Found the Oil Leak, how do I seal it?

#1

Drifting

Thread Starter

Member Since: Dec 2007

Location: Sumter South Carolina

Posts: 1,661

Likes: 0

Received 7 Likes

on

7 Posts

So I'm pretty sure this is how the oil was coming from the plenum. I tested the plenum with water before putting it on but I guess oil is thin enough to get though. I think the oil was leaking from the lifter valley into the intake runners, then with the cam overlap was being shot up the runners to where it leaked out. I figure I will just run some epoxy like liquid nail to seal up the plenum, but how do I seal up the lifter valley? It almost looks as if the angle of the stealth ram is not the same angle as the heads. Maybe like a half a degree off... Any ideas?

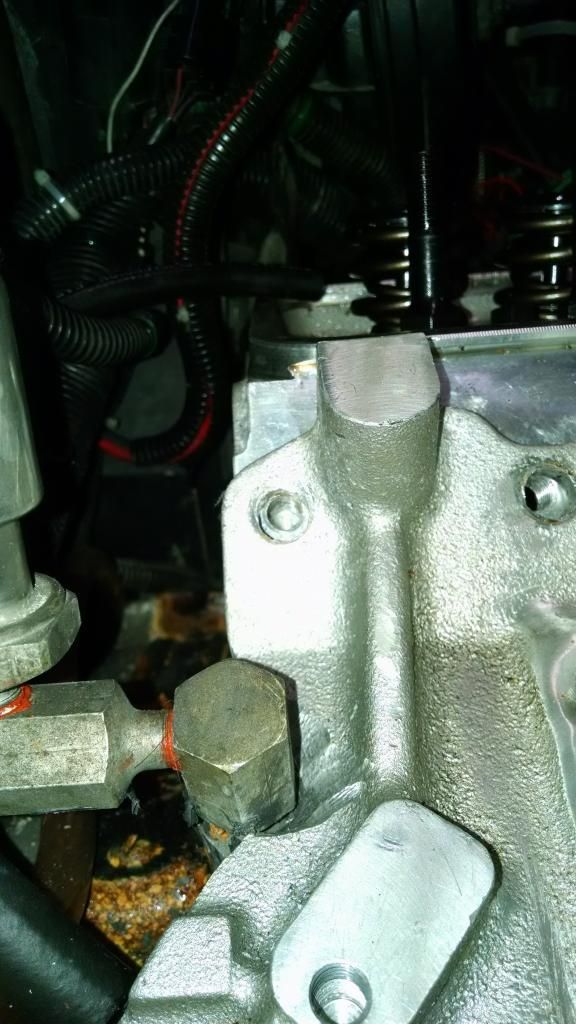

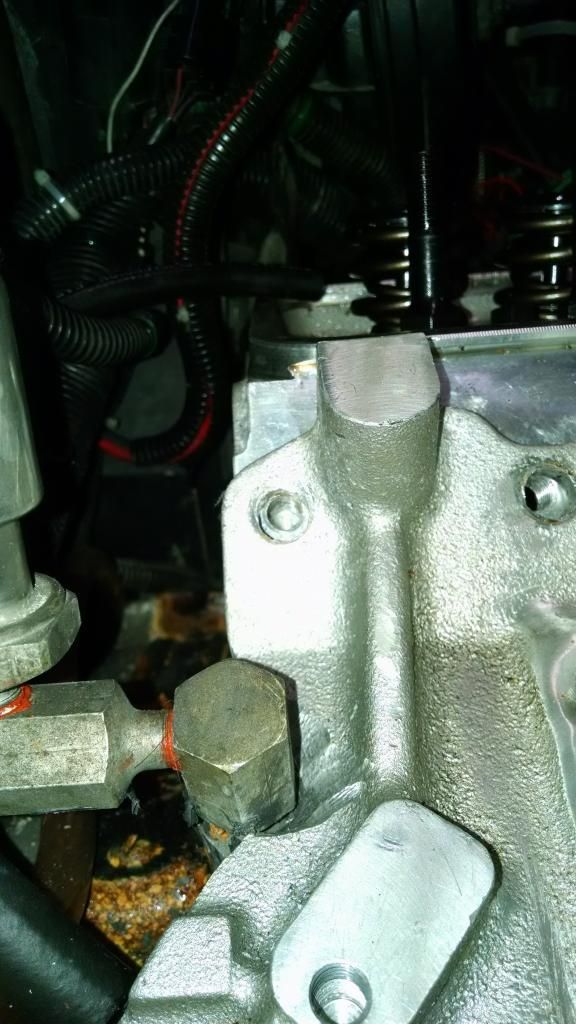

Here is where the oil was leaking...

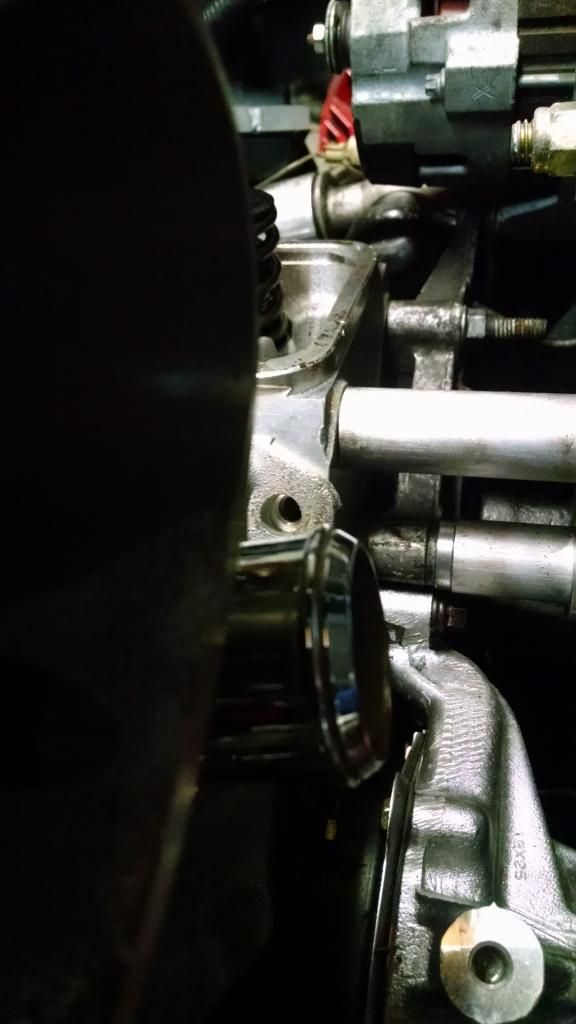

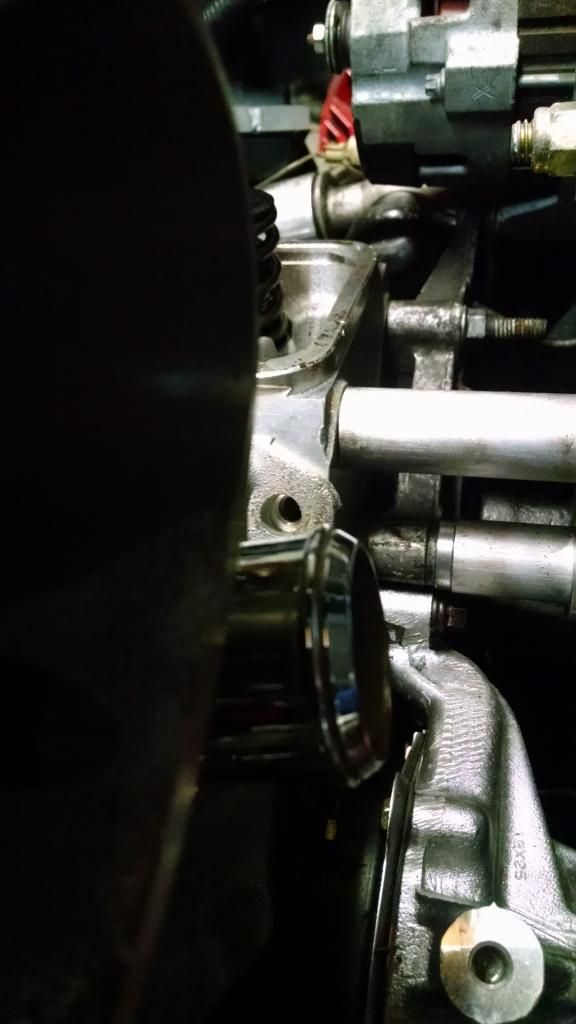

Here is from the lifter valley...

and here is the result incase you missed my last post...

Here is where the oil was leaking...

Here is from the lifter valley...

and here is the result incase you missed my last post...

#2

Drifting

Thread Starter

Member Since: Dec 2007

Location: Sumter South Carolina

Posts: 1,661

Likes: 0

Received 7 Likes

on

7 Posts

what if I used a 1266 instead of a 1206 gasket? Also have read reference to permatex hi-tack or eddlebrock gasgacinch? Any opinions on doing the 2066 and covering it in one of these compounds?

#3

Le Mans Master

Member Since: Oct 2002

Location: Las Vegas - Just stop perpetuating myths please.

Posts: 7,098

Received 373 Likes

on

356 Posts

I think blackozvet was correct and u have oil leak from the distributor. The distributor seals the pressurized oil galley in the block. I cant see the back of the intake vlvs but the stems and intake runners dont have any oil on them. And oil will quickly cake onto the back of vlvs and stems if leaking into the intake runners.

Cant tell if the intakes gaskets are wet from oil at the bottom of the intake runners or thats shiny black RTV. But i can see that no sealer was used on the intake bolts and any positive pressure will work it way through to the lower pressure side. So oil could be forced out the bolts and onto the intake bolt flange. But not unless both your breathers are blocked then the intake becomes positive press. U could use a combination fuel pressure and vacuum gauge to measure your intake when running. If u see positive pressure u know the problem. But blip the throttle and watch the gauge also as vacuum needs to decrease to zero - not positive - with open throttle. I dont expect even a large amount of blowby could cause a positive press in the intake.

Expecting overlap and reversion to push oil to top of the intake and out through a pin hole is kinda unbelievable to me. Normal idle vacuum will be max vac and air will be stucked in not forced out. Not wanting to be sarcastic but i just dont see it happening.

Cant tell if the intakes gaskets are wet from oil at the bottom of the intake runners or thats shiny black RTV. But i can see that no sealer was used on the intake bolts and any positive pressure will work it way through to the lower pressure side. So oil could be forced out the bolts and onto the intake bolt flange. But not unless both your breathers are blocked then the intake becomes positive press. U could use a combination fuel pressure and vacuum gauge to measure your intake when running. If u see positive pressure u know the problem. But blip the throttle and watch the gauge also as vacuum needs to decrease to zero - not positive - with open throttle. I dont expect even a large amount of blowby could cause a positive press in the intake.

Expecting overlap and reversion to push oil to top of the intake and out through a pin hole is kinda unbelievable to me. Normal idle vacuum will be max vac and air will be stucked in not forced out. Not wanting to be sarcastic but i just dont see it happening.

#4

Drifting

Thread Starter

Member Since: Dec 2007

Location: Sumter South Carolina

Posts: 1,661

Likes: 0

Received 7 Likes

on

7 Posts

This is kind of what I thought initially and why I was so baffled but I'm telling you it absolutely is coming off the bottom of the plenum and down the runners.

This is a completely new engine. The oil isn't caked on because I haven't even gotten it out of the garage yet. The oil pooling doesn't happen until the engine is turned off then it seaps out. The picture of the wet intake gaskets is completely oil. It is not wet rtv. My breathers are on both side and brand new. I blew through them and they are not clogged and every easy to blow through. The intake runner on the head was covered in a thin layer of oil also when I took off the manifold.

The cam is 112* overlap and gross lift is around .625 . So it is big and considering I had all the ignition problems and have only run the car in 3-5 minute bursts the rings prob have yet to seat and some blow by is happening. Since I had all these vacuum leaks my map sensor was reading hardly any vacuum at idle but I guess this answers the question why.

Long story short there IS oil coming down the runner from the plenum. There may be additional oil from the distributor or manifold bolts but the majority is coming from the plenum. You can't see it well in the pictures but it is there. And how else do you explain oil between the front passenger side set of two injectors. Yes I said front. That isn't coming from the distributor or bolts in the manifold.

Now back to my question. How do I get the manifold to seal between the head?

This is a completely new engine. The oil isn't caked on because I haven't even gotten it out of the garage yet. The oil pooling doesn't happen until the engine is turned off then it seaps out. The picture of the wet intake gaskets is completely oil. It is not wet rtv. My breathers are on both side and brand new. I blew through them and they are not clogged and every easy to blow through. The intake runner on the head was covered in a thin layer of oil also when I took off the manifold.

The cam is 112* overlap and gross lift is around .625 . So it is big and considering I had all the ignition problems and have only run the car in 3-5 minute bursts the rings prob have yet to seat and some blow by is happening. Since I had all these vacuum leaks my map sensor was reading hardly any vacuum at idle but I guess this answers the question why.

Long story short there IS oil coming down the runner from the plenum. There may be additional oil from the distributor or manifold bolts but the majority is coming from the plenum. You can't see it well in the pictures but it is there. And how else do you explain oil between the front passenger side set of two injectors. Yes I said front. That isn't coming from the distributor or bolts in the manifold.

Now back to my question. How do I get the manifold to seal between the head?

#5

Safety Car

Couple scenarios you need to look into further IMO.....

First, I can see on the gasket impression that the intake is sitting too high.

Look at the center intake bolt hole impression in the gasekt in that 3rd pic. The intake is half a hole too high.....

You need to slot the intake bolt holes so that the intake bolts do not touch the bolt hole when the intake is bolted up to the head. If they touch it can keep the intake from sitting down and clamping the gasket properly. It looks like you have good gasket impression all the way around but if that bolt is in a bind it will pry the intake flange out at the bottom.

Take a look at my intake thats on the 92... I had to slot the crap out of my bolt holes because the cyl heads are cut down so far for compression and since the intake ports in my heads have a slightly raised floor I had to keep the flange as high as possible..

Also in case you don't know. The 4 inner intake bolts in the cyl head on each side are drilled and threaded all the way thru the flange of the cyl head in to the pushrod area of the cyl heads... there is alot of oil in that area and you should seal the threads of the bolts with PTFE teflon or silicone. The outer bolts go to water jacket - so seal them as well.

Second thing I would look at... Appears the lower valley pan (under the plenum) on your intake has been cut out and re-welded? I would check over that welded are very carefully. Lots of oil splash in the lifter valley. A few pin holes would leak bad in that are of the intake.

Will

First, I can see on the gasket impression that the intake is sitting too high.

Look at the center intake bolt hole impression in the gasekt in that 3rd pic. The intake is half a hole too high.....

You need to slot the intake bolt holes so that the intake bolts do not touch the bolt hole when the intake is bolted up to the head. If they touch it can keep the intake from sitting down and clamping the gasket properly. It looks like you have good gasket impression all the way around but if that bolt is in a bind it will pry the intake flange out at the bottom.

Take a look at my intake thats on the 92... I had to slot the crap out of my bolt holes because the cyl heads are cut down so far for compression and since the intake ports in my heads have a slightly raised floor I had to keep the flange as high as possible..

Also in case you don't know. The 4 inner intake bolts in the cyl head on each side are drilled and threaded all the way thru the flange of the cyl head in to the pushrod area of the cyl heads... there is alot of oil in that area and you should seal the threads of the bolts with PTFE teflon or silicone. The outer bolts go to water jacket - so seal them as well.

Second thing I would look at... Appears the lower valley pan (under the plenum) on your intake has been cut out and re-welded? I would check over that welded are very carefully. Lots of oil splash in the lifter valley. A few pin holes would leak bad in that are of the intake.

Will

Last edited by rklessdriver; 02-09-2015 at 10:52 AM.

#6

Le Mans Master

Member Since: Oct 2002

Location: Las Vegas - Just stop perpetuating myths please.

Posts: 7,098

Received 373 Likes

on

356 Posts

Okay the oil that was coating the plenum falls out after s/d. And rkless got it with the bad sealing. Yes if u had machine work on the block deck or heads the intake needs to be matched. Elongating the holes or different thickness gaskets are band-aids for what is a deeper wound needing stitches. Lingenfelter and D. Vizard have tables for this in thier books but for some reason ive never found them on the internet/google. The intake needs different machining on the flanges than on the ends so u need a machine shop that knows what theryre doing.

If u know how much metal was removed from the block deck and then the heads i could PM u the correct machining numbers for the intake - if it falls within the chart. I have seen some engines with so much metal removed the numbers were off my charts.

If u know how much metal was removed from the block deck and then the heads i could PM u the correct machining numbers for the intake - if it falls within the chart. I have seen some engines with so much metal removed the numbers were off my charts.

#7

Drifting

Thread Starter

Member Since: Dec 2007

Location: Sumter South Carolina

Posts: 1,661

Likes: 0

Received 7 Likes

on

7 Posts

The block was a remanned unit from summit 4 bolt. My engine builder did not deck it but went over it very thoroughly though. He is top notch and I trust he knows his stuff. If it needed to be decked he would have said something. Now if it has been decked from summit I don't know. Best I can tell is place the intake onto the head without a gasket and clean and just compare visually even though that is a very rough estimate. Should at least tell me if the angle is off.

I see what you mean by the bolt holes. The problem I had was there is so much porting to get to the 1206 gasket there is very little material on the outer part of the runner to seal to. If that intake sits lower it will leak on top. I almost think having the thicker gasket would help with this problem. If I end up having to cut off some of the manifold that just won't be cheap. I will have to have it built up and cut down or it will sit way too low into the valley and leak on top....

All good ideas thanks guys. I will go over all the welds with jb weld or liquid nail if they look even close to questionable.

I see what you mean by the bolt holes. The problem I had was there is so much porting to get to the 1206 gasket there is very little material on the outer part of the runner to seal to. If that intake sits lower it will leak on top. I almost think having the thicker gasket would help with this problem. If I end up having to cut off some of the manifold that just won't be cheap. I will have to have it built up and cut down or it will sit way too low into the valley and leak on top....

All good ideas thanks guys. I will go over all the welds with jb weld or liquid nail if they look even close to questionable.

#8

Team Owner

Member Since: Oct 2004

Location: altered state

Posts: 81,242

Received 3,043 Likes

on

2,602 Posts

St. Jude Donor '05

Mr gasket 106 (pretty sure) is a thicker gasket for the 1206 double check to verify. Had mine on for yrs no fancy print o seal works well. Ive had a lot of milling done to block heads and intake seals up perfect.

Not a fan of the Fel Pro waterpump and intake gaskets they seem to turn to mush quick for some reason

Not a fan of the Fel Pro waterpump and intake gaskets they seem to turn to mush quick for some reason

#9

Le Mans Master

Member Since: Oct 2002

Location: Las Vegas - Just stop perpetuating myths please.

Posts: 7,098

Received 373 Likes

on

356 Posts

Now that the intake is off and u have replace the gaskets once u clean off the old gaskets u can set the intake down for a fit up. If it sits on the heads and the head bolt holes are unreachable then the block/heads where cut - u need to correct the intake.

If head bolt holes are a touch above the intake holes then u can shim with cardboard or whatever and measure with a feeler gauge. U want the gap to match the gasket compressed height. And the intake ends will need the same clearance.

Id like to have dollar for every intake that is pulled down by the bolts then have the intake leak.

Sorry but dont have any ideas for those thin runner surfaces. Yea if the gasket slides u could have leaks. Maybe seal it to the head and let it harden.

Hope this helps.

If head bolt holes are a touch above the intake holes then u can shim with cardboard or whatever and measure with a feeler gauge. U want the gap to match the gasket compressed height. And the intake ends will need the same clearance.

Id like to have dollar for every intake that is pulled down by the bolts then have the intake leak.

Sorry but dont have any ideas for those thin runner surfaces. Yea if the gasket slides u could have leaks. Maybe seal it to the head and let it harden.

Hope this helps.

#10

Melting Slicks

you can see in the photo that the manifold is not clamping down on the bottom half of the surface, as rckless said its sitting too high.

the oil you can see on the bottom of the gasket surface is the oil being sucked into the intake under vacuum (throttle off) Intakes are good at sealing air but not so good at sealing hot oil, hence the intake oil leaks.

you need to wipe the gaskets clean (are they still on the head surfaces ?) or if not use another pair of intake gaskets that are clean (no RTV , gasket goo, etc)

put 3 intake bolts in (front, centre, rear on each side) finger tight.

using a feeler gauge measure the points front and rear from the diagram below,

whatever the difference is (if it is significant) it needs to be machined that much to make the intake sit flat. 10 thou or more difference top to bottom measurement can be enough to cause problems.

Also as mentioned before, intake bolts can cause a problem in clamping down, place a rag into the valley and run a thread tap thru each thread, galling on alloy intake threads (on the cylinder heads) can also cause problems clamping down intakes, probably best to do this before measuring the intake clearance.

When running steel bolts in and out of an alloy thread using a lubricant, thread anti-sieze makes a great lube for this purpose, to stop ruining your soft threads in the heads.

the oil you can see on the bottom of the gasket surface is the oil being sucked into the intake under vacuum (throttle off) Intakes are good at sealing air but not so good at sealing hot oil, hence the intake oil leaks.

you need to wipe the gaskets clean (are they still on the head surfaces ?) or if not use another pair of intake gaskets that are clean (no RTV , gasket goo, etc)

put 3 intake bolts in (front, centre, rear on each side) finger tight.

using a feeler gauge measure the points front and rear from the diagram below,

whatever the difference is (if it is significant) it needs to be machined that much to make the intake sit flat. 10 thou or more difference top to bottom measurement can be enough to cause problems.

Also as mentioned before, intake bolts can cause a problem in clamping down, place a rag into the valley and run a thread tap thru each thread, galling on alloy intake threads (on the cylinder heads) can also cause problems clamping down intakes, probably best to do this before measuring the intake clearance.

When running steel bolts in and out of an alloy thread using a lubricant, thread anti-sieze makes a great lube for this purpose, to stop ruining your soft threads in the heads.

#11

Drifting

Thread Starter

Member Since: Dec 2007

Location: Sumter South Carolina

Posts: 1,661

Likes: 0

Received 7 Likes

on

7 Posts

Here it is lined up without a gasket. It looks like the angle is pretty close to spot on. However the bolt holes look problematic from one side to the other. Up and down they seem right but side to side across from one another don't line up when the manifold lays flat.

So should I just widen the holes? I'm afraid the manifold might migrate over time and be off center.... Or will the clamp force be more than enough to hold it in place?

So should I just widen the holes? I'm afraid the manifold might migrate over time and be off center.... Or will the clamp force be more than enough to hold it in place?

#13

Drifting

Thread Starter

Member Since: Dec 2007

Location: Sumter South Carolina

Posts: 1,661

Likes: 0

Received 7 Likes

on

7 Posts

I will measure it correctly and do it right. My feeler gauges only go up to .030 so I guess I can use a machinist ruler and razor to line it up? I grabbed a couple of generic longer bolts that I will cut the heads off to make studs so I can see how they line up in the holes...

#14

Le Mans Master

Member Since: Oct 2002

Location: Las Vegas - Just stop perpetuating myths please.

Posts: 7,098

Received 373 Likes

on

356 Posts

U need a brand new intake or original intake just to set on the heads and see how that lines up with the bolt holes. If the same problem with the bolts remain then problem should/could be in the block deck or maybe heads. If they line up correctly then its the intake.

Geeze rith'r, this is getting more complicated by the post. Dont want to be the bad news delivery man here but if the bolt holes dont line up says either the block was decked crooked making the heads cocked or the intake is distorted possibly from a lot of welding (maybe crooked heads too).

U have my sympathies as when u try some innovation u can see some unexpected setback before u get any rewards.

Geeze rith'r, this is getting more complicated by the post. Dont want to be the bad news delivery man here but if the bolt holes dont line up says either the block was decked crooked making the heads cocked or the intake is distorted possibly from a lot of welding (maybe crooked heads too).

U have my sympathies as when u try some innovation u can see some unexpected setback before u get any rewards.

#16

Drifting

Thread Starter

Member Since: Dec 2007

Location: Sumter South Carolina

Posts: 1,661

Likes: 0

Received 7 Likes

on

7 Posts

Well finally some good news! I made my own aligent studs so I could see how everything was seated and lined up. Everything looks textbook perfect. I measured just like you blackozvet told me and it looks pretty close if not spot on. I ordered a thick gasket from Mr. Gasket in the theory it might compress more but feeling its construction it might not. I used my snake camera to get a look at the inside of the runner and it lines up perfect with just a hair overlap which I can shave if needed. The distance to seal the lifter valley will require some serious glob of rtv but I hope that won't be a problem since I have a breather on both sides of the valves so they can take the pressure and not blast out the rtv.

The studs are in different places but good news is none are hung up on then manifold. The holes are large enough to compensate for the slight misalignment.

This might have all been an error on my part and it won't leak this time? Should I go ahead and use the thicker gasket since it all lines up or order another felpro regular? Only thing that slightly concerns me is I can feel the weight of the manifold is not totally on the gasket in between the runners. I can push it easily with a screwdriver where the other sections are harder to move (all this is not bolted down) but I assume then gasket will compress and take up the .005 or so of variance.

The studs are in different places but good news is none are hung up on then manifold. The holes are large enough to compensate for the slight misalignment.

This might have all been an error on my part and it won't leak this time? Should I go ahead and use the thicker gasket since it all lines up or order another felpro regular? Only thing that slightly concerns me is I can feel the weight of the manifold is not totally on the gasket in between the runners. I can push it easily with a screwdriver where the other sections are harder to move (all this is not bolted down) but I assume then gasket will compress and take up the .005 or so of variance.

#17

Melting Slicks

So is the gap difference 005 thou ?

the Mr Gasket's are thicker and softer, they can be used to take up that make difference,

Also dont forget, run a tap thread thru all your intake threads, then use a lubricant and decent quality intake manifold bolts, such as ARP, doing that can save you a lot of grief !

the Mr Gasket's are thicker and softer, they can be used to take up that make difference,

Also dont forget, run a tap thread thru all your intake threads, then use a lubricant and decent quality intake manifold bolts, such as ARP, doing that can save you a lot of grief !

#19

Melting Slicks

#20

Drifting

Thread Starter

Member Since: Dec 2007

Location: Sumter South Carolina

Posts: 1,661

Likes: 0

Received 7 Likes

on

7 Posts

Picture it from the extreme. If I had a pillow between two pieces of wood, could I accurately measure the distance between the pillow and one side of the wood? No because I could shove a finger inbetween if I wanted to. They are not two pieces of solid material like a valve stem and rocker.....

If it leaks it isn't due to lack of me measuring, it is lack of me having some sort of angle calipers that probably exist for some specialized machinist that would cost another $200 for me to use once. I don't understand why there isn't a company that will stand up and say yea, we make a product you can use like rtv that won't be destroyed by gasoline. However all anyone is willing to say is "resistant" so any variance i can't measure could be compensated. Why paper instead of rubber also? I know newer manifolds make rubber with guides why not for ours?

Last edited by rithsleeper; 02-17-2015 at 12:07 PM.