Rocker R&R

#1

Le Mans Master

Thread Starter

Still kinda new to LS engines, so bear with me. GEN Is I know

I'm pulling heads and I keep seeing that the pedestals, rockers and pushrods must be kept in order. I did it, but kinda scratching my head - I don't see any machining or alternate PNs on the pedestals or rockers, so I assume they're all "standard" parts...correct? Leaving only the pushrods to be adjusted if need be for preload. I guess there are always machining tolerances, but I would think they'd be PDC given modern equipment.

Is there really a tolerance stack such that each ***'y is unique? Is there a way to tell the pushrods apart if they're different lengths?

Thanks!

I'm pulling heads and I keep seeing that the pedestals, rockers and pushrods must be kept in order. I did it, but kinda scratching my head - I don't see any machining or alternate PNs on the pedestals or rockers, so I assume they're all "standard" parts...correct? Leaving only the pushrods to be adjusted if need be for preload. I guess there are always machining tolerances, but I would think they'd be PDC given modern equipment.

Is there really a tolerance stack such that each ***'y is unique? Is there a way to tell the pushrods apart if they're different lengths?

Thanks!

#3

Team Owner

The PRs are all the same length and all the supporting hardware, i.e. rocker stands, rocker arms, lifter length (and plunger travel), valve spring installed heights, etc are of predetermined sizes.

LS engine valve trains are a non-adjustable, "net build"design. Put everything together and torque to spec.

I'm speaking of STOCK engines here of course. On the highly modified engines (barring full roller aftermarket rockers), PR length is again routinely used to set lifter preload, but here again, the rocker bolts get torqued down to 22 lbft.

LSx trivia: the LS7 is the only LS engine whose heads do not use a rocker rail/stand. Their rockers register directly on the heads themselves.

Btw, I'm like you in that I think the "keep everything in order mantra" comes under the category of "best practice". Potential specific wear patterns would be the only reason I think they should be kept together.

LS engine valve trains are a non-adjustable, "net build"design. Put everything together and torque to spec.

I'm speaking of STOCK engines here of course. On the highly modified engines (barring full roller aftermarket rockers), PR length is again routinely used to set lifter preload, but here again, the rocker bolts get torqued down to 22 lbft.

LSx trivia: the LS7 is the only LS engine whose heads do not use a rocker rail/stand. Their rockers register directly on the heads themselves.

Btw, I'm like you in that I think the "keep everything in order mantra" comes under the category of "best practice". Potential specific wear patterns would be the only reason I think they should be kept together.

Last edited by LoneStarFRC; 07-15-2016 at 12:31 AM.

The following users liked this post:

nsogiba (07-15-2016)

#4

Le Mans Master

Thread Starter

Thanks; I get the whole "do it the same way every time" as a means to form good habits. I bought a GEN I rocker/pushrod organizer years ago and it's been used many, many times.

Last edited by billla; 07-15-2016 at 09:23 AM.

#5

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

billla

Some more FUN LSX Facts:

- The rockers are pretty good! The only flaw is the small roller bearing retainer cap can pop out and puke the needle bearings out. Many up grade to a better design trunion. The gold standard use to be the COMP CAMS trunion up-grade but even that has shown a flaw. The new gold standard is a new bushing that gets pressed in. Don't know the manufacture.

- There is an aluminum rocker pedestal that the rockers sit on. It can and does wear where the rocker sits in the perch. That will cause the rocker to sit on the valve crooked. Check that for wear.

Why were you pulling the heads?? Ive done quite a few LS head R&R jobs. Ive also learned some valuable lessons!

1. The head bolt holes are BLIND HOLES!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

If there is ANY LIQUID in the bottom of the bolt holes when you go to bolt the head back onto the block, the block will hydro and RUPTURE! MAKE SURE that each hole is liquid and debris FREE. DO NOT USE A TAP to clean the bolt holes. Use a modified old head bolt. The head bolts are a ONE TIME USE, Torque To Yield bolt!

2. I will not do any head replacements unless the person is willing to up-grade to ARP Head Studs or some other manufactures head studs. LS1/6 head bolt holes are easily stripped out of the block. Using head studs helps eliminate that problem.

Hope this helps.

Bill

Some more FUN LSX Facts:

- The rockers are pretty good! The only flaw is the small roller bearing retainer cap can pop out and puke the needle bearings out. Many up grade to a better design trunion. The gold standard use to be the COMP CAMS trunion up-grade but even that has shown a flaw. The new gold standard is a new bushing that gets pressed in. Don't know the manufacture.

- There is an aluminum rocker pedestal that the rockers sit on. It can and does wear where the rocker sits in the perch. That will cause the rocker to sit on the valve crooked. Check that for wear.

Why were you pulling the heads?? Ive done quite a few LS head R&R jobs. Ive also learned some valuable lessons!

1. The head bolt holes are BLIND HOLES!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

If there is ANY LIQUID in the bottom of the bolt holes when you go to bolt the head back onto the block, the block will hydro and RUPTURE! MAKE SURE that each hole is liquid and debris FREE. DO NOT USE A TAP to clean the bolt holes. Use a modified old head bolt. The head bolts are a ONE TIME USE, Torque To Yield bolt!

2. I will not do any head replacements unless the person is willing to up-grade to ARP Head Studs or some other manufactures head studs. LS1/6 head bolt holes are easily stripped out of the block. Using head studs helps eliminate that problem.

Hope this helps.

Bill

#6

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

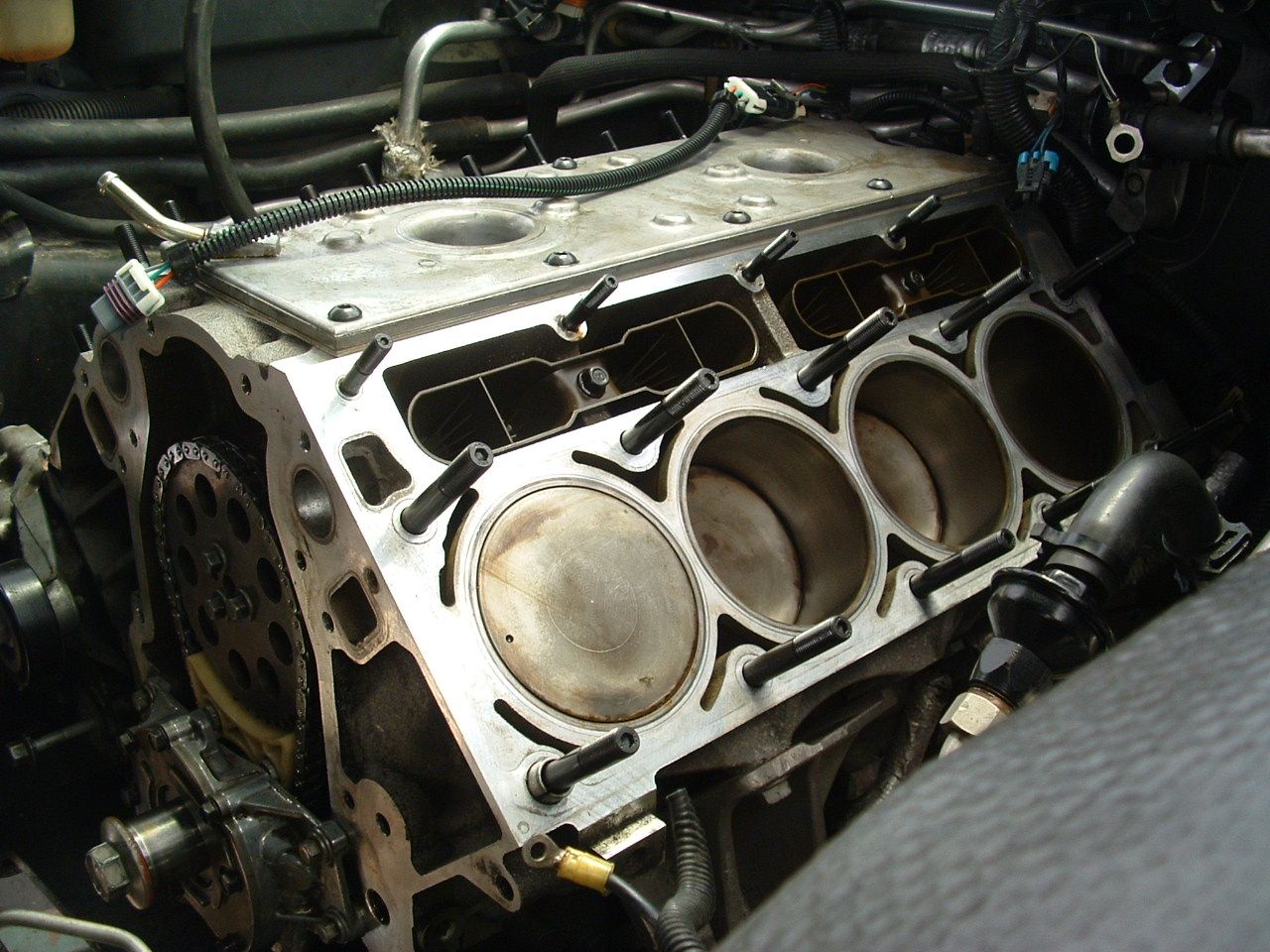

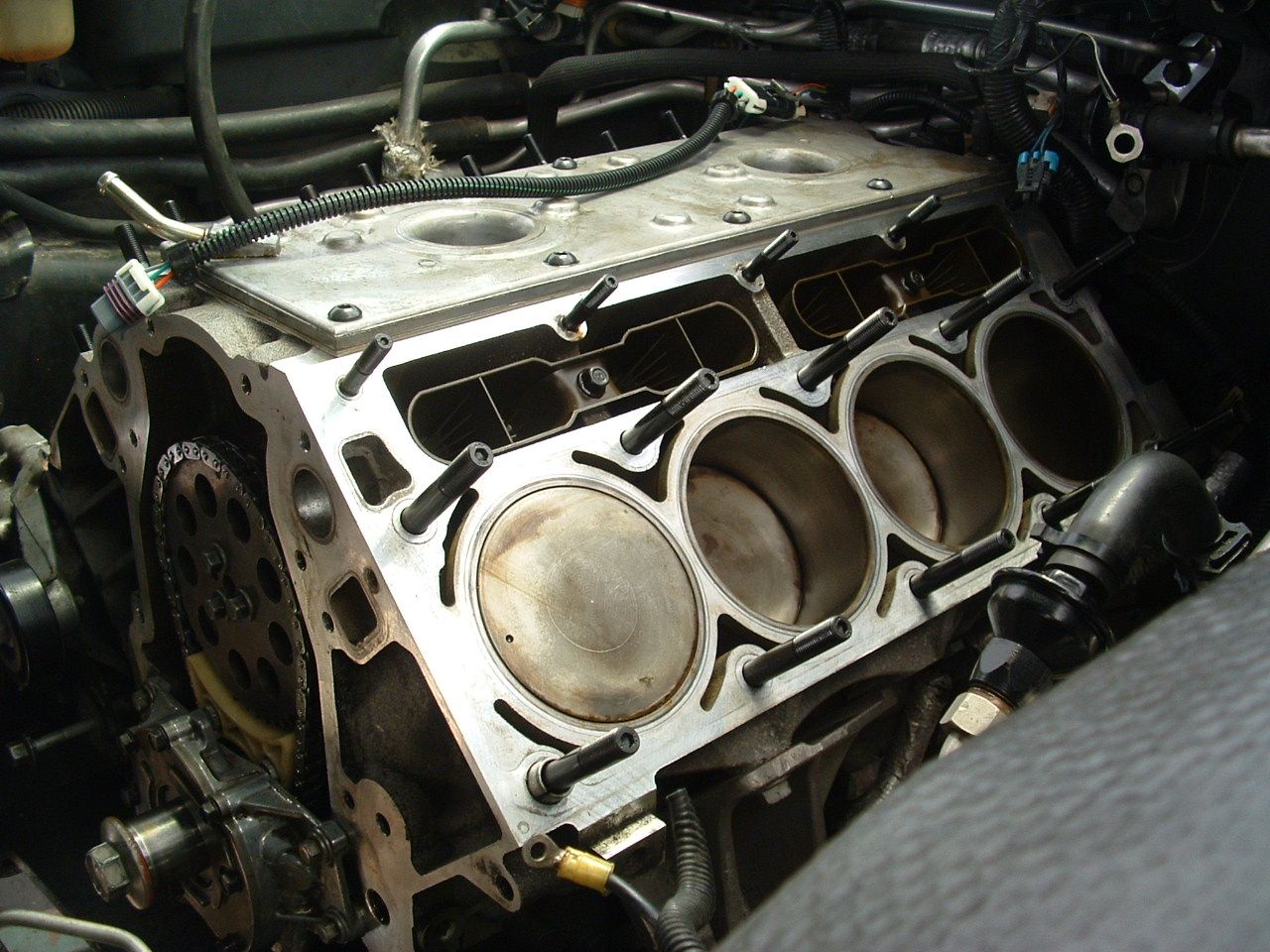

ARP Head studs installed:

YES,, the heads can be installed over the studs with the engine in the engine bay!

YES,, the heads can be installed over the studs with the engine in the engine bay!

#8

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

#9

Le Mans Master

Thread Starter

All good information, thanks!

Yeah, I just finished the CompCams trunnion upgrade - I'm reading the threads; I'm frankly not concerned with my completely stock valvetrain...but I guess we'll see. Straub is selling the bushed rockers through a number of outlets.

Broken valve spring; I tried a borescope to inspect but couldn't get a good view. I have also had some overheating issues after 2 water pumps, so I figured...well heck, I might as well. Fixing the oil pressure sender "while I'm in there" - anything else I should be doing?

I hear you on the ARP studs - I use nothing but ARP in my GEN I builds...but in this case I'm going to stick with the FelPro replacement bolts. Good heads up on the blind holes - I always blow 'em out anyway.

Broken valve spring; I tried a borescope to inspect but couldn't get a good view. I have also had some overheating issues after 2 water pumps, so I figured...well heck, I might as well. Fixing the oil pressure sender "while I'm in there" - anything else I should be doing?

I hear you on the ARP studs - I use nothing but ARP in my GEN I builds...but in this case I'm going to stick with the FelPro replacement bolts. Good heads up on the blind holes - I always blow 'em out anyway.

Last edited by billla; 07-15-2016 at 12:04 PM.

#10

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

TRUST ME ON THIS ONE!! Blowing out the holes doesn't always get ALL the liquid out!

Use a LONG "Q" Tip or a swab on a wire and insert it in the hole to the very BOTTOM. If it comes out DRY & CLEAN, "THEN" you are OK!

Use a LONG "Q" Tip or a swab on a wire and insert it in the hole to the very BOTTOM. If it comes out DRY & CLEAN, "THEN" you are OK!

#11

Team Owner

Parts organization is to keep those parts that wore in as an assembly to be re-installed as an assembly as previously stated.

Not sure if you are doing a cam or not, but new lifter trays while apart will help keep things in line and if you do a cam later help with holding up the lifters. Plus their cheap.

I use ARP studs as well.

Not sure if you are doing a cam or not, but new lifter trays while apart will help keep things in line and if you do a cam later help with holding up the lifters. Plus their cheap.

I use ARP studs as well.

Last edited by vettenuts; 07-15-2016 at 01:50 PM.

#12

Team Owner

#14

Team Owner

#15

Pro