New member with C3 suspension questions

#1

Instructor

Thread Starter

Thanks in advance. I have been a casual observer for a few months now following the purchase of my first C3. I have found a ton of great information and am at the point where I thought I would jump in and ask some of the questions I have.

Scenario: Numbers matching 1975 convertible in driver condition with an all original rear diff and suspension. The diff case is damaged due to the stub axles wearing into the case and the stub axles pull out from the case. I have read a ton about the soft steel used on the mid 70's C3 stubs and am positive the stubs have worn to the point the c clips are toast given the axles pulling out from the diff housing when the car is raised. The car is an L48 4-speed A/C car and has the original 3.55 gear set.

Knowing I was going to have to spend to fix the issue, I found a very lightly used 1979 rear suspension that was set up in a hot rod with a 4 link. The set up had been sitting in a garage for over 20 years. I date coded the housing to 1979 and it came with a 10 leaf, 2.5" wide spring, complete half shafts and rear spindles/axles. The only thing it was missing are the trailing arm housing. It even came with rear rotors, etc. The bad part is that everything was painted lemon yellow to protect from rust??

I've been stripping paint and de rusting everything and plan on using the 1979 diff, half shafts and spring. I will get rebuilt trailing arms with new spindles, etc.

My questions relate to swapping the 1979 diff and spring with the stock 1975 unit. I know the new diff is 3.36(?) based on 'net info and a rough calculation counting the turns. The unit is bone dry at the stub axles and pinion so I plan on draining, cleaning and painting the unit. Just to be sure, I'm going to replace the c clips and side axle seals. I'll repaint, etc. I understand the '79 spring is wider by .25" than the '75, but other than a new mounting plate for the spring, will everything else bolt up? The set up came with 2.5" OD half shafts. I'm wracking my brain trying to find any other info on line which may hold up the swap. I'll naturally keep all the "born with" parts, but am excited to resolve the other issues.

Thanks again!

Scenario: Numbers matching 1975 convertible in driver condition with an all original rear diff and suspension. The diff case is damaged due to the stub axles wearing into the case and the stub axles pull out from the case. I have read a ton about the soft steel used on the mid 70's C3 stubs and am positive the stubs have worn to the point the c clips are toast given the axles pulling out from the diff housing when the car is raised. The car is an L48 4-speed A/C car and has the original 3.55 gear set.

Knowing I was going to have to spend to fix the issue, I found a very lightly used 1979 rear suspension that was set up in a hot rod with a 4 link. The set up had been sitting in a garage for over 20 years. I date coded the housing to 1979 and it came with a 10 leaf, 2.5" wide spring, complete half shafts and rear spindles/axles. The only thing it was missing are the trailing arm housing. It even came with rear rotors, etc. The bad part is that everything was painted lemon yellow to protect from rust??

I've been stripping paint and de rusting everything and plan on using the 1979 diff, half shafts and spring. I will get rebuilt trailing arms with new spindles, etc.

My questions relate to swapping the 1979 diff and spring with the stock 1975 unit. I know the new diff is 3.36(?) based on 'net info and a rough calculation counting the turns. The unit is bone dry at the stub axles and pinion so I plan on draining, cleaning and painting the unit. Just to be sure, I'm going to replace the c clips and side axle seals. I'll repaint, etc. I understand the '79 spring is wider by .25" than the '75, but other than a new mounting plate for the spring, will everything else bolt up? The set up came with 2.5" OD half shafts. I'm wracking my brain trying to find any other info on line which may hold up the swap. I'll naturally keep all the "born with" parts, but am excited to resolve the other issues.

Thanks again!

#2

Thanks in advance. I have been a casual observer for a few months now following the purchase of my first C3. I have found a ton of great information and am at the point where I thought I would jump in and ask some of the questions I have.

Scenario: Numbers matching 1975 convertible in driver condition with an all original rear diff and suspension. The diff case is damaged due to the stub axles wearing into the case and the stub axles pull out from the case. I have read a ton about the soft steel used on the mid 70's C3 stubs and am positive the stubs have worn to the point the c clips are toast given the axles pulling out from the diff housing when the car is raised. The car is an L48 4-speed A/C car and has the original 3.55 gear set.

Knowing I was going to have to spend to fix the issue, I found a very lightly used 1979 rear suspension that was set up in a hot rod with a 4 link. The set up had been sitting in a garage for over 20 years. I date coded the housing to 1979 and it came with a 10 leaf, 2.5" wide spring, complete half shafts and rear spindles/axles. The only thing it was missing are the trailing arm housing. It even came with rear rotors, etc. The bad part is that everything was painted lemon yellow to protect from rust??

I've been stripping paint and de rusting everything and plan on using the 1979 diff, half shafts and spring. I will get rebuilt trailing arms with new spindles, etc.

My questions relate to swapping the 1979 diff and spring with the stock 1975 unit. I know the new diff is 3.36(?) based on 'net info and a rough calculation counting the turns. The unit is bone dry at the stub axles and pinion so I plan on draining, cleaning and painting the unit. Just to be sure, I'm going to replace the c clips and side axle seals. I'll repaint, etc. I understand the '79 spring is wider by .25" than the '75, but other than a new mounting plate for the spring, will everything else bolt up? The set up came with 2.5" OD half shafts. I'm wracking my brain trying to find any other info on line which may hold up the swap. I'll naturally keep all the "born with" parts, but am excited to resolve the other issues.

Thanks again!

Scenario: Numbers matching 1975 convertible in driver condition with an all original rear diff and suspension. The diff case is damaged due to the stub axles wearing into the case and the stub axles pull out from the case. I have read a ton about the soft steel used on the mid 70's C3 stubs and am positive the stubs have worn to the point the c clips are toast given the axles pulling out from the diff housing when the car is raised. The car is an L48 4-speed A/C car and has the original 3.55 gear set.

Knowing I was going to have to spend to fix the issue, I found a very lightly used 1979 rear suspension that was set up in a hot rod with a 4 link. The set up had been sitting in a garage for over 20 years. I date coded the housing to 1979 and it came with a 10 leaf, 2.5" wide spring, complete half shafts and rear spindles/axles. The only thing it was missing are the trailing arm housing. It even came with rear rotors, etc. The bad part is that everything was painted lemon yellow to protect from rust??

I've been stripping paint and de rusting everything and plan on using the 1979 diff, half shafts and spring. I will get rebuilt trailing arms with new spindles, etc.

My questions relate to swapping the 1979 diff and spring with the stock 1975 unit. I know the new diff is 3.36(?) based on 'net info and a rough calculation counting the turns. The unit is bone dry at the stub axles and pinion so I plan on draining, cleaning and painting the unit. Just to be sure, I'm going to replace the c clips and side axle seals. I'll repaint, etc. I understand the '79 spring is wider by .25" than the '75, but other than a new mounting plate for the spring, will everything else bolt up? The set up came with 2.5" OD half shafts. I'm wracking my brain trying to find any other info on line which may hold up the swap. I'll naturally keep all the "born with" parts, but am excited to resolve the other issues.

Thanks again!

http://www.thevettenet.com/corvette_specs.php?year=1979

I think, but I'm not 100% sure, but all the differentials are the same from 1965 to 1979 and are interchangeable. In 1980, there was a change to an aluminum one. Not sure about '63 - '64.

Other more knowledgeable folks will chime in.

Last edited by blk79nj; 03-31-2017 at 08:22 PM.

The following users liked this post:

Highlander1732 (04-01-2017)

#3

Instructor

Thread Starter

I appreciate the insight and am hoping that will be the case. It would be disappointing to get this far and find another big ticket item that would prevent the swap.

Hello, welcome to the forum. My understanding is that an automatic equipped '79 should have a 3.55 rear gear.

http://www.thevettenet.com/corvette_specs.php?year=1979

I think, but I'm not 100% sure, but all the differentials are the same from 1965 to 1979 and are interchangeable. In 1980, there was a change to an aluminum one. Not sure about '63 - '64.

Other more knowledgeable folks will chime in.

http://www.thevettenet.com/corvette_specs.php?year=1979

I think, but I'm not 100% sure, but all the differentials are the same from 1965 to 1979 and are interchangeable. In 1980, there was a change to an aluminum one. Not sure about '63 - '64.

Other more knowledgeable folks will chime in.

#4

Race Director

The rear end cover can be swapped if you want to kept the original width leaf spring....assuming that is it still good and doe snot need to be re-arched.

If you are installing the leaf spring that came in the parts you have...and you have already removed it from the rear end cover of teh 1979 differential. There IS a process in how you MUST (or should) re-install this spring so you DO NOT snap the ears off the rear end cover when you are installing it and applying the CORRECT TORQUE to the bottom center four bolts for the leaf spring.

Making sure you have the CORRECT LENGTH bolts where the leaf spring is mounted to the rear end cover is a MUST also....If you install ones that are too long...you WILL poke a hole into your differential and oil will seep out.

SO...if you plan on buying a new leaf spring...this is also quite important because the new springs....even though you may get a 7 leaf or 9 leaf spring...the thicknesses of EACH LEAF is thicker than the factory...so using the correct factory bolts may not work due to you are now using bolts that do not have enough threads going into the rear end cover.

The half shafts did change in diameter but they will work due to the universal joints are the same.

If you plan on replacing the universal joints...this is also something that I do at my shop and that is use the SOLID SPICER U-joints and I NEVER put a universal joint in a Corvette that has a grease fitting in it. NEVER! But do as you wish. And...if you plan on installing your own U-joints...you will need the inner bearing flange attached to your spindle to bolt to the u-joint flange that attaches to it to give it strength so you can press out and in your new u-joints.

IF you axle ratio is not the same...then the driven gear for your speedometer in your transmission will need to be changes so your speedometer will read correctly. There is a 'speedometer calculator' on the internet that can help you in that....if needed.

DUB

If you are installing the leaf spring that came in the parts you have...and you have already removed it from the rear end cover of teh 1979 differential. There IS a process in how you MUST (or should) re-install this spring so you DO NOT snap the ears off the rear end cover when you are installing it and applying the CORRECT TORQUE to the bottom center four bolts for the leaf spring.

Making sure you have the CORRECT LENGTH bolts where the leaf spring is mounted to the rear end cover is a MUST also....If you install ones that are too long...you WILL poke a hole into your differential and oil will seep out.

SO...if you plan on buying a new leaf spring...this is also quite important because the new springs....even though you may get a 7 leaf or 9 leaf spring...the thicknesses of EACH LEAF is thicker than the factory...so using the correct factory bolts may not work due to you are now using bolts that do not have enough threads going into the rear end cover.

The half shafts did change in diameter but they will work due to the universal joints are the same.

If you plan on replacing the universal joints...this is also something that I do at my shop and that is use the SOLID SPICER U-joints and I NEVER put a universal joint in a Corvette that has a grease fitting in it. NEVER! But do as you wish. And...if you plan on installing your own U-joints...you will need the inner bearing flange attached to your spindle to bolt to the u-joint flange that attaches to it to give it strength so you can press out and in your new u-joints.

IF you axle ratio is not the same...then the driven gear for your speedometer in your transmission will need to be changes so your speedometer will read correctly. There is a 'speedometer calculator' on the internet that can help you in that....if needed.

DUB

#5

Melting Slicks

If you plan on replacing the universal joints...this is also something that I do at my shop and that is use the SOLID SPICER U-joints and I NEVER put a universal joint in a Corvette that has a grease fitting in it. NEVER! But do as you wish.

DUB[/QUOTE]

Curious why you wouldn't use a U joint with a grease fitting in a Corvette.

DUB[/QUOTE]

Curious why you wouldn't use a U joint with a grease fitting in a Corvette.

#6

Race Director

A re-greasabe U-joint is weaker due (in my opinion) to being cross drilled so grease can get to each cap....so...it is common practice for me to not put a re-greasble U-joint in....because I work on seriously stout Corvettes with a lot of HP and torque...along with the ones that are quite mild mannered.

And YES...I have never had a Corvette come into my shop where the U-joint literally broke. I have seen them where they were so worn out they broke the caps and the half shaft spun around destroying much of the underbody area.

But knowing my luck...if I did not put the correct design in when servicing them. And something went really wrong....then the owner would be looking at me...and hold me liable and I would be having to deal with it...and honestly...it is not that big of a deal for me to stand my ground with my customers and let them know what I will do and what I won't do. Obviously...everybody can choose to do what they want to do.

DUB

Last edited by DUB; 04-03-2017 at 05:32 PM.

#7

Instructor

There are alot of valid points made but, one thought you might consider is that servicing greaseable u-joints in confined areas is sometimes next to impossible or extremely frustrating!

The run of the mill part store brands are middle road guality at best. Definitely request Spicer brand if possible.

A solid joint is stronger, but also has the correct amount of lube installed ,so no fuss after installing.

Just drive and enjoy!

The run of the mill part store brands are middle road guality at best. Definitely request Spicer brand if possible.

A solid joint is stronger, but also has the correct amount of lube installed ,so no fuss after installing.

Just drive and enjoy!

#8

Racer

There are alot of valid points made but, one thought you might consider is that servicing greaseable u-joints in confined areas is sometimes next to impossible or extremely frustrating!

The run of the mill part store brands are middle road guality at best. Definitely request Spicer brand if possible.

A solid joint is stronger, but also has the correct amount of lube installed ,so no fuss after installing.

Just drive and enjoy!

The run of the mill part store brands are middle road guality at best. Definitely request Spicer brand if possible.

A solid joint is stronger, but also has the correct amount of lube installed ,so no fuss after installing.

Just drive and enjoy!

If you habitually hit up the shock loads, you're more likely to bust the needle bearings or the stock rear-end, but you might as well go for solid joints. You'll just have to take them out and lube up every so often. How many actually stay on top of that chore?

#9

Race Director

Top be fair and balanced, you won't have a problem with a well made (Spicer) greasable u-joint on a typical street/moderate performance application if you orient the zerks on the compression side of their connections. Especially with an automatic.

If you habitually hit up the shock loads, you're more likely to bust the needle bearings or the stock rear-end, but you might as well go for solid joints. You'll just have to take them out and lube up every so often. How many actually stay on top of that chore?

If you habitually hit up the shock loads, you're more likely to bust the needle bearings or the stock rear-end, but you might as well go for solid joints. You'll just have to take them out and lube up every so often. How many actually stay on top of that chore?

with the part that SPICER U-joints with grease fitting them are a quality product...even though I do not use them...but it still stands to reason..WHY put in a weaker U-joint....automatic or manual. It is not like the price for each are so different that it should cause someone to go broke.

with the part that SPICER U-joints with grease fitting them are a quality product...even though I do not use them...but it still stands to reason..WHY put in a weaker U-joint....automatic or manual. It is not like the price for each are so different that it should cause someone to go broke.You kinda lost me here on making sure the U-joint is correctly orientated so the 'zerks are on the compression side of their connections'. All I do know about those U-joints that I have seen and have removed, etc. The main thing is that usually they never get the zerk fitting correctly positioned so a grease gun COULD grease it again if it needed it. Not that it matters to me due to not using them... but I am confused on why it matters? SO...****thinking about it**** Unless you are referring to the direction of the tip of the zerk fitting is pointing towards the direction it normally rotates....or having it facing opposite of its normal rotation. I would assume you want it pointing towards the direction it normally rotates to if the concern is grease being slung out of the zerk fitting is why you mentioned that.

And honestly....and I know people can do as they wish here....but....I have never taken out a solid U -joint to grease it again. If I am taking the U-joint out...I am putting a new one in its place....and this is usually due to the U-joint is looking like it has been there for decades anyway. And at a 50,000+ mile interval...that I have found to be very consistent....is a long time.

People can pick and choose what they want to use and I am NOT here judging anybody......I am only commenting on how I do things at my shop where I am held liable for my work. All advice, comments and suggestions here are FREE....so it obviously is up to a person to determine what they want to do with it.

DUB

#10

Racer

with the part that SPICER U-joints with grease fitting them are a quality product...even though I do not use them...but it still stands to reason..WHY put in a weaker U-joint....automatic or manual. It is not like the price for each are so different that it should cause someone to go broke.

with the part that SPICER U-joints with grease fitting them are a quality product...even though I do not use them...but it still stands to reason..WHY put in a weaker U-joint....automatic or manual. It is not like the price for each are so different that it should cause someone to go broke.You kinda lost me here on making sure the U-joint is correctly orientated so the 'zerks are on the compression side of their connections'. All I do know about those U-joints that I have seen and have removed, etc. The main thing is that usually they never get the zerk fitting correctly positioned so a grease gun COULD grease it again if it needed it. Not that it matters to me due to not using them... but I am confused on why it matters? SO...****thinking about it**** Unless you are referring to the direction of the tip of the zerk fitting is pointing towards the direction it normally rotates....or having it facing opposite of its normal rotation. I would assume you want it pointing towards the direction it normally rotates to if the concern is grease being slung out of the zerk fitting is why you mentioned that.

And honestly....and I know people can do as they wish here....but....I have never taken out a solid U -joint to grease it again. If I am taking the U-joint out...I am putting a new one in its place....and this is usually due to the U-joint is looking like it has been there for decades anyway. And at a 50,000+ mile interval...that I have found to be very consistent....is a long time.

People can pick and choose what they want to use and I am NOT here judging anybody......I am only commenting on how I do things at my shop where I am held liable for my work. All advice, comments and suggestions here are FREE....so it obviously is up to a person to determine what they want to do with it.

DUB

Good points, and as I mentioned, you should use solid joints if you're a likely candidate for doing major damage. But it would be nice if we could make those choices based on research rather than anecdotal evidence. I'm sure we've all broken a u-joint but where did it break and why?

Well, without finding any good write-ups on testing all this, I'm sharing what I have heard and seen. When I received my order and found out I got the greasable type in error a couple years ago I started reading everything I could find and decided to use them. Even Spicer provided me information that they were just about as strong as a solid joint. If anybody feels like breaking a few for the sake of testing I'd be very interested to see the results.

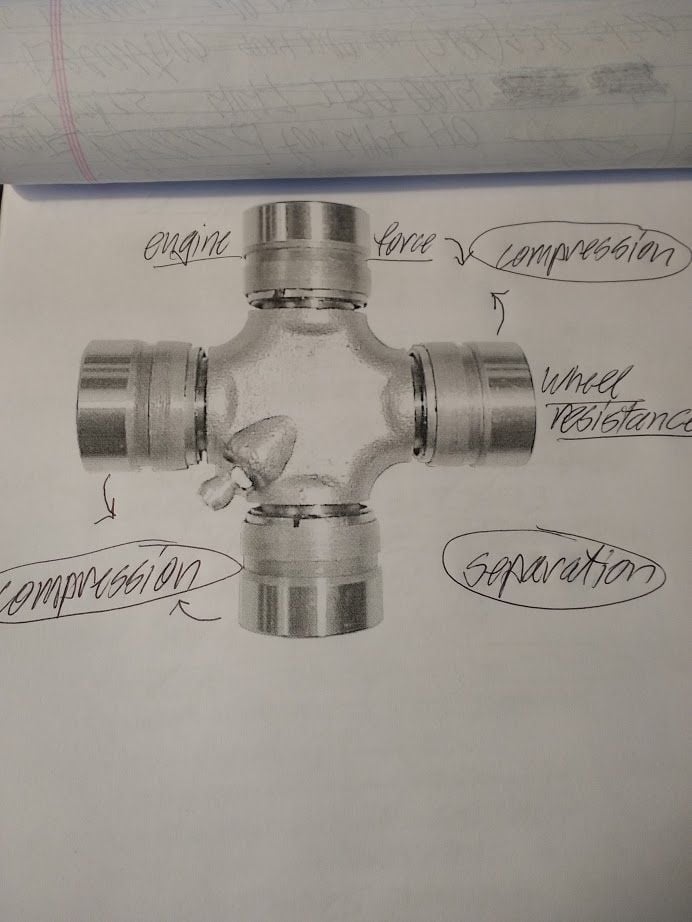

Attached is my explanation of the sage advice regarding the position of the zerk fitting in the "compression" side of the drive trunnions.

Last edited by Silvertone; 04-03-2017 at 07:51 PM.

#11

Race Director

Unless I am mistaken...installing them like this..will cause of one of the U-joints on each half shaft to be positioned in manner that you will not be able to get to the U-joint????

DUB

DUB

#12

Racer

Its OK to flip the joint over so the zerk is most accessible in the widest angled gap of the shaft.

The only thing that matters is the fitting be placed in front of the rotation of one of the two driven trunnions. If the zerk is behind the driven trunnion, that area is subject to being ripped apart.