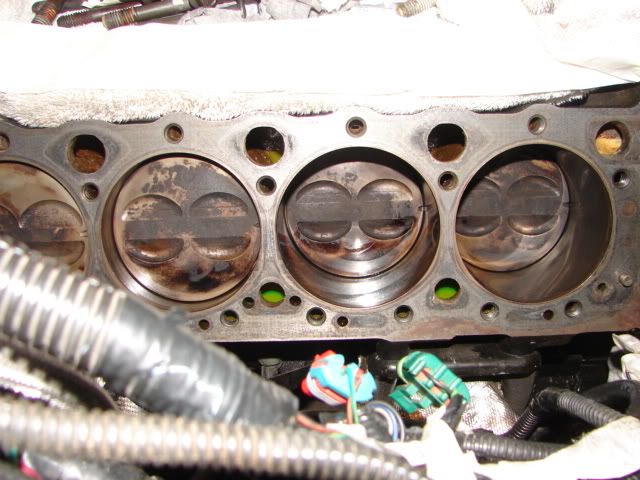

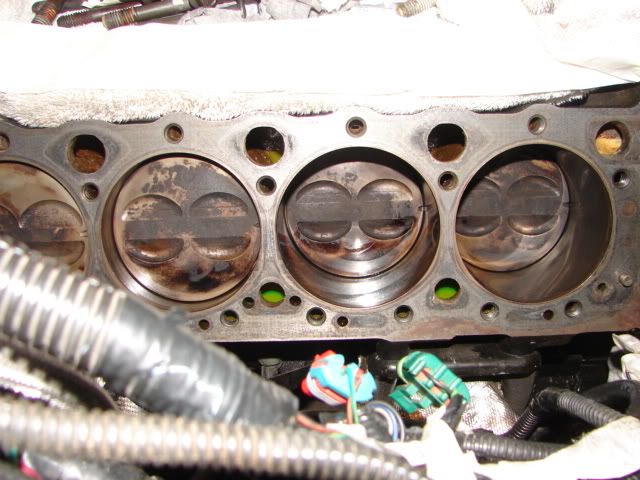

did I do a good enough job (see pictures) cleaning piston tops on 93 lt1?

#1

Race Director

Thread Starter

Ive got my heads off for a head swap and am wondering if I did a good enough job cleaning my piston tops and scrape the deck.

To scrape the deck, I found perfect 4" diameter circular cardboard box lids that I shoved into each cylinder to cover it from scraping debris falling inside it. I used a shop -vac to clean out anything that did fall in there.

For the deck surface: I also did a once-over w/ a scotch brite pad and was extremely careful to have everything masked off such that no scotch-brite particles (aluminum oxide? ) could fall into the pistons or oil galleys.

To clean the piston tops, I sprayed chlorinated (the nasty stuff) brake parts cleaner onto the pistons and 'rubbed hard' with a soft 100% cotton cloth.

I think I did a fine job and unless you can convince me otherwise, Im going to stop here.

I could go inside there with a scotch-brite pad to the piston tops, but Id be adding 'scotch-brite' particles to the inside of the motor which Id be totally reliant on good luck to be able to get them all out.

Also, I figure its gonna dirty again real-fast so whats the point?

Anyways, does it look like I did a good enough job here? Or would you do more? If you would do more, how would you do it.

Finally, what should I coat the inside of the bores with? 5w-30 mobil 1 oil? Or something else?

To scrape the deck, I found perfect 4" diameter circular cardboard box lids that I shoved into each cylinder to cover it from scraping debris falling inside it. I used a shop -vac to clean out anything that did fall in there.

For the deck surface: I also did a once-over w/ a scotch brite pad and was extremely careful to have everything masked off such that no scotch-brite particles (aluminum oxide? ) could fall into the pistons or oil galleys.

To clean the piston tops, I sprayed chlorinated (the nasty stuff) brake parts cleaner onto the pistons and 'rubbed hard' with a soft 100% cotton cloth.

I think I did a fine job and unless you can convince me otherwise, Im going to stop here.

I could go inside there with a scotch-brite pad to the piston tops, but Id be adding 'scotch-brite' particles to the inside of the motor which Id be totally reliant on good luck to be able to get them all out.

Also, I figure its gonna dirty again real-fast so whats the point?

Anyways, does it look like I did a good enough job here? Or would you do more? If you would do more, how would you do it.

Finally, what should I coat the inside of the bores with? 5w-30 mobil 1 oil? Or something else?

#2

Safety Car

You did fine. Like you said no reason to really clean them up as carbon is gonna start all over again, once you fire it.

The deck surface is the most important thing.

I'd recomend a light coat of ATF on the cyl walls. Just put some on a lint free rag or paper towell and wipe the cyl down. Motor oil would work just fine as well.

Will

The deck surface is the most important thing.

I'd recomend a light coat of ATF on the cyl walls. Just put some on a lint free rag or paper towell and wipe the cyl down. Motor oil would work just fine as well.

Will

#3

hi, i dont know if you have thought of this but you may want to run a thread tap in all of your head bolt holes. i used a vacuum cleaner right at the head surface and bolt hole while taping the holes to catch all of the cleanings. also, you may want to use a new loctite product called head bolt and water jacket sealer. if you use this product it sets up pretty fast so do all of your torqing as quickly as possible. i used this product on my last head replacement. see ya

#4

yep...good ;nuff for infame rebuild.

I 2nd the tap. use it and save yerself a ton of potential trouble. Tap out ALL the head bolt holes AND use trhead sealer on ALL head bolt holes. Some go thru.

I use a wire wheel in the drill on pistons and in frame I will use a reamer or some tool to break away as much of the cyl ridge as possible,. That ridge can collect crap on top and the first time the crank cycles the rings will come up to the ridge (if still there) with dirt on top of the ring and break that ring...happens everyday to rebuild projects.It does not hurt anything to wash out the cyl with a solvent in spray or liquid form since its not cycling. Spray ATF or engine oil on cyl walls before assembly.

I 2nd the tap. use it and save yerself a ton of potential trouble. Tap out ALL the head bolt holes AND use trhead sealer on ALL head bolt holes. Some go thru.

I use a wire wheel in the drill on pistons and in frame I will use a reamer or some tool to break away as much of the cyl ridge as possible,. That ridge can collect crap on top and the first time the crank cycles the rings will come up to the ridge (if still there) with dirt on top of the ring and break that ring...happens everyday to rebuild projects.It does not hurt anything to wash out the cyl with a solvent in spray or liquid form since its not cycling. Spray ATF or engine oil on cyl walls before assembly.

Last edited by leesvet; 03-04-2012 at 06:15 PM.

#5

Race Director

Thread Starter

hi, i dont know if you have thought of this but you may want to run a thread tap in all of your head bolt holes. i used a vacuum cleaner right at the head surface and bolt hole while taping the holes to catch all of the cleanings. also, you may want to use a new loctite product called head bolt and water jacket sealer. if you use this product it sets up pretty fast so do all of your torqing as quickly as possible. i used this product on my last head replacement. see ya

This is good advice.

I didnt catch the tap-pings though. I plan a throrough garden hose flush of the block once I got the timing cover and heads on.

#6

Race Director

Thread Starter

yep...good ;nuff for infame rebuild.

I 2nd the tap. use it and save yerself a ton of potential trouble. Tap out ALL the head bolt holes AND use trhead sealer on ALL head bolt holes. Some go thru.

I use a wire wheel in the drill on pistons and in frame I will use a reamer or some tool to break away as much of the cyl ridge as possible,. That ridge can collect crap on top and the first time the crank cycles the rings will come up to the ridge (if still there) with dirt on top of the ring and break that ring...happens everyday to rebuild projects.It does not hurt anything to wash out the cyl with a solvent in spray or liquid form since its not cycling. Spray ATF or engine oil on cyl walls before assembly.

I 2nd the tap. use it and save yerself a ton of potential trouble. Tap out ALL the head bolt holes AND use trhead sealer on ALL head bolt holes. Some go thru.

I use a wire wheel in the drill on pistons and in frame I will use a reamer or some tool to break away as much of the cyl ridge as possible,. That ridge can collect crap on top and the first time the crank cycles the rings will come up to the ridge (if still there) with dirt on top of the ring and break that ring...happens everyday to rebuild projects.It does not hurt anything to wash out the cyl with a solvent in spray or liquid form since its not cycling. Spray ATF or engine oil on cyl walls before assembly.

Good advice.