Disappointment on the dyno with my 408

#1

Burning Brakes

Thread Starter

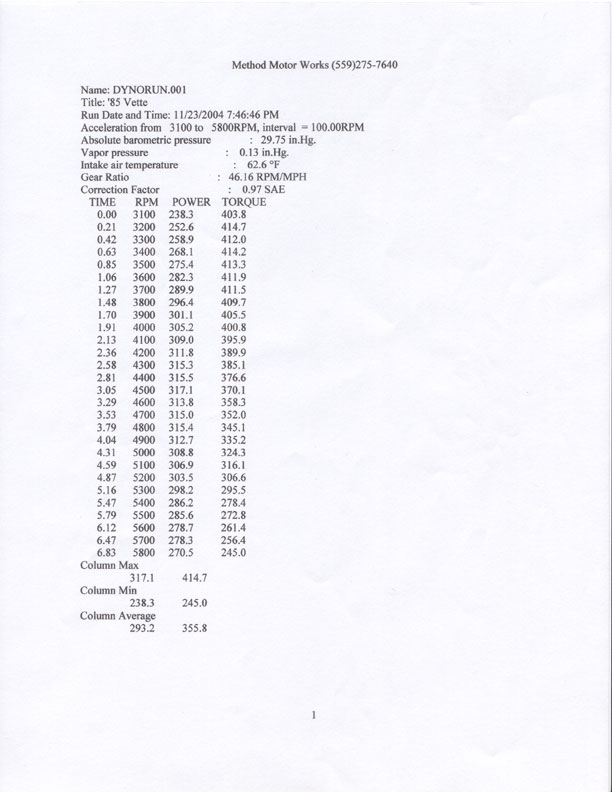

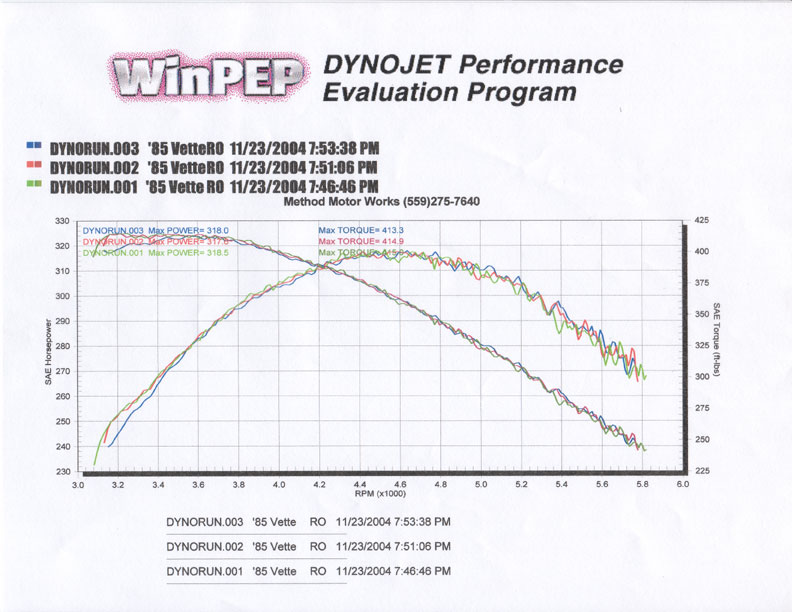

Finally I got some time and took my car to the dyno and the results were less than impressive. It made made just 318.5 RWHP and 415.0 RWTQ..boo hoo..  I just don't understand why it was so low but I have a few ideas...after showing the dyno sheets to the guy who tuned the DFI and a friend of mine with alot of chassis dyno experience (runs the dyno at Whipple Superchargers) they both noticed that as the HP curve came up it started oscillating up and down slightly as it came up, leading them to believe the car was slipping the tires on the drum and one thing I noticed was that the guy strapped it down from the rear shock mounts going back to anchor points on the dyno as opposed to tying it down more vertically and loading the tire harder on the drum..I dunno..that might be the case..anybody have any suggestions??...I'm certain that the A/F is right on as the EMIC who tuned it (autotrenddiagnostics.com) is super knowledgable and uses a Horiba A/F monitor, and put alot of time into mapping the car and data logging it on the road...The car seems incredibily strong just driving it..NO COMPLAINTS THERE!!....My friend at Whipple did voice some concern over the fuel system...I have a Walbro 340, 255lph pump with hot wire kit and stock fuel lines...he says there's no way that system will support the kind of HP this engine is capable of making and is suggesting I go to a custom pickup with an Aeromotive or Weldon pump, #8 feed lines, #6 return, and high flow filters...Anybody run into this yet?

I just don't understand why it was so low but I have a few ideas...after showing the dyno sheets to the guy who tuned the DFI and a friend of mine with alot of chassis dyno experience (runs the dyno at Whipple Superchargers) they both noticed that as the HP curve came up it started oscillating up and down slightly as it came up, leading them to believe the car was slipping the tires on the drum and one thing I noticed was that the guy strapped it down from the rear shock mounts going back to anchor points on the dyno as opposed to tying it down more vertically and loading the tire harder on the drum..I dunno..that might be the case..anybody have any suggestions??...I'm certain that the A/F is right on as the EMIC who tuned it (autotrenddiagnostics.com) is super knowledgable and uses a Horiba A/F monitor, and put alot of time into mapping the car and data logging it on the road...The car seems incredibily strong just driving it..NO COMPLAINTS THERE!!....My friend at Whipple did voice some concern over the fuel system...I have a Walbro 340, 255lph pump with hot wire kit and stock fuel lines...he says there's no way that system will support the kind of HP this engine is capable of making and is suggesting I go to a custom pickup with an Aeromotive or Weldon pump, #8 feed lines, #6 return, and high flow filters...Anybody run into this yet?

I just don't understand why it was so low but I have a few ideas...after showing the dyno sheets to the guy who tuned the DFI and a friend of mine with alot of chassis dyno experience (runs the dyno at Whipple Superchargers) they both noticed that as the HP curve came up it started oscillating up and down slightly as it came up, leading them to believe the car was slipping the tires on the drum and one thing I noticed was that the guy strapped it down from the rear shock mounts going back to anchor points on the dyno as opposed to tying it down more vertically and loading the tire harder on the drum..I dunno..that might be the case..anybody have any suggestions??...I'm certain that the A/F is right on as the EMIC who tuned it (autotrenddiagnostics.com) is super knowledgable and uses a Horiba A/F monitor, and put alot of time into mapping the car and data logging it on the road...The car seems incredibily strong just driving it..NO COMPLAINTS THERE!!....My friend at Whipple did voice some concern over the fuel system...I have a Walbro 340, 255lph pump with hot wire kit and stock fuel lines...he says there's no way that system will support the kind of HP this engine is capable of making and is suggesting I go to a custom pickup with an Aeromotive or Weldon pump, #8 feed lines, #6 return, and high flow filters...Anybody run into this yet?

I just don't understand why it was so low but I have a few ideas...after showing the dyno sheets to the guy who tuned the DFI and a friend of mine with alot of chassis dyno experience (runs the dyno at Whipple Superchargers) they both noticed that as the HP curve came up it started oscillating up and down slightly as it came up, leading them to believe the car was slipping the tires on the drum and one thing I noticed was that the guy strapped it down from the rear shock mounts going back to anchor points on the dyno as opposed to tying it down more vertically and loading the tire harder on the drum..I dunno..that might be the case..anybody have any suggestions??...I'm certain that the A/F is right on as the EMIC who tuned it (autotrenddiagnostics.com) is super knowledgable and uses a Horiba A/F monitor, and put alot of time into mapping the car and data logging it on the road...The car seems incredibily strong just driving it..NO COMPLAINTS THERE!!....My friend at Whipple did voice some concern over the fuel system...I have a Walbro 340, 255lph pump with hot wire kit and stock fuel lines...he says there's no way that system will support the kind of HP this engine is capable of making and is suggesting I go to a custom pickup with an Aeromotive or Weldon pump, #8 feed lines, #6 return, and high flow filters...Anybody run into this yet?

#2

Safety Car

Member Since: Aug 2002

Location: New Albany IN

Posts: 4,812

Likes: 0

Received 1 Like

on

1 Post

St. Jude Donor '03-'04-'06-'08-'09

SOunds like you have a monster of a motor there! You would think with that much cubic inches you would be able to pull more HP.....however 415 for torque at the Rear wheels is pretty impressive. I would guess your close to 475-500 at the crank.

It sounds like the wheelspin problem on the rollers could be a culprit if that is what is happening...if thats the case, I would go back and tell them to do it right!

How does it feel on the streets?

It sounds like the wheelspin problem on the rollers could be a culprit if that is what is happening...if thats the case, I would go back and tell them to do it right!

How does it feel on the streets?

#3

Burning Brakes

Member Since: Apr 2002

Location: Cleveland OH

Posts: 1,126

Likes: 0

Received 0 Likes

on

0 Posts

You have to give some more details on your buildup, but I'm running the same Racetronix pump as you are and making 405rwhp in the 396. What size are your injectors. Did you get A/F readings from your dyno run? A scan of the sheet might help locate a possible issue.

Ron

Ron

#4

Safety Car

If the dyno did not put fans in front of the raidator then the cooling and the air flow would not be the same as driving the car.

I never trust a dyno for a car, engine dyno ok but.

When I dyno the results are far from what the car can realy do .

Saturday I was helping a newbe with his 86 vett and told him for each 10 degrees the temp rises on the engine he will lose a 10th or half of that in the 1/4 mile, another guy told him that was not true.

At that point I told him to throw out his passenger and he will gain a 10th .He did and guess what. Told him to cool down the car to at least 180 degres and gained .30.

By the end of the night he was one of the last 3 in the finals and this was his first time he was racing.

What you were told about the fuel is true but if the air /fuel is correct for your normal driving that you do, why go to the expense of changing everything unless you are going to race it.

I never trust a dyno for a car, engine dyno ok but.

When I dyno the results are far from what the car can realy do .

Saturday I was helping a newbe with his 86 vett and told him for each 10 degrees the temp rises on the engine he will lose a 10th or half of that in the 1/4 mile, another guy told him that was not true.

At that point I told him to throw out his passenger and he will gain a 10th .He did and guess what. Told him to cool down the car to at least 180 degres and gained .30.

By the end of the night he was one of the last 3 in the finals and this was his first time he was racing.

What you were told about the fuel is true but if the air /fuel is correct for your normal driving that you do, why go to the expense of changing everything unless you are going to race it.

#5

Burning Brakes

Thread Starter

I did scan the dyno readouts..I just need to put them on my server and post them in here..I'll try to do that in the morning...I am using 30# injectors...the motor is in my sig..but it's a 408..with 10.3:1 compression, Dart Pro1 200's, Comp Hyd Roller with .503/.510 and 224/230 @ .050 w/112 LC...Ported and matched SuperRam, 58mm LPE T/B, LPE Headers, gutted cat and flowmasters....The thing is really quick on the road...I really thought it would be significantly higher based on seat of the pants driving...it has about 400miles on it now.

#6

Burning Brakes

Thread Starter

Yeah true..the A/F is right on I'm sure..in fact the tuner even put in the correction factor into the DFI when he tuned it..when I go back I will data log it with my laptop when we make the run since I do have the WB02 on my DFI..we did have fans on the car and ambient air temps were in the low 60's

#7

Le Mans Master

Member Since: Jan 2003

Location: Portland Oregon

Posts: 8,596

Likes: 0

Received 16 Likes

on

15 Posts

Your strange spikes could be the result of noise in the tach pick up from the dyno. On my mustang dyno, I have had some problems with getting a decent tach signal on some cars. For some reason it doesn't like the GM LS1 style CNP ignition. On those cars I either have to use an optical tach or use one of the coil driver wires as a tach source and use my low current tach pick up. When the problem rears its ugly head I get all kinds of noise on the power curve.

If that isn't the problem then it coule be they way it was strapped down, or sometimes depending on the EFI setup and if your system used a knock sensor, it could have picked up some knock and was retarding the spark which is a common problem on GM cars using the stock EFI systems. On my dyno I have a a craddle type which means that the tires sits in a craddle of two pairs of rolls. When I strap a car down it is being pulled back against the rear roll, and the car is also strapped down in the front as well. I also have a way to pull the car straight down into the craddle which I have used only on very high powered cars.

If that isn't the problem then it coule be they way it was strapped down, or sometimes depending on the EFI setup and if your system used a knock sensor, it could have picked up some knock and was retarding the spark which is a common problem on GM cars using the stock EFI systems. On my dyno I have a a craddle type which means that the tires sits in a craddle of two pairs of rolls. When I strap a car down it is being pulled back against the rear roll, and the car is also strapped down in the front as well. I also have a way to pull the car straight down into the craddle which I have used only on very high powered cars.

#8

What type of dyno was it? Was it a Mustang dyno or a dynojet?

I don't think it's an issue with how it was strapped down. If that was the case then you wouldn't make such good torque numbers. Can you post a picture of the graph?

That's a pretty mild cam for that much engine. Maybe it's running out of air in the upper RPM band. It makes killer torque down low but it just can't continue to pull enough air through it to keep making power. The actual graph would really help a lot.

I don't think it's an issue with how it was strapped down. If that was the case then you wouldn't make such good torque numbers. Can you post a picture of the graph?

That's a pretty mild cam for that much engine. Maybe it's running out of air in the upper RPM band. It makes killer torque down low but it just can't continue to pull enough air through it to keep making power. The actual graph would really help a lot.

#9

Burning Brakes

Thread Starter

Originally Posted by tjwong

Your strange spikes could be the result of noise in the tach pick up from the dyno. On my mustang dyno, I have had some problems with getting a decent tach signal on some cars. For some reason it doesn't like the GM LS1 style CNP ignition. On those cars I either have to use an optical tach or use one of the coil driver wires as a tach source and use my low current tach pick up. When the problem rears its ugly head I get all kinds of noise on the power curve.

If that isn't the problem then it coule be they way it was strapped down, or sometimes depending on the EFI setup and if your system used a knock sensor, it could have picked up some knock and was retarding the spark which is a common problem on GM cars using the stock EFI systems. On my dyno I have a a craddle type which means that the tires sits in a craddle of two pairs of rolls. When I strap a car down it is being pulled back against the rear roll, and the car is also strapped down in the front as well. I also have a way to pull the car straight down into the craddle which I have used only on very high powered cars.

If that isn't the problem then it coule be they way it was strapped down, or sometimes depending on the EFI setup and if your system used a knock sensor, it could have picked up some knock and was retarding the spark which is a common problem on GM cars using the stock EFI systems. On my dyno I have a a craddle type which means that the tires sits in a craddle of two pairs of rolls. When I strap a car down it is being pulled back against the rear roll, and the car is also strapped down in the front as well. I also have a way to pull the car straight down into the craddle which I have used only on very high powered cars.

#10

Burning Brakes

Thread Starter

Originally Posted by Nathan Plemons

What type of dyno was it? Was it a Mustang dyno or a dynojet?

I don't think it's an issue with how it was strapped down. If that was the case then you wouldn't make such good torque numbers. Can you post a picture of the graph?

That's a pretty mild cam for that much engine. Maybe it's running out of air in the upper RPM band. It makes killer torque down low but it just can't continue to pull enough air through it to keep making power. The actual graph would really help a lot.

I don't think it's an issue with how it was strapped down. If that was the case then you wouldn't make such good torque numbers. Can you post a picture of the graph?

That's a pretty mild cam for that much engine. Maybe it's running out of air in the upper RPM band. It makes killer torque down low but it just can't continue to pull enough air through it to keep making power. The actual graph would really help a lot.

#12

Forgive me if you already know this, some people don't. Torque is equal to horsepower * 5252 / RPM

As such there are two ways to make horsepower. Make mega torque at a low RPM or make lower torque and turn mega RPM's.

Obviously you've got the mega torque part of it down, 400+ ft. lbs @ 2800 RPM's is pretty impressive. Even after the torque starts to fall off you'll notice that HP continues to climb because the RPM is going up. Eventually torque falls faster than the RPM can compensate and then HP starts to fall again.

So to make big horsepower what you've got to do is get that torque peak to hold into the upper RPM band, or at least drop off more slowly. Honestly your torque peak starts falling off way too quickly at way too soon an RPM. That cam is bigger than mine, so even for the added displacement I wouldn't think your torque should start to fall off until you're in the 4500 RPM range at least.

My personal experience with this would be that there's a flow restriction somewhere. The cam is kinda small for that motor, but that just means it should have excellent street manners, it should still make more top end than that. I think something be it intake or exhaust is choking your engine by 3800 RPM's.

Here's a good illustration of that, here's my car with my ported heads vs non ported heads

You'll notice that below 4500 RPM's it might as well be the exact same graph. Above that though you can see that the ported heads allowed the engine to keep breathing and the torque curve was maintained better. It still drops off but it doesn't drop off nearly as quickly and as such the HP number is much higher. You see for whatever the difference in the torque is, this is amplified by RPM. A small torque difference equals a pretty big HP difference.

Your engine is only as good as it's worst flowing component. Something is choking it and it's happening so early in the RPM band because of the extra displacment. The same setup on a 350 might not start to drop off until 4500-4800 RPM's.

Do you by chance have flow numbers for your heads? Are they rough cast or ported? Your exhaust sounds OK, my only concern there is the cats. You mention gutted cats, did you put a pipe through them or just hollow them out? If they are just hollowed that could be a restriction as well. You see that large chamber in the middle of your exhaust can cause extra turbulance. You might try unbolting the exhaust at the headers and see if you pick up anything.

As such there are two ways to make horsepower. Make mega torque at a low RPM or make lower torque and turn mega RPM's.

Obviously you've got the mega torque part of it down, 400+ ft. lbs @ 2800 RPM's is pretty impressive. Even after the torque starts to fall off you'll notice that HP continues to climb because the RPM is going up. Eventually torque falls faster than the RPM can compensate and then HP starts to fall again.

So to make big horsepower what you've got to do is get that torque peak to hold into the upper RPM band, or at least drop off more slowly. Honestly your torque peak starts falling off way too quickly at way too soon an RPM. That cam is bigger than mine, so even for the added displacement I wouldn't think your torque should start to fall off until you're in the 4500 RPM range at least.

My personal experience with this would be that there's a flow restriction somewhere. The cam is kinda small for that motor, but that just means it should have excellent street manners, it should still make more top end than that. I think something be it intake or exhaust is choking your engine by 3800 RPM's.

Here's a good illustration of that, here's my car with my ported heads vs non ported heads

You'll notice that below 4500 RPM's it might as well be the exact same graph. Above that though you can see that the ported heads allowed the engine to keep breathing and the torque curve was maintained better. It still drops off but it doesn't drop off nearly as quickly and as such the HP number is much higher. You see for whatever the difference in the torque is, this is amplified by RPM. A small torque difference equals a pretty big HP difference.

Your engine is only as good as it's worst flowing component. Something is choking it and it's happening so early in the RPM band because of the extra displacment. The same setup on a 350 might not start to drop off until 4500-4800 RPM's.

Do you by chance have flow numbers for your heads? Are they rough cast or ported? Your exhaust sounds OK, my only concern there is the cats. You mention gutted cats, did you put a pipe through them or just hollow them out? If they are just hollowed that could be a restriction as well. You see that large chamber in the middle of your exhaust can cause extra turbulance. You might try unbolting the exhaust at the headers and see if you pick up anything.

#13

Burning Brakes

Thread Starter

Originally Posted by Nathan Plemons

Forgive me if you already know this, some people don't. Torque is equal to horsepower * 5252 / RPM

As such there are two ways to make horsepower. Make mega torque at a low RPM or make lower torque and turn mega RPM's.

Obviously you've got the mega torque part of it down, 400+ ft. lbs @ 2800 RPM's is pretty impressive. Even after the torque starts to fall off you'll notice that HP continues to climb because the RPM is going up. Eventually torque falls faster than the RPM can compensate and then HP starts to fall again.

So to make big horsepower what you've got to do is get that torque peak to hold into the upper RPM band, or at least drop off more slowly. Honestly your torque peak starts falling off way too quickly at way too soon an RPM. That cam is bigger than mine, so even for the added displacement I wouldn't think your torque should start to fall off until you're in the 4500 RPM range at least.

My personal experience with this would be that there's a flow restriction somewhere. The cam is kinda small for that motor, but that just means it should have excellent street manners, it should still make more top end than that. I think something be it intake or exhaust is choking your engine by 3800 RPM's.

Here's a good illustration of that, here's my car with my ported heads vs non ported heads

You'll notice that below 4500 RPM's it might as well be the exact same graph. Above that though you can see that the ported heads allowed the engine to keep breathing and the torque curve was maintained better. It still drops off but it doesn't drop off nearly as quickly and as such the HP number is much higher. You see for whatever the difference in the torque is, this is amplified by RPM. A small torque difference equals a pretty big HP difference.

Your engine is only as good as it's worst flowing component. Something is choking it and it's happening so early in the RPM band because of the extra displacment. The same setup on a 350 might not start to drop off until 4500-4800 RPM's.

Do you by chance have flow numbers for your heads? Are they rough cast or ported? Your exhaust sounds OK, my only concern there is the cats. You mention gutted cats, did you put a pipe through them or just hollow them out? If they are just hollowed that could be a restriction as well. You see that large chamber in the middle of your exhaust can cause extra turbulance. You might try unbolting the exhaust at the headers and see if you pick up anything.

As such there are two ways to make horsepower. Make mega torque at a low RPM or make lower torque and turn mega RPM's.

Obviously you've got the mega torque part of it down, 400+ ft. lbs @ 2800 RPM's is pretty impressive. Even after the torque starts to fall off you'll notice that HP continues to climb because the RPM is going up. Eventually torque falls faster than the RPM can compensate and then HP starts to fall again.

So to make big horsepower what you've got to do is get that torque peak to hold into the upper RPM band, or at least drop off more slowly. Honestly your torque peak starts falling off way too quickly at way too soon an RPM. That cam is bigger than mine, so even for the added displacement I wouldn't think your torque should start to fall off until you're in the 4500 RPM range at least.

My personal experience with this would be that there's a flow restriction somewhere. The cam is kinda small for that motor, but that just means it should have excellent street manners, it should still make more top end than that. I think something be it intake or exhaust is choking your engine by 3800 RPM's.

Here's a good illustration of that, here's my car with my ported heads vs non ported heads

You'll notice that below 4500 RPM's it might as well be the exact same graph. Above that though you can see that the ported heads allowed the engine to keep breathing and the torque curve was maintained better. It still drops off but it doesn't drop off nearly as quickly and as such the HP number is much higher. You see for whatever the difference in the torque is, this is amplified by RPM. A small torque difference equals a pretty big HP difference.

Your engine is only as good as it's worst flowing component. Something is choking it and it's happening so early in the RPM band because of the extra displacment. The same setup on a 350 might not start to drop off until 4500-4800 RPM's.

Do you by chance have flow numbers for your heads? Are they rough cast or ported? Your exhaust sounds OK, my only concern there is the cats. You mention gutted cats, did you put a pipe through them or just hollow them out? If they are just hollowed that could be a restriction as well. You see that large chamber in the middle of your exhaust can cause extra turbulance. You might try unbolting the exhaust at the headers and see if you pick up anything.

#15

I wouldn't be quite as worried about that. For some reason my car has always made an extremely smooth dyno curve and some cars just don't. I can't really explain. There is a "smoothing" adjustment in the dynojet software, maybe his got turned down some?

#16

Le Mans Master

Member Since: Mar 2002

Location: Castro Valley Calif.

Posts: 5,884

Likes: 0

Received 2 Likes

on

1 Post

St. Jude Donor '03-'04-'05-'06-'07-'08-'09-'10-'11-'12-'13-'14-'15-'16-'17-'18-'19-'20-'21-'22

'23-'24

Originally Posted by eguyett1985

Also, notice how relatively smooth your curve is without the oscillations that mine has...what's up with that??

I agree with Nathan's analysis, but I really believe your curve issue might be as simple as backing your cam off 4*........ maybe even 6. I could be way off base here, but if Comp ground 4* into it, that's pushing your peak way too low for a big inch motor that has a low torque curve inherent anyway. I think you're really close to what you want

Nice setup......... I hope to meet you sometime on one of our GTGs.

Nice setup......... I hope to meet you sometime on one of our GTGs.

#17

Originally Posted by eguyett1985

I still wonder though if lack of fuel volume could come into play here..that would definetlely choke it off also as bsfc would be reduced.

#18

Originally Posted by Caboboy

Evan, I think the tires are skipping.......that graph is a pretty clear indication IMHO

#19

Burning Brakes

Thread Starter

Originally Posted by Nathan Plemons

Curious why you think so? Because of the rough graph or the fact that the power drops off?

#20

Burning Brakes

Thread Starter

Originally Posted by Caboboy

Evan, I think the tires are skipping.......that graph is a pretty clear indication IMHO

I agree with Nathan's analysis, but I really believe your curve issue might be as simple as backing your cam off 4*........ maybe even 6. I could be way off base here, but if Comp ground 4* into it, that's pushing your peak way too low for a big inch motor that has a low torque curve inherent anyway. I think you're really close to what you want Nice setup......... I hope to meet you sometime on one of our GTGs.

Nice setup......... I hope to meet you sometime on one of our GTGs.

I agree with Nathan's analysis, but I really believe your curve issue might be as simple as backing your cam off 4*........ maybe even 6. I could be way off base here, but if Comp ground 4* into it, that's pushing your peak way too low for a big inch motor that has a low torque curve inherent anyway. I think you're really close to what you want

Nice setup......... I hope to meet you sometime on one of our GTGs.

Nice setup......... I hope to meet you sometime on one of our GTGs.