C5 Z06 180 degree header build thread

#81

Instructor

Thread Starter

If a header manufacture wishes to copy my design and give me a royalty for each set produced, they are welcome to borrow them next winter for measuring and duplicating. Of course all my secrets are exposed here so I doubt that would happen.

But as for me making another set, not likely. I like to take on challenges and make things happen. I don't enjoy making the same thing twice, too many other things to enjoy taking on.

But as for me making another set, not likely. I like to take on challenges and make things happen. I don't enjoy making the same thing twice, too many other things to enjoy taking on.

#82

Instructor

Thread Starter

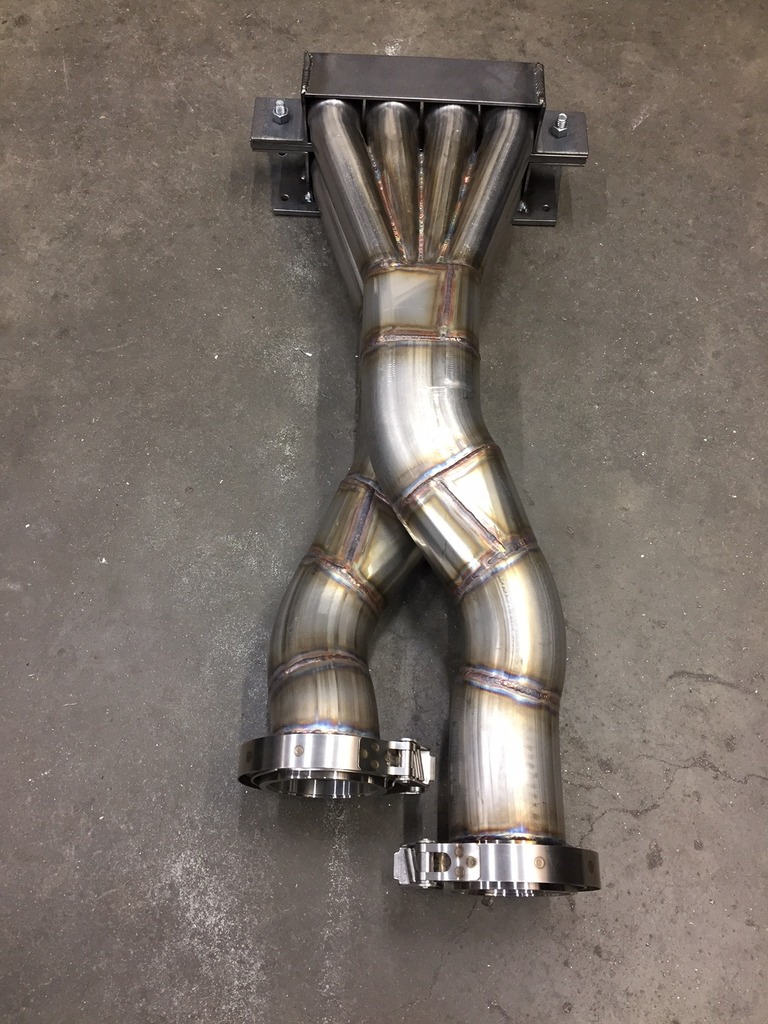

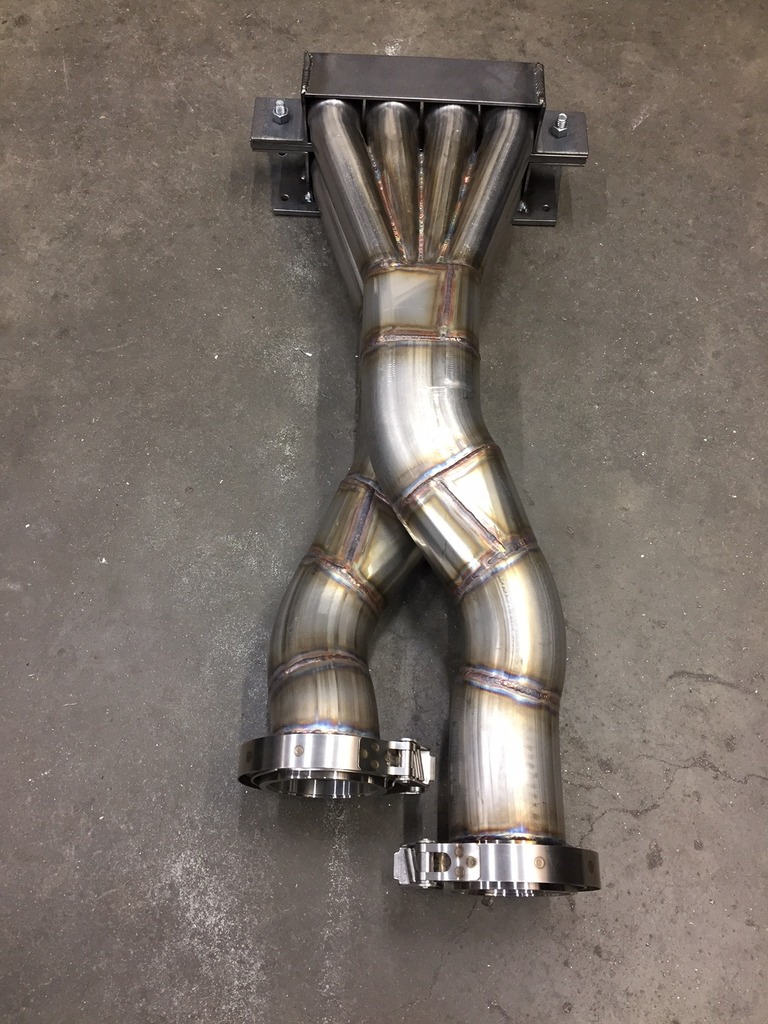

Finally back to where I started. The 4 into 1 merge collectors are complete.

I had to offset the location of the V bands as I could not get both of them side by side in the exhaust tunnel. I gave myself a little extra room as they will probably be a bit of pain to slide over the flanges as tight as they are to the sides and top of the tunnel so they are spaced a generous 2 1/4" away from each other.

I had to offset the location of the V bands as I could not get both of them side by side in the exhaust tunnel. I gave myself a little extra room as they will probably be a bit of pain to slide over the flanges as tight as they are to the sides and top of the tunnel so they are spaced a generous 2 1/4" away from each other.

The following users liked this post:

VFR RC46 (01-29-2020)

#83

Finally back to where I started. The 4 into 1 merge collectors are complete.

I had to offset the location of the V bands as I could not get both of them side by side in the exhaust tunnel. I gave myself a little extra room as they will probably be a bit of pain to slide over the flanges as tight as they are to the sides and top of the tunnel so they are spaced a generous 2 1/4" away from each other.

I had to offset the location of the V bands as I could not get both of them side by side in the exhaust tunnel. I gave myself a little extra room as they will probably be a bit of pain to slide over the flanges as tight as they are to the sides and top of the tunnel so they are spaced a generous 2 1/4" away from each other.

#84

Team Owner

Looks like you have all the necessary measurements tooling and jigs ready to go. When are you starting production? I could be interested....

#85

Instructor

Thread Starter

#86

Instructor

Thread Starter

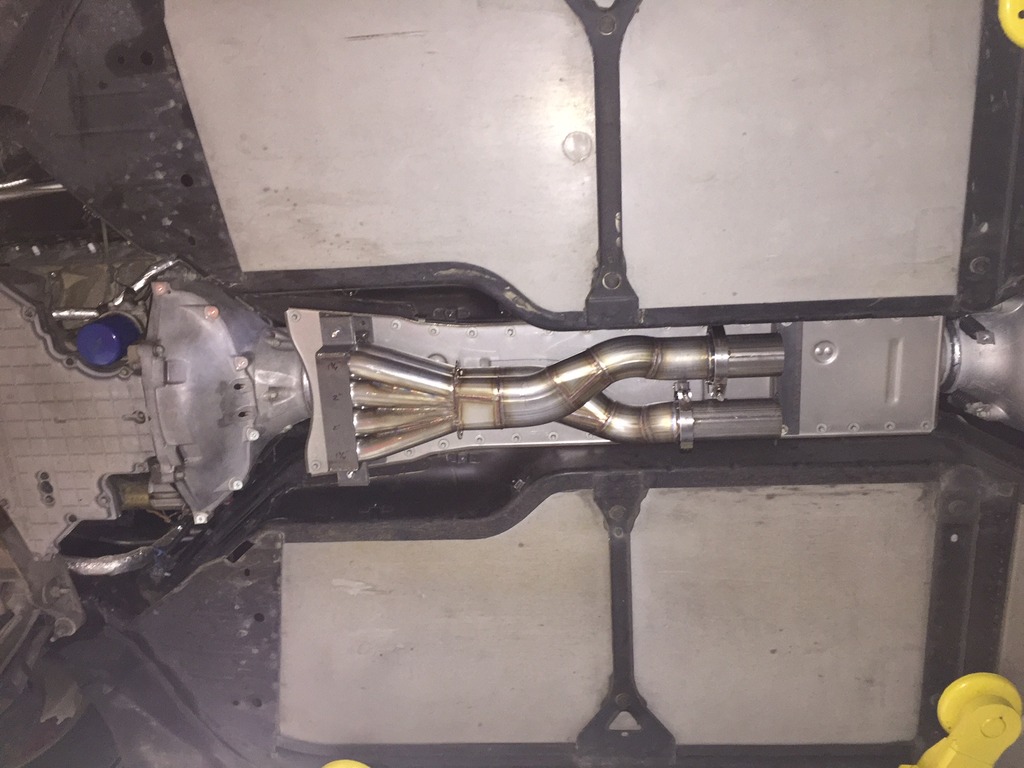

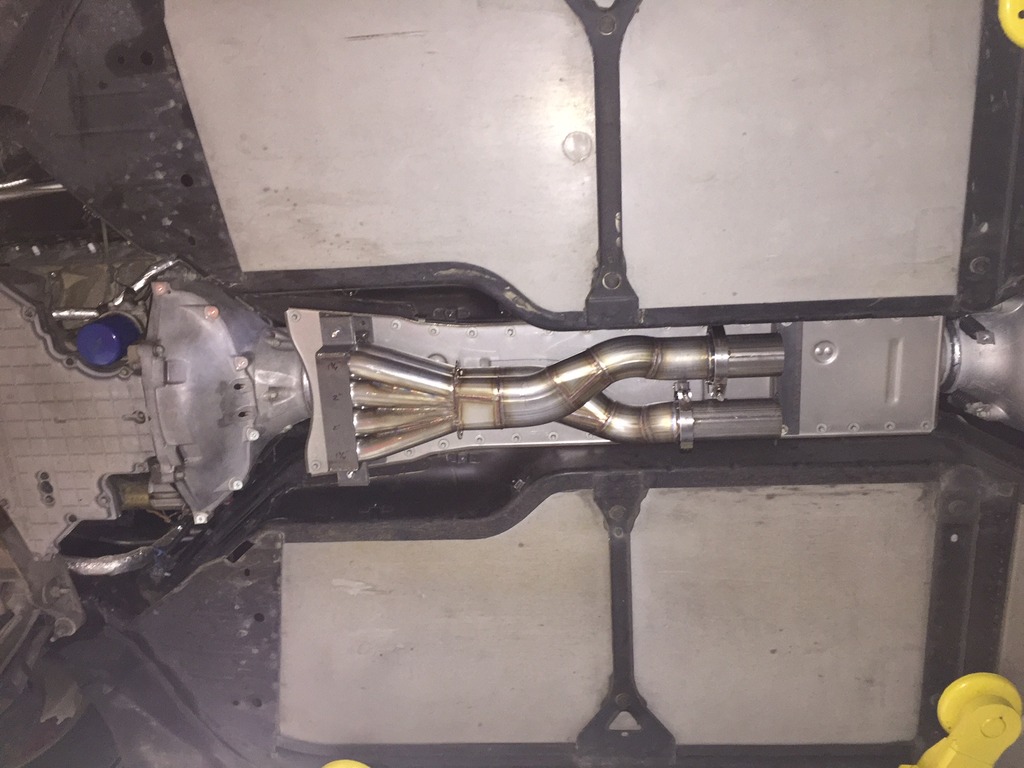

Back to square one.

The V bands ended up a little lower than I had hoped, even with the bottom of the seat rails. I needed the room up top to allow the clamp to slide over the flanges. In hindsight I should have gone with 2 bolt flanges but I hate gaskets and 2 3/4" V bands were only a few bucks more.

The V bands ended up a little lower than I had hoped, even with the bottom of the seat rails. I needed the room up top to allow the clamp to slide over the flanges. In hindsight I should have gone with 2 bolt flanges but I hate gaskets and 2 3/4" V bands were only a few bucks more.

The following users liked this post:

VFR RC46 (01-29-2020)

#89

hmmmmm ........

Well, you definitely know more about this than me. Probably more than everyone else on here. Combined.

So if you say back to square one who am I to say otherwise.

Still, considering what you have shown us this far, we figured you could just show us a few more slick tricks.

Well, you definitely know more about this than me. Probably more than everyone else on here. Combined.

So if you say back to square one who am I to say otherwise.

Still, considering what you have shown us this far, we figured you could just show us a few more slick tricks.

#92

Safety Car

Back to square one.

The V bands ended up a little lower than I had hoped, even with the bottom of the seat rails. I needed the room up top to allow the clamp to slide over the flanges. In hindsight I should have gone with 2 bolt flanges but I hate gaskets and 2 3/4" V bands were only a few bucks more.

The V bands ended up a little lower than I had hoped, even with the bottom of the seat rails. I needed the room up top to allow the clamp to slide over the flanges. In hindsight I should have gone with 2 bolt flanges but I hate gaskets and 2 3/4" V bands were only a few bucks more.

#93

Drifting

You're a metalworker, why not weld in a groove or slot into the tunnel plate that'll give you the room you need right at that section?

#94

Me reading this thread:

What is a 180 header?

Ohh neat! Could it really sound that much better?

But that is a race motor, they all sound awesome.

Ohh I understand what he is doing, but wow I don't know.......

video of C5 with 180 headers plays.

Holy wow that sounds great! Please let this happen.

What is that jig for? Ohh he is starting at the heads and working back.

Ohh that is the collector! That might work!

Ohh no, that is a beautiful!

This thing is going to work!

Wow, I can't wait to hear it!!!!!!!!!

Awesome work, true engineering there.

What is a 180 header?

Ohh neat! Could it really sound that much better?

But that is a race motor, they all sound awesome.

Ohh I understand what he is doing, but wow I don't know.......

video of C5 with 180 headers plays.

Holy wow that sounds great! Please let this happen.

What is that jig for? Ohh he is starting at the heads and working back.

Ohh that is the collector! That might work!

Ohh no, that is a beautiful!

This thing is going to work!

Wow, I can't wait to hear it!!!!!!!!!

Awesome work, true engineering there.

#95

Instructor

Thread Starter

hmmmmm ........

Well, you definitely know more about this than me. Probably more than everyone else on here. Combined.

So if you say back to square one who am I to say otherwise.

Still, considering what you have shown us this far, we figured you could just show us a few more slick tricks.

Well, you definitely know more about this than me. Probably more than everyone else on here. Combined.

So if you say back to square one who am I to say otherwise.

Still, considering what you have shown us this far, we figured you could just show us a few more slick tricks.

Interesting idea. I may have to look into that if the V band clamps end up dragging.

It is but it has a smallish cam and the same compression as the LS6. Hopefully I will get a very similar result with this set of 180 degree headers.

Once again, thanks for all the compliments and suggestions. And sorry for taking so long, hope the noise is worth the wait.

#96

Safety Car

So what you're saying is, wiggle room to fit v-bands is currently maxxed out? I was thinking since they're sandwiched in the jig, there may be more wiggle after they come out. Unless I'm forgetting something here.

#97

I had to laugh at the last picture showing the weld table and the paper backed insulation.

Last edited by danh52; 02-20-2017 at 01:35 PM.

#99

Drifting

Probably from grinding (most likely) or MIG

don't see what the problem is

don't see what the problem is