How-To repair EBCM avoiding costly repairs through ABSfixer or Fleabay

#61

Drifting

Thread Starter

#62

#63

Team Owner

This is awesome for you later model guys!

Wish it were that easy with the 1997 - 2000

Thanks,Matt

Wish it were that easy with the 1997 - 2000

Thanks,Matt

#65

Just completed this a few minutes ago on my '02. I just re-flowed the solder (with some new) on the existing relay. After clearing all the historical codes, no new ones are returning.

I didn't have a clear understanding of that hole in the cover until I got mine apart. It is a 1/8" passage through the shell to the front plate - you cannot hit a circuit board even if you wanted to. I used a Craftsman 1/8" punch, set the closest beveled mounting ear on a bench vise, and kept hammering until the sound changed indicating that the bead had broken. Then screwdrivers all around to finish separating the silicone.

An alternative to the punch would be a self-tapping screw that has a minor diameter of around 1/8" to get a good bite. Sorry I don't have an exact dimension, but hopefully this helps.

I second the comments by blackdak318 to get a hot iron. I had a little pointy 15W that worked on the smaller terminals, but didn't have enough oomph to melt the large center lug. The old 120W gun made short work of it.

I also pass my thanks on to all the contributors here. This forum is invaluable.

Todd

Picture of my 1/8 punch in the hole.

I didn't have a clear understanding of that hole in the cover until I got mine apart. It is a 1/8" passage through the shell to the front plate - you cannot hit a circuit board even if you wanted to. I used a Craftsman 1/8" punch, set the closest beveled mounting ear on a bench vise, and kept hammering until the sound changed indicating that the bead had broken. Then screwdrivers all around to finish separating the silicone.

An alternative to the punch would be a self-tapping screw that has a minor diameter of around 1/8" to get a good bite. Sorry I don't have an exact dimension, but hopefully this helps.

I second the comments by blackdak318 to get a hot iron. I had a little pointy 15W that worked on the smaller terminals, but didn't have enough oomph to melt the large center lug. The old 120W gun made short work of it.

I also pass my thanks on to all the contributors here. This forum is invaluable.

Todd

Picture of my 1/8 punch in the hole.

#66

I pulled mine out of my 03 ZO6 and sent it to someone I found on Ebay. They fixed it for $50 and I didn't have to pull it apart. It's been working perfectly for the last two years.

#68

Instructor

Member Since: Mar 2010

Location: Sacramento CA

Posts: 129

Likes: 0

Received 0 Likes

on

0 Posts

Just completed this a few minutes ago on my '02. I just re-flowed the solder (with some new) on the existing relay. After clearing all the historical codes, no new ones are returning.

I didn't have a clear understanding of that hole in the cover until I got mine apart. It is a 1/8" passage through the shell to the front plate - you cannot hit a circuit board even if you wanted to. I used a Craftsman 1/8" punch, set the closest beveled mounting ear on a bench vise, and kept hammering until the sound changed indicating that the bead had broken. Then screwdrivers all around to finish separating the silicone.

An alternative to the punch would be a self-tapping screw that has a minor diameter of around 1/8" to get a good bite. Sorry I don't have an exact dimension, but hopefully this helps.

I second the comments by blackdak318 to get a hot iron. I had a little pointy 15W that worked on the smaller terminals, but didn't have enough oomph to melt the large center lug. The old 120W gun made short work of it.

I also pass my thanks on to all the contributors here. This forum is invaluable.

Todd

Picture of my 1/8 punch in the hole.

I didn't have a clear understanding of that hole in the cover until I got mine apart. It is a 1/8" passage through the shell to the front plate - you cannot hit a circuit board even if you wanted to. I used a Craftsman 1/8" punch, set the closest beveled mounting ear on a bench vise, and kept hammering until the sound changed indicating that the bead had broken. Then screwdrivers all around to finish separating the silicone.

An alternative to the punch would be a self-tapping screw that has a minor diameter of around 1/8" to get a good bite. Sorry I don't have an exact dimension, but hopefully this helps.

I second the comments by blackdak318 to get a hot iron. I had a little pointy 15W that worked on the smaller terminals, but didn't have enough oomph to melt the large center lug. The old 120W gun made short work of it.

I also pass my thanks on to all the contributors here. This forum is invaluable.

Todd

Picture of my 1/8 punch in the hole.

#69

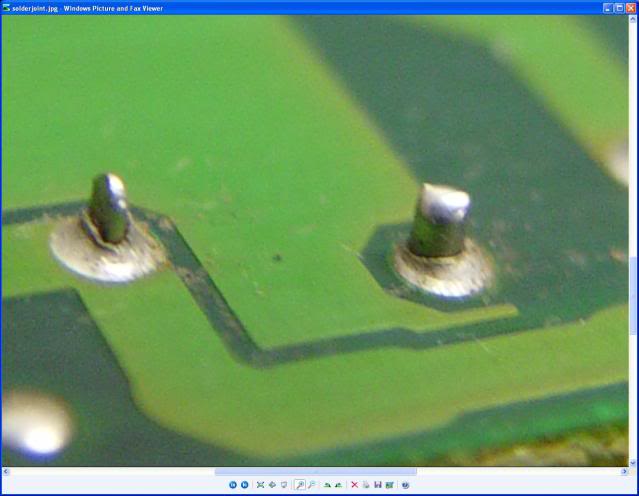

Here's a pic I took before my repair, and have zoomed in on two of the terminals in question. You can see it in the OP's 3rd pic too, on the relay center terminal. It appears as if a rift/ridge barrier has formed between the post & the circuit board it should be connected to. Re-melting the solder and adding some new took care of my C1242. As Lucky said above, "a classic case of insufficient solder/cold solder joints". Not sure exactly which it is (because all of my solder joints have never looked like this

), but clearly the solder is not doing it's job of connecting part A to part B. My worst looking terminals were on the load-side of the relay. Perhaps high current, vibration, and repetition along with lack of solder are a formula for this type of failure. Clearly the joints did work for 7+ years before failing, and mine was intermittent for several months before going consistent.

), but clearly the solder is not doing it's job of connecting part A to part B. My worst looking terminals were on the load-side of the relay. Perhaps high current, vibration, and repetition along with lack of solder are a formula for this type of failure. Clearly the joints did work for 7+ years before failing, and mine was intermittent for several months before going consistent.Todd

Last edited by toddk; 08-30-2011 at 08:47 AM.

#70

Tech Contributor

Here's a pic I took before my repair, and have zoomed in on two of the terminals in question. You can see it in the OP's 3rd pic too, on the relay center terminal. It appears as if a rift/ridge barrier has formed between the post & the circuit board it should be connected to. Re-melting the solder and adding some new took care of my C1242. As Lucky said above, "a classic case of insufficient solder/cold solder joints". Not sure exactly which it is (because all of my solder joints have never looked like this

), but clearly the solder is not doing it's job of connecting part A to part B. My worst looking terminals were on the load-side of the relay. Perhaps high current, vibration, and repetition along with lack of solder are a formula for this type of failure.

), but clearly the solder is not doing it's job of connecting part A to part B. My worst looking terminals were on the load-side of the relay. Perhaps high current, vibration, and repetition along with lack of solder are a formula for this type of failure. Todd

#73

Instructor

Member Since: Mar 2010

Location: Sacramento CA

Posts: 129

Likes: 0

Received 0 Likes

on

0 Posts

#74

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

TTT

#75

Drifting

Thread Starter

Thanks to all who've attempted this, if it weren't for you guys I wouldn't be as sure of this fix as I am now. Of course there isn't any issue with mine, but it certainly helps to see so many follow this write and clear codes permanently.

#78

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

Short answer,,,, no

#79

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

Long answer,, Its a completely different EBTCM. Do you have a front or rear mounted EBTCM??

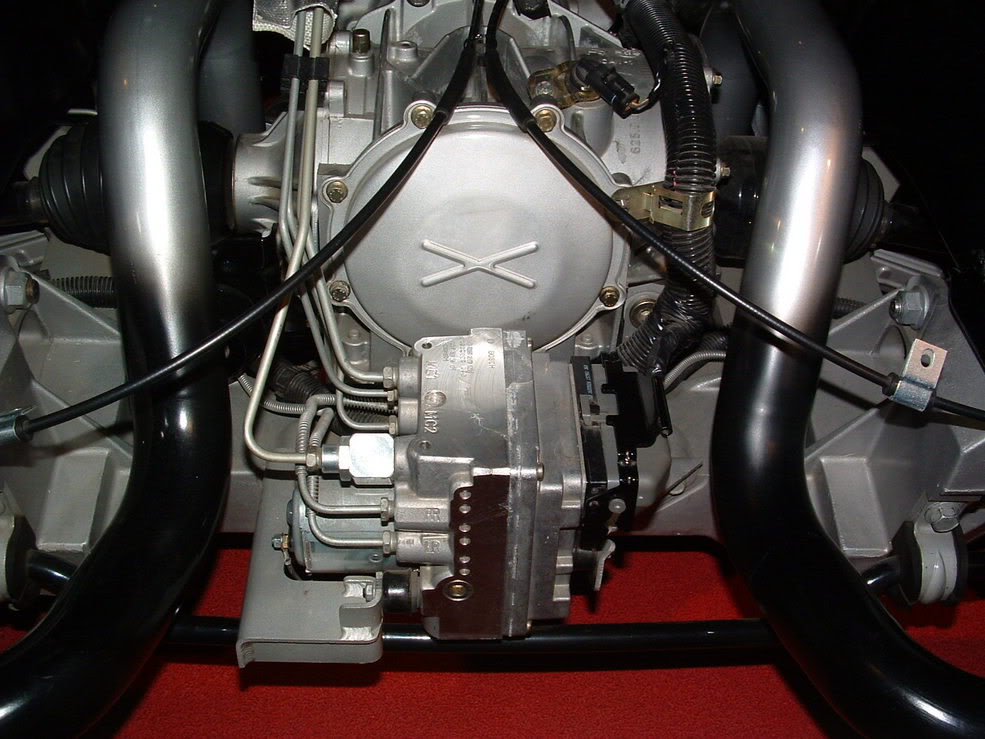

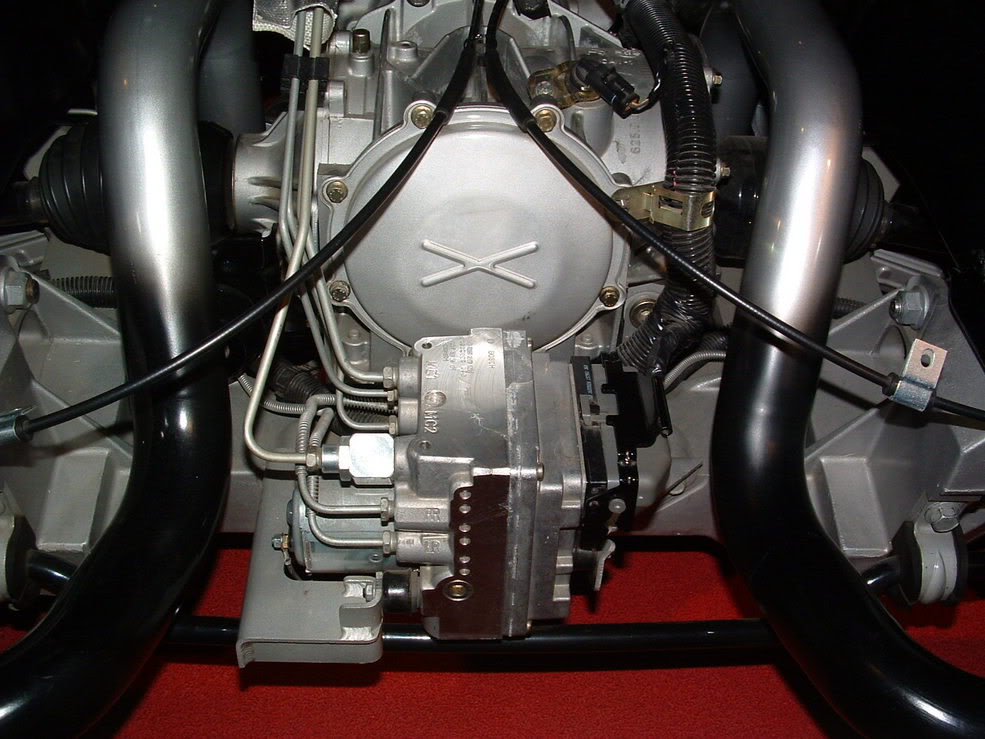

Rear Mount =

BC

Rear Mount =

BC

only cost $50.. If I had seen this I would have done it myself.

only cost $50.. If I had seen this I would have done it myself.