1968 427/390 idle mixture screws completely ineffective

#41

Instructor

Thread Starter

Member Since: Jun 2010

Location: Fritsla Sweden

Posts: 173

Likes: 0

Received 0 Likes

on

0 Posts

Here are the dimensions for the brass low speed bleeds - all dimensions are in inches:

Outside diameter: 0.122

Inside diameter (hole diameter): 0.052 (#55 diameter drill)

Length: 0.100

Note that the outside diameter is just under an eight of an inch, so you can use some 1/8" round stock and simply sand off a few thousands in the lathe. Run the #55 drill through the stock, and part off 2 lengths to the .100 dimension.

Tap them in from the top of the airhorn with a 1/8" diameter pin punch until they're flush with the casting surface as shown in my photo above.

Outside diameter: 0.122

Inside diameter (hole diameter): 0.052 (#55 diameter drill)

Length: 0.100

Note that the outside diameter is just under an eight of an inch, so you can use some 1/8" round stock and simply sand off a few thousands in the lathe. Run the #55 drill through the stock, and part off 2 lengths to the .100 dimension.

Tap them in from the top of the airhorn with a 1/8" diameter pin punch until they're flush with the casting surface as shown in my photo above.

Thanks again....

/Martin

#42

Instructor

Thread Starter

Member Since: Jun 2010

Location: Fritsla Sweden

Posts: 173

Likes: 0

Received 0 Likes

on

0 Posts

Let's not forget the problem #1 with this "new carb". The power piston nylon retainer were cocked BADLY in the bore, not seated properly, so when the airhorn was jammed down with the screws the PP could almost not move from full-fat condition. But sure, the car started and was running....sort of.

As Lars said, I'm sitting in south-west of Sweden and the Corvette season ends in about 8-9 weeks, so I take the opportunity to be able to road test before season ends, and also learn a lot along the way.

Its truly admirable by Lars to share all this information and have that patience....

/Martin

#43

Race Director

Member Since: Apr 2011

Location: North of Toronto - Ontario

Posts: 10,853

Received 3,138 Likes

on

2,069 Posts

I couldn't agree more. The #1 problem is that very, very few individuals have the whole picture (Lars is one of them obviously), and also realize that trying to out-smart the entire engineering department that designed this stuff back in the days is a bad idea. It's almost as a lot of the so called "experts" think the engineers back in the 60s were stupid or something. That makes me tired.

Especially the patience part

Mooser

#44

Race Director

Member Since: Apr 2011

Location: North of Toronto - Ontario

Posts: 10,853

Received 3,138 Likes

on

2,069 Posts

Wait, that looks familiar...Let me check that while I'm swapping manifolds...

And this is why I read all these posts that even remotely talk about something I'm working on.

My carb is functioning and actually not too bad, start-up is a little but after a minute or two it will settle down. My mix screws are at around 5 as set with a vac-gage to the steadiest point I could get (still bounces around a little but less than 2" or so)

but after a minute or two it will settle down. My mix screws are at around 5 as set with a vac-gage to the steadiest point I could get (still bounces around a little but less than 2" or so)

Finding and fixing things that are there but wrong is one thing, but knowing that something is missing..... That's where these troubleshooting threads are so great, you never know what you'll come across.

Now, do I fix it (make a set of bleed plugs) or wait

Mooser

My carb is functioning and actually not too bad, start-up is a little

but after a minute or two it will settle down. My mix screws are at around 5 as set with a vac-gage to the steadiest point I could get (still bounces around a little but less than 2" or so)

but after a minute or two it will settle down. My mix screws are at around 5 as set with a vac-gage to the steadiest point I could get (still bounces around a little but less than 2" or so)Finding and fixing things that are there but wrong is one thing, but knowing that something is missing..... That's where these troubleshooting threads are so great, you never know what you'll come across.

Now, do I fix it (make a set of bleed plugs) or wait

Mooser

#45

Tech Contributor

Member Since: Aug 1999

Location: At my Bar drinking and wrenching in Lafayette Colorado

Posts: 13,654

Received 4,924 Likes

on

1,930 Posts

Keep in mind that not all model Q-Jets have the bleeds - some do not. I use and install the bleeds in 2 cases:

Lars

- When the carb should have them and they're missing

- When proper idle mixture & mixture control cannot be achieved with the mixture screws less than 5 turns out on divorced choke carbs and 6 turns on an integral choke carb

Lars

#46

Race Director

Member Since: Apr 2011

Location: North of Toronto - Ontario

Posts: 10,853

Received 3,138 Likes

on

2,069 Posts

Keep in mind that not all model Q-Jets have the bleeds - some do not. I use and install the bleeds in 2 cases:

Lars

- When the carb should have them and they're missing

- When proper idle mixture & mixture control cannot be achieved with the mixture screws less than 5 turns out on divorced choke carbs and 6 turns on an integral choke carb

Lars

Part of me (curiosity) wants me to take it apart and get a better understanding of how it all of this really works.

The other part of me (practical) says to send it to Lars and be done with it.

Mooser

Oh, how do you know if the carb should have them or not?

#47

Instructor

Thread Starter

Member Since: Jun 2010

Location: Fritsla Sweden

Posts: 173

Likes: 0

Received 0 Likes

on

0 Posts

Been e busy week at work. I digged out the 1/8" brass core and a #55 drill bit and worked on the restrictors this morning:

Tomorrow I will:

- Install the restrictors

- Lower float setting to 0.400"

and see what happens.

But tonight is crayfish party time up here, and that means lots of cold beers, so the small parts installation have to wait tomorrow noon or so.

I will get back tomorrow. Hopefully.

Tomorrow I will:

- Install the restrictors

- Lower float setting to 0.400"

and see what happens.

But tonight is crayfish party time up here, and that means lots of cold beers, so the small parts installation have to wait tomorrow noon or so.

I will get back tomorrow. Hopefully.

#48

Instructor

Thread Starter

Member Since: Jun 2010

Location: Fritsla Sweden

Posts: 173

Likes: 0

Received 0 Likes

on

0 Posts

Lars,

The restrictors are installed:

and I lowered the float level to approx. 0.400".

As usual car starts easily and warms up without problems. However I still have nozzle drip, and no way I can close the throttle plates more without killing the engine. The idle screws have some effect, but not very much, but some. It feels like the car runs from the primaries 90% and idle circuit 10% or something.

It could be worth mentioning also that I checked the CO with an exhaust gas analyzer earlier this week, and the CO at idle was only 0.18%...I would have prefered 1-2%. My 0.18 reading indicates too little fuel at idle.

Before I'm losing it, what can be expected from a L36 stock engine at idle:

- Absolutely zero nozzle drip?

- If both idle screws are screwed in and seated -> engine dies instantly?

- If idle circuit is working 100% - can throttle blades be closed completely without engine dying?

It still feels like something is very off in my setup - the "dynamic" range of the idle screws is extremely low, only way to keep engine alive is to crank up throttle plates, but then the drip starts again. Add the low CO reading to that also....hmm....

When it comes to fine tuning I actually have a good wideband I could hook up, but that probably don't help me with my current idle issues.

Could it be that the air bypass holes in the bores are too small, and the idle metering tubes are too small for my 427? Given the list of screwed up things so far nothing would surpise me.

/Martin

The restrictors are installed:

and I lowered the float level to approx. 0.400".

As usual car starts easily and warms up without problems. However I still have nozzle drip, and no way I can close the throttle plates more without killing the engine. The idle screws have some effect, but not very much, but some. It feels like the car runs from the primaries 90% and idle circuit 10% or something.

It could be worth mentioning also that I checked the CO with an exhaust gas analyzer earlier this week, and the CO at idle was only 0.18%...I would have prefered 1-2%. My 0.18 reading indicates too little fuel at idle.

Before I'm losing it, what can be expected from a L36 stock engine at idle:

- Absolutely zero nozzle drip?

- If both idle screws are screwed in and seated -> engine dies instantly?

- If idle circuit is working 100% - can throttle blades be closed completely without engine dying?

It still feels like something is very off in my setup - the "dynamic" range of the idle screws is extremely low, only way to keep engine alive is to crank up throttle plates, but then the drip starts again. Add the low CO reading to that also....hmm....

When it comes to fine tuning I actually have a good wideband I could hook up, but that probably don't help me with my current idle issues.

Could it be that the air bypass holes in the bores are too small, and the idle metering tubes are too small for my 427? Given the list of screwed up things so far nothing would surpise me.

/Martin

#49

Tech Contributor

Member Since: Aug 1999

Location: At my Bar drinking and wrenching in Lafayette Colorado

Posts: 13,654

Received 4,924 Likes

on

1,930 Posts

They sold you a real piece of crap carb there... hard to tell what else is completely screwed up on it...

In answer to your questions:

There should be no nozzle drip whatsoever at idle

The idle mixture screws, if screwed in and seated, should kill the engine

Throttle blades cannot be fully closed - normal for some throttle blade opening.

The mixture adjustment range on the idle mixture screws should be 17-20:1 for engine kill screwed all the way in, to around 12.5:1 screwed out about 6 turns.

What type of float is installed in the carb?

In answer to your questions:

There should be no nozzle drip whatsoever at idle

The idle mixture screws, if screwed in and seated, should kill the engine

Throttle blades cannot be fully closed - normal for some throttle blade opening.

The mixture adjustment range on the idle mixture screws should be 17-20:1 for engine kill screwed all the way in, to around 12.5:1 screwed out about 6 turns.

What type of float is installed in the carb?

#50

Instructor

Thread Starter

Member Since: Jun 2010

Location: Fritsla Sweden

Posts: 173

Likes: 0

Received 0 Likes

on

0 Posts

They sold you a real piece of crap carb there... hard to tell what else is completely screwed up on it...

In answer to your questions:

There should be no nozzle drip whatsoever at idle

The idle mixture screws, if screwed in and seated, should kill the engine

Throttle blades cannot be fully closed - normal for some throttle blade opening.

The mixture adjustment range on the idle mixture screws should be 17-20:1 for engine kill screwed all the way in, to around 12.5:1 screwed out about 6 turns.

What type of float is installed in the carb?

In answer to your questions:

There should be no nozzle drip whatsoever at idle

The idle mixture screws, if screwed in and seated, should kill the engine

Throttle blades cannot be fully closed - normal for some throttle blade opening.

The mixture adjustment range on the idle mixture screws should be 17-20:1 for engine kill screwed all the way in, to around 12.5:1 screwed out about 6 turns.

What type of float is installed in the carb?

This is the float they installed when I got the carb:

Last week I put in a brand new float, looked identical though.

I could check the CO reading again after the installation of the air bleeds, and also have the analyzer hooked up while turning the mixture screws. But as long as I can eyeball the nozzle drip something else must be pretty off. Given that this carb probably was from a completely different application - could it be that the idle bleed holes and rest of idle circuit is simply too unmatched for this engine? I guess the idle circuit must look different for a little small-block than a frustrated 427?

Martin

#51

Instructor

Thread Starter

Member Since: Jun 2010

Location: Fritsla Sweden

Posts: 173

Likes: 0

Received 0 Likes

on

0 Posts

Lars,

Do you agree with me that it's most likely too little fuel dumped via the idle circuit? After warming up the car today I turned the idle mixture screws out 5-6 turns and closed the throttle plate so the engine barely runs, idles at 550 rpm or so. I I hold my hand over the airhorn to choke it somewhat idle speed goes up ALOT approx. to 1000rpm.

I can use my friends professional exhaust gas analyzer and measure lambda in the tailpipes (I have removed the AIR belt) and take lambda readings as a function of idle screws in 1/2 turn increments. Just to see what happens.

Could the idle down tube and channel restrictor be too under-dimensioned for this setup?

Were the diemsnions of these parts different for different applications?

Thanks.

Do you agree with me that it's most likely too little fuel dumped via the idle circuit? After warming up the car today I turned the idle mixture screws out 5-6 turns and closed the throttle plate so the engine barely runs, idles at 550 rpm or so. I I hold my hand over the airhorn to choke it somewhat idle speed goes up ALOT approx. to 1000rpm.

I can use my friends professional exhaust gas analyzer and measure lambda in the tailpipes (I have removed the AIR belt) and take lambda readings as a function of idle screws in 1/2 turn increments. Just to see what happens.

Could the idle down tube and channel restrictor be too under-dimensioned for this setup?

Were the diemsnions of these parts different for different applications?

Thanks.

#52

Tech Contributor

Member Since: Aug 1999

Location: At my Bar drinking and wrenching in Lafayette Colorado

Posts: 13,654

Received 4,924 Likes

on

1,930 Posts

There is no point in using a CO meter on a carb when you have a visible drip out the main discharge nozzle: That would be like using leak detector on a tire with a knife in the sidewall...

It's time to open up your IFR orifices at the bottom of the idle tubes: You need a .038 - .039 drill, or you can do as I do and simply use a piece of model airplane .038 piano wire and stick it in a hand drill: Poke this down the IFR tubes and "wear" yourself through the restrictor at the bottom. Blow it out well in both directions... this should give you good idle mixture response in the 3-turn range. I've seen guys open them up as much as .042, but this is a little severe on a street driven engine, since the IFR orifice will affect cruise mixture as well as idle - you don't want to get it TOO rich.

Here's the setup I use to fix the problem carbs with mis-matched IFR's installed by those nasty commercial carb builders:

Lars

It's time to open up your IFR orifices at the bottom of the idle tubes: You need a .038 - .039 drill, or you can do as I do and simply use a piece of model airplane .038 piano wire and stick it in a hand drill: Poke this down the IFR tubes and "wear" yourself through the restrictor at the bottom. Blow it out well in both directions... this should give you good idle mixture response in the 3-turn range. I've seen guys open them up as much as .042, but this is a little severe on a street driven engine, since the IFR orifice will affect cruise mixture as well as idle - you don't want to get it TOO rich.

Here's the setup I use to fix the problem carbs with mis-matched IFR's installed by those nasty commercial carb builders:

Lars

#53

Instructor

Thread Starter

Member Since: Jun 2010

Location: Fritsla Sweden

Posts: 173

Likes: 0

Received 0 Likes

on

0 Posts

It's time to open up your IFR orifices at the bottom of the idle tubes: You need a .038 - .039 drill, or you can do as I do and simply use a piece of model airplane .038 piano wire and stick it in a hand drill: Poke this down the IFR tubes and "wear" yourself through the restrictor at the bottom. Blow it out well in both directions... this should give you good idle mixture response in the 3-turn range. I've seen guys open them up as much as .042, but this is a little severe on a street driven engine, since the IFR orifice will affect cruise mixture as well as idle - you don't want to get it TOO rich....

If you ever visit Scandinavia let me know. I can bring out the Swedish chef outfit and cook Swedish meatballs while we discuss commercial carb builders and enjoy a cold one...

Stay tuned (my carb doesn't) - I'll be back in a few days after the piano wire exercise.

(BTW: Perhaps a stupid question, but how did a stock Corvette L36 idled back in 1968, given that the 1968 QJet did not have any idle air bleeds in the corners like I have now, and used ported vacuum advance? After our discussions it feels impossible to not have nozzle drip if the majority of idle air goes through the main venturi rings....hmmm....)

/Martin

#54

Tech Contributor

Member Since: Aug 1999

Location: At my Bar drinking and wrenching in Lafayette Colorado

Posts: 13,654

Received 4,924 Likes

on

1,930 Posts

How did a stock Corvette L36 idled back in 1968, given that the 1968 QJet did not have any idle air bleeds in the corners like I have now, and used ported vacuum advance? After our discussions it feels impossible to not have nozzle drip if the majority of idle air goes through the main venturi rings....hmmm....)

/Martin

/Martin

Last edited by lars; 08-21-2012 at 04:51 PM.

#55

Instructor

Thread Starter

Member Since: Jun 2010

Location: Fritsla Sweden

Posts: 173

Likes: 0

Received 0 Likes

on

0 Posts

Lars,

I used a 0.039" piano wire and enlarged the idle tubes. Cleaned everything up very carefully, and check everything over. I did make some notes and observations while having the carb on the bench:

- Idle down restrictors is 0.052" (a #55 drill fits exactly).

- Hole in throttle bore where idle screw tips enters is approx. 0.063".

Hate to say it - but I still can't close the throttle plates enough to completely stop the dripping. If I back out the screws all the way I can get it to idle at around 600rpm with little nozzle drip. If I screw in each idle screw it dies instantly when seating the screw. So it gets some fuel from the idle circuit at least.

I also noticed when the carb was on the bench that if I want the idle transition slot "square", i.e. approx. 0.040" "wide" (looking from the underside) I must be able to close my plates MUCH more than I can now.

Engine pulls around 15-20" vacuum at the lowest idle I can get with idle screws backed out all the way.

Now: I could admit defeat. But i can't say how much I hate to do that. Since the carb's faith is questionable I was think of trying the following:

1) Enlarge the idle down restriction.

2) Possibly enlarge the idle screw holes in the bore.

I have very little to loose now.

Thanks.

Martin

I used a 0.039" piano wire and enlarged the idle tubes. Cleaned everything up very carefully, and check everything over. I did make some notes and observations while having the carb on the bench:

- Idle down restrictors is 0.052" (a #55 drill fits exactly).

- Hole in throttle bore where idle screw tips enters is approx. 0.063".

Hate to say it - but I still can't close the throttle plates enough to completely stop the dripping. If I back out the screws all the way I can get it to idle at around 600rpm with little nozzle drip. If I screw in each idle screw it dies instantly when seating the screw. So it gets some fuel from the idle circuit at least.

I also noticed when the carb was on the bench that if I want the idle transition slot "square", i.e. approx. 0.040" "wide" (looking from the underside) I must be able to close my plates MUCH more than I can now.

Engine pulls around 15-20" vacuum at the lowest idle I can get with idle screws backed out all the way.

Now: I could admit defeat. But i can't say how much I hate to do that. Since the carb's faith is questionable I was think of trying the following:

1) Enlarge the idle down restriction.

2) Possibly enlarge the idle screw holes in the bore.

I have very little to loose now.

Thanks.

Martin

#56

Instructor

Thread Starter

Member Since: Jun 2010

Location: Fritsla Sweden

Posts: 173

Likes: 0

Received 0 Likes

on

0 Posts

UPDATE Sunday morning:

I was thinking of my idle issues last night and obviously my engine wants more fuel. To increase the amount of fuel being pulled through the idle circuit I did one experiment this morning. Just above the idle down tube there is an air bleed hole drilled at an angle into the main venturi area so the idle fuel gets mixed up with air. I have not measured the sizes of these air bleeds (yet). But I guess if this hole is restricted the pulling force of the idle fuel can be controlled.

After warming up the car with nozzle drip, I use two steel wires to almost plug these air bleeds. The idle speed went up like crazy, and I could EASILY close the throttle plates all the way down so 0 nozzle drip.

I also get the best idle screw response ever. With this test I could easily get the engine to idle very smooth at 650rpm, and pull 21-22" vacuum (very stable). If I removed the wires the engined dies instantly (of course).

What's you experience with this given the above observations? Does all Qjets have this idle down air bleed? Should I plug this bleed in some way? Or...?

Thanks.

I was thinking of my idle issues last night and obviously my engine wants more fuel. To increase the amount of fuel being pulled through the idle circuit I did one experiment this morning. Just above the idle down tube there is an air bleed hole drilled at an angle into the main venturi area so the idle fuel gets mixed up with air. I have not measured the sizes of these air bleeds (yet). But I guess if this hole is restricted the pulling force of the idle fuel can be controlled.

After warming up the car with nozzle drip, I use two steel wires to almost plug these air bleeds. The idle speed went up like crazy, and I could EASILY close the throttle plates all the way down so 0 nozzle drip.

I also get the best idle screw response ever. With this test I could easily get the engine to idle very smooth at 650rpm, and pull 21-22" vacuum (very stable). If I removed the wires the engined dies instantly (of course).

What's you experience with this given the above observations? Does all Qjets have this idle down air bleed? Should I plug this bleed in some way? Or...?

Thanks.

Last edited by voscreature; 08-26-2012 at 12:43 PM.

#57

Tech Contributor

Member Since: Aug 1999

Location: At my Bar drinking and wrenching in Lafayette Colorado

Posts: 13,654

Received 4,924 Likes

on

1,930 Posts

Would you shoot a quick photo of the air bleed holes you're talking about...? I wonder if the commercial builder removed the restrictors from those holes... The other very real posibility is that your carb is a mix-match of components, and it's quite likely that the bleed size is not the correct size for the rest of the components - excellent troubleshooting job!

Last edited by lars; 08-26-2012 at 01:18 PM.

#58

Tech Contributor

Member Since: Aug 1999

Location: At my Bar drinking and wrenching in Lafayette Colorado

Posts: 13,654

Received 4,924 Likes

on

1,930 Posts

Ah... yes.. you're talking about the high speed bleeds... The size (or lack of) high speed air bleeds has a HUGE effect on fuel metering across the entire metering range, including idle. It alters the differential pressure on the fuel metering system from idle through cruise. If the commercial builder removed or altered the bleeds, it will screw up metering at idle, transition, and cruise/WOT.

Here is a 1973 carb with the correct bleeds installed. Hole size is drill size #57:

Here is a '67 carb with slightler larger bleeds: The hole is drill size # 53. The '67 can use larger high speed air bleeds because it does not utilize the idle air bypass holes:

And here is a commecially-built carb where the builder has simply removed the bleeds altogether - this carb is screwed up across the range:

If I were you, I'd start with a stock '73 bleed size of #57 and see how it responds from there (since it appears you have mostly a '73 carb).

"Lars, why do you hate those commecially-built carbs so much...?"

Lars

Here is a 1973 carb with the correct bleeds installed. Hole size is drill size #57:

Here is a '67 carb with slightler larger bleeds: The hole is drill size # 53. The '67 can use larger high speed air bleeds because it does not utilize the idle air bypass holes:

And here is a commecially-built carb where the builder has simply removed the bleeds altogether - this carb is screwed up across the range:

If I were you, I'd start with a stock '73 bleed size of #57 and see how it responds from there (since it appears you have mostly a '73 carb).

"Lars, why do you hate those commecially-built carbs so much...?"

Lars

Last edited by lars; 08-26-2012 at 01:56 PM.

#59

Instructor

Thread Starter

Member Since: Jun 2010

Location: Fritsla Sweden

Posts: 173

Likes: 0

Received 0 Likes

on

0 Posts

Lars,

I will get back with more pictures tonight. But I'm 100% sure I do not have any brass inserts in the bleed holes.

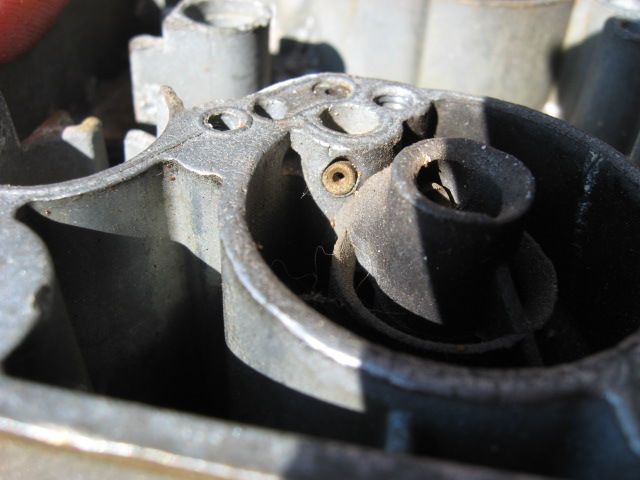

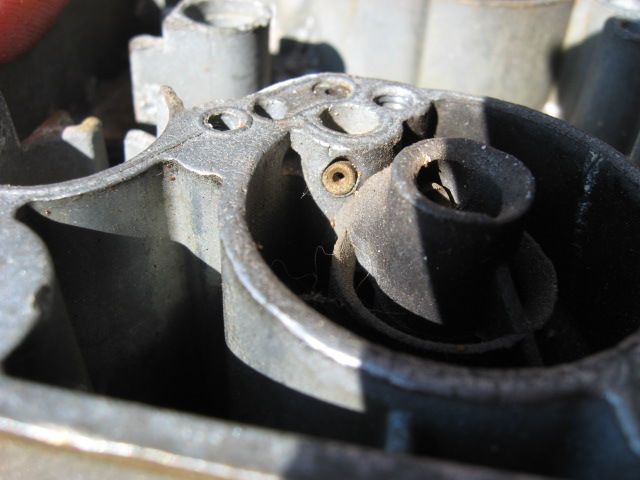

However, I actually referred to the bleed holes that exits directly in the idle down channel:

When I plugged those holes the car idles perfectly without any nozzle drip at all.

I couldn't resist the temptation this morning to try and plug the high speed bleed holes, but after warming up the car and lowering idle I could not get any noticeable change in idle speed when I blocked these holes. But blocking the other bleeds have a huge impact on amount of fuel drawn.

But the air bleed holes that exits in the idle down tube feels critical? If these holes are large the amount of fuel drawn through the idle tubes must be very very limited since it sucks air directly from these bleeds. Since the idle down channel restriction is 0.052" and these holes are (I will check dimensions later) in the same order of magnitude, (if not larger) I imagine that the vacuum is lost in the idle feed tubes leading to my lean idle condition and associated nozzle drip.

Were the holes I referred to used as a calibration method also?

Thanks.

I will get back with more pictures tonight. But I'm 100% sure I do not have any brass inserts in the bleed holes.

However, I actually referred to the bleed holes that exits directly in the idle down channel:

When I plugged those holes the car idles perfectly without any nozzle drip at all.

I couldn't resist the temptation this morning to try and plug the high speed bleed holes, but after warming up the car and lowering idle I could not get any noticeable change in idle speed when I blocked these holes. But blocking the other bleeds have a huge impact on amount of fuel drawn.

But the air bleed holes that exits in the idle down tube feels critical? If these holes are large the amount of fuel drawn through the idle tubes must be very very limited since it sucks air directly from these bleeds. Since the idle down channel restriction is 0.052" and these holes are (I will check dimensions later) in the same order of magnitude, (if not larger) I imagine that the vacuum is lost in the idle feed tubes leading to my lean idle condition and associated nozzle drip.

Were the holes I referred to used as a calibration method also?

Thanks.

#60

Tech Contributor

Member Since: Aug 1999

Location: At my Bar drinking and wrenching in Lafayette Colorado

Posts: 13,654

Received 4,924 Likes

on

1,930 Posts

Ah - those holes! Yes, those are a critical calibrated size to assure proper idle fuel metering, and if the commercial builder drilled them (common "trick"), your idle fuel metering will be completely messed up. Notice on the '67 carb shown above how small those air bleed holes are compared to the #53 hole in the high speed bleed: I'll measure it for you. Notice on the commerically-built carb photo that those air bleed holes have been drilled - I'll bet yours have been drilled, too. Fixing that air bleed will have a huge effect on your idle metering circuit.

Lars

Lars