[Z06] Thermal effciciency vis-a-vis plug location, chamber shape/size, and rod ratio

#1

Race Director

Thread Starter

Member Since: May 2000

Location: Redondo Beach USA

Posts: 12,487

Received 1,974 Likes

on

1,188 Posts

This topic is an answer to Power Shifter's question from the nearby thread on spark plug wires.

"If you get time, explaneing why less ignition timeing is desirable, if you have very eficient combustion event would illustrative in the way you do so well!! Thanks, Ric"

Long ago when engineers were trying to get a handle on internal combustion engines they developed a number of simple models that expressed thermal efficiency as a function of combustion characteristics and compression ratio. These simple, closed form expressions fall out of the primordal muck of thermdynamics and gave a hint as to the best design geometries that will maximize thermal efficiency, and, of course, maximizing thermal efficiency maximizes torque/power output and fuel efficiecy. You can find a discussion of these simple combustion models at the front of almost any IC engine textbook under a chapter title such as "idealized cycles and processes".

The models assume that heat is added to an ideal gas working fluid and do not take into account changes in fluid properties as real fuel is oxidized with air. In these simple models, thermal efficiency is expressed purely as function of compression ratio. They do not give exact results, far from actual experience in fact because there are so many other real world issues they do not account for; however, even with their simplifying assumptions they give a sense of direction in actual physical geometry and dimensions and a theoretical ideal that we can measure real world designs against.

Three of the common models are "combustion at constant volume", "combustion at constant pressure", and a "combined cycle" where combustion is partially at constant pressure and partially at constant volume.

It turns out that the greatest thermal efficiency for a given compression ratio is achieved by combustion at constant volume. In a real engine this would mean that combustion would occur instantaneously at a hair past TDC, but in the real world of finite flame propagation speeds, not to mention detonation and actual working stress limitations of the engine structure, combustion at constant volume can't be attained, but the closer we can get to this ideal, the more efficient the engine.

If the spark plug is located at the geometric center of a (preferably round) combustion chamber, then average flame propagation distance is minimized and combustion takes a minimum amount of clock time. Minimum flame propogation travel means that less ignition advance is required, and a chamber that requires the least advance is also the one that comes closest to achieving combustion at constant volume.

Trouble with a "pure" hemi is that the combustion chamber is the width of the bore, so combustion is fairly slow on large bore engines, and compression is limited due to detonation problems because of the relatively long time that the last of the mixture is exposed to high temperature and pressure before being consummed by the flame front. The simple thermodynamic models just say we should initiate combustion at the center of the chamber, but don't consider the real world limitation of detonation and large bores. The hemisphere diameter can be reduced with quench area to achieve shorter flame travel and more detonation resistance, but then valve size is restricted. The logical development of the hemi is the four-valve pentroof chamber, and these have both excellent thermal efficiency (a central spark plug for short flame travel) and allow generous valve size, but at the expense of a lot of mechanical complexity, weight, and bulk. In the real world we we can't place the spark plug close to the actual geometric center of the chamber, but the desirability to do this indicates that an extended tip plug is best; however, I don't think you can measure a consistent difference between regular tip and extended tip plugs, but I do note that most modern engine use extended tip plugs.

As a real world illustration my Cosworth Vega - with the seminal Cosworth narrow angle four valve combustion chamber (and an extended tip plug) requires about 32 degrees of advance for maximum power, but my '63 Special High Performance small block requires 38 degrees. I don't know the range of timing required to achieve peak power in a modern Corvette SB, but I would bet it is closer to the CV than a vintage SB, which means it has a more efficient chamber than the vintage SB.

In the late forties, GM developed the modern OHV engine with a "quench" combustion chamber. Since the (somewhat idealized) combustion chamber is only about half the width of the bore, detonation resistance was increased to run higher compression ratios (which means higher efficiency), but the spark plug was not at the ideal location. Ever since then, OEMs and the aftermarket have been playing with the plug location (and overall geometry) on quench chambers trying to get better combustion efficiency, which is normally indicated by less ignition advance to achieve peak brake torque. GM Powertrain has done an excellent job of "reinventing" the quench chamber every 10 to 20 years and despite the theoretical disadvantage of the quench chamber as opposed to the four valve pentroof, they still end up with more torque, power, and fuel efficiency in a given package volume and mass. Sometimes good detail design wins out over "theoretical" ideals.

Combustion at constant volume is also the theoretical basis for longer rods. The longer the rod relative to the stroke, the more time the piston will spend near top dead center, so combustion comes closer to the ideal of combustion at constant volume, but I question whether a change from a 5.7" rod to a 6.0 inch rod in a small block will make any measureable difference. The difference in rod/stroke ratio and the amount the piston "dwells" near TDC is just not that different.

Duke

[Modified by SWCDuke, 6:43 PM 8/6/2003]

"If you get time, explaneing why less ignition timeing is desirable, if you have very eficient combustion event would illustrative in the way you do so well!! Thanks, Ric"

Long ago when engineers were trying to get a handle on internal combustion engines they developed a number of simple models that expressed thermal efficiency as a function of combustion characteristics and compression ratio. These simple, closed form expressions fall out of the primordal muck of thermdynamics and gave a hint as to the best design geometries that will maximize thermal efficiency, and, of course, maximizing thermal efficiency maximizes torque/power output and fuel efficiecy. You can find a discussion of these simple combustion models at the front of almost any IC engine textbook under a chapter title such as "idealized cycles and processes".

The models assume that heat is added to an ideal gas working fluid and do not take into account changes in fluid properties as real fuel is oxidized with air. In these simple models, thermal efficiency is expressed purely as function of compression ratio. They do not give exact results, far from actual experience in fact because there are so many other real world issues they do not account for; however, even with their simplifying assumptions they give a sense of direction in actual physical geometry and dimensions and a theoretical ideal that we can measure real world designs against.

Three of the common models are "combustion at constant volume", "combustion at constant pressure", and a "combined cycle" where combustion is partially at constant pressure and partially at constant volume.

It turns out that the greatest thermal efficiency for a given compression ratio is achieved by combustion at constant volume. In a real engine this would mean that combustion would occur instantaneously at a hair past TDC, but in the real world of finite flame propagation speeds, not to mention detonation and actual working stress limitations of the engine structure, combustion at constant volume can't be attained, but the closer we can get to this ideal, the more efficient the engine.

If the spark plug is located at the geometric center of a (preferably round) combustion chamber, then average flame propagation distance is minimized and combustion takes a minimum amount of clock time. Minimum flame propogation travel means that less ignition advance is required, and a chamber that requires the least advance is also the one that comes closest to achieving combustion at constant volume.

Trouble with a "pure" hemi is that the combustion chamber is the width of the bore, so combustion is fairly slow on large bore engines, and compression is limited due to detonation problems because of the relatively long time that the last of the mixture is exposed to high temperature and pressure before being consummed by the flame front. The simple thermodynamic models just say we should initiate combustion at the center of the chamber, but don't consider the real world limitation of detonation and large bores. The hemisphere diameter can be reduced with quench area to achieve shorter flame travel and more detonation resistance, but then valve size is restricted. The logical development of the hemi is the four-valve pentroof chamber, and these have both excellent thermal efficiency (a central spark plug for short flame travel) and allow generous valve size, but at the expense of a lot of mechanical complexity, weight, and bulk. In the real world we we can't place the spark plug close to the actual geometric center of the chamber, but the desirability to do this indicates that an extended tip plug is best; however, I don't think you can measure a consistent difference between regular tip and extended tip plugs, but I do note that most modern engine use extended tip plugs.

As a real world illustration my Cosworth Vega - with the seminal Cosworth narrow angle four valve combustion chamber (and an extended tip plug) requires about 32 degrees of advance for maximum power, but my '63 Special High Performance small block requires 38 degrees. I don't know the range of timing required to achieve peak power in a modern Corvette SB, but I would bet it is closer to the CV than a vintage SB, which means it has a more efficient chamber than the vintage SB.

In the late forties, GM developed the modern OHV engine with a "quench" combustion chamber. Since the (somewhat idealized) combustion chamber is only about half the width of the bore, detonation resistance was increased to run higher compression ratios (which means higher efficiency), but the spark plug was not at the ideal location. Ever since then, OEMs and the aftermarket have been playing with the plug location (and overall geometry) on quench chambers trying to get better combustion efficiency, which is normally indicated by less ignition advance to achieve peak brake torque. GM Powertrain has done an excellent job of "reinventing" the quench chamber every 10 to 20 years and despite the theoretical disadvantage of the quench chamber as opposed to the four valve pentroof, they still end up with more torque, power, and fuel efficiency in a given package volume and mass. Sometimes good detail design wins out over "theoretical" ideals.

Combustion at constant volume is also the theoretical basis for longer rods. The longer the rod relative to the stroke, the more time the piston will spend near top dead center, so combustion comes closer to the ideal of combustion at constant volume, but I question whether a change from a 5.7" rod to a 6.0 inch rod in a small block will make any measureable difference. The difference in rod/stroke ratio and the amount the piston "dwells" near TDC is just not that different.

Duke

[Modified by SWCDuke, 6:43 PM 8/6/2003]

#2

Le Mans Master

The stock LS6 runs with 22 degrees total advance at WOT high loads (MAP > ~ 23). Any more total advance than that during WOT high load will not result in additional power on a stock LS6. It usually just causes knock.

Of course lower loads get more timing.

Of course lower loads get more timing.

#3

Melting Slicks

Member Since: Oct 2000

Location: Stamford CT.

Posts: 2,524

Likes: 0

Received 0 Likes

on

0 Posts

Thank you very much Duke. Jim Fueling showed the value of the 3 valve head, and apparently was not able to protect the design, and get licence fee's, the lighter, simpler design makes it a good bet to see it in more V8's.. 5.7 or 6.0 in past small blocks? Some very good builders went with 5.85 in high hp/tq street/strip combo's. So the point is to try to get as much burn/heat out of the fuel, right? So how long before someone can figure out how to heat the fuel(microwave?)wiel still keeping it under control(not burning) before it's in the combustion chamber, to speed the burn and getting closer to the just past TDC ideal BOOM? Thanks again. Ric

[Modified by Power Shifter, 11:39 PM 8/6/2003]

[Modified by Power Shifter, 11:39 PM 8/6/2003]

#4

Race Director

Thread Starter

Member Since: May 2000

Location: Redondo Beach USA

Posts: 12,487

Received 1,974 Likes

on

1,188 Posts

some very good builders went with 5.85 in high hp/tq street/strip combo's. So the point is to try to get as much burn/heat out of the fuel, right?

So how long before someone can figure out how to heat the fuel(microwave?)wiel still keeping it under control(not burning) before it's in the combustion chamber, to speed the burn and getting closer to the just past TDC ideal BOOM?

"The stock LS6 runs with 22 degrees total advance at WOT high loads (MAP > ~ 23). Any more total advance than that during WOT high load will not result in additional power on a stock LS6. It usually just causes knock."

Very impressive! I would have guessed closer to 30 degress. If only 22 degrees is required for peak WOT torque/power that means it's a VERY efficient combustion chamber and is a primary reason for the LS6' high specific output and low specific fuel consumption.

The GM Powertrain guys really did their homework and produced what IMO is the best general purpose all around automobile engine available today. It's output per unit package volume and unit mass and specific fuel consumption that defines "high tech", not the number of cams and valves.

Duke

#5

Le Mans Master

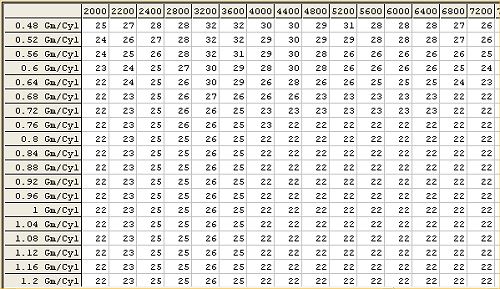

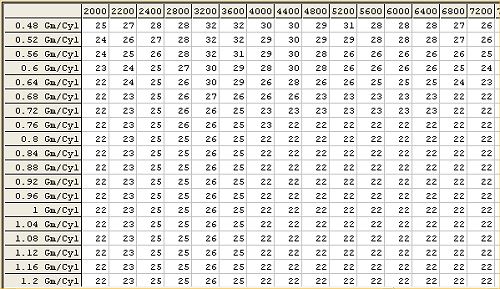

Here is a view of the stock upper load/upper RPM timing values for the 2002 LS6

Click image for a larger view :)

Click image for a larger view :)

#6

Team Owner

The GM Powertrain guys really did their homework and produced what IMO is the best general purpose all around automobile engine available today. It's output per unit package volume and unit mass and specific fuel consumption that defines "high tech", not the number of cams and valves.

Duke

Duke

I forcast a day when each combustion chamber will have not only its own coil, but also its own knock sensor, and ignition system pick-up for optimal power delivery on every cycle. Essentially, we'd have 8 perfect 1 cylinder motors working together - and if we added the 4 valve per cylinder head to it, then even more output!!! Somehow, I'm betting that Chevy will acheive 500 hp from the LS series without abandoning push rods, and thus 4 valve per cylinder potentials won't be realized in a chevy platform. :seeya :cheers:

#7

Melting Slicks

Member Since: Oct 2000

Location: Stamford CT.

Posts: 2,524

Likes: 0

Received 0 Likes

on

0 Posts

So how long before someone can figure out how to heat the fuel(microwave?)wiel still keeping it under control(not burning) before it's in the combustion chamber, to speed the burn and getting closer to the just past TDC ideal BOOM?

Actually, the cooler the fuel, the better. Heating the fuel and vaporizing it removes energy from the air, thus cooling it, which increases density, higher mixture density means more power.

Duke[/QUOTE]

I am just supposing, and trying to pick your brain. Yes cooler fuel is more dense. But that's the case before the combustion chamber,right? I was just museing that in the chamber you have to excite the fuel to get it to burn, so if there was a way to excite it in the chamber(heat it before ignition) with a micro wave(pie in the sky)at the base of the injector? you might be able to get more useable heat on the burn, with even less timeing? Just a thought. Ric

#8

Race Director

Thread Starter

Member Since: May 2000

Location: Redondo Beach USA

Posts: 12,487

Received 1,974 Likes

on

1,188 Posts

Commercial gasolines' energy content is about 19,000 BTUs per pound, and this is the energy that is released upon combustion. The heat to evaporate the liquid fuel comes from the incoming air and vaporaization of the fuel cools the incoming air making it more dense. This is the same process that allows a "swamp cooler" of keep a house cool in the desert. Subsequent compression of the mixture increases the temperature and pressure of the mixture making it easily igniteable with a spark, and once combustion initiates, the mixture burns rapidly and quite completely.

Over the years various products have been advertised that "align" or "magnetize" or "ionize" the "fuel molecules" producing more power and better fuel economy. They are all snake oil!

Duke

Over the years various products have been advertised that "align" or "magnetize" or "ionize" the "fuel molecules" producing more power and better fuel economy. They are all snake oil!

Duke

#9

Melting Slicks

Member Since: Oct 2000

Location: Stamford CT.

Posts: 2,524

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the effort Duke. I was looking for some 'out of the box' museing. Maybe next time. Ric