C5 Torque tube tear down and re-build with pics

#42

Drifting

Thread Starter

Up date, I never installed the couplers in the original orientation because I was not aware of it. Anyways everything is fine, the cars old vibrations are gone and the car feels super smooth now compared to when the couplers were old. Since I re-built the torque tube with stock GM 10mm couplers the cars been in the high tens quarter mile and made over with no problems.

Roger

Roger

#43

Team Owner

Member Since: Apr 2001

Location: Overwhelmed as one would be, placed in my position.... DFW, TX

Posts: 36,451

Likes: 0

Received 2 Likes

on

2 Posts

St. Jude Donor '05

The snap ring replaced the part where there are 11 bolts holding it together in 2000. These pics are quite timely because I'm disassembling my tube today. I don't have a snap ring plier big enough for the ring in the torque tube so I've got to borrow one today. I'm afraid to see what I'll find even though I've had no problems. I'm replacing my clutch so I'm doing it all at once. All because my slave cylinder leaked.

The following users liked this post:

old stingray (09-07-2016)

#47

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

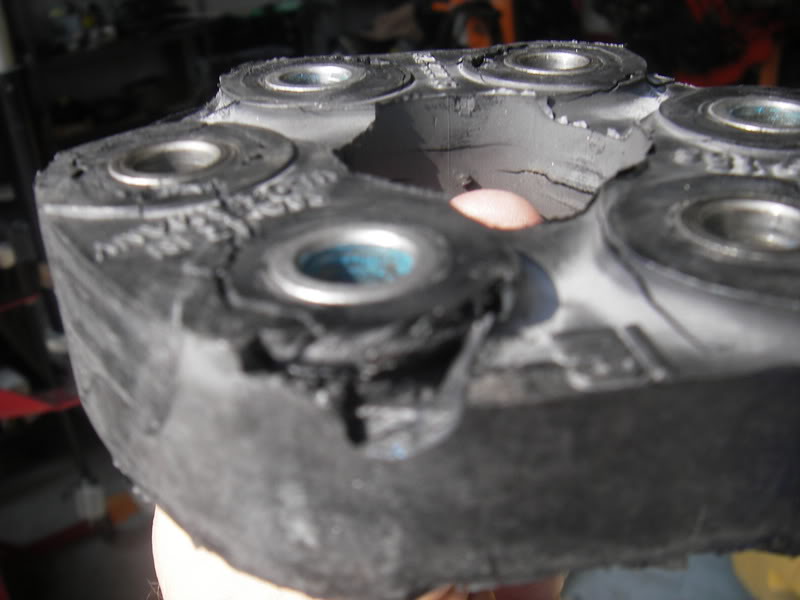

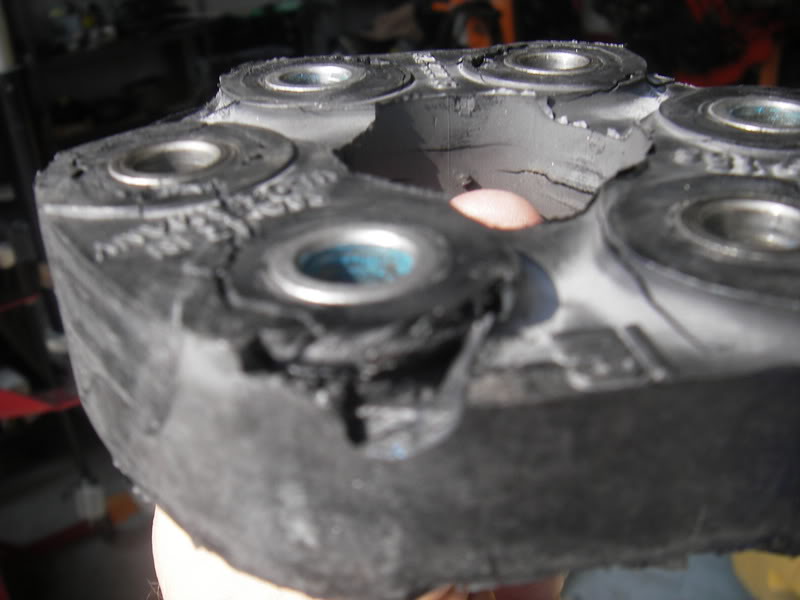

We disassembled the Torque Tube on my buddy’s 2000 A4 Coupe Saturday. He has a knocking noise in the drive train when it’s in gear. He was convinced that it was a cracked flex plate so,,,,,,,,,, we removed the drivetrain to install a new one. While it was out, just for the hell of it, we popped open the Torque tube. YEP,, the rubber isolator GUBLIOS were cracked and worn.

Had to order them and found out that AutoZone has DORMAN replacements. They make excellent replacement parts. We should have them by Wednesday.

Found out that 97-2000 use smaller /thinner Gublios. 2001 -2004 use thicker more robust Gublios. They cost $56 each for aftermarket parts house replacements

The snap ring is a SNAP to get out IF,,,,,,, you have the larger snap ring removal tools. Be careful when you remove it as if it flies off the snap ring pliers it does so violently!!!

Bill

Had to order them and found out that AutoZone has DORMAN replacements. They make excellent replacement parts. We should have them by Wednesday.

Found out that 97-2000 use smaller /thinner Gublios. 2001 -2004 use thicker more robust Gublios. They cost $56 each for aftermarket parts house replacements

The snap ring is a SNAP to get out IF,,,,,,, you have the larger snap ring removal tools. Be careful when you remove it as if it flies off the snap ring pliers it does so violently!!!

Bill

#48

Intermediate

The Dorman part number is 935-102 and it looks like they are only offered in the 10mm version based on the info I found on Dorman's website. Also, my local O'reilly's qouted me $39 each plus another $5 for shipping since they are special order only. Of course, it was going to be 5-7 days vs. 2 from Autozone.

#49

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

Great post! Thanks for adding the info!

Bill

Bill

#50

Race Director

FWIW: When mine were going bad they felt like I was riding over rumble strips but only under moderate acceleration. Easy or hard acceleration I didn't feel it.

I'm running the poly bushings from the Drive Shaft Shop now and expect them to out live me. I also went from a 10mm prop shaft to a 12mm one.

I'm running the poly bushings from the Drive Shaft Shop now and expect them to out live me. I also went from a 10mm prop shaft to a 12mm one.

#51

Melting Slicks

Member Since: Jan 2009

Location: Easley/Anderson South Carolina

Posts: 2,127

Likes: 0

Received 32 Likes

on

24 Posts

In the middle of this now. It can be done with out the snap ring pliers, I had to do it that way. My pliers weren't big enough and I broke both of them that I had. Used good all flat headed screw drivers, one scratch awl, and a large pair of channel locks. Takes some patience but can be done. The hardest part that no one has even mentioned is the torx socket cap bolts. Man those are a pita. I broke 2 bits, twisted 5 others before coming loose. I have an email into ARP for new replacements, I will not go back with the torx style bolts. F that crap.

3 new bearings, 2 six shooter 12 mm couplers and new bolts. Will be good as new, zero signs of rubbing inside the tube.

3 new bearings, 2 six shooter 12 mm couplers and new bolts. Will be good as new, zero signs of rubbing inside the tube.

#52

That's what I did to get mine off essentially.. I put it back on with a regular pair of long needle nose pliers.

#53

Melting Slicks

Member Since: Jan 2009

Location: Easley/Anderson South Carolina

Posts: 2,127

Likes: 0

Received 32 Likes

on

24 Posts

Yup that's about what I did. I would be done by now had the torx heads not stripped out. Still waiting on ARP to respond to make sure their bolts exceed the 11.9 rating the originals were.

#54

Le Mans Master

Member Since: Sep 2003

Location: Farmington CT

Posts: 6,126

Received 160 Likes

on

125 Posts

Cruise-In VII Veteran

I may have missed it, but here are some things to consider,

1. If you have an early 97-00 shaft, you can tap out the bolt holes to use the later bolts and couplers (Don't ask for help on this one from me, I'd buy the 01 up TT/PS as they are now pretty inexpensive to start a rebuild on the new TT)

2. www.rpmtransmissions.com sells the poly couplers

2a. I never understood the reason for the arrows on the OEM couplers, but they are there and noted in the shop manual as stated by Lucky

3. The snap ring on the 01up is going to need some big SR pliers(bland point here, but not something most people will have)

4. 2000's may or may not have the old tube with the newer shaft inside

5. Would be a good idea to replace the 3 bearings also

6. During R/I, use caution near the PS weights, you may find the bolt in that position requiring to be first in the sequence to get in front of the weight

7. Buy 5 cans of 'brake cleaner', put your diff on a steel drip pan and clean that disgusting pig

8. Who pissed off Lucky as he has left the board in the past year?

1. If you have an early 97-00 shaft, you can tap out the bolt holes to use the later bolts and couplers (Don't ask for help on this one from me, I'd buy the 01 up TT/PS as they are now pretty inexpensive to start a rebuild on the new TT)

2. www.rpmtransmissions.com sells the poly couplers

2a. I never understood the reason for the arrows on the OEM couplers, but they are there and noted in the shop manual as stated by Lucky

3. The snap ring on the 01up is going to need some big SR pliers(bland point here, but not something most people will have)

4. 2000's may or may not have the old tube with the newer shaft inside

5. Would be a good idea to replace the 3 bearings also

6. During R/I, use caution near the PS weights, you may find the bolt in that position requiring to be first in the sequence to get in front of the weight

7. Buy 5 cans of 'brake cleaner', put your diff on a steel drip pan and clean that disgusting pig

8. Who pissed off Lucky as he has left the board in the past year?

#55

Instructor

#57

Instructor

from the manual:

IMPORTANT: If the coupling orientation mark has been lost during the

cleaning or disassembly process, the coupling MUST be

installed with the directional arrow pointed toward the flange

to which it mounts.

#58

Interesting. The shop that told me that was the one that installed them and 300 miles later 2 of the bolts backed out.

I took it to a different place got an new assembly.

I took it to a different place got an new assembly.

#59

Instructor

#60

Advanced

Would bad couplers make the prop shaft look bent? Took my torque tube out yesterday and rotating the prop shaft, it was .097 out of balance during rotation. Could this be because of the couplers? Haven't taken it apart yet, that will have to wait til next weekend but just looking for some information...Thanks!

The following users liked this post:

Kj814fun (03-22-2016)