ecs instal

#181

Drifting

Thread Starter

its around 0°c, so i leaned out the mixture to 11.8 or so and went sideways for the first time in second (auto). does the rear always go to the left? thats good, btw, you end up in the weeds and not in oncoming traffic. the car now pulls 0.64g in second at 5500 rpm. also i was seeng iats around 8°c max. so that ecs intercooler really does an excellent job.

well, i had some fun, but a few minutes later there was a pinging sound. i thought the blower pulley came off again. but no, its the water pump pulley that broke off. strange, because the wp is the newest part on the car, i installed it with the blower last summer.

so apparently the $100 savings on the airtex pump were not worth it. what do i do now, get an om pump or a ls3 pump? on genes site the pump seems to be discontinued. how come?

there was nowhere to stop and i drove the car for a 1/4 mile without the pump. hopefully i didnt destroy the heads.

well, i had some fun, but a few minutes later there was a pinging sound. i thought the blower pulley came off again. but no, its the water pump pulley that broke off. strange, because the wp is the newest part on the car, i installed it with the blower last summer.

so apparently the $100 savings on the airtex pump were not worth it. what do i do now, get an om pump or a ls3 pump? on genes site the pump seems to be discontinued. how come?

there was nowhere to stop and i drove the car for a 1/4 mile without the pump. hopefully i didnt destroy the heads.

Last edited by romandian; 12-17-2015 at 04:19 AM.

#182

Race Director

Member Since: Dec 2010

Location: Atlanta, GA

Posts: 10,426

Received 1,260 Likes

on

1,055 Posts

2020 Corvette of the Year Finalist (performance mods)

C5 of Year Winner (performance mods) 2019

that's a pretty common issue on non gm waterpumps... you can tack weld the pulley on so that it won't come off

#183

Drifting

Thread Starter

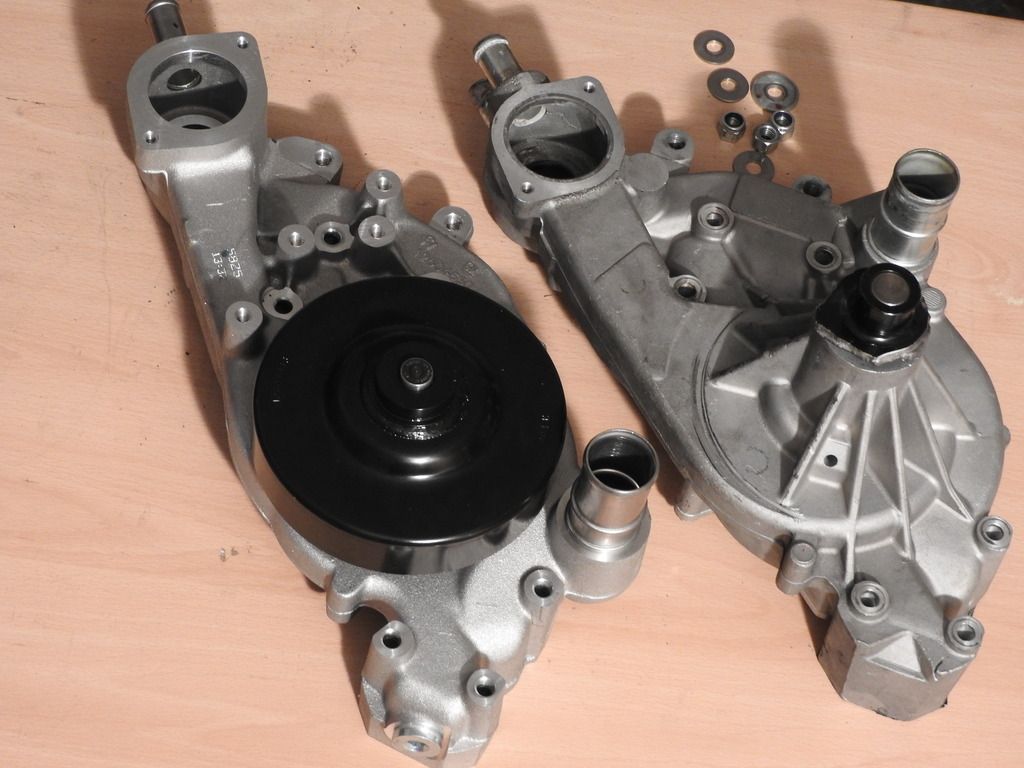

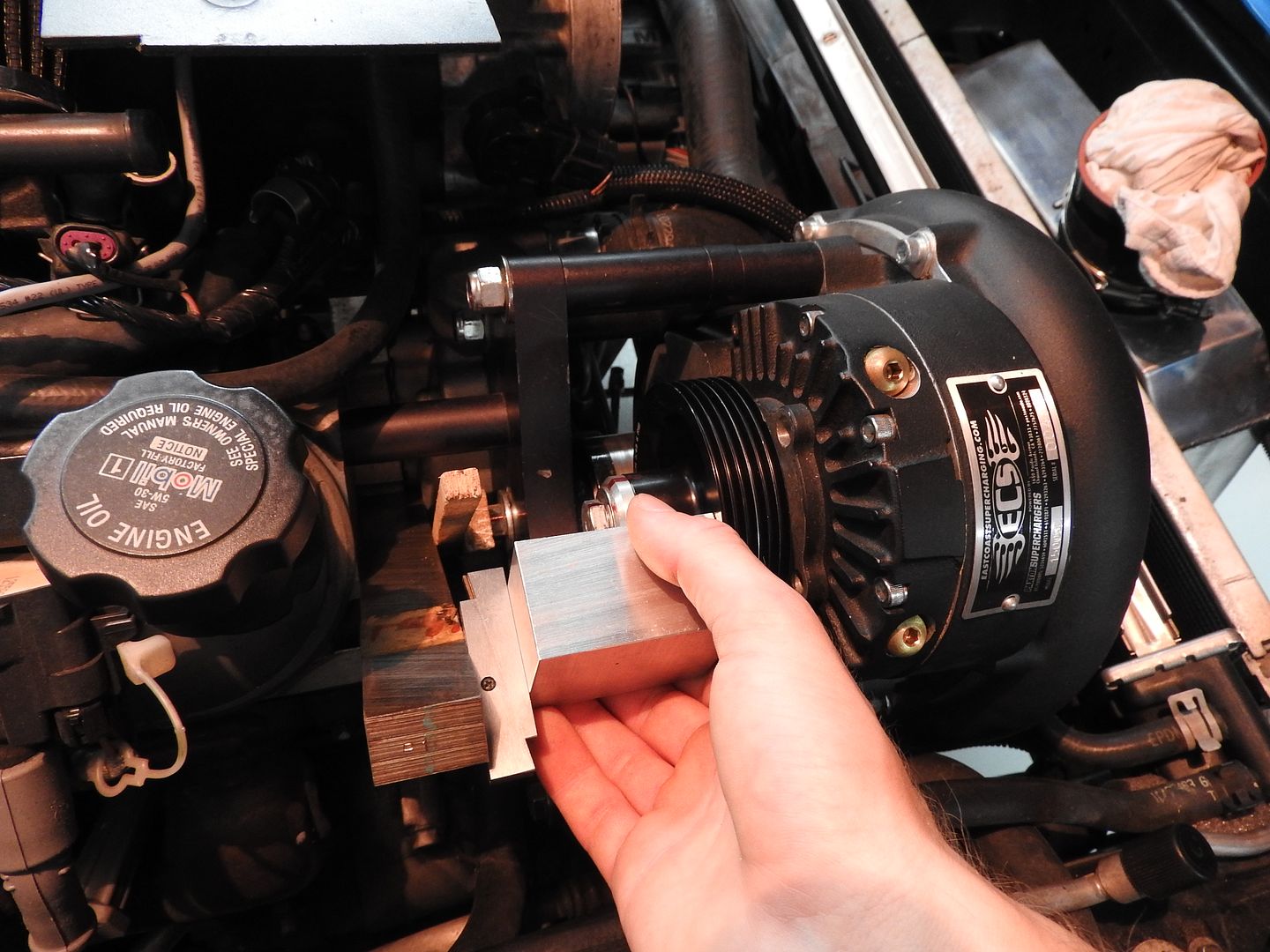

this is it:

welding wouldnt have helped, i guess.

there are the ls1/6 evans pump and one from edelbrock (8896) for $350-400. should i get one of those?

i always thought the load was from the balancer to the blower, but maybe the other accessories are loaded as well. is the ps pulley next?

welding wouldnt have helped, i guess.

there are the ls1/6 evans pump and one from edelbrock (8896) for $350-400. should i get one of those?

i always thought the load was from the balancer to the blower, but maybe the other accessories are loaded as well. is the ps pulley next?

Last edited by romandian; 12-22-2015 at 01:14 PM.

#184

Race Director

Member Since: May 2004

Location: Raleigh, NC

Posts: 16,664

Received 1,193 Likes

on

1,052 Posts

St. Jude Donor '15

What brand were you running?

I replaced mine with an AC Delco OEM one, no problems so far

I replaced mine with an AC Delco OEM one, no problems so far

#185

Race Director

Member Since: Dec 2010

Location: Atlanta, GA

Posts: 10,426

Received 1,260 Likes

on

1,055 Posts

2020 Corvette of the Year Finalist (performance mods)

C5 of Year Winner (performance mods) 2019

I would go with an oem pump personally... the tighter the belt is the more stress it puts on everything... the power steering pulley is composite and can come apart, I've seen it happen and it's pretty nasty... you can replace it with an ls2 power steering pulley, it's cheap, made of metal, and a direct replacement... I didn't need a different sized belt when I replaced mine

#186

Drifting

Thread Starter

actually i was wrong saying it was airtex (that was for the jeep), it was a pronto pump (not more than 1000 miles on it).

im going to ask edelbrock and evans about their pumps and blowers and the warranty. i now have to practically take everything off.

im also considering the aluminum ps pulley, but i looks like the abs has to come off, so i dont know yet. im not spinning the engine much over 6000, so it might be fine.

im going to ask edelbrock and evans about their pumps and blowers and the warranty. i now have to practically take everything off.

im also considering the aluminum ps pulley, but i looks like the abs has to come off, so i dont know yet. im not spinning the engine much over 6000, so it might be fine.

Last edited by romandian; 12-22-2015 at 06:11 PM.

#187

Race Director

Member Since: Dec 2010

Location: Atlanta, GA

Posts: 10,426

Received 1,260 Likes

on

1,055 Posts

2020 Corvette of the Year Finalist (performance mods)

C5 of Year Winner (performance mods) 2019

you can remove the power steering pulley without removing the ebcm, you will need to remove the bracket from under it which is a few bolts plus the 2 nuts on the side and you can push it down far enough to get a puller on the power steering pulley

#189

Drifting

Thread Starter

evans have an excellent customer service, they got back to me on the same day. the pump however is $570, because you have to get the pulley separately. thats a difference of $300, so i think ill get the ls3 pump.

Last edited by romandian; 10-09-2017 at 03:09 AM.

#190

Race Director

Member Since: Dec 2010

Location: Atlanta, GA

Posts: 10,426

Received 1,260 Likes

on

1,055 Posts

2020 Corvette of the Year Finalist (performance mods)

C5 of Year Winner (performance mods) 2019

I think you will be better off with an oem pump anyway in my opinion... you might want to do some research on the newer pumps because I believe there is a difference in the pulley width... I'm not 100% but I want to say the early ls7 waterpumps had a larger pulley that will support 10 rib belts while the newer ones will barely support an 8 rib, something to that effect... if you are running a 6 rib that won't be an issue but if you ever decide to upgrade like many of us do then you might find yourself replacing it again

#191

Race Director

Member Since: May 2004

Location: Raleigh, NC

Posts: 16,664

Received 1,193 Likes

on

1,052 Posts

St. Jude Donor '15

I know the LS2 pump pullies are fairly wide.. with a 6 rib on there I'm maybe using half of the pulley width

I think it was LS3/7 when they want to the more narrow pulley

I think it was LS3/7 when they want to the more narrow pulley

#192

Race Director

Member Since: Dec 2010

Location: Atlanta, GA

Posts: 10,426

Received 1,260 Likes

on

1,055 Posts

2020 Corvette of the Year Finalist (performance mods)

C5 of Year Winner (performance mods) 2019

#193

Drifting

Thread Starter

thanks. i decided to go with this:

https://www.rockauto.com/catalog/mor...nid=498&jpid=3

the ls1 pump is a stupid design because of the leverage on the pulley. actually im surprised it works at all.

https://www.rockauto.com/catalog/mor...nid=498&jpid=3

the ls1 pump is a stupid design because of the leverage on the pulley. actually im surprised it works at all.

#194

Drifting

Thread Starter

hi everybody, im back. i was so pissed about the new pump breaking, that i let the car sit for almost 10 months (i have other ones to play with).

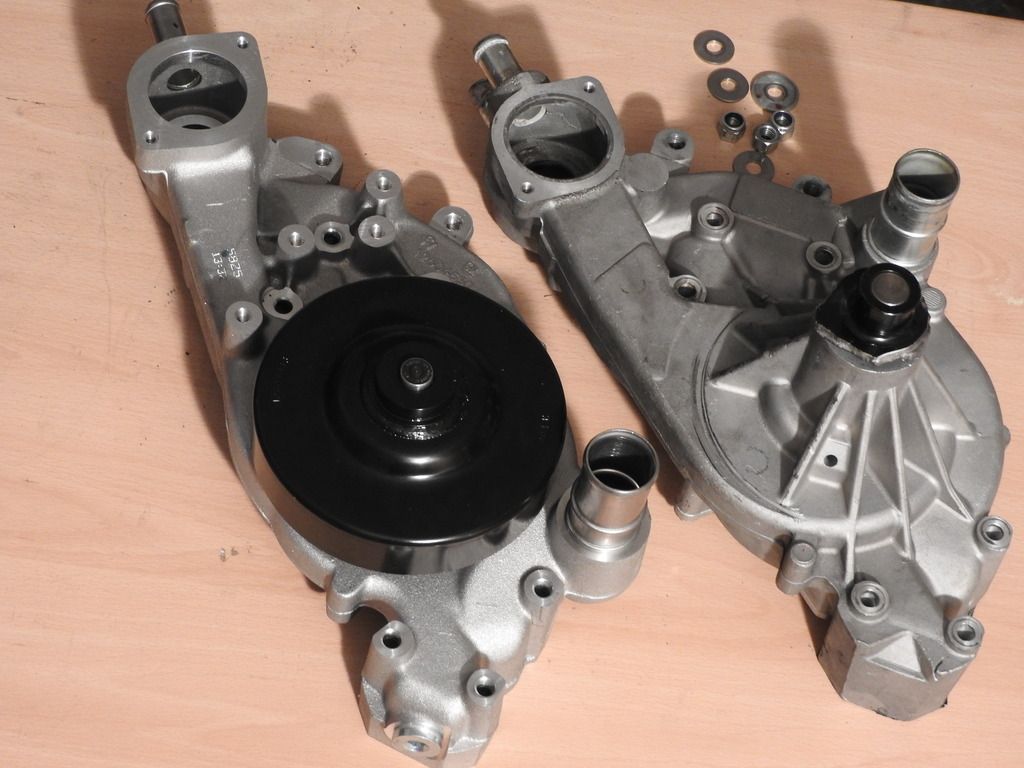

the other day i unpacked the new pump. surprise, the inlet is on the other side, i didnt realise that.

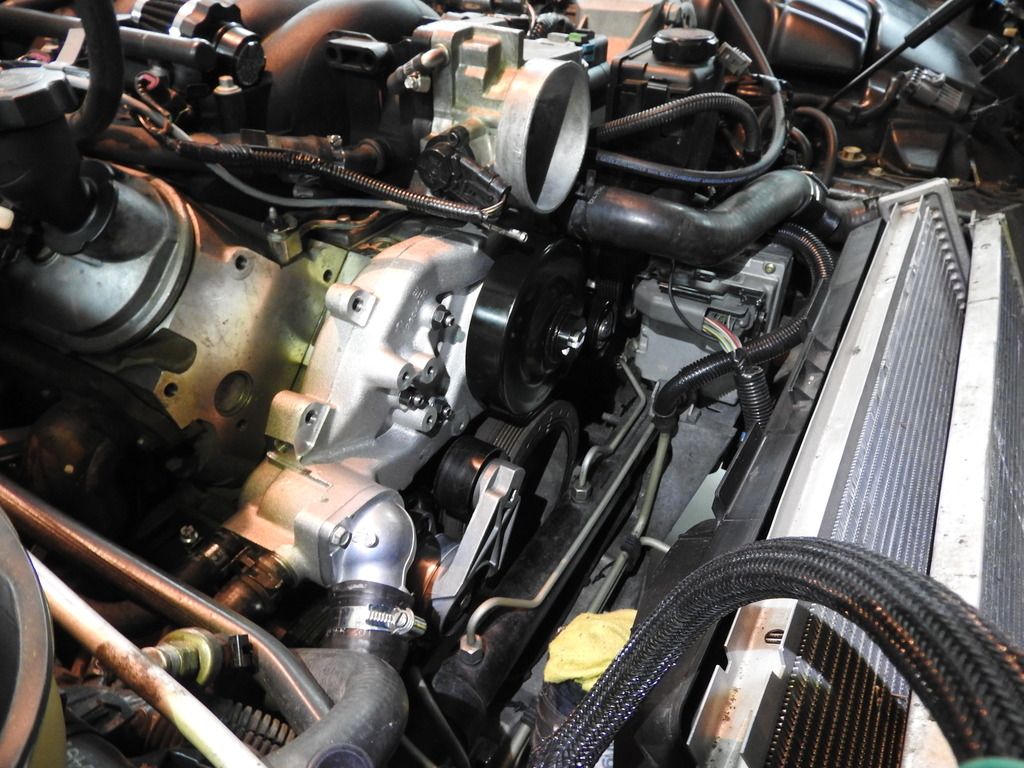

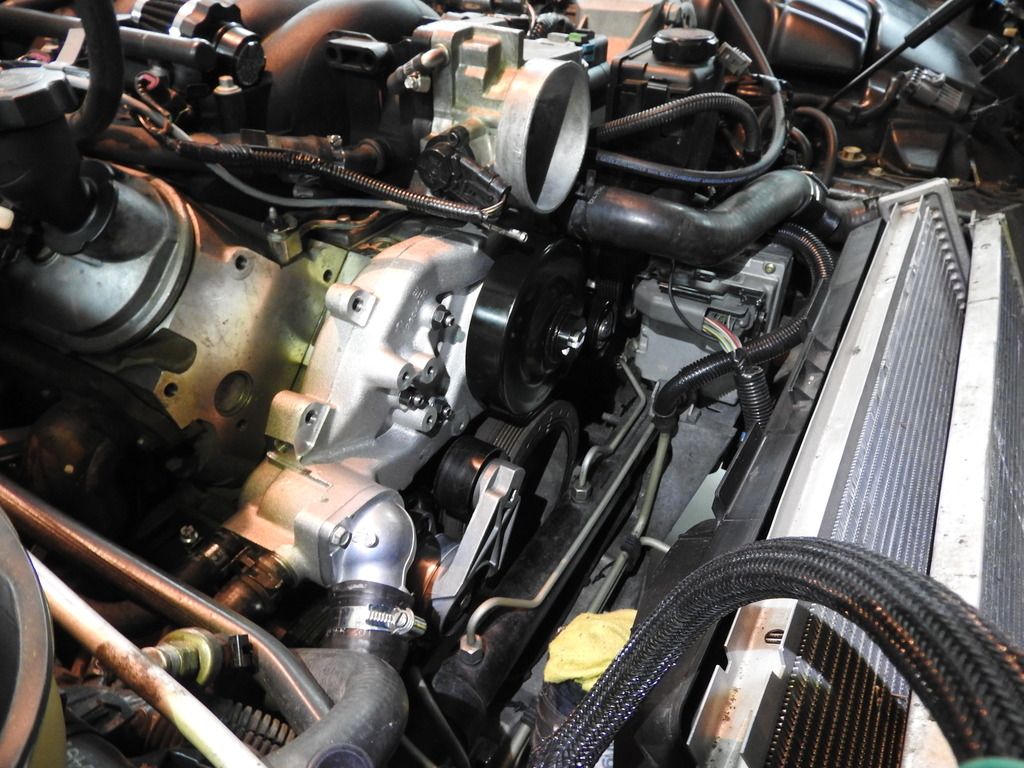

i checked the dimensions and it seemed o.k except the additional bosses. i cut off the lower one and milled the others down by 3 mm. surprisingly the old pump somehow came out without taking off the spung tensioner, i couldnt believe it and even the throttlebody stayed in place. it had to come out later so i could bent the vapour tube a little as well as the tb heater tube. then the new pump went in:

being paranoid, i converted the water pump bolts to studs. i didnt like the specified 30 nm on the 8x1.25 bolts.

the old 160° thermostat didnt fit, but i was lucky and found one locally (cost me a 100 miles drive and $100, swiss prices, you know). dont worry if the engine runs warmer in the beginning, mine started at 95°c but settled to 78°c after a couple of days.

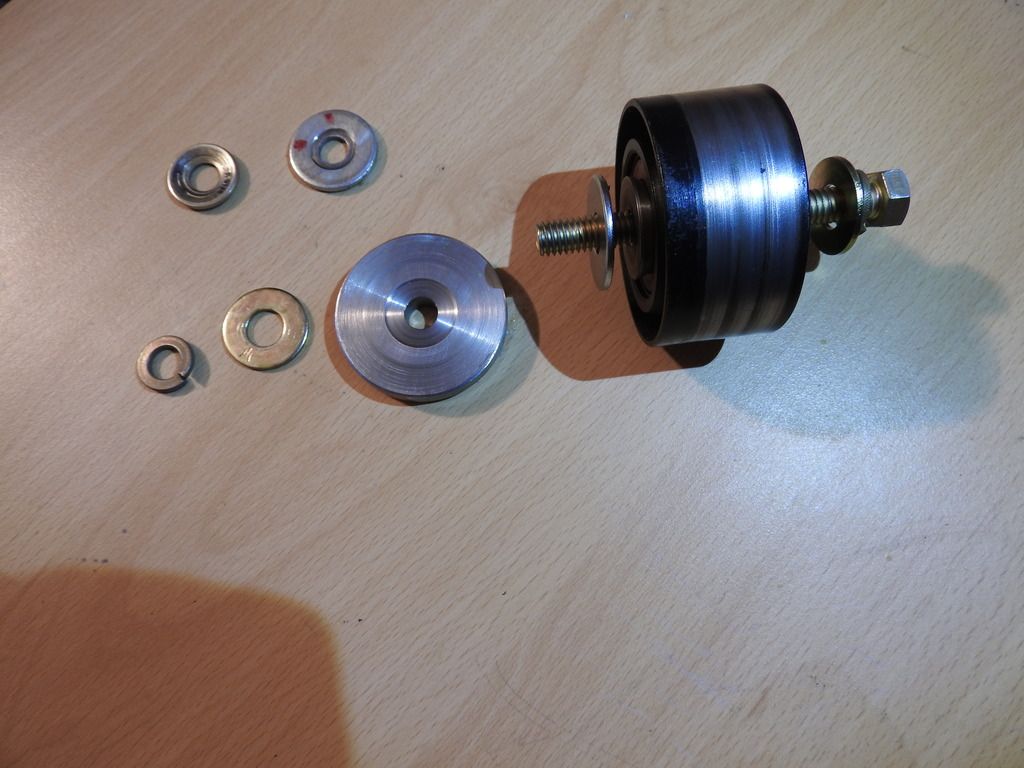

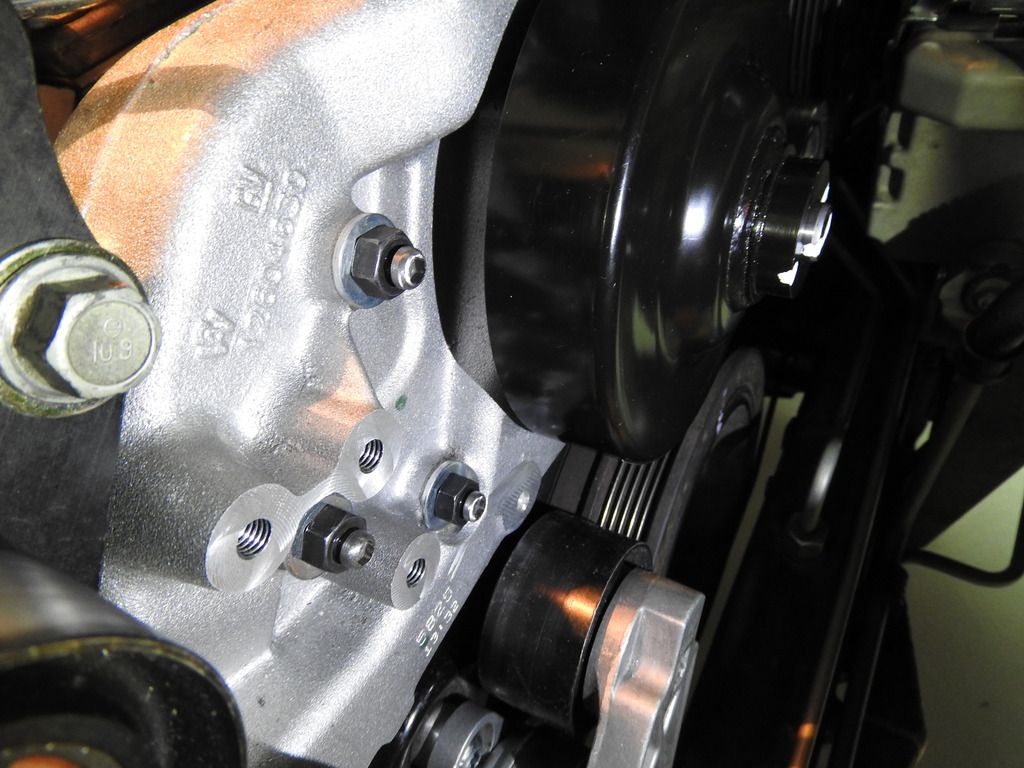

i ordered some imperial hardware from fastenal, paied $70 shipping for half a pound of bolts and nuts and was able to do some improvements to the mounting of the blower:

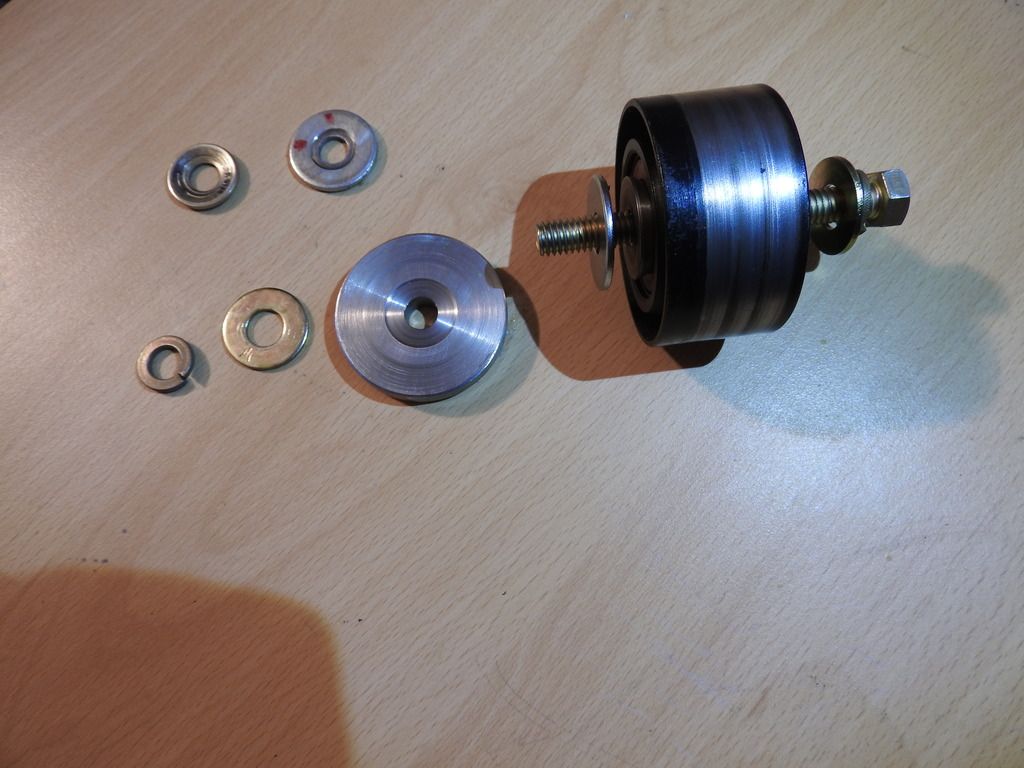

i made a washer from prehard and spaced the manual tensioner pulley furter out. its a bit larger and will bridge the scratches the rotating mounting stud left behind (as mentiond earlier). i also put a hardened washer (2 mm) between bolt and bearing so the head woul stick out more and i could grab it more easily with a wrench. i converted the pivoting bolt to a stud with a bigger washer, made a "real washer" for the bolt riding the slot to distribute the load. you can see the previous munched up washers in the picture. the bolts were too short to do it better before. i also put hardened washers under all four studs.

i had to space out the two big spacers between block and mounting plate by 1.6 mm to match the pump. weirdly enough the blower pulley is closer to the block by 0.7 mm now, but it migh be a measurement problem as its not easy to do, or some slight variation of the angle the mounting plate sits at.

well, the belt runns 1 mm offset from center of the spung tensioner pulley now, 1 mm offset on the manual pulley and doesnt jump off the blower pulley, so what more do i want, its a success.

belt started chirping, though, without me doing anything bad to it, so i have to check that out now.

the other day i unpacked the new pump. surprise, the inlet is on the other side, i didnt realise that.

i checked the dimensions and it seemed o.k except the additional bosses. i cut off the lower one and milled the others down by 3 mm. surprisingly the old pump somehow came out without taking off the spung tensioner, i couldnt believe it and even the throttlebody stayed in place. it had to come out later so i could bent the vapour tube a little as well as the tb heater tube. then the new pump went in:

being paranoid, i converted the water pump bolts to studs. i didnt like the specified 30 nm on the 8x1.25 bolts.

the old 160° thermostat didnt fit, but i was lucky and found one locally (cost me a 100 miles drive and $100, swiss prices, you know). dont worry if the engine runs warmer in the beginning, mine started at 95°c but settled to 78°c after a couple of days.

i ordered some imperial hardware from fastenal, paied $70 shipping for half a pound of bolts and nuts and was able to do some improvements to the mounting of the blower:

i made a washer from prehard and spaced the manual tensioner pulley furter out. its a bit larger and will bridge the scratches the rotating mounting stud left behind (as mentiond earlier). i also put a hardened washer (2 mm) between bolt and bearing so the head woul stick out more and i could grab it more easily with a wrench. i converted the pivoting bolt to a stud with a bigger washer, made a "real washer" for the bolt riding the slot to distribute the load. you can see the previous munched up washers in the picture. the bolts were too short to do it better before. i also put hardened washers under all four studs.

i had to space out the two big spacers between block and mounting plate by 1.6 mm to match the pump. weirdly enough the blower pulley is closer to the block by 0.7 mm now, but it migh be a measurement problem as its not easy to do, or some slight variation of the angle the mounting plate sits at.

well, the belt runns 1 mm offset from center of the spung tensioner pulley now, 1 mm offset on the manual pulley and doesnt jump off the blower pulley, so what more do i want, its a success.

belt started chirping, though, without me doing anything bad to it, so i have to check that out now.

#195

Drifting

Thread Starter

so as we can view old photobucket stuff again (by downloading the "fix photobucket" add ons for firefox or chrome), i thought i would update the thread.

i have been driving and tuning the car for two years now and it still lives, maybe due to the lambda sensor being after the cats and a slight offset on the analog logging port. both make the mixture look leaner than it is.

i was seeing 170 kpa/80% duty with the ecs restrictor and 195 kpa/95% without at 6000 rpm. stock balancer, 3.45 pulley, "60 lbs" injectors. i would pass 100% duty at 6200. the lingenfelter "255" pump produced a drop in fp of over 20 psi.

so i thought better wiring would help. there is the caspers harness for $40+ and racetronix harness for $60+. i got the caspers harness, because its sold by many distributors and i could combine shiping with other stuff. (neither jegs or summit carry racetronix.) well, it was a mistake, i then got the racetronix after all, directly from them, it cost me $160. as you can see, it has a thicker wire and comes with all plugs, while you have to cut up the stock wiring wth the caspers. you just get much more for the money with racetronix.

as you can also see, the racetronix for some weird reason has a thinner wire from the "bab plug" to the pump connector. as the section is 2 or 3 feet i cut it out. i also installed a separate 6mm2 ground to the battery.

inspite of all my efforts the harness produced zero effect. the sensor showed 1.86v before and after (3.5 bar). that is quite surprising, because better wiring has produced an increase of at least 0.5v on other cars. so if the stock wiring is in good shape, it is no restriction for the 12 amps the pump is pulling at 13.5v.

i have been driving and tuning the car for two years now and it still lives, maybe due to the lambda sensor being after the cats and a slight offset on the analog logging port. both make the mixture look leaner than it is.

i was seeing 170 kpa/80% duty with the ecs restrictor and 195 kpa/95% without at 6000 rpm. stock balancer, 3.45 pulley, "60 lbs" injectors. i would pass 100% duty at 6200. the lingenfelter "255" pump produced a drop in fp of over 20 psi.

so i thought better wiring would help. there is the caspers harness for $40+ and racetronix harness for $60+. i got the caspers harness, because its sold by many distributors and i could combine shiping with other stuff. (neither jegs or summit carry racetronix.) well, it was a mistake, i then got the racetronix after all, directly from them, it cost me $160. as you can see, it has a thicker wire and comes with all plugs, while you have to cut up the stock wiring wth the caspers. you just get much more for the money with racetronix.

as you can also see, the racetronix for some weird reason has a thinner wire from the "bab plug" to the pump connector. as the section is 2 or 3 feet i cut it out. i also installed a separate 6mm2 ground to the battery.

inspite of all my efforts the harness produced zero effect. the sensor showed 1.86v before and after (3.5 bar). that is quite surprising, because better wiring has produced an increase of at least 0.5v on other cars. so if the stock wiring is in good shape, it is no restriction for the 12 amps the pump is pulling at 13.5v.

Last edited by romandian; 10-09-2017 at 03:17 AM.

#196

Drifting

Thread Starter

i then came up with the idea to block the fuel being pumped to the siphone pump in the right tank. it should be about 30 l/h or 14% of the main pumps flow. im using the lingenfelter upgrade pump, actually a walbro grj420 and same as racetronixs, that is supposed to flow about 220 l/h at 4 bar and 13.5v. so i installed and electric shut off valve in the feed line (5/16") near the right fuel hat. initial testing showed an decrease in duty of 2-4%. thats much less than expected and after i reduced the duty to 80% with the following mods it showed no effect at all.

so i got myself a 380l/h pump and a regulator, both from aem as well as a 7 micron filter from wix. i removed the stock filter/regulator and blocked off the feed line. i used a 10mm rubber hose for the installation. btw, a 3/8" rubber hose has an id of 3/8, while an 3/8 nylon hose has an od of 3/8. you can stick one into the other. the fuel goes from the pipe on the hat into a t. from the t to the original feed line i blocked off and through the original orifice to the siphone pump and also to the front of the car. there it goes to the filter and through the regulator to the fuel rail. so its still a returnless system. the return from the regulator goes throuh the original feed line back to where the filter/regulator was and into the original return line that was attached to it. so now we have a larger line and a regulator and big filter in front. the only other trick i used was to slipp the hose on the feed pipe on the hat directly, securing it with a hose clamp and two additional clamps wired together. this avoids the quick-connect-to-hose-addapter with a 7 mm id.

in this way i picked up 0.7 bar of fuel pressure and reduced the duty by a solid 6%.

so i got myself a 380l/h pump and a regulator, both from aem as well as a 7 micron filter from wix. i removed the stock filter/regulator and blocked off the feed line. i used a 10mm rubber hose for the installation. btw, a 3/8" rubber hose has an id of 3/8, while an 3/8 nylon hose has an od of 3/8. you can stick one into the other. the fuel goes from the pipe on the hat into a t. from the t to the original feed line i blocked off and through the original orifice to the siphone pump and also to the front of the car. there it goes to the filter and through the regulator to the fuel rail. so its still a returnless system. the return from the regulator goes throuh the original feed line back to where the filter/regulator was and into the original return line that was attached to it. so now we have a larger line and a regulator and big filter in front. the only other trick i used was to slipp the hose on the feed pipe on the hat directly, securing it with a hose clamp and two additional clamps wired together. this avoids the quick-connect-to-hose-addapter with a 7 mm id.

in this way i picked up 0.7 bar of fuel pressure and reduced the duty by a solid 6%.

Last edited by romandian; 10-09-2017 at 03:19 AM.

#197

Drifting

Thread Starter

i did some testing of the pumps. i had the aem "380l/h" (50-1005) pump through a 2mm orifice in a bucket. at 12.1v, from a battery, it pumped 291l/h and produced 3.7 bar. at 12.85v, connected to my running cherokee, it was 307l/h and 4.1 bar. voltage always measured at pump terminals. thats 15% less than expected (pump is rated at 13.5v) and more like the 320 pump. i exchanged some emails with aem and while they agreed this was low, they didnt respond to the question, whether i should exchange the pump. the test was done through the check valve that comes with the pump, btw, it has an id around 4mm.

i then tested my "lingenfelter" in tank in the car. i had it pump through an valve (adjustable orifice) that i set to 4 bar. at 12.3 volts it pumped 237l/h and at 12.7v it was 251l/h (with a charger connected). with the engine running it must be getting a higher voltage, because im logging at least 14.5v during a pull. as this "255" pump is rated at 255l/h at 3 bar (i forget the voltage), its actually performing better than expected.

i then installed the aem in the car. i had the lingenfelter pump from the tank and the aem from a container in the engine compartement through the filter, regulator and everything, except the lingenfelter was pumping through several feet of 10mm hose. they produced the same pressure through the same orifice (adjustable valve), the aem was maybe 0.1 bar higher. quite remarkable.

originally i planed to have both pumps in series. well, that didnt work. you can see the "in series setup" with a check valve in the post above. while the lingenfelter had no problems pumping through the aem (it lost maybe 0.2 bar), when i turned the aem on, nothing much happened, it only mitigated the small pressure loss. i checked this again and again in disbelieve, but the aem in line with the lingenfelter did nothing. when connected in parallel, however, the pumps easily produced up to 6 bars, i didnt go higher because the filter is rated at 3.5 bars (aem pumping from the container again).

so my question is: has anybody had any success with two pumps in line (in series)? how come it doesnt work for me? this experience is clearly contrary to what theory sais.

i then tested my "lingenfelter" in tank in the car. i had it pump through an valve (adjustable orifice) that i set to 4 bar. at 12.3 volts it pumped 237l/h and at 12.7v it was 251l/h (with a charger connected). with the engine running it must be getting a higher voltage, because im logging at least 14.5v during a pull. as this "255" pump is rated at 255l/h at 3 bar (i forget the voltage), its actually performing better than expected.

i then installed the aem in the car. i had the lingenfelter pump from the tank and the aem from a container in the engine compartement through the filter, regulator and everything, except the lingenfelter was pumping through several feet of 10mm hose. they produced the same pressure through the same orifice (adjustable valve), the aem was maybe 0.1 bar higher. quite remarkable.

originally i planed to have both pumps in series. well, that didnt work. you can see the "in series setup" with a check valve in the post above. while the lingenfelter had no problems pumping through the aem (it lost maybe 0.2 bar), when i turned the aem on, nothing much happened, it only mitigated the small pressure loss. i checked this again and again in disbelieve, but the aem in line with the lingenfelter did nothing. when connected in parallel, however, the pumps easily produced up to 6 bars, i didnt go higher because the filter is rated at 3.5 bars (aem pumping from the container again).

so my question is: has anybody had any success with two pumps in line (in series)? how come it doesnt work for me? this experience is clearly contrary to what theory sais.

Last edited by romandian; 09-30-2017 at 01:00 PM.

#198

Drifting

Thread Starter

no feedback on the pumps in series?

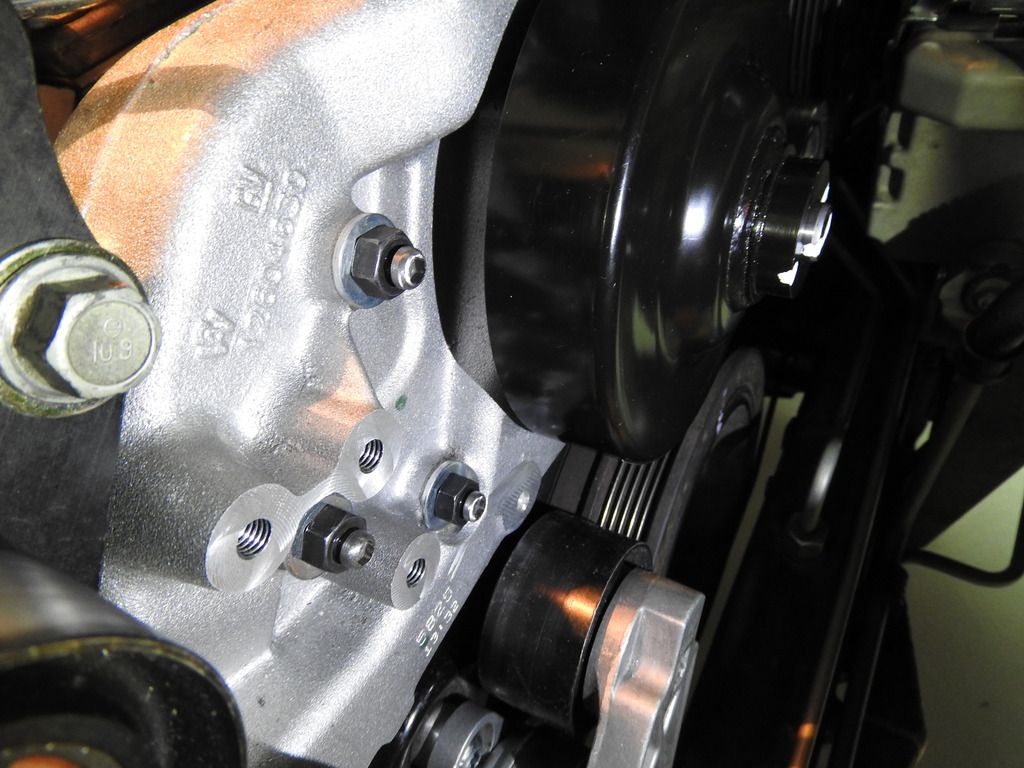

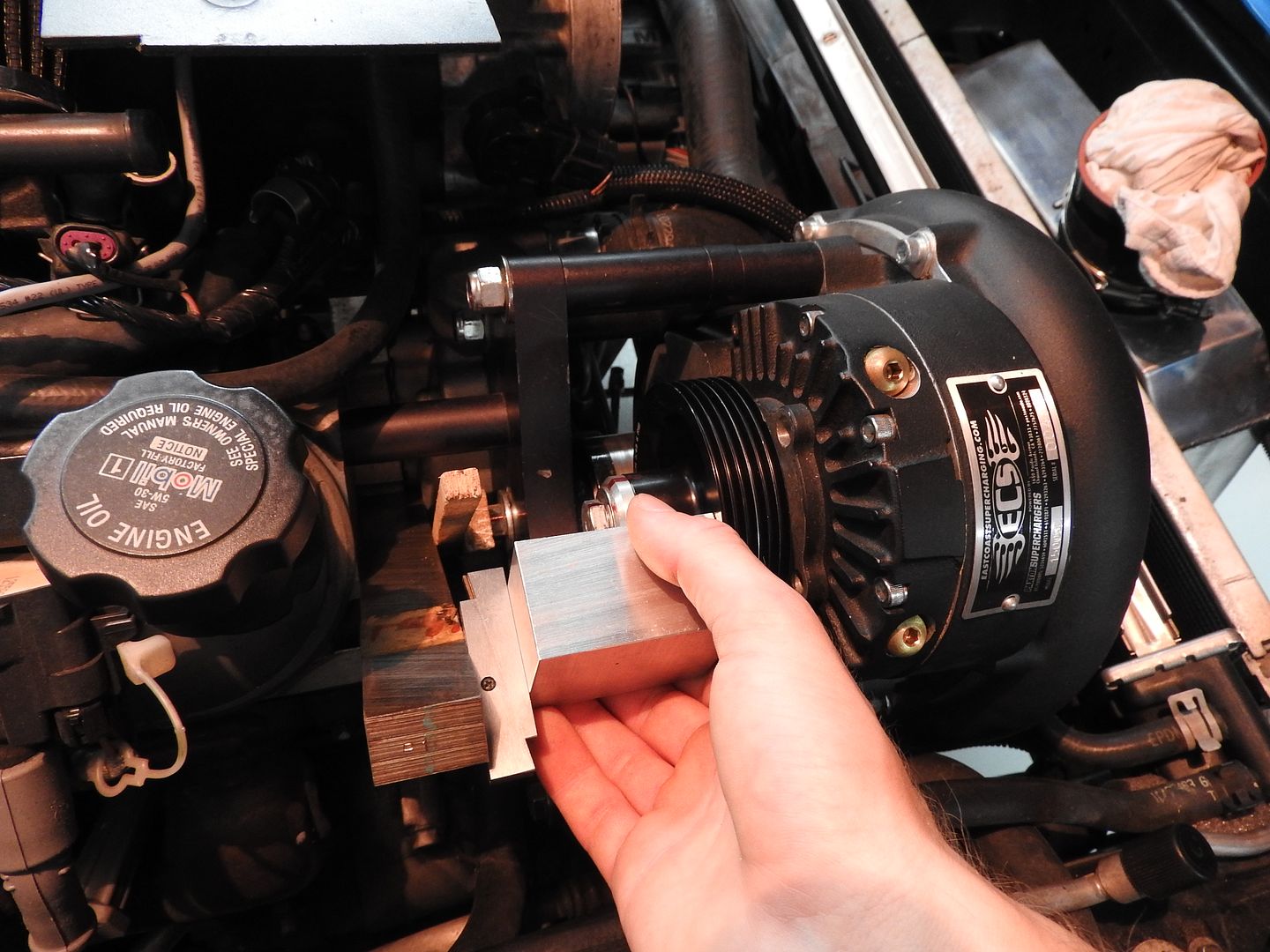

whatever i did to align the belt, it would jump a rib now and then and mostly when i was on the rev limiter. so i preparation for a smalley pulley i figured it couldnt hurt to mount the blower it a more sturdy way. i made two solid brackets that register on the block and replace two of the round spacers. they will not let the subplate move anywhere and take the load from the pump:

whatever i did to align the belt, it would jump a rib now and then and mostly when i was on the rev limiter. so i preparation for a smalley pulley i figured it couldnt hurt to mount the blower it a more sturdy way. i made two solid brackets that register on the block and replace two of the round spacers. they will not let the subplate move anywhere and take the load from the pump:

Last edited by romandian; 10-09-2017 at 03:30 AM.

#200

Drifting

Thread Starter

some random thoughts (i will be updating this post):

1) the ecs kit works. however dont expect it to be like buying a lego kit. it doesnt fall into place itself. thats fine, because its well thought out. like my intake, i was sure it would not go on. well, its been there for two years, happily. if it seems not to work, come back next day and try again. you need stong hands to bent all the aluminum lines.

2) the rubber elbow going on the supercharger inlet seemed to big, taking up too much space around sway bar etc. well its just right facilitating installation without removal of the blower. where its sort of kinked, imagine how round it will be with 1 bar pressure.

3) well, about the belt. i was sure , i didnd neeed more than 10 pounds of boost. i think the 6 ribb belt is just fine with the ecs restrictor. yes, it will be fine. then remooving restritor got me to like 16 psi and probems with the belt.

4) transmission (4l60e). its rated at 488 nm. i thought the 99 ls1 had more stock, like 500 nm. anyways, this is the weak link. if it still lives behind the 800-900 nm my engine should have, its on borrowed time and probably due to:

a) i never flored it in first gear, i even set the shift point to 4000 rpm recently, to keep me out of trouble. so no 1-2 shifts at wot. we dont drag over here btw, this type of racing is not allowed.

b) it never had to downshift under any kind of torque, i manually downshift and then floor it. im talking mainly about 3-2 shifts. it has seen 4-3 wot shifts, but thats at rpms that hardly provide any boost.

c) i have read that 3-4 shifts are a weak point of the trans and it has seen none at full boost, as the speed limit here is 120 kmh.

5) pressure regulator. no idea what the fp was with the regulator that was in there when i got the car. i then changed it for a new one with other stuff like oil etc, during the install of the blower. with that one fp was 4.5 bar at idle. later i changed it for another one and fp was 4.25. im not going to name the regulators, because there is no designation on them and checking my receipts i might make a mistake. anyways, there seems to be a substantial variation between the filter/regulators.

6) belt length. somehow i see people strugling to get the belt on, popular thought being: the shorter the belt the higher the tension, or whatever. well, imo wrong. get the longest belt you can get a "decent" preload on, without the belt on the mechanical tensioner touching itself on top. the further up you get the tensioner, the better the wrap. if theres a gap of maybe 0.25" you will have no trouble getting the belt on, no soapy watter spraying on the wp pulley etc.

7) fuel pressure in returnless system. not really sure what to think about it. on one hand it works on stock cars like it is. on the other hand fp at injector is hardly controlled. stock with regulator in the back, ft at injector will depend on losses from line restriction and from "backpressure" being created by acceleration. 0.5 g being around 0.4 bar on first thought. in my current system with the regulator up front, fp is totally at the mercy of the pump. as soon as fp drops lower than regulated, your depending on the pump operating perfectly, the voltage getting to it and the constellation of the stars. i have been wondering if lambda differences under different ambient temps can be attributed to the voltage regulation of alternator output (the cooler, the higher).

8) oil fill. i put the blower on the bench and changed the oil. one bottle was not enough, so i put in about 1/4 of another one. well, wrong, although i have yet to see any warning to the contrary anywhere. the dipstick is designed to work at the angle the blower is installed. 70° roughly? i wonder how this works in other cars at differen angles. well, anyway, on the first outing blower spit out a considerable amount of oil. there was a layer of rubbery gunk everywhere, as it made the belt slip really good. two hours of cleaning. so i sucked out a bit of oil. blower still spitting. i sucked out some more. got spitting at readline. sucked out more. dipstick in car showing nothing. i wrapped the breather in paper and it was still comming out. sucked out some more, new paper and still some oil came out. so now im not sure how much oil i have in there and its still "breathing" out, albeight dipstick is dry.

any advice or thoughts on this? if your not aware of the oil spraying out, it might be the cause of your belt slip. at what rpm do the 4 oz (is it, i believe?) start spraying out? or is my blower dying?

9) shift "hysteresis". dont forget: if the car is accelerating faster you need more room between shift speed and shift rpm. kind of makes sence. this got me really good, i thought the trans was giving up the ghost.

10) rpm belt. first thing i knew it was shorter. i got one size larger than my continental belt and it was shorter (after break in). next thing i knew my power steering pulley broke. coincidence? you tell me. as this wrecked the belt i got the next size longer and this fortunately is working, providing optimal wrap. this is gates k060888rpm/pk2258 (on 3.15 pulley).

1) the ecs kit works. however dont expect it to be like buying a lego kit. it doesnt fall into place itself. thats fine, because its well thought out. like my intake, i was sure it would not go on. well, its been there for two years, happily. if it seems not to work, come back next day and try again. you need stong hands to bent all the aluminum lines.

2) the rubber elbow going on the supercharger inlet seemed to big, taking up too much space around sway bar etc. well its just right facilitating installation without removal of the blower. where its sort of kinked, imagine how round it will be with 1 bar pressure.

3) well, about the belt. i was sure , i didnd neeed more than 10 pounds of boost. i think the 6 ribb belt is just fine with the ecs restrictor. yes, it will be fine. then remooving restritor got me to like 16 psi and probems with the belt.

4) transmission (4l60e). its rated at 488 nm. i thought the 99 ls1 had more stock, like 500 nm. anyways, this is the weak link. if it still lives behind the 800-900 nm my engine should have, its on borrowed time and probably due to:

a) i never flored it in first gear, i even set the shift point to 4000 rpm recently, to keep me out of trouble. so no 1-2 shifts at wot. we dont drag over here btw, this type of racing is not allowed.

b) it never had to downshift under any kind of torque, i manually downshift and then floor it. im talking mainly about 3-2 shifts. it has seen 4-3 wot shifts, but thats at rpms that hardly provide any boost.

c) i have read that 3-4 shifts are a weak point of the trans and it has seen none at full boost, as the speed limit here is 120 kmh.

5) pressure regulator. no idea what the fp was with the regulator that was in there when i got the car. i then changed it for a new one with other stuff like oil etc, during the install of the blower. with that one fp was 4.5 bar at idle. later i changed it for another one and fp was 4.25. im not going to name the regulators, because there is no designation on them and checking my receipts i might make a mistake. anyways, there seems to be a substantial variation between the filter/regulators.

6) belt length. somehow i see people strugling to get the belt on, popular thought being: the shorter the belt the higher the tension, or whatever. well, imo wrong. get the longest belt you can get a "decent" preload on, without the belt on the mechanical tensioner touching itself on top. the further up you get the tensioner, the better the wrap. if theres a gap of maybe 0.25" you will have no trouble getting the belt on, no soapy watter spraying on the wp pulley etc.

7) fuel pressure in returnless system. not really sure what to think about it. on one hand it works on stock cars like it is. on the other hand fp at injector is hardly controlled. stock with regulator in the back, ft at injector will depend on losses from line restriction and from "backpressure" being created by acceleration. 0.5 g being around 0.4 bar on first thought. in my current system with the regulator up front, fp is totally at the mercy of the pump. as soon as fp drops lower than regulated, your depending on the pump operating perfectly, the voltage getting to it and the constellation of the stars. i have been wondering if lambda differences under different ambient temps can be attributed to the voltage regulation of alternator output (the cooler, the higher).

8) oil fill. i put the blower on the bench and changed the oil. one bottle was not enough, so i put in about 1/4 of another one. well, wrong, although i have yet to see any warning to the contrary anywhere. the dipstick is designed to work at the angle the blower is installed. 70° roughly? i wonder how this works in other cars at differen angles. well, anyway, on the first outing blower spit out a considerable amount of oil. there was a layer of rubbery gunk everywhere, as it made the belt slip really good. two hours of cleaning. so i sucked out a bit of oil. blower still spitting. i sucked out some more. got spitting at readline. sucked out more. dipstick in car showing nothing. i wrapped the breather in paper and it was still comming out. sucked out some more, new paper and still some oil came out. so now im not sure how much oil i have in there and its still "breathing" out, albeight dipstick is dry.

any advice or thoughts on this? if your not aware of the oil spraying out, it might be the cause of your belt slip. at what rpm do the 4 oz (is it, i believe?) start spraying out? or is my blower dying?

9) shift "hysteresis". dont forget: if the car is accelerating faster you need more room between shift speed and shift rpm. kind of makes sence. this got me really good, i thought the trans was giving up the ghost.

10) rpm belt. first thing i knew it was shorter. i got one size larger than my continental belt and it was shorter (after break in). next thing i knew my power steering pulley broke. coincidence? you tell me. as this wrecked the belt i got the next size longer and this fortunately is working, providing optimal wrap. this is gates k060888rpm/pk2258 (on 3.15 pulley).

Last edited by romandian; 10-18-2017 at 01:11 AM.