/produ...99&CtgID=16047

Cam: Comp Cams. Billet Custom grind 282/288 advertised duration, 230/236 duration @ .050 with lift of .591 intake, .593 exhaust with 1.52 rockers on a 111 LSA.

Timing Chain: http://www.summitracing.com/parts/CLO-9-3145A/

Timing cover: http://www.summitracing.com/parts/CLO-9-225/

Oil Pan: http://www.summitracing.com/parts/NAL-12557558/

Pan Gasket: http://www.summitracing.com/parts/FPP-1886/

Oil Pump: http://www.summitracing.com/parts/MEL-10552/

Lifters: http://www.summitracing.com/parts/CCA-850-16/

Instalation kit: http://www.summitracing.com/parts/CCA-08-1000/

Main bearings:http://www.summitracing.com/parts/CLE-MS909H/

Rod Bearing:http://www.summitracing.com/parts/CLE-CB663HN/

Flywheel bolts: not yet

Balancer bolt: got ARP one

Clutch:http://www.summitracing.com/parts/MCL-6911-07/

TOP END:

Head Studs: http://www.summitracing.com/parts/ARP-134-4001/

Heads: http://www.summitracing.com/parts/RHS-12024/

Head Gasket http://www.summitracing.com/parts/FEL-1010/

In. Valve: http://www.summitracing.com/parts/CCA-6009-8/

Ex. Valve: http://www.summitracing.com/parts/CCA-6012-8/

Valve seal: http://www.summitracing.com/parts/CCA-529-16/

Installation tool: http://www.summitracing.com/parts/CCA-5334/

Spring locator: http://www.summitracing.com/parts/CCA-4696-16/

Spring Shims: http://www.summitracing.com/parts/CCA-4757/

Springs: http://www.summitracing.com/parts/CCA-26120-16/

Spring retainer: http://www.summitracing.com/parts/CCA-795-16/

Valve locks: http://www.summitracing.com/parts/CCA-613-16/

Guide plates: http://www.summitracing.com/parts/CCA-4808-8/

Rocker studs: http://www.summitracing.com/parts/ARP-100-7101/

Rockers: http://www.summitracing.com/parts/CCA-1604-16/

Intake Manifold: http://www.summitracing.com/parts/EDL-71041/

Intake manifold gasket: http://www.summitracing.com/parts/FEL-1206/

MSD Ignition: http://www.summitracing.com/parts/MSD-8362/

Distributor Dyna Module: http://www.ecklers.com/product.asp?p...1&dept_id=1785

Fuel pump: http://www.summitracing.com/parts/ACF-41240/

Fuel pump push rod: http://www.summitracing.com/parts/CCA-4607/

Last edited by C3Paul; 12-17-2011 at 08:31 AM.

#2

Race Director

You do realize the crank is externally balanced ? They make the same crank internally balanced you are going to have to change it

http://www.summitracing.com/parts/SCA-935050L

By the book How to Build the Small Block Chevrolet by SA books, the only book you need

http://www.summitracing.com/parts/SCA-935050L

By the book How to Build the Small Block Chevrolet by SA books, the only book you need

Last edited by MotorHead; 05-07-2011 at 07:40 PM.

#3

Burning Brakes

Thread Starter

You do realize the crank is externally balanced ? They make the same crank internally balanced you are going to have to change it

http://www.summitracing.com/parts/SCA-935050L

By the book How to Build the Small Block Chevrolet by SA books, the only book you need

http://www.summitracing.com/parts/SCA-935050L

By the book How to Build the Small Block Chevrolet by SA books, the only book you need

I do have the How to build SBC books and found them very useful.

Also, I spoke to Scat Tech. Dep. before I bought the crank and was told that I should be OK to internally balance the crank.

(I will be pretty PO if it turn out to be externally balanced crank)

Guess, I will find out 100% when the assembly goes for balancing!?

#4

Race Director

Click on your crank link and look beside "Engine Balance" then click on my link and look at the same

#5

Race Director

You do realize the crank is externally balanced ? They make the same crank internally balanced you are going to have to change it

http://www.summitracing.com/parts/SCA-935050L

By the book How to Build the Small Block Chevrolet by SA books, the only book you need

http://www.summitracing.com/parts/SCA-935050L

By the book How to Build the Small Block Chevrolet by SA books, the only book you need

Buy the right crank. Tech steered you wrong. It can be done but will cost more than shipping it back and getting the correct crank even from Europe.

Buy the right crank. Tech steered you wrong. It can be done but will cost more than shipping it back and getting the correct crank even from Europe.I would swap out the Single plane for a Performer RPM too. Almost the exact same port size but the Team G is a 2800 to 7200 RPM intake with an adapter plate needed. The Performer RPM is a 1500 to 6500 RPM intake with the correct mounting flange. Your hydraulic cam is probably a 1800 to 5800 operating range and you will probably never see over 6000 RPM. Much better match for your specs. It you were running a solid roler I could see it.

Last edited by 63mako; 05-07-2011 at 09:41 PM.

#6

Burning Brakes

Thread Starter

Hello,

Point taken, I will exchange the crank for this internally balanced one http://www.summitracing.com/parts/SCA-935050L

Thank you (Better safe than sorry)

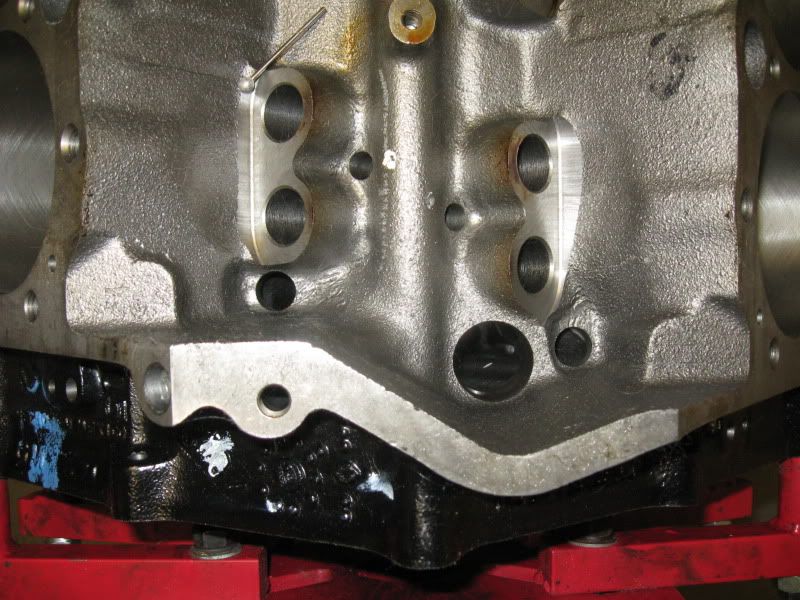

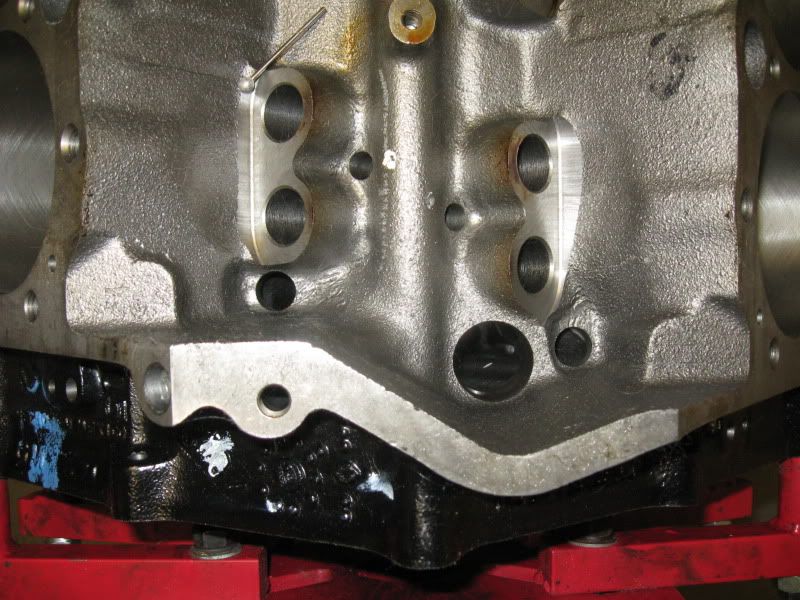

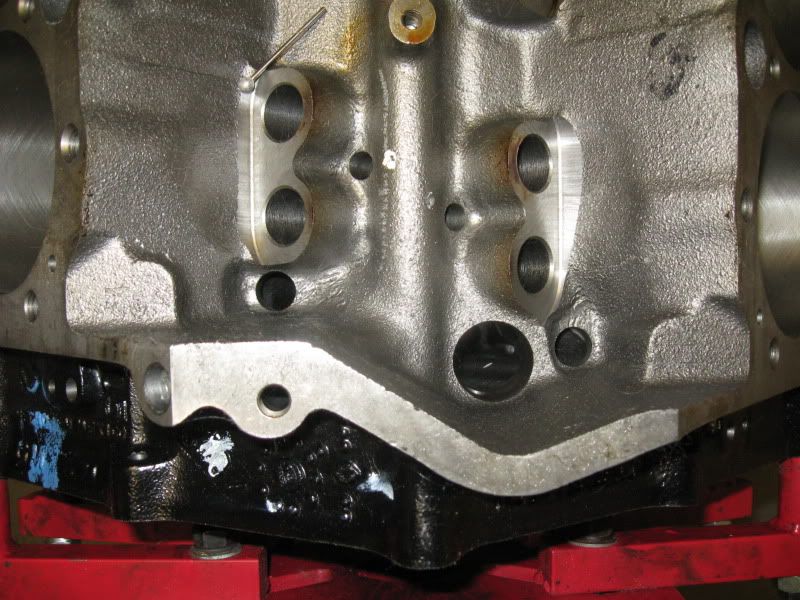

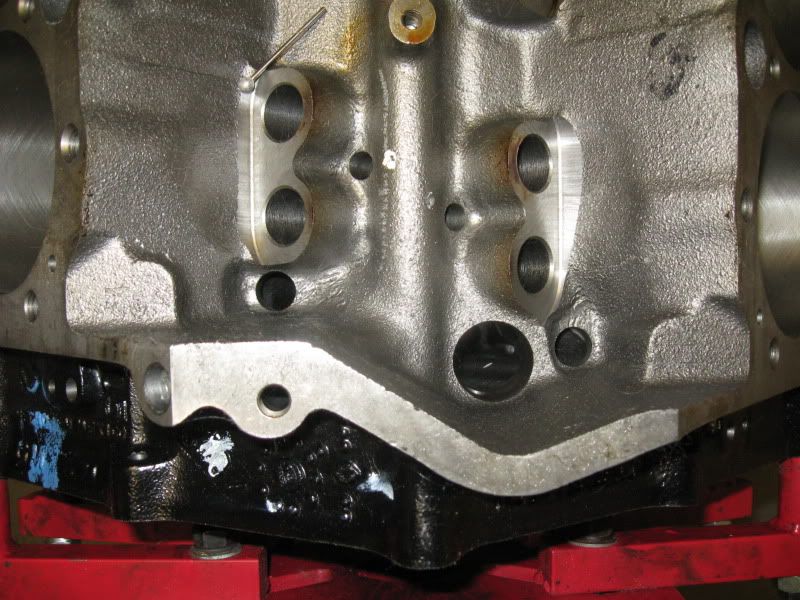

I will need to stroke clearance the block so to get the feel for it I started cleaning the oil passages.

How far do I go with the grinding?

Do I just smooth out the passage?

Point taken, I will exchange the crank for this internally balanced one http://www.summitracing.com/parts/SCA-935050L

Thank you (Better safe than sorry)

I will need to stroke clearance the block so to get the feel for it I started cleaning the oil passages.

How far do I go with the grinding?

Do I just smooth out the passage?

Last edited by C3Paul; 05-08-2011 at 08:35 AM.

#8

Burning Brakes

Thread Starter

It took me 2 years to get this far.

I will be taking pictures of the build, so hopefully more people will get the courage and assemble their own engines.

If I can do it, everyone can!!

Paul

#9

Race Director

On the other hand you might be able to find a externally balanced flywheel and balancer locally.

My previous 406ci was externally balanced and it made it to 550HP @ 6000RPM. It had a solid roller cam though. My new 427ci is a little smoother and it will rev to 7500RPM while I wouldn't go past 6500RPM with the 406ci

It has to be balanced correctly or you will have no end of trouble. The best route to go is internally balanced. Best dual plane IMHO is the RPM Air Gap

Crank up the vol

My previous 406ci was externally balanced and it made it to 550HP @ 6000RPM. It had a solid roller cam though. My new 427ci is a little smoother and it will rev to 7500RPM while I wouldn't go past 6500RPM with the 406ci

It has to be balanced correctly or you will have no end of trouble. The best route to go is internally balanced. Best dual plane IMHO is the RPM Air Gap

Crank up the vol

#10

Burning Brakes

Thread Starter

The best route to go is internally balanced. Best dual plane IMHO is the RPM Air Gap

I will swap or buy a new crank, but I want internally balanced rotating assembly!!

With regards of the intake, I will go with the single plane for now and if it turns out to be a dog I can always replace it with Performer RPM at a later date.

(Also, my car is 4 speed manual so the single plane may work OK, I shall report back once this engine is running in my car)

Last edited by C3Paul; 05-08-2011 at 09:57 AM.

#11

Melting Slicks

...I would swap out the Single plane for a Performer RPM too. Almost the exact same port size but the Team G is a 2800 to 7200 RPM intake with an adapter plate needed. The Performer RPM is a 1500 to 6500 RPM intake with the correct mounting flange. Your hydraulic cam is probably a 1800 to 5800 operating range and you will probably never see over 6000 RPM. Much better match for your specs. It you were running a solid roler I could see it.

http://www.summitracing.com/parts/EDL-7104/

#12

Race Director

Nothing wrong with the single plane, that's all I have been using from as far back as I can remember

Talk to Summit and see if they will give you a break on shipping or anything since obviously you were steered wrong by the brain surgeon at Scat

Talk to Summit and see if they will give you a break on shipping or anything since obviously you were steered wrong by the brain surgeon at Scat

#13

Burning Brakes

Thread Starter

One way, or another I will have the Internally balanced crank.

Leaving the intake aside for now, how far do I need to go with the grinding job?

Just a little tickle or a proper grind?

Leaving the intake aside for now, how far do I need to go with the grinding job?

Just a little tickle or a proper grind?

#14

Team Owner

I don't know anything about your crank shaft. But your rod bearings say NON chamfered. So when you look at the crank rod throws see if they are machined square or with a radius

Clevite rod bearings are marked top and bottom.

I recommend buying rotating kits. That way everything fits together

Clevite rod bearings are marked top and bottom.

I recommend buying rotating kits. That way everything fits together

Last edited by gkull; 05-08-2011 at 10:31 AM.

#15

Burning Brakes

Thread Starter

I don't know anything about your crank shaft. But your rod bearings say NON chamfered. So when you look at the crank rod throws see if they are machined square or with a radius

Clevite rod bearings are marked top and bottom.

I recommend buying rotating kits. That way everything fits together

Clevite rod bearings are marked top and bottom.

I recommend buying rotating kits. That way everything fits together

#16

Team Owner

So the rod bearings are wrong. Those shorty headers are pretty worthless and they might actually be smaller than the head ports

#17

Burning Brakes

Thread Starter

Just checked and measured the ports on the heads and the headers and they are IDENTICAL 1.35”x1.40”

The headers are McJack shorty headers. http://www.vetteheaders.com/servlet/...orvette/Detail

#18

Race Director

Just debur any rough edges or anything sticking out you don't need to overdo it.

That is a cast crank and I had a cast Scat 9000 crank a while back and was able to use the cheaper Clevite P series bearings so make sure you use the correct bearings.

See if you can get the same guy at Scat on the phone he should know

That is a cast crank and I had a cast Scat 9000 crank a while back and was able to use the cheaper Clevite P series bearings so make sure you use the correct bearings.

See if you can get the same guy at Scat on the phone he should know

#19

Le Mans Master

Member Since: Mar 2008

Location: Oxford MA-----You just lost the game!!!!

Posts: 5,948

Likes: 0

Received 62 Likes

on

52 Posts

Just polish up the lifter valley and passages, you don't really need to remove much material, just make it shiny. The object here is to make a surface that the oil will not cling to, so it just slides right on down back into the pan.

Scott

#20

Burning Brakes

Thread Starter

Hi, I really need your help on this one.

I spoke to Scat Dealer here in the UK and he is happy to take my crank and exchange it for the 935050L crank.

BUT,

He is saying that it will be lot more difficult to balance the 935050L crank with the 6” rod, because the counter weights in this crank are smaller and he is advising against adding weight to balance the crank.

Apparently I will be better off to keep my existing crank and take away weight to internally balance the crank.

Something to do with BOB weight?

This 935060L crank is asking for INTERNAL front balancer and EXTERNAL Flywheel

This is link to the Scat catalogue PAGE 2 : http://www.scatcrankshafts.com/catalogs/2011/24-45.pdf

935050L *Balances at 1830 to 1850 grams with std weighted flywheel , neutral std balancer & one piece mallary in counterweight 1

Help

I spoke to Scat Dealer here in the UK and he is happy to take my crank and exchange it for the 935050L crank.

BUT,

He is saying that it will be lot more difficult to balance the 935050L crank with the 6” rod, because the counter weights in this crank are smaller and he is advising against adding weight to balance the crank.

Apparently I will be better off to keep my existing crank and take away weight to internally balance the crank.

Something to do with BOB weight?

This 935060L crank is asking for INTERNAL front balancer and EXTERNAL Flywheel

This is link to the Scat catalogue PAGE 2 : http://www.scatcrankshafts.com/catalogs/2011/24-45.pdf

935050L *Balances at 1830 to 1850 grams with std weighted flywheel , neutral std balancer & one piece mallary in counterweight 1

Help

Last edited by C3Paul; 05-09-2011 at 06:52 AM.