Head Gasket Roller Cam Swap

#1

Burning Brakes

Thread Starter

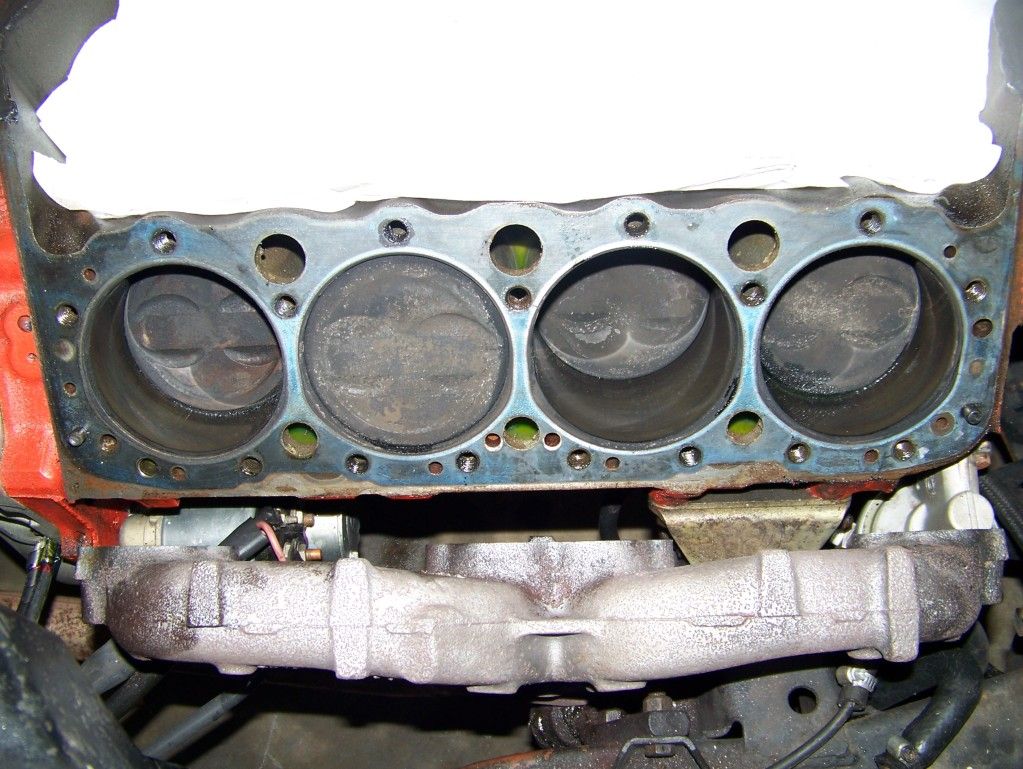

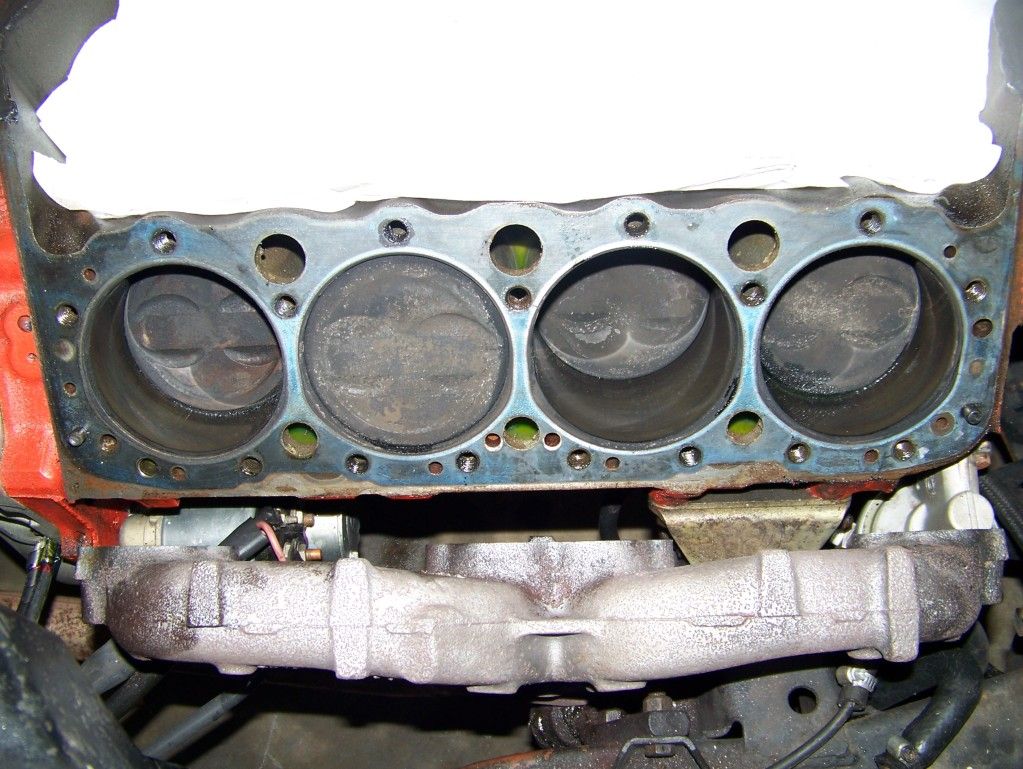

Changing out the unknown head gasket,and installing a roller cam.Hope to get more go outta my L48...Head gasket will be a Felpro 1094 .015 thickness 4.100 bore.Should give me a bump on compression and better quench.On tear down discovered head bolts had no sealant! Yikes! Maybe oil or coolant seeping into cylinders.Found out a Felpro 7733pt2 gasket was used,.039 thickness 4.125 bore.Should get a bump in compression with the new head gaskets for sure.Cylinders looked like this when heads were removed.

[IMG] [/IMG]

[/IMG]

No abnormal wear or scratches on bores.No noticeable ridge detected other than some carbon buildup.Proceeded to remove F/T cam.Pics of roller cam next to F/T in background.You can see the wear pattern on the F/T lobes.Notice the lobe difference on the new billet Crane Cam 119821.

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

Installed heads with new 1094 gaskets,new bolts with SEALANT!!

Installing new cam as careful as can be,lubing bearing and lobe surfaces.

[IMG] [/IMG]

[/IMG]

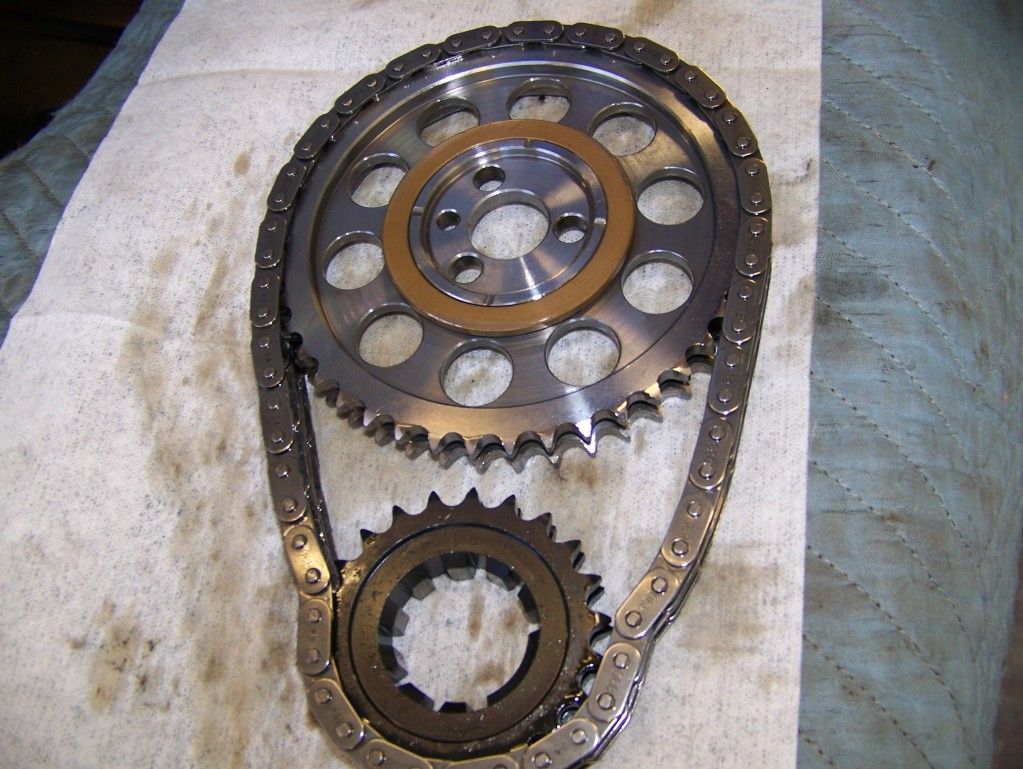

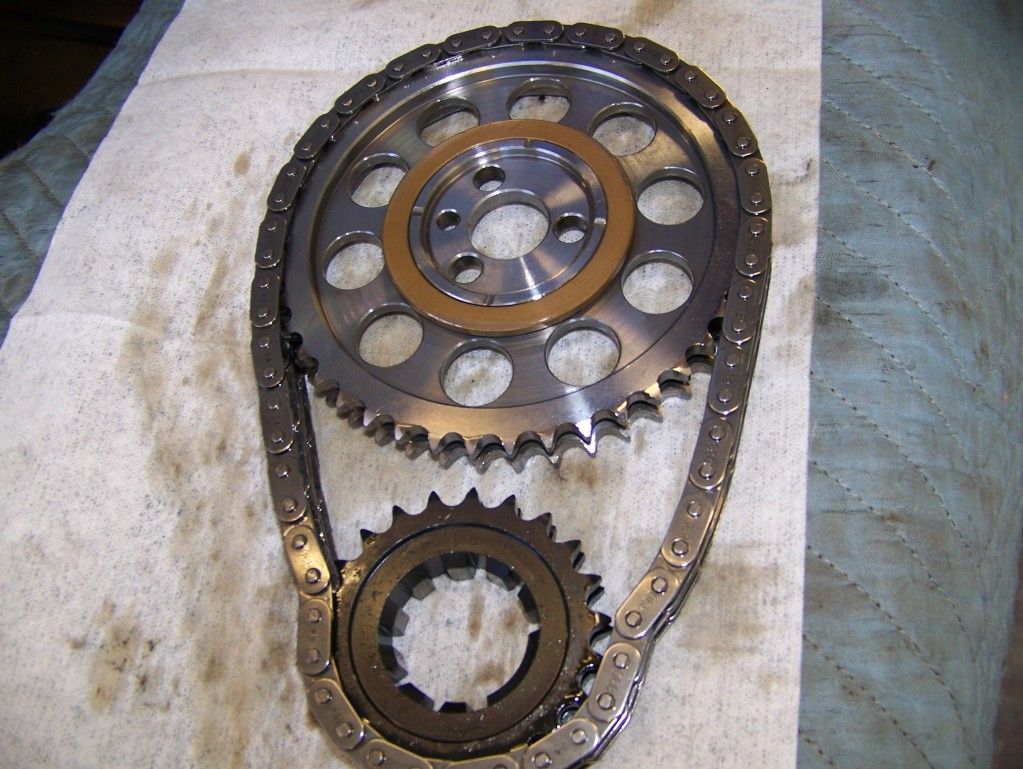

Timing set with bronze thrust washer and 9 keyways to advance or retard cam.

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

Dialed in the cam,needed to advance 2 deg to match cam card.used the A2 keyway on timing gear.Lined up the A2 mark on crank gear with the mark on the cam gear.Check cam timing with cam card on intake and exhaust opening @ .050 lift all good. Hope I did it right! All seems to be good.Remember that dot to dot marks line up on the timing set is TDC for # 6 cylinder compression stroke and it's TDC #1 for exhaust stroke.Kinda confusing at first but it all works.

Install the Cloyes timing cover 9-221 with built in roller button.Need to drop oil pan to remove and install the timing cover.I was able to lower the pan by removing all bolts and just loosen the two larger rear bolts.This way I still had the one piece pan gasket in place.Cloyes cover requires button bolts or allen head fasteners with washers.The stock timing cover bolts won't work!!

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

Set the cam end play with the slightest amount of movement.No way to use a dial indicator with engine in car.Cloyes cover makes this pretty easy to do.There is hardly any movement of the cam with that timing set anyways,don't see how the cam will move forward to cause any problems.Maybe when the timing set gets really worn after many miles.

[IMG] [/IMG]

[/IMG]

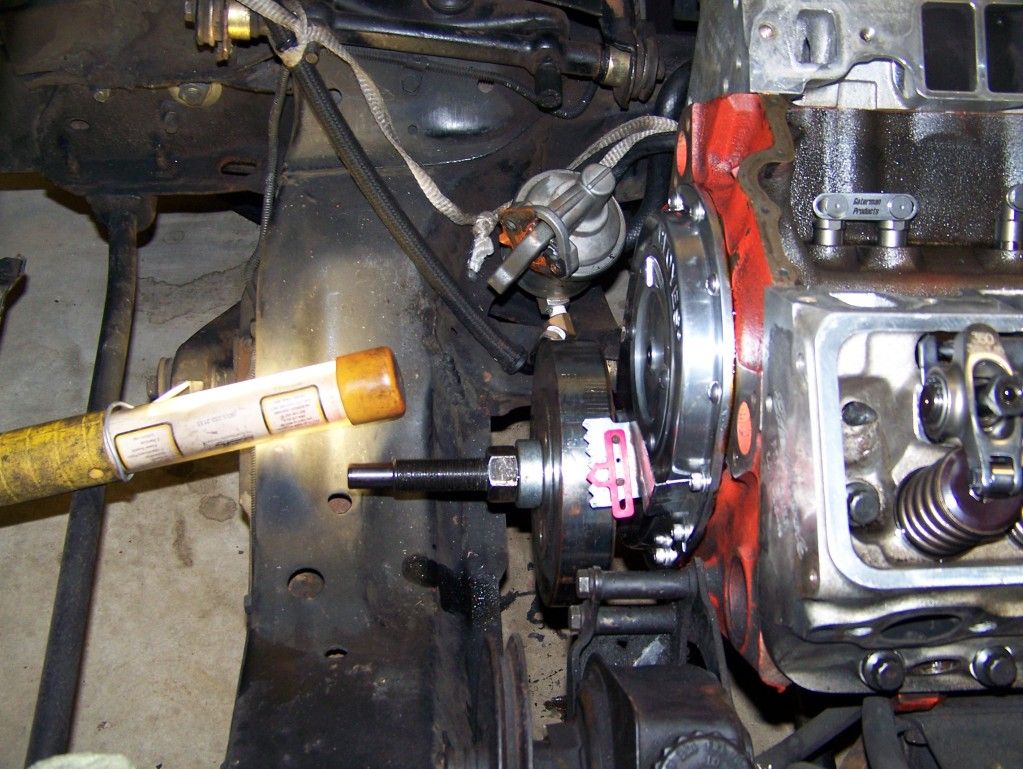

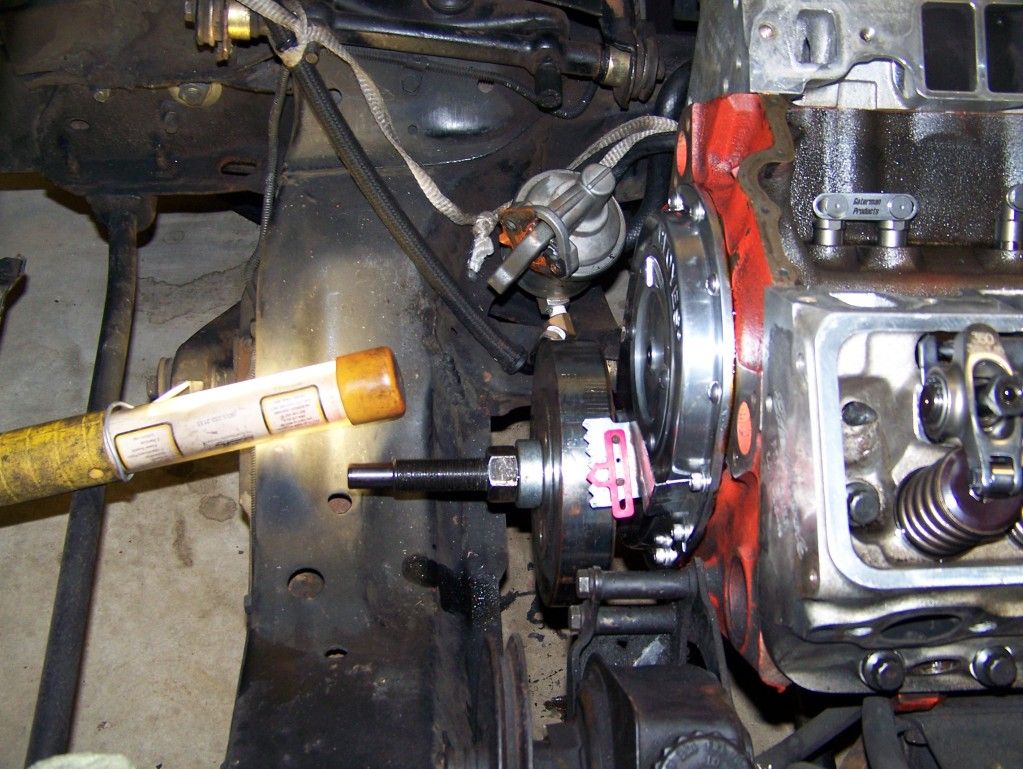

Installing balancer with proper tool

[IMG] [/IMG]

[/IMG]

Checking pushrod length,came out to 7.100 per Gaterman lifter specs.Witness marks show at center of valve stem good to go.Using Comp Cams .105 pushrods.

[IMG] [/IMG]

[/IMG]

Adjusting valves.Rotate engine till exhaust valve on cylinder is just opening then adjust intake to zero lash plus 3/4 turn.Rotate engine till intake is 3/4 closed then adjust exhaust to zero lash plus 3/4 turn.Did this for all 8 cylinders.Hopefully this will be spot on.Figured I'll do the valve adjustment before the intake install to see the lifters in action.

[IMG] [/IMG]

[/IMG]

Intake installed ready for next step.Looks like the short water pump won't fit with the Cloyes Cover,will have to figure something out.Either dbl gaskets or a spacer will be needed...time to take a break!!

[IMG] [/IMG]

[/IMG]

[IMG]

[/IMG]

[/IMG]No abnormal wear or scratches on bores.No noticeable ridge detected other than some carbon buildup.Proceeded to remove F/T cam.Pics of roller cam next to F/T in background.You can see the wear pattern on the F/T lobes.Notice the lobe difference on the new billet Crane Cam 119821.

[IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG]Installed heads with new 1094 gaskets,new bolts with SEALANT!!

Installing new cam as careful as can be,lubing bearing and lobe surfaces.

[IMG]

[/IMG]

[/IMG]Timing set with bronze thrust washer and 9 keyways to advance or retard cam.

[IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG]Dialed in the cam,needed to advance 2 deg to match cam card.used the A2 keyway on timing gear.Lined up the A2 mark on crank gear with the mark on the cam gear.Check cam timing with cam card on intake and exhaust opening @ .050 lift all good. Hope I did it right! All seems to be good.Remember that dot to dot marks line up on the timing set is TDC for # 6 cylinder compression stroke and it's TDC #1 for exhaust stroke.Kinda confusing at first but it all works.

Install the Cloyes timing cover 9-221 with built in roller button.Need to drop oil pan to remove and install the timing cover.I was able to lower the pan by removing all bolts and just loosen the two larger rear bolts.This way I still had the one piece pan gasket in place.Cloyes cover requires button bolts or allen head fasteners with washers.The stock timing cover bolts won't work!!

[IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG]Set the cam end play with the slightest amount of movement.No way to use a dial indicator with engine in car.Cloyes cover makes this pretty easy to do.There is hardly any movement of the cam with that timing set anyways,don't see how the cam will move forward to cause any problems.Maybe when the timing set gets really worn after many miles.

[IMG]

[/IMG]

[/IMG]Installing balancer with proper tool

[IMG]

[/IMG]

[/IMG]Checking pushrod length,came out to 7.100 per Gaterman lifter specs.Witness marks show at center of valve stem good to go.Using Comp Cams .105 pushrods.

[IMG]

[/IMG]

[/IMG]Adjusting valves.Rotate engine till exhaust valve on cylinder is just opening then adjust intake to zero lash plus 3/4 turn.Rotate engine till intake is 3/4 closed then adjust exhaust to zero lash plus 3/4 turn.Did this for all 8 cylinders.Hopefully this will be spot on.Figured I'll do the valve adjustment before the intake install to see the lifters in action.

[IMG]

[/IMG]

[/IMG]Intake installed ready for next step.Looks like the short water pump won't fit with the Cloyes Cover,will have to figure something out.Either dbl gaskets or a spacer will be needed...time to take a break!!

[IMG]

[/IMG]

[/IMG]

Last edited by iokepakai; 01-24-2013 at 08:12 PM.

#2

Race Director

How many miles on the solid flat tappet cam? It was on it's way out. Crane cams hydraulic roller preload is 1/4 to 1/2 turn. Less will rev higher before float, more will float at lower RPM.

http://www.cranecams.com.au/pdfs/pp1110c.pdf

http://www.cranecams.com.au/pdfs/pp1110c.pdf

#3

Burning Brakes

Thread Starter

How many miles on the solid flat tappet cam? It was on it's way out. Crane cams hydraulic roller preload is 1/4 to 1/2 turn. Less will rev higher before float, more will float at lower RPM.

http://www.cranecams.com.au/pdfs/pp1110c.pdf

http://www.cranecams.com.au/pdfs/pp1110c.pdf

Interesting! My Crane Cam install sheet that came with cam specified at 1/2 to 1 turn.The instructions with the Gaterman roller lifters specified 3/4 turn.Will dbl check for sure...Mahalo's

#5

Instructor

Member Since: Jan 2013

Location: Battle Creek MI

Posts: 167

Likes: 0

Received 0 Likes

on

0 Posts

Looks like I'm too late, but I was going to offer a tip. I've cleaned MANY a nasty looking piston like that to near new with a simple off the shelf spray from the auto parts store.

Aircraft Stripper.

Won't harm the pistons whatsoever (it's designed for aluminum) and will take carbon, oil and varnish off the pistons in very short order. Very effective labor and time saver

Aircraft Stripper.

Won't harm the pistons whatsoever (it's designed for aluminum) and will take carbon, oil and varnish off the pistons in very short order. Very effective labor and time saver

#6

Team Owner

For 4.00 - 4.060 bores you want to get 4.060 bore gaskets because they have more between cylinder sealing and that gap out to larger bore gaskets is CC's of lost compression.

They are just plain weaker.

Just a heads up. My original experience with Cloyes was not a good one. When you use a cam gear with a thrust washer depending on the brand it can actually end up farther forward. I has to machine the adjustable button shorter because it was mashed against.

The other problem with thrust washers is timing chain alignment. Some times you have to adjust the crank sprocket out farther for a vert alignment.

Cloyes with clear the back of standard water pumps. Higher volume no!

They are just plain weaker.

Just a heads up. My original experience with Cloyes was not a good one. When you use a cam gear with a thrust washer depending on the brand it can actually end up farther forward. I has to machine the adjustable button shorter because it was mashed against.

The other problem with thrust washers is timing chain alignment. Some times you have to adjust the crank sprocket out farther for a vert alignment.

Cloyes with clear the back of standard water pumps. Higher volume no!

#7

Race Director

Cam was 1 year old,close to 5K miles.All lifters were spinning in bores.They were EDM Crower lifters and Crower 00340 cam.Pretty mild lift and duration.Wear may be the use of Valvoline racing oil that was used at first,Then I switched to Zrod oil shortly after install.

Interesting! My Crane Cam install sheet that came with cam specified at 1/2 to 1 turn.The instructions with the Gaterman roller lifters specified 3/4 turn.Will dbl check for sure...Mahalo's

Interesting! My Crane Cam install sheet that came with cam specified at 1/2 to 1 turn.The instructions with the Gaterman roller lifters specified 3/4 turn.Will dbl check for sure...Mahalo's

#8

Race Director

For 4.00 - 4.060 bores you want to get 4.060 bore gaskets because they have more between cylinder sealing and that gap out to larger bore gaskets is CC's of lost compression.

They are just plain weaker.

Just a heads up. My original experience with Cloyes was not a good one. When you use a cam gear with a thrust washer depending on the brand it can actually end up farther forward. I has to machine the adjustable button shorter because it was mashed against.

The other problem with thrust washers is timing chain alignment. Some times you have to adjust the crank sprocket out farther for a vert alignment.

Cloyes with clear the back of standard water pumps. Higher volume no!

They are just plain weaker.

Just a heads up. My original experience with Cloyes was not a good one. When you use a cam gear with a thrust washer depending on the brand it can actually end up farther forward. I has to machine the adjustable button shorter because it was mashed against.

The other problem with thrust washers is timing chain alignment. Some times you have to adjust the crank sprocket out farther for a vert alignment.

Cloyes with clear the back of standard water pumps. Higher volume no!

#11

Le Mans Master

Member Since: Oct 2002

Location: Las Vegas - Just stop perpetuating myths please.

Posts: 7,098

Received 373 Likes

on

356 Posts

I've read of a lot of posts claiming roller rocker noise recently. And no one talks 'bout clearancing their roller rocker arms. But crane has a tech article for this: http://www.cranecams.com/uploads/instructions/425e_.pdf. Crane says 0.040" clearance at the retainer and clears the stud also (0.060" for stamped rocker but no spec for roller rockers).

Just a heads up if u haven't buttoned it up and fired it yet. And maybe someone else here has done this as i'm curious myself.

I've seen pix showing a paper clip used as a go -nogo gauge.

BTW those are nice looking rocker arms IOKE.

Hope this helps,

cardo0

Just a heads up if u haven't buttoned it up and fired it yet. And maybe someone else here has done this as i'm curious myself.

I've seen pix showing a paper clip used as a go -nogo gauge.

BTW those are nice looking rocker arms IOKE.

Hope this helps,

cardo0

#12

Burning Brakes

Thread Starter

Will need spacers for the water pump to clear the Cloyes cover with the high flow water pump. Ordered 1/4 spacers,hope it doesn't throw off the belt alignment to much will have to see.Did a compression test before tear down and after assembly with new head gaskets and roller cam results below.

Before After

1 150 178

3 150 180

5 145 181

7 155 193

2 155 195

4 150 185

6 140 175

8 150 178

New head gaskets and cam really upped the static compression.These readings, before and after were taken on cold engine.Didn't expect it to increase that much!! 35 psi on some cylinders.Must have had some leakage with the old head gaskets.

Will have to check on the roller rocker clearance,they were pretty quiet even with the solid cam that was in their before the swap to the roller. Thanks for the tip.....

Before After

1 150 178

3 150 180

5 145 181

7 155 193

2 155 195

4 150 185

6 140 175

8 150 178

New head gaskets and cam really upped the static compression.These readings, before and after were taken on cold engine.Didn't expect it to increase that much!! 35 psi on some cylinders.Must have had some leakage with the old head gaskets.

Will have to check on the roller rocker clearance,they were pretty quiet even with the solid cam that was in their before the swap to the roller. Thanks for the tip.....

#13

Team Owner

Instead of using water pump spacers the smarter fix is to use "Button Head allen Screws" and machine the cloyes timing cover thinner. The spacers end up with twin gaskets and the pulleys will be off.

The cam has more to do with trapped compression than the minor cc change of a thinner head gasket

The cam has more to do with trapped compression than the minor cc change of a thinner head gasket

#14

Le Mans Master

I considered the Fel-Pro 1094's until I read this footnote on the application section on Summit's webpage:

"Use in some Sportsman drag race and flat top Oval Track catagories."

I decided to go with the full cylinder head replacement gasket set instead as my vette will likely sit more often than be driven. I went with the FEL-PRO HS 7733 PT-2 Head Gasket Set.

"Use in some Sportsman drag race and flat top Oval Track catagories."

I decided to go with the full cylinder head replacement gasket set instead as my vette will likely sit more often than be driven. I went with the FEL-PRO HS 7733 PT-2 Head Gasket Set.

#15

Burning Brakes

Thread Starter

#16

Burning Brakes

Thread Starter

I considered the Fel-Pro 1094's until I read this footnote on the application section on Summit's webpage:

"Use in some Sportsman drag race and flat top Oval Track catagories."

I decided to go with the full cylinder head replacement gasket set instead as my vette will likely sit more often than be driven. I went with the FEL-PRO HS 7733 PT-2 Head Gasket Set.

"Use in some Sportsman drag race and flat top Oval Track catagories."

I decided to go with the full cylinder head replacement gasket set instead as my vette will likely sit more often than be driven. I went with the FEL-PRO HS 7733 PT-2 Head Gasket Set.

#17

Burning Brakes

Thread Starter

Instead of using water pump spacers the smarter fix is to use "Button Head allen Screws" and machine the cloyes timing cover thinner. The spacers end up with twin gaskets and the pulleys will be off.

The cam has more to do with trapped compression than the minor cc change of a thinner head gasket

The cam has more to do with trapped compression than the minor cc change of a thinner head gasket

#18

Team Owner

The timing cover only hits on the lower 1/3 of the back plate on the water pump. I think i bent the outer edges down and then machined off a little bit of the cloyes for clearance.

It is just a crappy product and i was pissed that I bought it.

It is just a crappy product and i was pissed that I bought it.

#20

Burning Brakes

Thread Starter

Great tip! Will try it..I see what you mean on the cam upping the compression numbers.Previous cam had the intake closing at 43deg ABDC.New roller cam intake closes at 34deg ABDC.New cam closes the intake earlier,thus upping the static compression...