Dang! What Wire Did I Cut?!

#1

Burning Brakes

Thread Starter

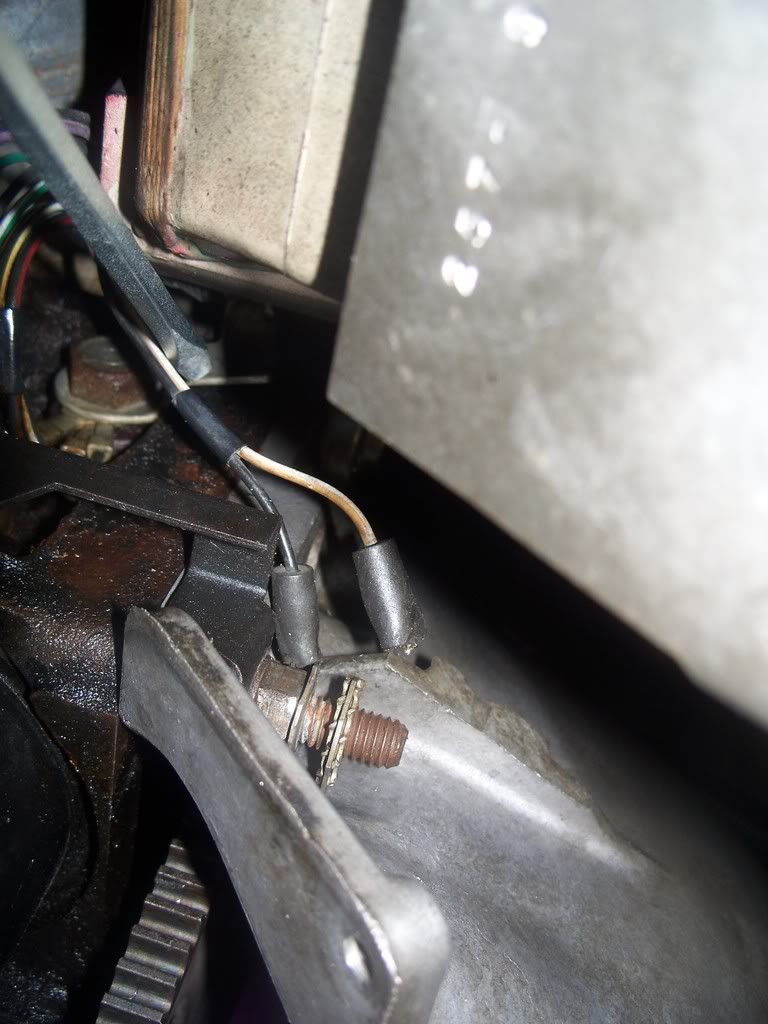

I have a 1991 L98 auto. Just finished rebuilding the transmission and was putting it back in. I was working with the star washers (I believe that is their name) that thread onto the lower left bell-housing bolt and as the nut (not pictured because I took it off after I realized the wire broke) tightened over the bolt it twisted and ran into the bell-housing causing it to break from the washer.

I don't have much experience with wiring/electricity on this car. If I had to guess, I would say its some sort of ground? Is there an easy AND safe fix and could someone explain that to me in detail?

I was hoping to have the car running by tomorrow night, so I hope this doesn't set me back another couple of days... I do know how to use a wire stripper too!

Here are the pictures, it is the yellow wire that is on top of a black one:

Much appreciated,

Jonathan

I don't have much experience with wiring/electricity on this car. If I had to guess, I would say its some sort of ground? Is there an easy AND safe fix and could someone explain that to me in detail?

I was hoping to have the car running by tomorrow night, so I hope this doesn't set me back another couple of days... I do know how to use a wire stripper too!

Here are the pictures, it is the yellow wire that is on top of a black one:

Much appreciated,

Jonathan

#5

Burning Brakes

Thread Starter

And how much does it matter that the ring terminal is flat and doesn't look exactly like the old wire end?

Thanks again, I can't wait to test out the tranny! And, of course, I'll have plenty of pics and vids to update my ongoing thread.

Jonathan

#6

Race Director

Member Since: Jan 2003

Location: Summerland B.C. Canada

Posts: 19,667

Likes: 0

Received 36 Likes

on

32 Posts

Better to buy the correct ring terminal for the wire size you are using(blue insulator). Also, I would think that there is some slack in the wire, somewhere down the line, that would allow you to make it reach the stud.

#7

Burning Brakes

Thread Starter

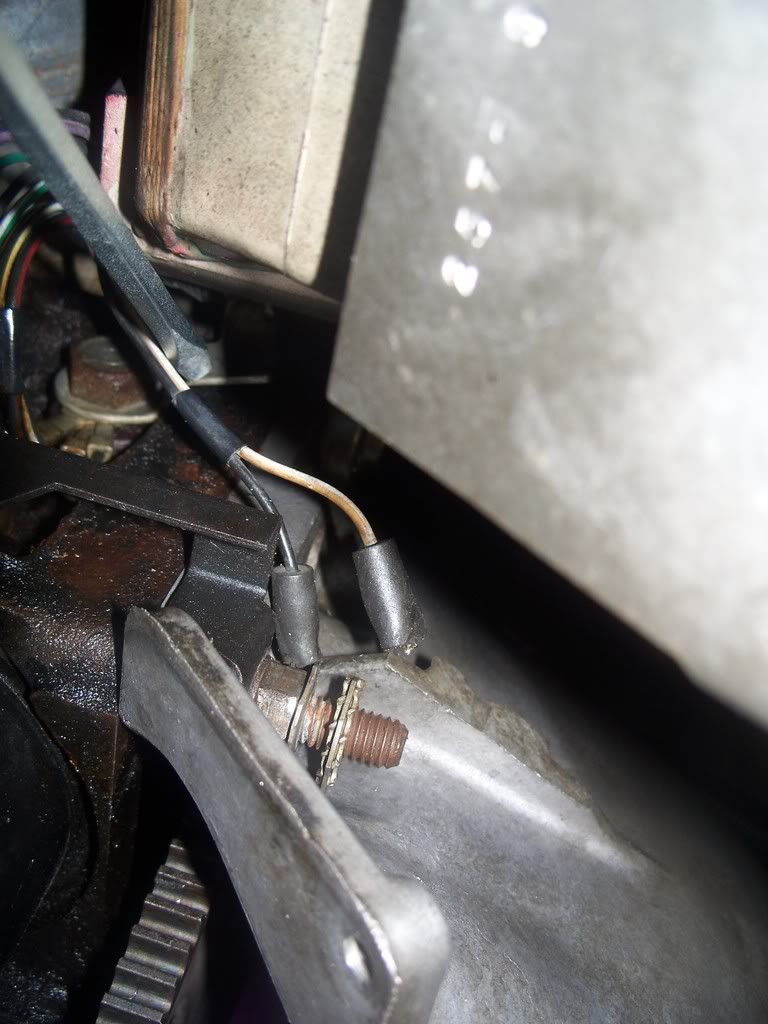

Yea, there was no real slack in the line, so I did have to connect a new piece of 16 gauge wire on and then crimp the 3/8 in (proper blue colored) ring terminal on. While I was doing that I noticed that the other old ring terminal was probably going to break when I threaded the nut back on. So I replaced that one too. I have 3/8 in heat shrink tubing, but that's a little too large, so its off to Home Depot to get the next smaller size that will hopefully slip over the ring terminal or I'll have to cut it off, put the tubing on, and then reinstall a new ring terminal. Oh well, overall I don't think I did too shabby for my first wiring work...

Thanks to everyone who replied!

One last question - I only crimped the connections once at each wire to connector location. Is it better to double crimp the wires to the connectors? And I figured that I should be crimping the metal inside the connector to the wire (and not the insulation) so that a metal-metal contact is made and not a metal-insulations contact. Is this rationale correct?

Here are some pics (that's my pink Vigilante 9.5 in TC in 2 of the pics):

Thanks to everyone who replied!

One last question - I only crimped the connections once at each wire to connector location. Is it better to double crimp the wires to the connectors? And I figured that I should be crimping the metal inside the connector to the wire (and not the insulation) so that a metal-metal contact is made and not a metal-insulations contact. Is this rationale correct?

Here are some pics (that's my pink Vigilante 9.5 in TC in 2 of the pics):

Last edited by janarvae; 07-18-2008 at 03:23 PM.

#8

Burning Brakes

Thread Starter

I keep having to replace that plastic conduit for the low oil level sensor - anyone have a better solution? I imagine heat shrink tubing, but how do I slip it on without cutting any wires?

Thanks,

Jonathan

Thanks,

Jonathan

#10

Race Director

Member Since: Jan 2003

Location: Summerland B.C. Canada

Posts: 19,667

Likes: 0

Received 36 Likes

on

32 Posts

#11

Burning Brakes

Thread Starter

Not a fan of insulated crimp connectors, due to the fact the some day they could become an open circuit. What I like to do is, remove the insulation from the terminal, crimp it, then add solder to the crimp terminal. Keeping in mind that the shrink tube should be installed before the final crimp.

Like I said before, I don't have much, if any, experience with wiring and thought it would shrink enough, but I tried it on a scrap wire first and it wasn't near tight enough. So I got one made for smaller gauge (which I should have been advised to do by the guy at Advance Auto in the first place) and figured I would cut the ring terminal off, slide the smaller heat shrink tubing on, and then crimp a new terminal on.

About the soldering, I was in Sears yesterday picking up something and was checking out the soldering irons. I didn't realize they were so inexpensive! I was expecting something in the $100 range, not $10.

Just shows my inexperience. I guess I have to go and get an iron and learn how to solder....

Just shows my inexperience. I guess I have to go and get an iron and learn how to solder....  I know I'm going to have to learn sooner or later..

I know I'm going to have to learn sooner or later..Any tips for a first-timer and what solder material to buy (I saw different types of wick, rosin) for the wiring and connectors?

Thanks again,

Jonathan

#13

Racer

Member Since: Sep 2007

Location: Bartonville Illinois

Posts: 393

Likes: 0

Received 0 Likes

on

0 Posts

Like with welding, make sure the wires are clean before soldering. If they are corroded they won't solder well.

I usually use un-insulated butt splices, crimp the splice on then solder and shrink tube. You don't want to solder lugs on though, it makes the connection brittle.

I usually use un-insulated butt splices, crimp the splice on then solder and shrink tube. You don't want to solder lugs on though, it makes the connection brittle.