How to improve torsional strength on a C3?

#21

Racer

Thread Starter

But that is theoretical, the car was never designed this way so just simply welding the birdcage to the frame could introduce more problems then it solves.

I do like the box welding of the frame as shown on the pictures above and i am also very interested to know why they changed from alu to rubber body mounts.

In the future my '80 will be stripped down to the bare frame and i am planning to rebould it as good as i can get it, so that is the change to modify things if worth it.

Thanks for sharing the knowlegde. The Corvette Power book is long gone out of the bookshops i guess?

#22

Le Mans Master

I understand that some folks who have installed a "shark Bar" that connects the upper shoulder belt mounting point to the floor seatbelt mounting point with a solid bar behind the seats along with a bar on the floor connecting the lower seatbelt mounts would help. I would think that the bar along with a front spreader bar between the shock towers (which I have and DEFINITELY helps rigidity) would be a BIG improvement. Some folks say the shark Bar does not work, others WITH the bar especially in convertibles say it is a big improvement. Any Sharkbar C3's that can comment?

http://vetteworksonline.net

I do have a heim jointed bar on each side of my C3, like a mini spreader bar, that connects the upper seat belt mount to the lower seat belt mount, but no shark bar on my 78. I can say that my car with the front spreader bar and the heim joint bars on either side behind the carpet does make the car stiffer-mostly the front spreader bar and MUCH quieter-no squeaks!

http://vetteworksonline.net

I do have a heim jointed bar on each side of my C3, like a mini spreader bar, that connects the upper seat belt mount to the lower seat belt mount, but no shark bar on my 78. I can say that my car with the front spreader bar and the heim joint bars on either side behind the carpet does make the car stiffer-mostly the front spreader bar and MUCH quieter-no squeaks!

#24

I understand that some folks who have installed a "shark Bar" that connects the upper shoulder belt mounting point to the floor seatbelt mounting point with a solid bar behind the seats along with a bar on the floor connecting the lower seatbelt mounts would help. I would think that the bar along with a front spreader bar between the shock towers (which I have and DEFINITELY helps rigidity) would be a BIG improvement. Some folks say the shark Bar does not work, others WITH the bar especially in convertibles say it is a big improvement. Any Sharkbar C3's that can comment?

Without the bars I can jack up one wheel of the car. With them its not possible, when I am jacking up any corner of the car both tires on the same side lift off the ground at the same time. So, atleast C4 chassis is stiffened by a great deal by these bars. I know the chassis is very different but maybe (and I do believe so) they would also help with C3 stiffness.

BTW. does a '70 coupe have a shoulder belt bolt connection in the B-pilars under the panels?

Last edited by ToniH; 05-02-2013 at 10:35 AM.

#25

Melting Slicks

Mines fairly stiff, I can't jack one wheel up without the other on the same side coming off the ground. If I jack the the rear wheel in the place where it it it supposed to be jacked, the front wheel on that side comes off the ground, that's the whole side of the engine to being lifted from a point way at the back.

#27

Team Owner

Member Since: Jun 2000

Location: Southbound

Posts: 38,928

Likes: 0

Received 1,468 Likes

on

1,247 Posts

Cruise-In II Veteran

#28

The more crossmembers in a ladder frame stiffens the torsional stiffness. One way to create more of a crossmember effect, front and rear motor plate's, the only good way to fix it is a full rollcage, triangulate.

#29

Melting Slicks

Camaros were way flexier than Corvettes in their stock form. If you had a bit of power and tires that hook, it didn't take many runs before the doors wouldn't open and close right anymore. I have even seen the windshield break on launch with stock bodied and framed Camaros. It is a must to tie the frames and body together on those cars.

The Vette Verts have no structural integrity in the body behind the doors. The top of the sides have a deck lid that opens so there is nothing tying them together from one side or the other. The doors have guides to try and tie the rear body to the closed doors so the doors don't fly open from all the flexing. A Shark bar or something like it makes a big difference on the Verts.

If you want to talk flexy, look at the 59 to 64 full size Chevys with the "X" frame. I have a 64 SS. Look at this 60 on Youtube. Talk about twist and flex!

The Vette Verts have no structural integrity in the body behind the doors. The top of the sides have a deck lid that opens so there is nothing tying them together from one side or the other. The doors have guides to try and tie the rear body to the closed doors so the doors don't fly open from all the flexing. A Shark bar or something like it makes a big difference on the Verts.

If you want to talk flexy, look at the 59 to 64 full size Chevys with the "X" frame. I have a 64 SS. Look at this 60 on Youtube. Talk about twist and flex!

Last edited by v2racing; 05-01-2013 at 09:34 PM.

#30

#32

Tech Contributor

Member Since: Jun 2004

Location: I tend to be leery of any guy who doesn't own a chainsaw or a handgun.

Posts: 18,346

Received 767 Likes

on

549 Posts

Several years ago I bought a used frame to modify to install a C4 suspension. While I was working on it I tried a few things to try to improve the overall stiffness (torsion and beam). I anchored the frame to my lift while I was doing the torsion measurements (@ 2000 ft-lbs).

First thing I did to the frame was finish all the seam welds.

My biggest desire was to put some sort of torsion box in the tunnel, and connect that to the frame rails, but there was minimal available room in the tunnel due to the 5 spd trans I had, so I tried another option, a bolt-in torsion tube between the trans crossmember and the pinion crossmember.

This gave me a couple hundred ft-lbs of additional rigidity.

I would have liked to have been able do something similar ahead of the trans crossmember, but obviously the engine and trans already occupies that real estate. So I tried to stiffen up the front half of the frame rails. I put some tubing inside the frame to add a bit of torsional resistance.

With that done I cut open the rear frame "kickups" and welded in an additional vertical wall to help resist the springiness of that area. I also added tubing between the upper shock mount and the pinion crossmember to help stiffen up that area. The C4 trailing arms placement allowed me room to install that piece.

I got about 40% improvement in the torsional readings with these mods. They weren't free (time, material, and about 30# of additional weight), but it was an engineering exercise I was interested in doing at the time. My "rules" were anything goes regarding frame modifications, but I did not want to cut up the bodywork. (If I had no restrictions on bodywork modifications I would have enlarged the tunnel a couple inches and built a "large" diameter torsion tube inside there to connect the rear 2/3 of the frame length.) Once I was done playing around with the frame and installing the C4 components I then swapped the body over onto it.

The stock frame can be improved with a little work obviously, but IMHO unless you can install some material in the Z (vertical) direction, either by a tunnel torsion tube or a cage with correct tubing orientation, there are significant limitations on how stiff you can make an essentially "two dimensional" frame. I mention "correct" tubing orientation, as I made a few test models during the frame build, and a few members kept asking for results with different configurations, so I kept modifying the model. Some of the models incorporated significant amounts of additional "tubing" without significant attending improvements in the torsional stiffness.

First thing I did to the frame was finish all the seam welds.

My biggest desire was to put some sort of torsion box in the tunnel, and connect that to the frame rails, but there was minimal available room in the tunnel due to the 5 spd trans I had, so I tried another option, a bolt-in torsion tube between the trans crossmember and the pinion crossmember.

This gave me a couple hundred ft-lbs of additional rigidity.

I would have liked to have been able do something similar ahead of the trans crossmember, but obviously the engine and trans already occupies that real estate. So I tried to stiffen up the front half of the frame rails. I put some tubing inside the frame to add a bit of torsional resistance.

With that done I cut open the rear frame "kickups" and welded in an additional vertical wall to help resist the springiness of that area. I also added tubing between the upper shock mount and the pinion crossmember to help stiffen up that area. The C4 trailing arms placement allowed me room to install that piece.

I got about 40% improvement in the torsional readings with these mods. They weren't free (time, material, and about 30# of additional weight), but it was an engineering exercise I was interested in doing at the time. My "rules" were anything goes regarding frame modifications, but I did not want to cut up the bodywork. (If I had no restrictions on bodywork modifications I would have enlarged the tunnel a couple inches and built a "large" diameter torsion tube inside there to connect the rear 2/3 of the frame length.) Once I was done playing around with the frame and installing the C4 components I then swapped the body over onto it.

The stock frame can be improved with a little work obviously, but IMHO unless you can install some material in the Z (vertical) direction, either by a tunnel torsion tube or a cage with correct tubing orientation, there are significant limitations on how stiff you can make an essentially "two dimensional" frame. I mention "correct" tubing orientation, as I made a few test models during the frame build, and a few members kept asking for results with different configurations, so I kept modifying the model. Some of the models incorporated significant amounts of additional "tubing" without significant attending improvements in the torsional stiffness.

#34

Le Mans Master

69427,

Impressive jig work on the frame modifications. In retrospect do you feel the extra effort was worth it versus simply box welding all the frame seams on the garage floor/jack stands?

I just got my 72 vert body off the frame last night, it's still on the dolly ready to be moved to storage tomorrow night, so I was planning to start frame work this weekend. After seeing your work, I guess I'm debating whether to focus on engine/driveline now (got a bare new LSX block ready to start focusing on) or devoting the next few months on that level of frame work. Your expertise and experience is appreciated.

Impressive jig work on the frame modifications. In retrospect do you feel the extra effort was worth it versus simply box welding all the frame seams on the garage floor/jack stands?

I just got my 72 vert body off the frame last night, it's still on the dolly ready to be moved to storage tomorrow night, so I was planning to start frame work this weekend. After seeing your work, I guess I'm debating whether to focus on engine/driveline now (got a bare new LSX block ready to start focusing on) or devoting the next few months on that level of frame work. Your expertise and experience is appreciated.

#35

Race Director

You can make them very stiff but at the cost of added weight.

Monty what's the plan this time N/A or Turbo or S/C ?

Monty what's the plan this time N/A or Turbo or S/C ?

#36

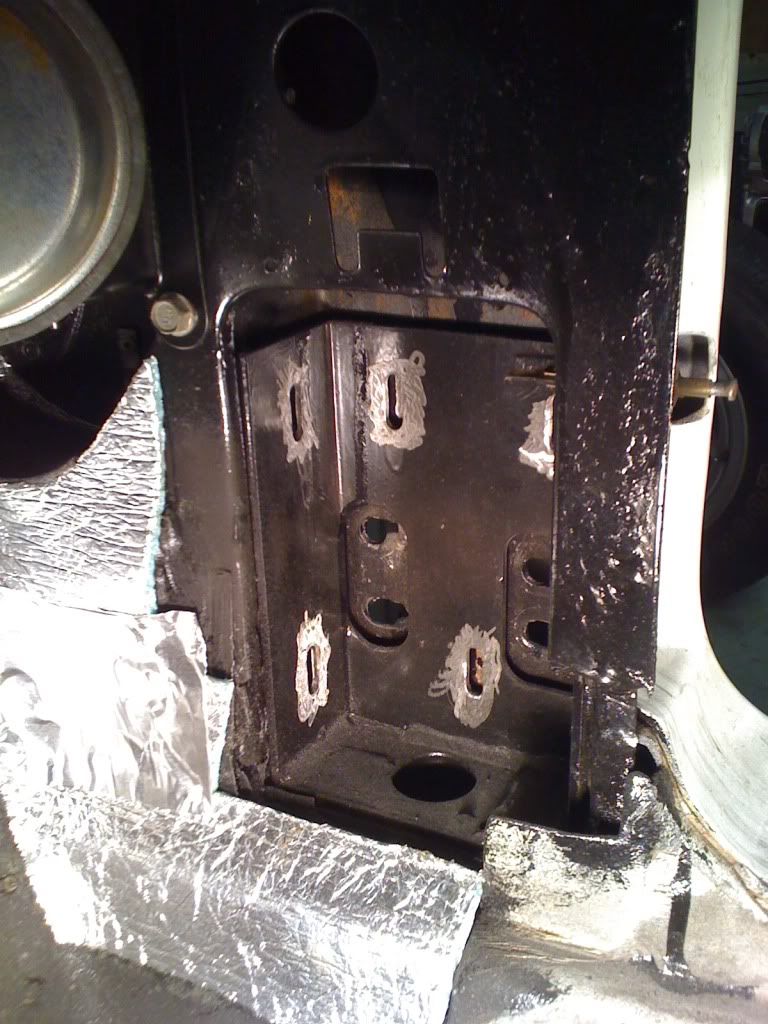

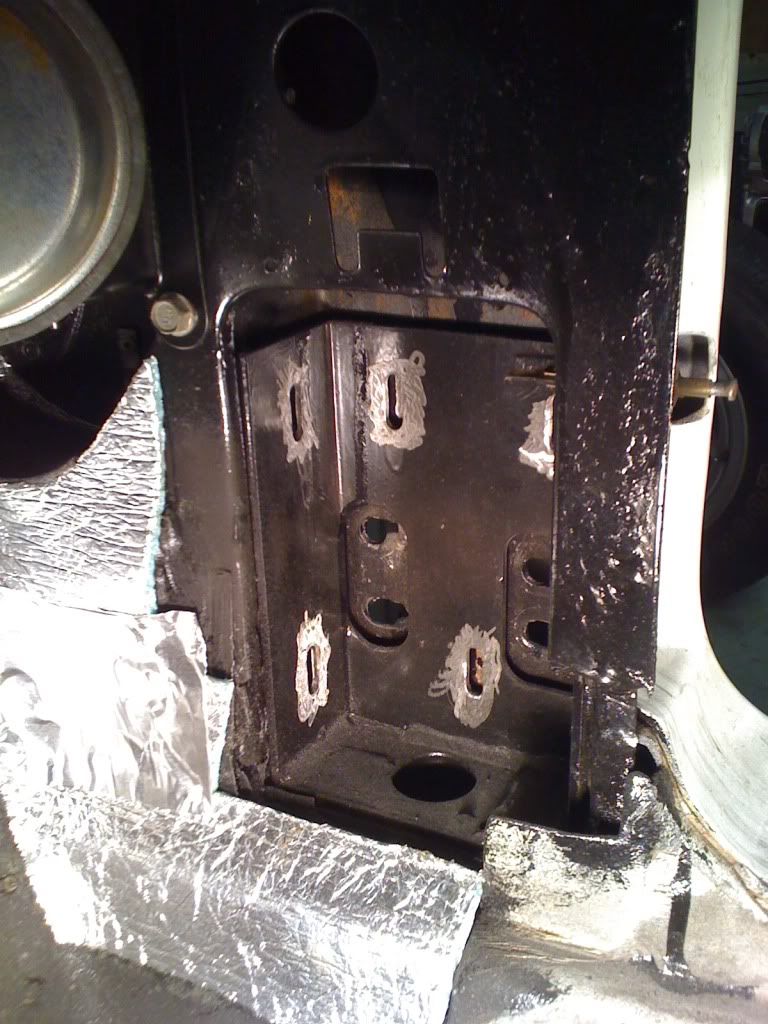

Drifting

When I had my frame out I also added gussets, boxed the front, and went over all the weld continuously. Another problem I had were the body mounts rotted out on my birdcage. I cut out my body mount areas in the A and B pillars, cleaned up the birdcage and welded new 3 piece rocker channel inserts on both sides of the birdcage, doubling the steel down both sides and into all 4 pillars. I also have a VBP spreader bar, and a BTO trans crossmember. I used poly body mounts, actually all poly throughout. Also, my vette weighs 3,180 lbs.

A Pillar

B Pillar

Center Rocker Channel

A Pillar

B Pillar

Center Rocker Channel

Last edited by MIKE80; 05-02-2013 at 06:29 PM.

#37

Burning Brakes

The problem with the vette is the chassis rails are too long for how tough they are, you could box them, seam weld etc but fro most people putting a cage in is easier.

When I drive my vette I can feel the shock waves running from corner to corner when I hit a bump, it's the chassis flexing. I drive my car very hard and it annoys me because I know that whatever I do to the suspension it'll always be there, it's just a crap design

So for me i'll fit a cage, one that triangulates the rear of the chassis and connected to door bars that follow the contour of the seats to end in the footwells, this will be more of a stiffening exercise than a safety one, although it'll help safety too.

The '70> Camaro is a great base for a pro tourer, the one piece shell at the rear is stiff and can be made very stiff very easily.

And the front frame rails are nice and short so don't flex much, just add solid frame mounts, a set of shocks and antiroll bars and you have an awesome corner carver

The Front steer design of the Camaro is a massive improvement over the crap vette design, i'd like the change the vette to front steer although this would require a new crossmember.

The '71 Camaro I had would run rings around my vette with 1/3rd of the work done to it.

All in all the vette has a great engine, trans, brakes and suspension....but has a crap frame and steering

My Camaro -

My vette -

When I drive my vette I can feel the shock waves running from corner to corner when I hit a bump, it's the chassis flexing. I drive my car very hard and it annoys me because I know that whatever I do to the suspension it'll always be there, it's just a crap design

So for me i'll fit a cage, one that triangulates the rear of the chassis and connected to door bars that follow the contour of the seats to end in the footwells, this will be more of a stiffening exercise than a safety one, although it'll help safety too.

The '70> Camaro is a great base for a pro tourer, the one piece shell at the rear is stiff and can be made very stiff very easily.

And the front frame rails are nice and short so don't flex much, just add solid frame mounts, a set of shocks and antiroll bars and you have an awesome corner carver

The Front steer design of the Camaro is a massive improvement over the crap vette design, i'd like the change the vette to front steer although this would require a new crossmember.

The '71 Camaro I had would run rings around my vette with 1/3rd of the work done to it.

All in all the vette has a great engine, trans, brakes and suspension....but has a crap frame and steering

My Camaro -

My vette -

#38

Le Mans Master

Motorhead,

Turbo, but I'm just at the bare block ( LSX 9.720" tall deck still in the box, and UPS stalking a pair of 305cc mast rec port LS7 12 degree heads) I just lifted the body off the frame last night, so I've got a ways to go (and alot of work).

Turbo, but I'm just at the bare block ( LSX 9.720" tall deck still in the box, and UPS stalking a pair of 305cc mast rec port LS7 12 degree heads) I just lifted the body off the frame last night, so I've got a ways to go (and alot of work).

#39

Team Owner