Doing Opti, making a video...have questions

#1

Drifting

Thread Starter

Hey guys i will be doing my opti on a 1995 and have some simple questions before starting. (i've never done this repair before so I need some clarification...thanks)

1)

The Service Manual says to remove a motor mount and lift the engine?? (to remove the crank shaft balancer). i've never seen that written in any threads that i've read. Necessary???

2)

are there any special tools required for this job? the Service manual keeps making reference to tool "J 39046" (again for the crank shaft balancer/shaft). i assume that's some type of puller?? didnt see that tool in the manual under the general Corvette maintenance tool list.

3)

Do the LT1's have issues with removing spark plugs? should i or do i need to use penetrating oil over night?

4)

I already bought 7mm Spark Plug wires, same as whats on there...i assume for 1k-2k light duty miles per year of driving i will be fine with the 7mm wires? would i see any major benefit going to 8mm??

5)

any good tips/tricks/info/advice......THANKS

1)

The Service Manual says to remove a motor mount and lift the engine?? (to remove the crank shaft balancer). i've never seen that written in any threads that i've read. Necessary???

2)

are there any special tools required for this job? the Service manual keeps making reference to tool "J 39046" (again for the crank shaft balancer/shaft). i assume that's some type of puller?? didnt see that tool in the manual under the general Corvette maintenance tool list.

3)

Do the LT1's have issues with removing spark plugs? should i or do i need to use penetrating oil over night?

4)

I already bought 7mm Spark Plug wires, same as whats on there...i assume for 1k-2k light duty miles per year of driving i will be fine with the 7mm wires? would i see any major benefit going to 8mm??

5)

any good tips/tricks/info/advice......THANKS

Last edited by mark970; 09-15-2017 at 07:03 PM.

The following users liked this post:

mic575 (09-15-2017)

#2

Instructor

Hey guys i will be doing my opti on a 1995 and have some simple questions before starting. (i've never done this repair before so I need some clarification...thanks)

1)

The Service Manual says to remove a motor mount and lift the engine?? (to remove the crank shaft balancer). i've never seen that written any any threads that i've read. Necessary???

I just did mine 2 weeks ago. I did not remove the motor from the mounts but I also did not remove the balancer hub. A plastic mallet, PB blaster, cursing, and finally a pry bar to lever it off the shaft.

2)

are there any special tools required for this job? the Service manual keeps making reference to tool "J 39046" (again for the crank shaft balancer/shaft). i assume that's some type of puller?? didnt see that tool in the manual under the general Corvette maintenance tool list.

Nothing special except a small tool to properly install the water pump drive seal. $25 on ebay

3)

Do the LT1's have issues with removing spark plugs? should i or do i need to use penetrating oil over night?

Tight quarters so it's good that you are planning to do this while you have the engine stripped. Do wires also. I would reinstall plugs with a small amount of antiseize

4)

I already bought 7mm wires, same as whats on there...i assume for 1k-2k light duty miles per year of driving i will be fine with the 7mm wires?

AC Delcos are 7 and that's what I used. Good luck finding the correct retainers. Got mine at Ecklers after buying a wrong set elsewhere

5)

any good tips/tricks/info/advice......THANKS

1)

The Service Manual says to remove a motor mount and lift the engine?? (to remove the crank shaft balancer). i've never seen that written any any threads that i've read. Necessary???

I just did mine 2 weeks ago. I did not remove the motor from the mounts but I also did not remove the balancer hub. A plastic mallet, PB blaster, cursing, and finally a pry bar to lever it off the shaft.

2)

are there any special tools required for this job? the Service manual keeps making reference to tool "J 39046" (again for the crank shaft balancer/shaft). i assume that's some type of puller?? didnt see that tool in the manual under the general Corvette maintenance tool list.

Nothing special except a small tool to properly install the water pump drive seal. $25 on ebay

3)

Do the LT1's have issues with removing spark plugs? should i or do i need to use penetrating oil over night?

Tight quarters so it's good that you are planning to do this while you have the engine stripped. Do wires also. I would reinstall plugs with a small amount of antiseize

4)

I already bought 7mm wires, same as whats on there...i assume for 1k-2k light duty miles per year of driving i will be fine with the 7mm wires?

AC Delcos are 7 and that's what I used. Good luck finding the correct retainers. Got mine at Ecklers after buying a wrong set elsewhere

5)

any good tips/tricks/info/advice......THANKS

I probably didn't describe it well but it will be clear when you do it.

Clean the mating surface of the balancer and Put anti seize on it when you reinstall

The seal on the water pump drive must be installed with the seal cone facing the engine. Otherwise it will leak. That's why you need that special tool. The opti drive seal just pushes on.

Run the engine for a few seconds before you reinstall the WP and fill the systems. Reattach all your removed connectors temporarily when you do this. Check for any Trouble codes immediately after.

I installed a drain hose on the bearing seal outlet on the water pump. I ground down a 3\16 barbed brass connector and used a length of 3/16 fuel line. Make sure it's secured so it doesn't rub against the balancer when all is back together. Tie wraps work well.

Good luck with the video.

Last edited by Drifter36; 09-15-2017 at 02:43 PM.

The following users liked this post:

mark970 (09-15-2017)

#4

Instructor

The opti drive must be mated properly. It is keyed so it can only fit one way. But the teeth are very fine and it can be difficult to mate. Hint, mate it first to the camshaft and sharpie a mark on the shaft at the middle 12 o'clock position. Now remove it, seat it in the opti and while holding the opti in approx the correct position, rotate the shaft until your mark is again at 12 o'clock..

I probably didn't describe it well but it will be clear when you do it.

Clean the mating surface of the balancer and Put anti seize on it when you reinstall

The seal on the water pump drive must be installed with the seal cone facing the engine. Otherwise it will leak. That's why you need that special tool. The opti drive seal just pushes on.

Run the engine for a few seconds before you reinstall the WP and fill the systems. Reattach all your removed connectors temporarily when you do this. Check for any Trouble codes immediately after.

I installed a drain hose on the bearing seal outlet on the water pump. I ground down a 3\16 barbed brass connector and used a length of 3/16 fuel line. Make sure it's secured so it doesn't rub against the balancer when all is back together. Tie wraps work well.

Good luck with the video.

I probably didn't describe it well but it will be clear when you do it.

Clean the mating surface of the balancer and Put anti seize on it when you reinstall

The seal on the water pump drive must be installed with the seal cone facing the engine. Otherwise it will leak. That's why you need that special tool. The opti drive seal just pushes on.

Run the engine for a few seconds before you reinstall the WP and fill the systems. Reattach all your removed connectors temporarily when you do this. Check for any Trouble codes immediately after.

I installed a drain hose on the bearing seal outlet on the water pump. I ground down a 3\16 barbed brass connector and used a length of 3/16 fuel line. Make sure it's secured so it doesn't rub against the balancer when all is back together. Tie wraps work well.

Good luck with the video.

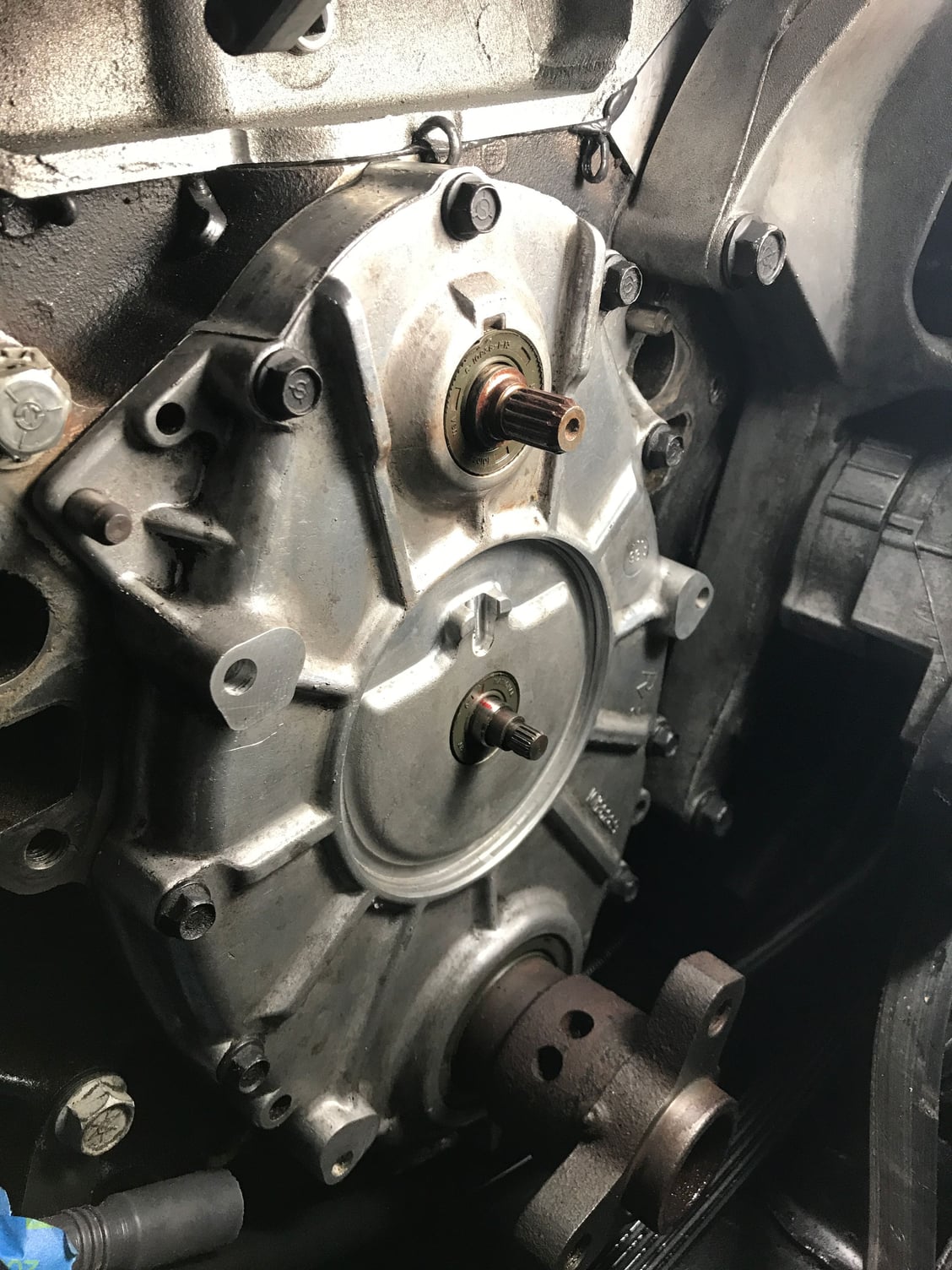

Here is the weep hole from the WP drive seal. Used a 2 foot section of 3/16 fuel line.

I think you can zoom in on this or the other photo and see the red Sharpie mark on the opti drive shaft.

The following users liked this post:

mark970 (09-15-2017)

#5

Drifting

Thread Starter

Drifter36 THANKS for taking the time to contribute!!! i much appreciate the help and the pictures say a lot. do i need to worry about snapping spark plugs when i remove them or does the aluminum heads help with removal (or make it more dangerous)? typically dissimilar metals is a bad thing...promotes corrosion.

Last edited by mark970; 09-15-2017 at 03:24 PM.

#6

Instructor

Drifter36 THANKS for taking the time to contribute!!! i much appreciate the help and the pictures say a lot. do i need to worry about snapping spark plugs when i remove them or does the aluminum heads help with removal (or make it more dangerous)? typically dissimilar metals is a bad thing...promotes corrosion.

I can't give you any insight into possible plug corrosion.. the PO had them replaced so I didn't do mine. Just did the wires.

#7

Drifting

Thread Starter

#8

Drifting

Thread Starter

#9

Drifting

Hey guys i will be doing my opti on a 1995 and have some simple questions before starting. (i've never done this repair before so I need some clarification...thanks)

1)

The Service Manual says to remove a motor mount and lift the engine?? (to remove the crank shaft balancer). i've never seen that written any any threads that i've read. Necessary???

2)

are there any special tools required for this job? the Service manual keeps making reference to tool "J 39046" (again for the crank shaft balancer/shaft). i assume that's some type of puller?? didnt see that tool in the manual under the general Corvette maintenance tool list.

3)

Do the LT1's have issues with removing spark plugs? should i or do i need to use penetrating oil over night?

4)

I already bought 7mm Spark Plug wires, same as whats on there...i assume for 1k-2k light duty miles per year of driving i will be fine with the 7mm wires?

5)

any good tips/tricks/info/advice......THANKS

1)

The Service Manual says to remove a motor mount and lift the engine?? (to remove the crank shaft balancer). i've never seen that written any any threads that i've read. Necessary???

2)

are there any special tools required for this job? the Service manual keeps making reference to tool "J 39046" (again for the crank shaft balancer/shaft). i assume that's some type of puller?? didnt see that tool in the manual under the general Corvette maintenance tool list.

3)

Do the LT1's have issues with removing spark plugs? should i or do i need to use penetrating oil over night?

4)

I already bought 7mm Spark Plug wires, same as whats on there...i assume for 1k-2k light duty miles per year of driving i will be fine with the 7mm wires?

5)

any good tips/tricks/info/advice......THANKS

I used the methods promoted here in the forum and youtube. So I did NOT detach motor mount. Instead, I used a long steel bar and a BFH to hammer the pulley from underneath. Pure hell. I can see where raising the engine would be easier. Pulling the engine might be easier. This was the most painful job I've ever done on a vehicle.

It took over a month of going out to the garage whenever I could, crawling under the car and pounding on it. That was my '96. My '95 took three times as long. You might have room for a puller if you raise the engine.

Plugs were relatively simple except for the last two on the passenger side, at the evaporator box. As long as the PO used anti seize, they come out cleanly.

Wires were only a PITA on the driver's side. I unbolted the PS pump and pushed it forward to route wires behind it. Idler pulley came out too. As did all the hoses. ASR unit unbolts at either end and place it aside.

I took the temp sensor off the water pump before removal and reinstalled after the pump was in place. It is tight in there, and the sensor stands out proud in brittle plastic.

Anti seize on the pulley surface as mentioned for the inevitable next visit. Locktite blue on the bolts though.

When the water pump failed on my '96, it didn't weep. It gushed. The weep hole hose would've done nothing to help, as the entire main bearing seal had blown out. So I passed on that canard.

Good luck!

Last edited by Renfield; 09-15-2017 at 03:58 PM.

The following users liked this post:

mark970 (09-15-2017)

#10

Drifting

Thread Starter

Renfield i like your post...brutally honest yet funny?? (im laughing with you not at you)

not to mention GREAT information...THANKS

not to mention GREAT information...THANKS

#12

Race Director

The plugs are a huge pain. I had to use a breaker bar on almost all of them. Be careful.

You don't need to lift the engine out, but you will probably have to whack off the crank pulley. It's held on by 3 bolts and a lot of corrosion. You'll want something to wedge it off. Others have banged it off from underneath, that didn't work for me though.

I should have done the weep hole mod, but did not. I figured if it lasted 135k without it, it's probably fine.

You don't need to lift the engine out, but you will probably have to whack off the crank pulley. It's held on by 3 bolts and a lot of corrosion. You'll want something to wedge it off. Others have banged it off from underneath, that didn't work for me though.

I should have done the weep hole mod, but did not. I figured if it lasted 135k without it, it's probably fine.

The following users liked this post:

mark970 (09-15-2017)

#13

Instructor

One last thought

If you remove the thermostat housing, the WP removal and reinstallation will be easier. I always refill the engine coolant through the water pump with the thermostat housing still out. Then I fill the rest from the coolant surge tank.

Good luck with the project!

If you remove the thermostat housing, the WP removal and reinstallation will be easier. I always refill the engine coolant through the water pump with the thermostat housing still out. Then I fill the rest from the coolant surge tank.

Good luck with the project!

#14

Drifting

Thread Starter

For the sake of learning, my approach will be baby steps. my first video will be just plugs and wires (yes i know our boy Chris Fix did that on a Corvette 5 years ago, i will def give him a shout out). I will video document everything i do and by taking steps i can display all "action vs. result" scenarios one repair at a time. i'm expecting this video series to take some time but hopefully it will be informative. the plugs and wires will be this weekend!!

#15

Race Director

Start by draining the engine coolant.

Remove air intake

Start removing the cooling hoses.

Remove serpentine belt.

Water pump, and one bolt will be hard to get there. It's the one nearest to the AC compressor.

Remove harmonic balancer bolts. 3 of them. Question, how do you guys get them loose? I have always needed my dad's help on that.

Then, the balancer must be removed. Seems I have had good luck on this. Never had to bang it out of place. It simply just came out.

Then the opti comes out.

I've never had to lift the engine.

I know 95-96 are different with the opti shaft. But on earlier LT1s, I just make note of what position the shaft on the opti I removed is in. Then, I get the new opti and match it. Goes in easily.

Remove air intake

Start removing the cooling hoses.

Remove serpentine belt.

Water pump, and one bolt will be hard to get there. It's the one nearest to the AC compressor.

Remove harmonic balancer bolts. 3 of them. Question, how do you guys get them loose? I have always needed my dad's help on that.

Then, the balancer must be removed. Seems I have had good luck on this. Never had to bang it out of place. It simply just came out.

Then the opti comes out.

I've never had to lift the engine.

I know 95-96 are different with the opti shaft. But on earlier LT1s, I just make note of what position the shaft on the opti I removed is in. Then, I get the new opti and match it. Goes in easily.

The following users liked this post:

mark970 (09-15-2017)

#16

Drifting

Thread Starter

Start by draining the engine coolant.

Remove air intake

Start removing the cooling hoses.

Remove serpentine belt.

Water pump, and one bolt will be hard to get there. It's the one nearest to the AC compressor.

Remove harmonic balancer bolts. 3 of them. Question, how do you guys get them loose? I have always needed my dad's help on that.

Then, the balancer must be removed. Seems I have had good luck on this. Never had to bang it out of place. It simply just came out.

Then the opti comes out.

I've never had to lift the engine.

I know 95-96 are different with the opti shaft. But on earlier LT1s, I just make note of what position the shaft on the opti I removed is in. Then, I get the new opti and match it. Goes in easily.

Remove air intake

Start removing the cooling hoses.

Remove serpentine belt.

Water pump, and one bolt will be hard to get there. It's the one nearest to the AC compressor.

Remove harmonic balancer bolts. 3 of them. Question, how do you guys get them loose? I have always needed my dad's help on that.

Then, the balancer must be removed. Seems I have had good luck on this. Never had to bang it out of place. It simply just came out.

Then the opti comes out.

I've never had to lift the engine.

I know 95-96 are different with the opti shaft. But on earlier LT1s, I just make note of what position the shaft on the opti I removed is in. Then, I get the new opti and match it. Goes in easily.

thanks again, great contribution!!

#17

Race Director

Oh, I did forget about saying to pull out the plug wires off the opti. I number them 1-4 top to bottom on both sides. Makes it easy to know where to put them on the opti. No problem Mark! Glad I could help in some way.

#18

Drifting

Thread Starter

#19

Pro

I am in the middle of doing this now. I am putting on a new water pump, cap, rotor and timing cover seals.

My balancer took about 3.5 hours to take off . There is a youtube video of a guy using a puller with washers that sit behind the balancer to help pull it. I am not a fan of hitting the balancer off, it still took some light taps with the puller engaged. If you go with this method there are a couple mods that I did. They may be helpful to you if you go this route.

. There is a youtube video of a guy using a puller with washers that sit behind the balancer to help pull it. I am not a fan of hitting the balancer off, it still took some light taps with the puller engaged. If you go with this method there are a couple mods that I did. They may be helpful to you if you go this route.

You will also need a balancer installation tool to reinstall the hub if you remove it.

My plugs were original when I changed them. Some were a bear but they came out.

On the wires I was doing a belt and tensioner , so with the tensioner and ps pump removed it helped getting at the plug wires on the cap.

Gary

My balancer took about 3.5 hours to take off

. There is a youtube video of a guy using a puller with washers that sit behind the balancer to help pull it. I am not a fan of hitting the balancer off, it still took some light taps with the puller engaged. If you go with this method there are a couple mods that I did. They may be helpful to you if you go this route.

. There is a youtube video of a guy using a puller with washers that sit behind the balancer to help pull it. I am not a fan of hitting the balancer off, it still took some light taps with the puller engaged. If you go with this method there are a couple mods that I did. They may be helpful to you if you go this route.You will also need a balancer installation tool to reinstall the hub if you remove it.

My plugs were original when I changed them. Some were a bear but they came out.

On the wires I was doing a belt and tensioner , so with the tensioner and ps pump removed it helped getting at the plug wires on the cap.

Gary

The following users liked this post:

mark970 (09-15-2017)

#20

Drifting

Thread Starter

I am in the middle of doing this now. I am putting on a new water pump, cap, rotor and timing cover seals.

My balancer took about 3.5 hours to take off . There is a youtube video of a guy using a puller with washers that sit behind the balancer to help pull it. I am not a fan of hitting the balancer off, it still took some light taps with the puller engaged. If you go with this method there are a couple mods that I did. They may be helpful to you if you go this route.

. There is a youtube video of a guy using a puller with washers that sit behind the balancer to help pull it. I am not a fan of hitting the balancer off, it still took some light taps with the puller engaged. If you go with this method there are a couple mods that I did. They may be helpful to you if you go this route.

You will also need a balancer installation tool to reinstall the hub if you remove it.

My plugs were original when I changed them. Some were a bear but they came out.

On the wires I was doing a belt and tensioner , so with the tensioner and ps pump removed it helped getting at the plug wires on the cap.

Gary

My balancer took about 3.5 hours to take off

. There is a youtube video of a guy using a puller with washers that sit behind the balancer to help pull it. I am not a fan of hitting the balancer off, it still took some light taps with the puller engaged. If you go with this method there are a couple mods that I did. They may be helpful to you if you go this route.

. There is a youtube video of a guy using a puller with washers that sit behind the balancer to help pull it. I am not a fan of hitting the balancer off, it still took some light taps with the puller engaged. If you go with this method there are a couple mods that I did. They may be helpful to you if you go this route.You will also need a balancer installation tool to reinstall the hub if you remove it.

My plugs were original when I changed them. Some were a bear but they came out.

On the wires I was doing a belt and tensioner , so with the tensioner and ps pump removed it helped getting at the plug wires on the cap.

Gary

Last edited by mark970; 09-15-2017 at 07:01 PM.