Fastener Torque & Lubrication

#1

Old Fart Pilot

Thread Starter

I'm finally beginning to reassemble my chassis for my '71 body-off restoration. As a newbie to all this, I know I don't have the knowledge and/or experience that many of you do, but I'm diving in anyway. I do lots of research and then if I'm still a bit unsure of something, I ask about it here.

With that said, here are some questions regarding chassis, body and general fasteners (not critical internal engine & differential parts, I left that up to my rebuilders):

1) Are torque values in the AIM for dry or lubricated fasteners?

2) Are there any fasteners that you specifically do or do not lubricate?

3) For lubrication, do you recommend anti-sieze or 30w oil or doesn't it really matter, especially for a future fair-weather only car?

4) If using lubrication, do you recommend nickel- or copper- based anti-sieze products (2600*F vs 1800*F) or the Lock-tite products?

5) I know dry torque targets should be reduced for lubricated fasteners, but what reduction values do you recommend (I've seen values of 10-30%)?

Many thanks to any and all that chime in to help me figure this all out

Paul

With that said, here are some questions regarding chassis, body and general fasteners (not critical internal engine & differential parts, I left that up to my rebuilders):

1) Are torque values in the AIM for dry or lubricated fasteners?

2) Are there any fasteners that you specifically do or do not lubricate?

3) For lubrication, do you recommend anti-sieze or 30w oil or doesn't it really matter, especially for a future fair-weather only car?

4) If using lubrication, do you recommend nickel- or copper- based anti-sieze products (2600*F vs 1800*F) or the Lock-tite products?

5) I know dry torque targets should be reduced for lubricated fasteners, but what reduction values do you recommend (I've seen values of 10-30%)?

Many thanks to any and all that chime in to help me figure this all out

Paul

#2

Le Mans Master

Member Since: Sep 2001

Location: Wellington, FL

Posts: 9,996

Received 417 Likes

on

288 Posts

St. Jude Donor '11-'12-'13-'14-'15-'16-'17-‘18-'19-'20-'21-'22-'23-'24

Have you tried the GM shop/service manual for your year Vette? If you don't have it, you might want to purchase one. It will come in very handy on all your reassembly work. Good luck with your project.

#4

Drifting

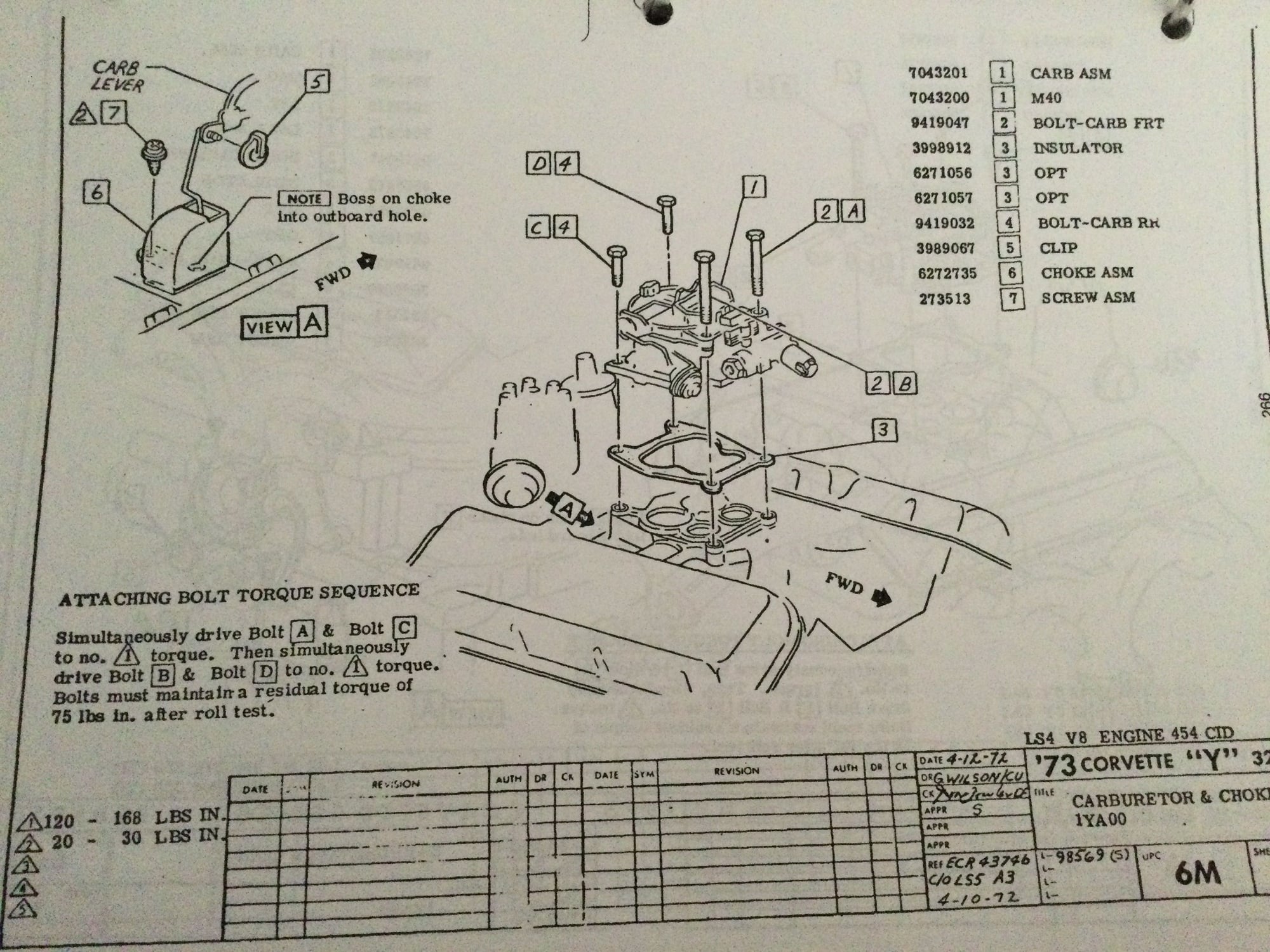

The AIM for my 73 shows torque valves for bolts/screws on each illustration page. Also shows the Chevrolet part number, of course after 49 years no dealer would have or be able to order the part. Make sure you are careful and notice when the Torque is Given in INCH POUDS.

#5

Old Fart Pilot

Thread Starter

Thanks. So if I've lubricated the fastener, I should use 70% of the listed torque in the AIM, correct? (I can't imagine that the factory line workers lubed every fastener during production.)

#7

Old Fart Pilot

Thread Starter

The AIM for my 73 shows torque valves for bolts/screws on each illustration page. Also shows the Chevrolet part number, of course after 49 years no dealer would have or be able to order the part. Make sure you are careful and notice when the Torque is Given in INCH POUDS.

#8

Melting Slicks

Lubricating fasteners helps ensure the applied torque to all hardware will be similar, necessary to maintain gasket and machined surface flatness while tightening for example

Lubrication also prevents 'cold welding' and similar, the seizure of fasteners, due to corrosion/oxidation or simple close contact of dissimilar metals and such.

It helps prevent degradation over time. It is almost always desirable to coat metal with some kind of protection.

On an engine almost all the hardware needs some kind of lube for these various reasons. Any metal exposed to air generally could benefit from a protective layer of oil for example.

On a chassis, you may not want much lubrication due the fear of vibration causing bolts to back out and that sort of behavior. This is the only reason I can think of you might not want to use alot or any lube for some hardware.

On the chassis there may not be any machined or gasket surfaces to worry about when it comes to fastener tightness.

The main concern I would think is still protection; you can lube the hardware after its been tightened though.

I believe most of the bolt materials match the chassis (steel -> steel) so dissimilar metals is not an issue.

The hardware of today is not like it was in the 70's. Bolts produced these days likely have different properties than they used to. Probably a bit better yield strength or elastic properties I would imagine.

You may be better off using modern hardware but it may require a different approach or torque setting than the original stuff.

I would therefore take the manual as a sort of 'guideline' for tightness, and instead of following by the book, evaluate each individual situation (bolt type, location, how it works, how easy to overtighten, how difficult to protect/lube, how often it should come back out if ever, whether you can tell if its backing out over time by itself, how easy to inspect or how often it can be inspected if at all, etc...) And dish out tight sequence and lube based on the logical thought consideration.

Lubrication also prevents 'cold welding' and similar, the seizure of fasteners, due to corrosion/oxidation or simple close contact of dissimilar metals and such.

It helps prevent degradation over time. It is almost always desirable to coat metal with some kind of protection.

On an engine almost all the hardware needs some kind of lube for these various reasons. Any metal exposed to air generally could benefit from a protective layer of oil for example.

On a chassis, you may not want much lubrication due the fear of vibration causing bolts to back out and that sort of behavior. This is the only reason I can think of you might not want to use alot or any lube for some hardware.

On the chassis there may not be any machined or gasket surfaces to worry about when it comes to fastener tightness.

The main concern I would think is still protection; you can lube the hardware after its been tightened though.

I believe most of the bolt materials match the chassis (steel -> steel) so dissimilar metals is not an issue.

The hardware of today is not like it was in the 70's. Bolts produced these days likely have different properties than they used to. Probably a bit better yield strength or elastic properties I would imagine.

You may be better off using modern hardware but it may require a different approach or torque setting than the original stuff.

I would therefore take the manual as a sort of 'guideline' for tightness, and instead of following by the book, evaluate each individual situation (bolt type, location, how it works, how easy to overtighten, how difficult to protect/lube, how often it should come back out if ever, whether you can tell if its backing out over time by itself, how easy to inspect or how often it can be inspected if at all, etc...) And dish out tight sequence and lube based on the logical thought consideration.

#9

Race Director

Member Since: Apr 2011

Location: North of Toronto - Ontario

Posts: 10,856

Received 3,139 Likes

on

2,070 Posts

Virtually all listed torque values are going to be dry unless specifically calling for a lubricant on the assembly (such as in the case where a thread sealer is called or in an engine where the bolts are called to be installed wet etc. On precision work toque will usually be changed to stretch or in some cases degrees.

I usually drop by about 20 for NEW fastener, 10 or so for cleaned up old ones (rougher surfaces) but honestly don't worry too much unless it's a moving type thing like suspension. If I don't put a torque wrench on it I know I'm going to be way over tightening it anyway.

For anti-seize I use silver for most everything unless I'm needing it for a ground path then I use the copper

Just my $.02

M

I usually drop by about 20 for NEW fastener, 10 or so for cleaned up old ones (rougher surfaces) but honestly don't worry too much unless it's a moving type thing like suspension. If I don't put a torque wrench on it I know I'm going to be way over tightening it anyway.

For anti-seize I use silver for most everything unless I'm needing it for a ground path then I use the copper

Just my $.02

M

#11

Racer

Thanks to all the posters. Lots of great info.

This got me thinking that using a thread locker i.e. Loctite, blue, red etc. would be considered a lubricant. I would say yes but what are your thoughts.

This got me thinking that using a thread locker i.e. Loctite, blue, red etc. would be considered a lubricant. I would say yes but what are your thoughts.

#12

Melting Slicks

I have not seen this question come up before, but I am pretty sure the published torque values would have to be dry. No way the guys on the assembly line were lubricating the threads on every bolt and nut.

The following users liked this post:

JETS C3-C4 (03-04-2022)

#13

Race Director

Member Since: Apr 2011

Location: North of Toronto - Ontario

Posts: 10,856

Received 3,139 Likes

on

2,070 Posts

Unless otherwise stated torque values are dry, anything that let the nut/bolt slide easier calls for reducing the toque value some. A lot of our stuff had the stipulation that torque values were on-top of the required installation torque (so if it took 5 ft-lbs to turn the bolt and they wanted 30 ft-lbs you needed to go up to 35 ft-lbs) The critical stuff we had to measure the bolt stretch...

Like stated above, these were "going in dry" using air-tools and then spot checked with hand torque wenches afterwards.

Tighten them up, if they're gr8... tighten them up more

M

Like stated above, these were "going in dry" using air-tools and then spot checked with hand torque wenches afterwards.

Tighten them up, if they're gr8... tighten them up more

M

#14

Old Fart Pilot

Thread Starter

Once again - LIP.......Learning In Progress....and I'm all ears  , well in this case on the forum I'm all EYES reading your responses.

, well in this case on the forum I'm all EYES reading your responses.

Thanks

, well in this case on the forum I'm all EYES reading your responses.

, well in this case on the forum I'm all EYES reading your responses.Thanks