Fuel Line Setup....

#1

Safety Car

Thread Starter

I like keeping things as simple as possible with my setup so the less complicated, the better off I am. Basically I will be running a Holley Double Pumper (850ish CFM), mechanical Holley fuel pump, stock 3/8" steel fuel line from the tank to the carburetor. I'm not sure what fuel filter to go with as I never ran a fuel filter on my first motor (I know, I don't want to hear it lol). Do I need to have a return line routed (I didn't before, I just had it blocked off with a bolt). I'm also considering running a fuel pressure regulator this time as the Holley fuel pump I have is supposed to be the biggest you can run without one but I think a regulator might be a good idea this time around. I'm shooting for 500ish horsepower area. Any suggestions? I don't want electric fuel pumps, I hate wiring more than just about anything in this world.

Last edited by bence13_33; 07-02-2018 at 05:10 PM.

#2

Le Mans Master

Member Since: Oct 2002

Location: Las Vegas - Just stop perpetuating myths please.

Posts: 7,098

Received 373 Likes

on

356 Posts

I like keeping things as simple as possible with my setup so the less complicated, the better off I am. Basically I will be running a Holley Double Pumper (850ish CFM), mechanical Holley fuel pump, stock 3/8" steel fuel line from the tank to the carburetor. I'm not sure what fuel filter to go with as I never ran a fuel filter on my first motor (I know, I don't want to hear it lol). Do I need to have a return line routed (I didn't before, I just had it blocked off with a bolt). I'm also considering running a fuel pressure regulator this time as the Holley fuel pump I have is supposed to be the biggest you can run without one but I think a regulator might be a good idea this time around. I'm shooting for 500ish horsepower area. Any suggestions? I don't want electric fuel pumps, I hate wiring more than just about anything in this world.

But as long as you have a return line you can use it to keep fresh fuel in the line to minimize/prevent vapor lock and help the pump regulate fuel pressure at the carb inlet. Myself I use a recirc line I installed at the qjet fuel inlet and through an 0.040" (something like that) orifice back to the return line. This gives me constant flow and constant pressure at the carb inlet - minimizing the possibility of the carb inlet needle not seating. Now if you use this return you want to use a tiny orifice (even 0.020") to minimize the amount of vapor produced in the fuel tank. And you need a operating charcoal canister w/purge for this or at least a vented fuel tank cap to relieve fuel pressure in the tank. Yes it becomes complicated somewhat.

Or you may just want to run the stock system using a fuel pump with a return connection but you will also need the charcoal canister purge system functional for that also. BTW you can still purchase BB fuel pumps with the retrun connection if your worried about enough flow though I'm sure they will have the correct fuel pressure for your Holley - but they should as some of the BB motors ran Holley carbs from the factory.

Once you have your system sorted out you only need a simple fuel filter anywhere convenient in the line and most will put it just before the carb with easy to remove ring clamps. Yes the fuel filter is a restriction somewhat and will reduce pressure but not by much and you could measure for yourself after install.

Hope this helps.

The following 2 users liked this post by cardo0:

bence13_33 (07-04-2018),

doorgunner (07-08-2018)

#4

Tech Contributor

Member Since: Aug 1999

Location: At my Bar drinking and wrenching in Lafayette Colorado

Posts: 13,654

Received 4,924 Likes

on

1,930 Posts

I like keeping things as simple as possible with my setup so the less complicated, the better off I am. Basically I will be running a Holley Double Pumper (850ish CFM), mechanical Holley fuel pump, stock 3/8" steel fuel line from the tank to the carburetor. I'm not sure what fuel filter to go with as I never ran a fuel filter on my first motor (I know, I don't want to hear it lol). Do I need to have a return line routed (I didn't before, I just had it blocked off with a bolt). I'm also considering running a fuel pressure regulator this time as the Holley fuel pump I have is supposed to be the biggest you can run without one but I think a regulator might be a good idea this time around. I'm shooting for 500ish horsepower area. Any suggestions? I don't want electric fuel pumps, I hate wiring more than just about anything in this world.

There are 2 ways to run an effective return line system:

1. The "easy" way is to simply put a small "bleed" orifice in the return line to "trickle" a small volume of fuel through the lines and back to the tank. GM did this with the return-type mechanical fuel pumps used on all post-'68 cars, as well as on several of the in-line filter carb systems with the "3rd nipple return" line coming off the filter installed near the carb inlet. A .060” bleed orifice allows constant cool fuel to pass right by the carb inlet. It works well, with minimal expense and installation hassle.

Simple return-style system with no regulator installed on my son’s 463 Pontiac. The bleed orifice is in the "-6" to "-4" reducer fitting to the far left on the carb inlet line - I just welded the reducer closed and drilled a hole in the weld. All lines are stainless hard lines:

2. The more sophisticated way to accomplish the same thing is to use a return-style regulator to maintain a specific pressure to the carb while returning un-needed fuel right back to the tank. This keeps a constant flow of fuel back to the tank, even when using a high pressure/high volume or modest pressure/modest volume pumps. It is very effective.

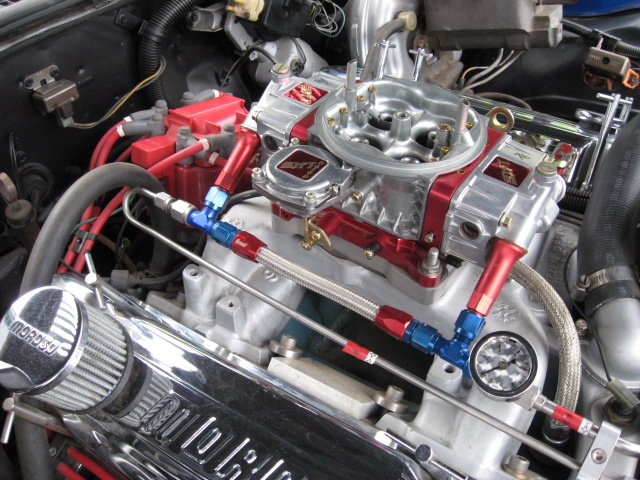

Setup with a fuel return line through a regulator installed at mid-manifold on a 420 small block I built a few years ago:

This one, on my own engine, has the reg installed towards the back of the engine so it is not visible from the front:

However you decide to do it, the important thing is to keep cool fuel moving through the lines and not get "dead-headed" to induce vapor lock or fuel boiling: This is essential on carbureted engines running on modern pump gas.

Lars

Last edited by lars; 07-05-2018 at 11:32 AM.

The following 2 users liked this post by lars:

doorgunner (07-08-2018),

lakerider57 (07-05-2018)

#5

Safety Car

Thread Starter

lars:

Thank you lars. I like the looks of the first setup. So you just welded the reducer shut and then drilled the appropriate sized hole to create the orifice? What size line would be suitable for the return line 5/16" or 1/4" ? I also like the idea of not running a regulator (I never have before). I'm wondering if this was a problem with my first motor with no return line and just a vented cap. At the end of the 1/4 mile if I bumped it into neutral my engine would want to stall out unless I throttled it a little bit.

Thank you lars. I like the looks of the first setup. So you just welded the reducer shut and then drilled the appropriate sized hole to create the orifice? What size line would be suitable for the return line 5/16" or 1/4" ? I also like the idea of not running a regulator (I never have before). I'm wondering if this was a problem with my first motor with no return line and just a vented cap. At the end of the 1/4 mile if I bumped it into neutral my engine would want to stall out unless I throttled it a little bit.

#6

Tech Contributor

Member Since: Aug 1999

Location: At my Bar drinking and wrenching in Lafayette Colorado

Posts: 13,654

Received 4,924 Likes

on

1,930 Posts

The factory return line on the GM cars is 5/16" line. The return line shown with the fixed bleed orifice above is a 1/4" line that runs down to the factory 5/16" line. There is very little flow running through that .060" diameter bleed hole, and it's almost impossible to get "-5" AN fittings and line, so I used 1/4" for the short segment from the carb to the factory 5/16 lines in the frame.

Lars

Last edited by lars; 07-05-2018 at 09:06 PM.

The following users liked this post:

doorgunner (07-08-2018)

#7

Drifting

I saw Lars solution two years ago and did the same thing. The only difference was that I threaded the inside of the reducer (about 2/3 of the way through) and made a "jet" out of a brass screw so i could easily change the orifice size. I started with .060 as Lars suggested and finally worked down to .020. This held the fuel pressure steady at 5psi at idle. With .060 the pressure bounced from 2-5 psi at idle. This greatly improved starting after it sat for 30 min or so.

#8

Tech Contributor

Member Since: Aug 1999

Location: At my Bar drinking and wrenching in Lafayette Colorado

Posts: 13,654

Received 4,924 Likes

on

1,930 Posts

Good job on the bleed orifice setup - glad to hear the solution worked for you. The .060 that I recommend is the same size as the bleed hole used by GM in the return-style filters, so it's a pretty safe place to start. At idle, the engine will run fine at 2-5 psi. In perspective, I once did a dyno test on a 455 that dyno'ed at 460-ish horsepower. I was noticing that the mixture was leaning out just a tad near redline rpm (5800), and re-jetting the secondaries didn't have any effect. I then remembered that I had not set the fuel pressure regulator, and the engine was running at 3 psi...

The following users liked this post:

doorgunner (07-08-2018)