Drilled Rotors vs. Slotted Rotors.... Engineer test..

#22

Team Owner

Member Since: Mar 2001

Location: small town in S.E Pa. PA

Posts: 21,325

Received 3,812 Likes

on

1,925 Posts

St. Jude Donor '03-'04

Here is alittle insider information for you..we used the BMW design for the C5 prototype early on...Ive posted this 6 or 7 years ago... We feel the BMW compounds were the softest pad with the highest percentage of friction, but they dust like crazy and they dont last too long...this is why they( BMW ) were giving free brakes for 50,000 miles. This was in the 95 and 96 models , I do not know how long that program was in force. we were very impressed with their set up..and did lots of testing in 1996 , for the C5 platform. BMW's brakes do stop, they dont fade, and you cant heat shock them...the conclusion was a similar design with a slightly harder compound where dust was not a real consideation, but stopping ability and longevity.. In my opinion, for a 3200 lb car the original OEM brakes are the best for a street C5.. You will not find too many BMW's with clean wheels...you could not feel any difference because you have a brake booster.. same thing with the guys who have ceramics.. they cant feel the difference but take a tape measure out and see how much farther a "Cold" panic stop will take you..lets just say your doing 70, and tractor trailor locks up his brakes, he is stopped about 140 feet, 150 feet, you do a panic stop with OEM brakes and everything is cool.. do the same thing with ceramics and hit the CB and tell him to open the back door because you're coming in...

Last edited by Evil-Twin; 03-20-2010 at 08:21 PM.

#24

Burning Brakes

Thread Starter

Member Since: Apr 2009

Location: Concord California

Posts: 1,163

Likes: 0

Received 4 Likes

on

4 Posts

Wow, so much feed back, I love it. Sorry about not posting the name of the engineer, but I was web searching and just did a cut and paste. All I can say on top of all of the positive and negative comments on this topic is this. If racing, go with slotted rotors, or used the drilled rotors that have smooth edges not cut with sharp angles where heat builds up. One comment, surface contact is lesson with too many holes so a balance is needed, for every hole you don't have pad contact da!. Now for me, I plan on using them for street use, not race track driving, so drilled will most likely work fine for me, I have used them in the past, (280Z & 280ZX application with no cracks for years). I like the looks, C6 Z06 still come with drilled rotors, as well as the ZR1, so if they were bad designs why are they still using them. 95% of vette owners want their vette to look good and don't race on the streets, the other 5% you hear in the crash vette forums. Slotted rotors wear your pads down for street use, not important for race cars because they re-build the brakes for every race so it is never an issue. I hope that answers the reason I posted this topic, I love the feedback and understand the views posted. Please keep it up... Shows we have professional members with experience and logic, keep them coming... Enjoy the ride...

#25

Team Owner

Member Since: Sep 2003

Location: Raleigh / Rolesville NC

Posts: 43,084

Likes: 0

Received 23 Likes

on

23 Posts

Drilled rotors will wear pads down just as fast as slotted rotors.

and the idea of race cars rebuilding brakes for ever race, is budget orientated. 98% of racers do not have this budget. racing you see on TV is only 2% of any racing if that.

a few other things about brakes that many ppl do not mention is the brakes are only as good as your front tires. "The rubber meets the road." The wider the front tire; the less tread; the quicker the car stops. The more aggressive the brake pads the quicker the car stops.

Down side of aggressive brake pads is DUST and noise.

Brake fluid should be flushed at least ONCE a year, no matter how much or how little you drive. Brake fluid absorbs water and reduces is effectiveness.

and the idea of race cars rebuilding brakes for ever race, is budget orientated. 98% of racers do not have this budget. racing you see on TV is only 2% of any racing if that.

a few other things about brakes that many ppl do not mention is the brakes are only as good as your front tires. "The rubber meets the road." The wider the front tire; the less tread; the quicker the car stops. The more aggressive the brake pads the quicker the car stops.

Down side of aggressive brake pads is DUST and noise.

Brake fluid should be flushed at least ONCE a year, no matter how much or how little you drive. Brake fluid absorbs water and reduces is effectiveness.

Last edited by AU N EGL; 03-21-2010 at 07:35 AM.

#26

Burning Brakes

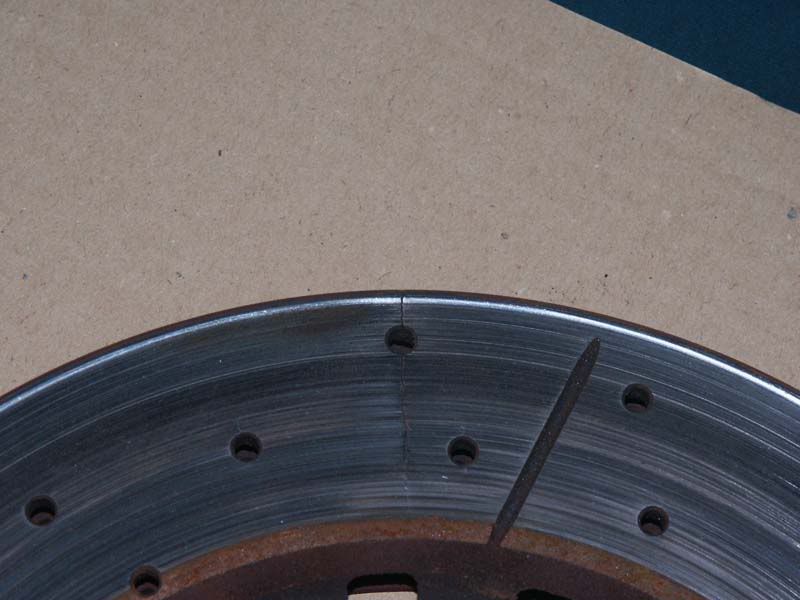

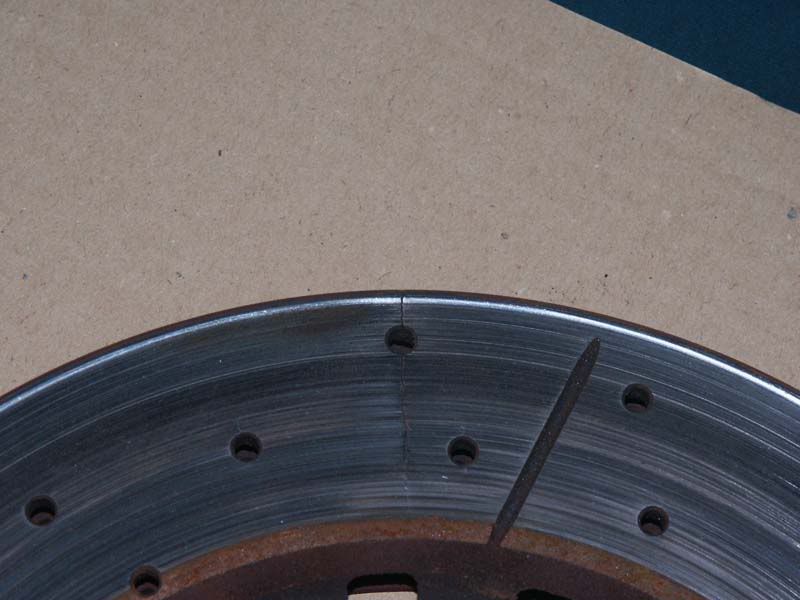

How is the coefficient of friction of a HOLE greater then solid sides ?

BUT what they did not say or show is REAL APPLICATIONS.

here are a few pics from minimal use on tracks

and less the one hour use. TWO twenty min session

and ONE twenty min session

Yup those drilled, milled or cast in holes work great.

Drill and slotted rotors are 40 year old technology to release or out gas asbestos brake pad gasses. Guess what? asbestos has not been used for brake pads in 40 years, so no need for holes.

Why do manufactures keep putting holes in rotors? because the customer wants them. PERIOD. No functional use.

That research was flawed.

BUT what they did not say or show is REAL APPLICATIONS.

here are a few pics from minimal use on tracks

and less the one hour use. TWO twenty min session

and ONE twenty min session

Yup those drilled, milled or cast in holes work great.

Drill and slotted rotors are 40 year old technology to release or out gas asbestos brake pad gasses. Guess what? asbestos has not been used for brake pads in 40 years, so no need for holes.

Why do manufactures keep putting holes in rotors? because the customer wants them. PERIOD. No functional use.

That research was flawed.

#27

Burning Brakes

Thread Starter

Member Since: Apr 2009

Location: Concord California

Posts: 1,163

Likes: 0

Received 4 Likes

on

4 Posts

Look, lets not kill the messenger here, I can take pictures of Drilled rotors on active street and track vehicles that are not cracked to off set some views here. The bottom line, drilled rotors cool down better than solid thus improving braking since HEAT is the killer for braking problems. Racing a car is not considered normal driving and thus puts a stress on car parts. I think we can agree that if drive where our front rotors are glowing like on Laguna Raceway here on the streets, we have other problems here don't we. Drilled rotors on the most part on the streets will work very well improving braking no matter what anybody says. If the holes didn't, they won't have done the ZR1 brakes with HOLES! Lets give the Engineers some credit here with even hearing what they have to say, just look at want they put on the vehicles and enough said!!.... OK, I have taken my meds.. I'm much better now... Enjoy the ride and install drilled rotors if you want to!

#28

Team Owner

Member Since: Sep 2003

Location: Raleigh / Rolesville NC

Posts: 43,084

Likes: 0

Received 23 Likes

on

23 Posts

Look, lets not kill the messenger here, I can take pictures of Drilled rotors on active street and track vehicles that are not cracked to off set some views here. The bottom line, drilled rotors cool down better than solid thus improving braking since HEAT is the killer for braking problems.

Racing a car is not considered normal driving and thus puts a stress on car parts. I think we can agree that if drive where our front rotors are glowing like on Laguna Raceway here on the streets, we have other problems here don't we. Drilled rotors on the most part on the streets will work very well improving braking no matter what anybody says.

If the holes didn't, they won't have done the ZR1 brakes with HOLES! Lets give the Engineers some credit here with even hearing what they have to say, just look at want they put on the vehicles and enough said!!....

the original study was not a double blind study by independent researchers. When you go on Brake manufactures webs sites, and read white papers or technical information they will say for street use only.

OK, I have taken my meds.. I'm much better now... Enjoy the ride and install drilled rotors if you want to!

Last edited by AU N EGL; 03-21-2010 at 12:48 PM.

#29

Melting Slicks

Member Since: Sep 2003

Location: Northville Michigan

Posts: 2,458

Likes: 0

Received 102 Likes

on

56 Posts

Just to verify where the Supercars of the world are going with their brake technology:

Porsche Drilled Carbon Ceramic Brakes

Lamborghini Drilled Carbon Ceramic Brakes

Ferrari Drilled Carbon Ceramic Brakes

Porsche Drilled Carbon Ceramic Brakes

Lamborghini Drilled Carbon Ceramic Brakes

Ferrari Drilled Carbon Ceramic Brakes

#30

Team Owner

Member Since: Sep 2003

Location: Raleigh / Rolesville NC

Posts: 43,084

Likes: 0

Received 23 Likes

on

23 Posts

those carbon rotors are for wt savings, not really better braking. and at $20 Large or some ridiculous amount of money.

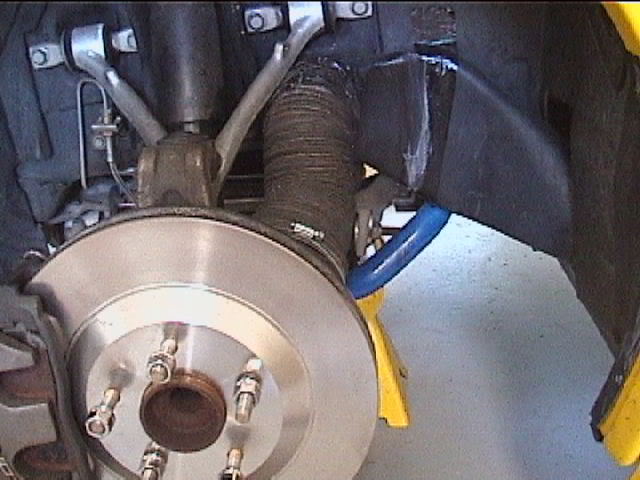

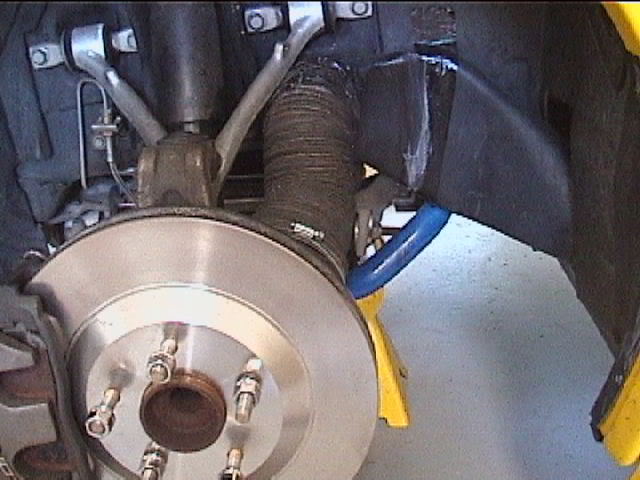

Then when you look at race cars;

an old C5R pic with Carbon rotors

C6R with Carbon Rotors

Now the the C6R uses steel rotors per racing rules

and my track only vette. Plain side Napa rotors, stock calipers ( which I toss out each winter) and great brake pads. PFC-01s or Wilwood H

Then when you look at race cars;

an old C5R pic with Carbon rotors

C6R with Carbon Rotors

Now the the C6R uses steel rotors per racing rules

and my track only vette. Plain side Napa rotors, stock calipers ( which I toss out each winter) and great brake pads. PFC-01s or Wilwood H

Last edited by AU N EGL; 03-22-2010 at 07:14 AM.

#31

Burning Brakes

You guys are right - Drag Racing - Stop once an hour!!! Think about that, in my case take basically cold brakes, run the car up to 152 MPH, in 1350 feet (9 sec.) then stop in a reasonable amount of distance - sure I have a parachute, but have not yet pulled it (saving that until I go 160, which may be this year) ceramic brakes don't work very well for this application because of the "cold" brake situation once in a while - I use Hawks, as they work just fine!! (also Baer Eradaspeeds)

JR

JR

#33

Former Vendor

I have $500 on the table for anyone who can prove this internet myth. Porsche's own literature states "cross drilled rotors" and with over 6yrs of research by various folks who have wanted to prove me wrong we've never once found any evidence of its existence. Great discussions have been had on "if" it could be done and while perhaps could be the costs would be outrageous. Nobody in the brake industry that I know gives this story any credit and just rolls their eyes when they hear it.

As to the chamfered holes; while chamfering the holes helps, how do you do that to the two inner surfaces?

#34

Are people still repeating this story today??

I have $500 on the table for anyone who can prove this internet myth. Porsche's own literature states "cross drilled rotors" and with over 6yrs of research by various folks who have wanted to prove me wrong we've never once found any evidence of its existence. Great discussions have been had on "if" it could be done and while perhaps could be the costs would be outrageous. Nobody in the brake industry that I know gives this story any credit and just rolls their eyes when they hear it.

As to the chamfered holes; while chamfering the holes helps, how do you do that to the two inner surfaces?

I have $500 on the table for anyone who can prove this internet myth. Porsche's own literature states "cross drilled rotors" and with over 6yrs of research by various folks who have wanted to prove me wrong we've never once found any evidence of its existence. Great discussions have been had on "if" it could be done and while perhaps could be the costs would be outrageous. Nobody in the brake industry that I know gives this story any credit and just rolls their eyes when they hear it.

As to the chamfered holes; while chamfering the holes helps, how do you do that to the two inner surfaces?

For those wondering, the SAE paper is: 1999-01-0142. It is completely valid (at least for the rotors and conditions used in that test) and done by GM researchers in a fairly controlled environment. Many things can be taken from it as well as from other research and track tests. The bottom line is that there is no "one answer" to all applications. Again, all test results must be evaluated for what was tested and how it was tested. If you intend to operate in very different conditions, it would be foolish to expect the same results to apply.

Generally speaking, race cars get the most performance out of J-hook or crescent shape face machining. Teams are not concerned much about pad wear or rotor life (outside of some endurance events or a few NASCAR tracks). Teams running drivers that are very sensitive to braking used to run cross-drilled rotors for qualifying, but that has pretty much gone away with the increased use of J-hooks.

For the street, cross-drilling is a cost-effective way of achieving more cold bite, better wet performance and some additional cooling at the upper temperatures. They will last just about as long as plain-faced rotors -- as long as the rotor is made from a good material (most aren't), is thermally post-processed (most aren't), has holes that are radius chamfered and/or peened (most don't), the pattern is balanced for full pad sweep (unlike some of the pictures posted in this thread) and doesn't see sustained temperatures of over 1200°F. This means that even the good ones can't be expected to last very long if used for intense track duty. Of course, that would not be street use, would it?

Any iron rotor will start cracking (first crazing, then developing actual cracks) when pushed hard enough. Drilling them will usually shorten the time is takes for crazing to develop into cracks. If you use cheap, crappy rotors, especially those that have been drilled, you will get what you paid for.

Chris

#35

Melting Slicks

Member Since: Dec 2003

Location: Near Jacksonville Fl.

Posts: 3,314

Likes: 0

Received 12 Likes

on

11 Posts

I'm with Todd TCE on this one, having worked with casting and forgings for many years.

It would be a nightmare if at all possible to cast the holes along with the fins.

BTW, in case anyone didn't notice when they put D/S rotors on the C6 they also increased the rotor dia. one inch on a lighter weight car.

Does that make you wonder.

It would be a nightmare if at all possible to cast the holes along with the fins.

BTW, in case anyone didn't notice when they put D/S rotors on the C6 they also increased the rotor dia. one inch on a lighter weight car.

Does that make you wonder.

#36

Drifting

With the Army going to the newer T-11 parachute i bet we can pick up the older T-10s for cheap. No need for rotors anymore haha. I'm just being funny here.

Tom

Tom

#37

Team Owner

Member Since: Sep 2003

Location: Raleigh / Rolesville NC

Posts: 43,084

Likes: 0

Received 23 Likes

on

23 Posts

I'm with Todd TCE on this one, having worked with casting and forgings for many years.

It would be a nightmare if at all possible to cast the holes along with the fins.

BTW, in case anyone didn't notice when they put D/S rotors on the C6 they also increased the rotor dia. one inch on a lighter weight car.

Does that make you wonder.

It would be a nightmare if at all possible to cast the holes along with the fins.

BTW, in case anyone didn't notice when they put D/S rotors on the C6 they also increased the rotor dia. one inch on a lighter weight car.

Does that make you wonder.

#38

Burning Brakes

Member Since: May 2008

Location: Mohegan Lake New York

Posts: 1,147

Likes: 0

Received 1 Like

on

1 Post

GREAT thread everybody intellegent input from well informed people,one thing i havn.t seen mentioned how much of a part of this whole equasion does metal fatigue play slotted ,drilled or solid.... drilled they may recover quicker but get 'em hot enough they're gonna crack ...solid get 'em hot they're gonna warp..... if you suffer from repeated component failure MAYBE your current brakes are too small/in adequate or you need to alter your driving style...AU N GEL I LIKE YOUR APPROACH THE BEST A KNOWN QUALITY ROTOR FREQUENTLY CHANGED...THESE ARE WEAR ITEMS put them through some serious heat cycles slotted drilled or solidv the high heat comprisezs the integrity or the part

#39

Team Owner

Member Since: Sep 2003

Location: Raleigh / Rolesville NC

Posts: 43,084

Likes: 0

Received 23 Likes

on

23 Posts

My calipers are changed each winter. My front rotors every 3-4 events it that. rear rotors every 5-7 events. Brake pads about the same.

Why have I not purchased a set of BBKs? Then I need to buy three sets of wheels to fit over the BBKs.

Also after driving many many BBK set ups, there are only few I would drop 4-5 or 6 Large or more on. Any less and not worth the

costs.

Yes Brake rotors and brake pads are DISPOSABLE ITEMS. No matter who makes them or size.

There was a thread about a year ago about metal fatigue on drilled rotors, Drilled and Slotted rotors vs plain sided rotors. Cracks start from fatigued metal, at any edge, the edge of the rotor and the edge of a hole.

Three years ago or so we had a thread on titanium rotors and how they did not transfer heat. Well no heat transfer, no stopping.

However, that said, for normal street to occasional weekend spirited driving, just about any rotor will do

Why have I not purchased a set of BBKs? Then I need to buy three sets of wheels to fit over the BBKs.

Also after driving many many BBK set ups, there are only few I would drop 4-5 or 6 Large or more on. Any less and not worth the

costs.

Yes Brake rotors and brake pads are DISPOSABLE ITEMS. No matter who makes them or size.

There was a thread about a year ago about metal fatigue on drilled rotors, Drilled and Slotted rotors vs plain sided rotors. Cracks start from fatigued metal, at any edge, the edge of the rotor and the edge of a hole.

Three years ago or so we had a thread on titanium rotors and how they did not transfer heat. Well no heat transfer, no stopping.

However, that said, for normal street to occasional weekend spirited driving, just about any rotor will do

Last edited by AU N EGL; 03-22-2010 at 03:35 PM.

#40

GREAT thread everybody intellegent input from well informed people,one thing i havn.t seen mentioned how much of a part of this whole equasion does metal fatigue play slotted ,drilled or solid.... drilled they may recover quicker but get 'em hot enough they're gonna crack ...solid get 'em hot they're gonna warp..... if you suffer from repeated component failure MAYBE your current brakes are too small/in adequate or you need to alter your driving style...AU N GEL I LIKE YOUR APPROACH THE BEST A KNOWN QUALITY ROTOR FREQUENTLY CHANGED...THESE ARE WEAR ITEMS put them through some serious heat cycles slotted drilled or solidv the high heat comprisezs the integrity or the part

Iron does a great job of handling the friction, strength and heat requirements -- to a point. Beyond that point they start to break down. The primary downsides to iron rotors are that they are heavy, will crack under extreme temperature usage and difficult to protect from corrosion.

Chris