Electronic geeks required

#61

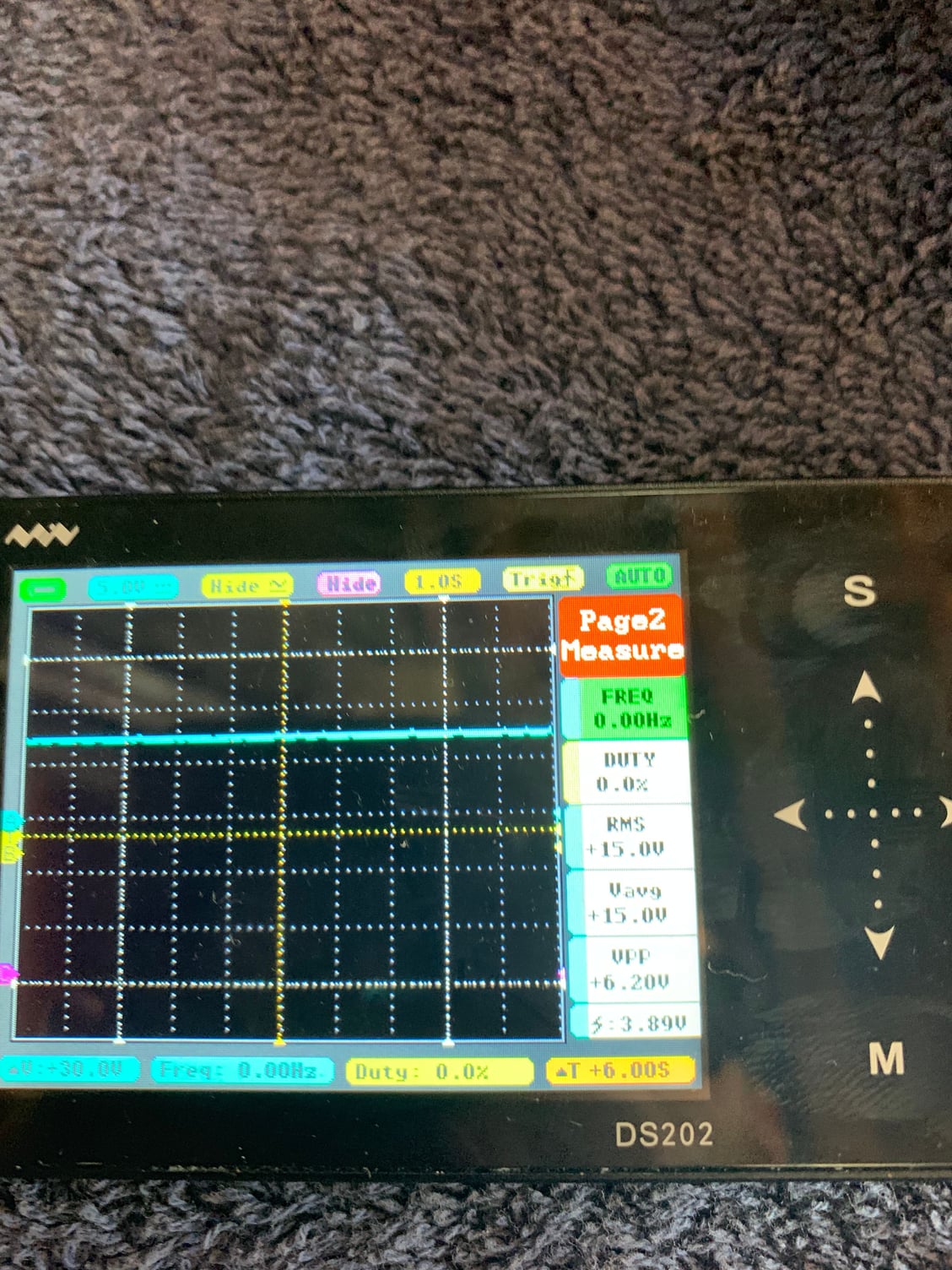

Acording to the specs on my scope it only measures up to 5v

i ordered this atenuator and will retest voltage ripple at idle and higher rpms when the atenuator comes in.

Hantek 20:1 Passive Attenuator For Pico, Other Makes, 300v Max https://www.amazon.com/dp/B007JL5JIG/ref=cm_sw_r_cp_api_i_3zRoCbFZP1Y0S

i ordered this atenuator and will retest voltage ripple at idle and higher rpms when the atenuator comes in.

Hantek 20:1 Passive Attenuator For Pico, Other Makes, 300v Max https://www.amazon.com/dp/B007JL5JIG/ref=cm_sw_r_cp_api_i_3zRoCbFZP1Y0S

#62

Race Director

Member Since: Apr 2007

Location: South Western Ontario

Posts: 11,061

Received 845 Likes

on

721 Posts

The following article is a good reference for this discussion.

https://moretraction.com/2018/08/31/2416/

https://moretraction.com/2018/08/31/2416/

Interesting article. They are correct about solenoids switching can produce voltage spikes and have the idea behind using ohms law to calculate voltage drops correct, but they make their point by saying a piece of 1/0* wire has 0.1 ohms of resistance. Who uses about 1000' of 1/0 wire for the circuit from the battery to the junction block?

* I'm assuming they mean 1/0 wire because 0/0 wire doesn't exist. It's either 0 or 1/0, as in the gauges go 0, 00, 000, 0000 or 1/0, 2/0, 3/0. 4/0.

Last edited by lionelhutz; 01-13-2019 at 12:22 AM.

#63

Race Director

Member Since: Apr 2007

Location: South Western Ontario

Posts: 11,061

Received 845 Likes

on

721 Posts

Acording to the specs on my scope it only measures up to 5v

i ordered this atenuator and will retest voltage ripple at idle and higher rpms when the atenuator comes in.

Hantek 20:1 Passive Attenuator For Pico, Other Makes, 300v Max https://www.amazon.com/dp/B007JL5JIG..._3zRoCbFZP1Y0S

i ordered this atenuator and will retest voltage ripple at idle and higher rpms when the atenuator comes in.

Hantek 20:1 Passive Attenuator For Pico, Other Makes, 300v Max https://www.amazon.com/dp/B007JL5JIG..._3zRoCbFZP1Y0S

That's not the issue. I looked that scope up when you posted it and it said 35V peak then you get a 10x probe which should allow it to measure up to 350V peak.

The probes have a little adjuster in the connector base. Make sure you connect the probe to the compensation terminals and then adjust the probe (with a plastic tool) until you get a clean square wave.

#64

Le Mans Master

Member Since: May 2003

Location: Fernandina Beach FL

Posts: 8,475

Received 3,216 Likes

on

1,729 Posts

2023 Restomod of the Year finalist

2020 C3 of the Year Winner - Modified

Interesting article. They are correct about solenoids switching can produce voltage spikes and have the idea behind using ohms law to calculate voltage drops correct, but they make their point by saying a piece of 1/0* wire has 0.1 ohms of resistance. Who uses about 100' of 1/0 wire for the circuit from the battery to the junction block?

* I'm assuming they mean 1/0 wire because 0/0 wire doesn't exist. It's either 0 or 1/0, as in the gauges go 0, 00, 000, 0000 or 1/0, 2/0, 3/0. 4/0.

* I'm assuming they mean 1/0 wire because 0/0 wire doesn't exist. It's either 0 or 1/0, as in the gauges go 0, 00, 000, 0000 or 1/0, 2/0, 3/0. 4/0.

However- if you figure the ambient temp the wire sees under the hood- .1 Ω might not be too far off for a 15-20ft run in a car.

Richard

Last edited by Richard454; 01-12-2019 at 11:40 PM.

#65

Race Director

Member Since: Apr 2007

Location: South Western Ontario

Posts: 11,061

Received 845 Likes

on

721 Posts

I meant 1000' in the last post. 10' of 1/0 is around 0.001 ohms. I highly doubt it gets hot enough when used in a car to make the resistance rise to 0.1 ohms. Maybe 0.0011 ohms or something like that.

Last edited by lionelhutz; 01-13-2019 at 12:22 AM.

#66

I think if your using 1000' then you're probably going to find you have bigger problems than the resistance.

#67

That's not the issue. I looked that scope up when you posted it and it said 35V peak then you get a 10x probe which should allow it to measure up to 350V peak.

The probes have a little adjuster in the connector base. Make sure you connect the probe to the compensation terminals and then adjust the probe (with a plastic tool) until you get a clean square wave.

The probes have a little adjuster in the connector base. Make sure you connect the probe to the compensation terminals and then adjust the probe (with a plastic tool) until you get a clean square wave.

I had a perfect square wave using the compensation terminal before testing began. After a few tests on the alternator I found that the square wave from compensation terminals was no longer nice and square.

I will test again.

I also need to find the function that counts frequency so I dont have to actually count waves on the screen.

Next test I will change rpm to make sure im getting alternator ripple not something else.

Last edited by Greengear; 01-13-2019 at 07:13 AM.

#68

Burning Brakes

The basic principles they discussed are sound, but they do not include the alternator which is producing much of the needed power. My battery is in the rear of the car, so I'm not sure if the alternator ground is more of a player than the battery ground.

And what about the battery fuse? That's a fairly high resistance.

I also agree about the no "butt splices"

#69

Le Mans Master

Member Since: May 2003

Location: Fernandina Beach FL

Posts: 8,475

Received 3,216 Likes

on

1,729 Posts

2023 Restomod of the Year finalist

2020 C3 of the Year Winner - Modified

BUT- the point being is the ambient temperature in a car under the hood- changes things. Not only resistance in the wire- but what about alternator performance- more ripple? What about chemical reactions in the battery(under-hood vs in the trunk)?

It might be small- but in the real world- it adds up.

Just like the percentage interest I receive from my savings account- might seem to some it really doesn't matter- but at the end of the year- big enough to get a 1099 on it- so yea- I'm not going to discount it.

Richard

#70

Le Mans Master

Thread Starter

#71

I agree. I've only seen splices fail due to extreme mechanical stress or because they weren't done properly. If properly done even years later with large currents they can be thermal imaged with no temperature increases at the splice.

#72

Burning Brakes

I've seen my share of loose butt connectors. I've also seen some cold solder joints, but fewer.

If you're going to solder it anyway, no need for a crimp connector. My 2 cents.

Last edited by DblTrbl; 01-13-2019 at 03:58 PM.

#73

Burning Brakes

So I'm stuck with theory. As we modify our cars with stockish wiring and add more electrical loads, you're going to see more ripple. The alternator, as a 3 phase bridge rectifier supply is going to create ripple. Roughly 14% of the output voltage. The battery acts as a filter to smooth this out. As the alternator is required to produce more current, the battery will be less and less effective as a filter. The distance between the battery and the alternator, the battery condition and the gauge of the wires from the battery to the alternator all will affect the battery's filtering ability. If you're reading more than 14%, then there is a good chance it's a PWM load or inductive kickback possibly from the coil(s), maybe electric fuel pump or electric fan.

If one of the 6 diodes in the alternator is shorted, I would guess you'd see some ripple also.

My apologies again, only theory. My non standard wired car should be running again shortly. I'll do some measurements for comparison with huge load shifts. I'm curious now.

Last edited by DblTrbl; 01-13-2019 at 04:33 PM.

#74

Le Mans Master

Thread Starter

I think the weather is really bad timing for this thread.

#75

Team Owner

I'm talking about unsolderd mechanical butt splices. If done correctly, yes. But how many people you know don't have the proper tools or experience for good connections? The right tools can be expensive.

I've seen my share of loose butt connectors. I've also seen some cold solder joints, but fewer.

If you're going to solder it anyway, no need for a crimp connector. My 2 cents.

I've seen my share of loose butt connectors. I've also seen some cold solder joints, but fewer.

If you're going to solder it anyway, no need for a crimp connector. My 2 cents.

how ever, on my wife's damn hated 01 Focus, I changed alt some years ago, and so it was checked out fine, turns out a bad solder connection to the tab from the freeking FACTORY failed, and the output wire was just hanging there next to the firewall, never noticed it somehow due to funky design....so out alt in place after wire was soldered by ME.....then the alt failed a couple weeks later, back to AZone and got another under lifetime warranty......PIA, HATE THAT CAR!!!!!

as for ripple, just rund the fans main current off the alt out stud and get hell over it, I don't bother with PWM controllers, I let the computer decide to turn on/off the fans, KISS principal certain asspects of crap just don't need to be over engineered......only trick I MAY consider is maybe putting the fans in series and when temp needed, switch to parallel be cute, but I too lazy....

#76

Took a few more looks at noise directly on alternator.

Settings are 20v - 10ms per division. This hantek 6022 has no measure feature wtf.

pics 1 fast idle

pic 2 maybe 2500 rpm.

I realized after that I could have captured rpm in the same pic using the holley sniper display.

Last edited by Greengear; 01-20-2019 at 02:59 PM.

#77

Le Mans Master

Thread Starter

Can you do it again across the battery posts, and ground to starter post?