[Z06] C6 Z06 Frequently Asked Questions(FAQ)

#1

Get Some!

Thread Starter

I will not only add post, but information will be added to existing post.

Quick word search: Press control F and you will get a find box. Type in whatever you are looking for ie: brakes and zip right to the next mention of that keyword.

Table of Contents:

Post #1 General technical info and specs; 07 Changes

Post #2 Corvetteforum acronyms

Post #3 Z06 vs. other cars

Post #4 Info about the aluminum frame

Post #5 The dry sump & how to change the oil

Post #6 FAQ on the C5 Z06

Post #7 How to read tire info & what it means

Post #8 Magnuson Moss warranty act

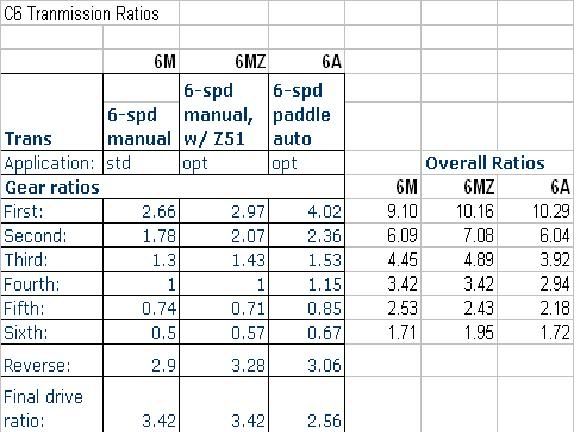

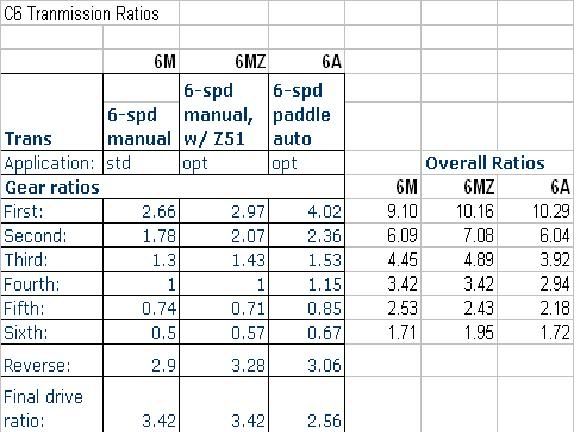

Post #9 Transmission gear ratios

Post #10 Cell phone mounting

Post #11 Weight difference between 1LZ & 2LZ option pkgs

Post #12 Explanations of spoilers and wings

Post #13/14/15 LS7 cam specs & heads and flow #s

Post #16 Z06 problems

Post #17 The history of Corvette name and symbol

Post #18 How to take better pics of your Corvette

Post #19/20 C6 Z06 Nurburgring test pics

Post #21 Nurburgring info, vids, threads

Post #22 Scanned Car&Driver and Motor Trend articles

Post #23 Is it Z oh 6 or Z zero 6?

Post #24 The 2006 C6/Z06 manual

Post #25 Dyno runs

Post #26 Octane discussion and explanation

Post #27 C6 Z06 brake discussions.

Post #28 Convertible discussions

Post #29 Track Reviews, harness bars, suspension discussions, etc.

Post #30 Z06 specific part numbers

Post #31 Wheel and Tire section

Post #32 How to install a switch for muffler valve activation

Post #33 Sound reduction for the C6 Z06

Post #34 LS1 vs. LS7 crank pics

Post #35 Bolt torque specs

Post #36 Weight reduction

Post #37 Tire Pressure Sensor Reset

Post #38 iPod your car

Post #39 Front license plate mounting

Post #40 Do you need a Cold Air Intake on the C6 Z06?

Post #41 & 42 & 43 Jacking procedures

Post #44 Drag racing discussions

Post #45 Emissions control pads in the intake snorkel

Post #46 The Official "Top Gear/Fifth Gear" Video Library

Post #47 How to modify your stock muffler

Post #48 How to clean your clutch reservoir.

Post #49 Xeon fog lights

Post #50 DIY – Rear Axle / Differential oil change, with pics

Post #51 Katech How-To: Check lifter preload

Post #52 Our own Congaman's videos!

Post #53 How to find who built your engine.

Post #54 Skip shift eliminator (CAGS)

Post #55 Summary of the Axle Shaft Issue for FAQ

How to post pics, etc. our Help section.

http://forums.corvetteforum.com/forumdisplay.php?f=31

Check out the C6 Gen FAQ sticky

http://forums.corvetteforum.com/show...81&forum_id=74

It will answer many questions that the C6 and Z06 have in common like Nav and radio questions, etc.

23 Page Z06 fact book.

http://forums.corvetteforum.com/show...1&forum_id=100

Updated info:

INFORMATION PROVIDED BY GENERAL MOTORS

2006 specs are up:

http://www.chevrolet.com/corvette/

CORVETTE Z06: RACING SUCCESS HELPS BREED THE FASTEST, MOST POWERFUL PRODUCTION CORVETTE EVER BUILT

DETROIT – By winning every race in the 2004 season, the Corvette C5-R racing team wrapped up the most successful era in Corvette’s 50-year racing history. In its five years, the C5-R racing program took 35 victories in 55 races, four American Le Mans Series championships and three double victories at the 24 Hours of Le Mans .

The Z06 sparked the second half of the C5’s life span with a Corvette model for the extreme performance enthusiast. Now, Team Corvette combines the numerous attributes of the sixth-generation Corvette with the technology and winning determination from the C5-R program to take the new Z06 to the next level in total performance.

Chevrolet introduced the 2006 Corvette Z06 at the North American International Auto Show. It is the fastest, most powerful car ever offered by Chevrolet and General Motors. It is comprised of an unprecedented level of capability and technology, making it one of the greatest performance values on the market. And with an unmistakably muscular appearance, the ’06 Z06 has a visual attitude that always looks ready to demonstrate Corvette’s winning attitude to any challenger around the globe.

“The new Z06 is the dividend from competing so successfully in endurance racing,” said Dave Hill, Corvette’s chief engineer. “It combines the strong attributes of the new, sixth-generation Corvette with the spirit, technology and know-how from the race program to form an American supercar with outstanding credentials.”

The new Z06 achieves 500 horsepower in an approximately 3130-pound (1419.7 kg) package and is expected to deliver 0-60 performance of less than 4 seconds, eclipse the quarter-mile in less than 12 seconds and deliver a top speed of more than 190 mph on a race track.

The links between racing and the production Z06 are both direct and indirect, as the vehicle was developed in conjunction with the forthcoming C6-R racecar, but they boil down to the application of lessons that could only have been learned after countless laps of endurance racing – everything from suspension geometry to aerodynamics. What the engineers developed was a totally unique vehicle that has its own powertrain, body structure and chassis system which are distinct from other Corvette models.

Previous Z06 models, from the original 1963 model to the 2001-04 editions, incorporated suspension and/or engine upgrades that complemented existing Corvette systems. Not surprisingly, the specs for the ’06 read like the blueprint of a champion. They include:

• LS7 7.0-liter/427-cubic-inch Gen IV V-8 with lightweight reciprocating components

• 500 horsepower (373 kw) at6200 rpm

• 475 lb.-ft. of torque (657 Nm) at 4800 rpm

• 7000 rpm redline

• Titanium connecting rods and intake valves

• Dry-sump engine lubrication system

• Engine hand-built at GM’s new Performance Build Center

• Aluminum body structure with one-piece hydroformed perimeter rails frame and magnesium front cradle

• Fixed roof design optimizes body rigidity and aerodynamics

• Carbon-fiber composite front fenders and front wheelhouses

• Unique front fascia incorporating a larger grille, cold-air scoop and lower air splitter

• Wide-body rear fenders and a unique rear spoiler incorporated with the CHMSL

• Huge 14-inch (355-mm) cross-drilled front disc brakes with six-piston calipers and 13.4-inch (340-mm) cross-drilled rear rotors with four-piston calipers

• 18 x 9.5-inch front wheels with 275/35ZR18 tires and 19 x 12-inch rear wheels with 325/30ZR19 tires

• 3-inch-diameter exhaust with bi-mode mufflers and larger polished stainless steel tips

• Engine, transmission and differential oil coolers; and steering cooler

• Rear-mounted battery to improve weight distribution

• Unique interior features including revised gauge cluster and lightweight two-tone seats with more aggressive bolsters

• Curb weight of 3130 pounds / 1419.7 kg (estimated)

• 3 inches (76.2 mm) wider than other Corvette models

• Vehicle developed simultaneously with C6-R racecar.

The features above are merely the highline points of the comprehensively designed Z06. What follows is a closer look at the vehicle’s unique attributes.

LS7 engine

The all-new LS7 of the ’06 Z06 reintroduces the 427-cubic-inch engine to the Corvette lineup. Unlike the previous 427 engine, which was a big-block design, the new 7.0-liter LS7 is a small-block V-8 – the largest-displacement small-block ever produced by GM and a tribute to its 50 years as a performance icon.

With 500 horsepower and 475 lb.-ft. of torque, it also is the most powerful passenger car engine ever produced by Chevrolet and GM. The LS7 is easily identified under the hood by red engine covers with black lettering.

The LS7 shares the same basic Gen IV V-8 architecture as the Corvette’s 6.0-liter LS2, but the LS7 uses a different cylinder block casting with pressed-in steel cylinder liners to accommodate the engine’s wide, 104.8-mm-wide cylinder bores; the LS2 has 101.6-mm bores. And when compared to the LS2, the LS7 also has a different front cover, oil pan, exhaust manifolds and cylinder heads.

Internally, the LS7’s reciprocating components make use of racing-derived lightweight technology, including titanium connecting rods and intake valves, to help boost horsepower and rpm capability. The rpm fuel shut-off limit is 7000 rpm.

The LS7’s specifications include:

• Unique cylinder block casting with large, 104.8-mm bores and pressed-in cylinder liners

• Forged steel main bearing caps

• Forged steel crankshaft

• Titanium connecting rods with 101.6-mm stroke

• Cast aluminum flat-top pistons

• 11.0:1 compression

• Dry-sump oiling system

• Camshaft with .591-inch lift

• Racing-derived CNC-ported aluminum cylinder heads with titanium intake valves and sodium-filled exhaust valves

• Titanium pushrods and valve springs

• Low-restriction air intake system

• Hydroformed exhaust headers with unique “quad flow” collector flanges.

“In many ways, the LS7 is a racing engine in a street car,” said Dave Muscaro, assistant chief engineer of small-block V-8 for passenger cars. “We’ve taken much of what we’ve learned over the years from the 7.0-liter C5-R racing program and instilled it here. There really has been nothing else like it offered in a GM production vehicle.”

One of the clearest examples of the LS7’s race-bred technology is its use of titanium connecting rods. They weigh just 480 grams apiece, almost 30 percent less than the rods in the LS2 V-8. Besides being lightweight, which enhances high-rpm performance and rpm range, titanium makes the rods extremely durable.

The LS7’s CNC-ported aluminum cylinder heads are all-new and designed to meet the high airflow demands of the engine’s 7.0-liter displacement, as it ingests approximately 100 cubic feet more air per minute than the Corvette’s 6.0-liter LS2 V-8 – an 18-percent increase in airflow. Consequently, a hydraulic roller camshaft with .591/.591-inch valve lift is used to allow plenty of air to circulate in and out of the engine.

To ensure optimal, uninterrupted airflow, the LS7’s heads have straight, tunnel-like intake runners. Very large by production-vehicle standards – even racing standards – they are designed to maintain fast airflow velocity, providing excellent torque at low rpm and exhilarating horsepower at high rpm. The heads feature 70-cc combustion chambers which are fed by huge, 56-mm-diameter titanium intake valves. The lightweight titanium valves weigh 21grams less than the stainless steel valves used in the LS2, despite the valve head having 22 percent more area. They are complemented by 41-mm sodium-filled exhaust valves, vs. 39.4-mm valves in the LS2. To accommodate the large valve face diameters, the heads’ valve seats are siamesed; and, taken from experience with the engines of C5-R racecars, the LS7’s valve angles are held at 12 degrees – versus 15 degrees for the LS2 – to enhance airflow through the ports.

All LS7 engines are assembled by hand at GM Powertrain’s new Performance Build Center in Wixom , Mich. The exacting standards to which they are built include deck-plate honing of the cylinders – a procedure normally associated with the building of racing engines and almost unheard of in a production-vehicle engine.

Dry sump oiling system

The LS7 has a dry-sump oiling system designed to keep the engine fully lubricated during the high cornering loads the Corvette Z06 is capable of producing. An engine compartment-mounted 8-quart reservoir delivers oil at a constant pressure to a conventional-style oil pump pick-up at the bottom of the engine. The pressurized oil feed keeps the oil pick-up continually immersed in oil at cornering loads exceeding 1 g.

Oil circulates through the engine and down to the oil pan, where it is sent back to the reservoir via a scavenge pump. The large-capacity reservoir, combined with a high efficiency air-to-oil cooler, provides necessary engine oil cooling under the demands of the engine’s power output. With the dry-sump system, oil is added to the engine via the reservoir tank – which includes the oil level dipstick.

The LS7’s dry-sump system was developed and tested on racetracks in the United States and Europe , including Germany ’s famed Nürburgring. And while common in racing cars, the Corvette Z06 is one of just a handful of production vehicles – and the only production Corvette – to ever incorporate such a high-performance oiling system.

Drivetrain

The Corvette Z06’s powertrain and drivetrain systems are matched to the LS7’s performance capability. The light, four-into-one headers discharge in to new, close-coupled catalytic converters and through to new “bi-modal” mufflers. The mufflers each feature a vacuum-actuated outlet valve, which controls exhaust noise during low-load operation but opens for maximum power.

At the rear of the LS7 engine, a single-mass flywheel and lightweight, high-capacity clutch channel torque to the rear transaxle. The six-speed manual transmission has been strengthened to handle the LS7’s increased torque load. The transmission includes a pump which sends transmission fluid to the front radiator for cooling. Upon its return, the fluid removes additional heat from the differential lube before returning to the transmission.

The M6 transmission connects to a limited-slip differential, with enlarged ring and pinion gears. Stronger axle half-shafts with tougher universal joints transmit power to the rear wheels.

Body structure

The Z06 has a unique aluminum body structure for optimum stiffness and light weight for the fixed-roof bodystyle. Perimeter rails are one-piece hydroformed members featuring cast suspension nodes, which replace many welded steel components on other Corvette models. Other castings, stampings and extrusions are combined into the innovative structure with state-of-the-art manufacturing technologies.

Advanced structural composites featuring carbon fiber are bonded to the aluminum structure. The wider front wheelhouses, for example, are carbon composites and the passenger compartment floors combine carbon-fiber skins with an ultra-lightweight balsa wood core.

Chassis system

The 2006 Corvette Z06 has a new magnesium cradle that serves as the attachment point for the engine and some front suspension components. Magnesium is lighter than aluminum yet incredibly strong. The magnesium cradle helps improve the front-to-rear weight distribution, as do carbon-fiber front fenders and wheelhouses. Engineers also moved the battery from underhood to a position in the rear cargo area, behind one of the rear wheels.

“This is an instance where the street car uses more advanced material than the racecar,” said Hill. “We’re constrained by rules to run the steel frame in the racecars, but we stretched to bring even more performance technology to the street for out customers.”

The mass reductions are offset by some added performance enablers, including dry-sump lubrication, 3-inch (76.2-mm) exhaust with outlet valves, larger wheels and tires, more power brake and stiffer roll stabilizers.

Suspension, brakes, wheels and tires

The Z06 retains the 106-inch (2686-mm) wheelbase of other Corvette models, as well as the short-long arm suspension and transverse leaf spring design, but it rides on all-new wheels, tires, brakes, as well as its own rear spring and roll stabilizer.

The firmer suspension works harmoniously with large 18 x 9.5-inch cast-spun aluminum wheels and 275/35ZR18 tires in the front, and 19 x 12-inch cast-spun aluminum wheels with 325/30ZR19 tires in the rear – the largest wheel-and-tire combination ever offered on a Corvette. The tires use the latest extended-mobility technology from Goodyear to provide a satisfactory ride, but still allow the vehicle to achieve lateral acceleration of more than 1 g. The extended-mobility tires eliminate the need – and weight – for a spare tire and jack or inflator kit, and reduce the chance of a sudden loss of handling capability.

“The Z06 enables the driver to turn excellent track lap times, but it also is quick to learn and is very forgiving for its performance level,” said Hill. “We tested its capability around the world to ensure it will feel at home on any road or race track.”

Complementing the suspension system and large rolling stock is an equally capable four-wheel disc brake system, consisting of 14-inch (355-mm) vented and cross-drilled front rotors and 13.4-inch (340-mm) vented and cross-drilled rear rotors. For comparison, the ’05 Corvette has 12.8-inch (325-mm) front and 12-inch (305-mm) rear rotors, while the ’05 Corvette with the Z51 has 13.4-inch (340-mm) and 13-inch (330-mm) rotors.

The front rotors are acted upon by huge, red-painted six-piston calipers that use six individual brake pads. Individual brake pads are used because they deliver more equalized wear compared to what would otherwise be a pair of very long single-piece pads. For the rear brakes, four-piston calipers with four individual brake pads are used. A Delphi four-channel ABS system is used, as is a very competent active handling system – complete with a Competitive Driving mode.

The large brakes bring an excellent level of stopping capability with the Z06, and with their four-wheel brake cooling, they provide excellent fade resistance and lining life during track duties.

Distinct design

The new Z06 has an unmistakable and aggressive appearance, with design cues that include:

• A wide front fascia with a large, forward-facing grille opening, a splitter along the bottom and “Gurney lips” along the sides to provide aerodynamic downforce

• A cold air scoop in front of the hood that integrates an air inlet system for the engine

• The trailing edge of the front wheel opening is radiused to achieve improved drag, but protects the body finish with a tough molding, and a large air extractor is located behind the wheel

• A fixed-roof bodystyle optimizes body rigidity and aerodynamics

• Wider rear fenders with flares cover the massive rear tires and a brake cooling scoop in front of the wheels visually balances the fender extractor

• A tall rear spoiler houses the CHMSL on the top of the rear fascia

• 10-spoke wheels

• Four larger stainless steel exhaust outlets

• New-design Z06 badging on the front fenders

While the function of the Z06’s design is to move air efficiently over the body and reduce lift, the net effect is a car that looks like a weight lifter whose muscles are straining the seams of his shirt.

“The Z06 has been sculpted very carefully, with every element in its design serving a performance function,” said Hill. “It also has a purposeful, menacing resemblance to the C6-R.”

The aerodynamics of the Z06’s exterior were shaped by the experiences of the Corvette racing program, where high-speed stability and cornering capability are paramount. And while the racecars use large rear wings, the Z06’s elevated spoiler provides sufficient downforce to balance the road-worthy front splitter without adversely affecting aerodynamic drag. The Z06’s Cd is .342.

Uncompromising amenities

For all its race-inspired functionality, the Z06 is designed to be a daily drivable high-performance vehicle. To that end, comfort and convenience are held to a very high standard. HID lighting, fog lamps, leather seating, dual-zone air conditioning, cabin air filtration and Head-Up Display (HUD) with track mode and g-meter are standard.

The Z06 also has a revised gauge cluster that displays the Z06 logo on the 7000-redline tachometer and has a new readout on the oil pressure gauge to reflect the higher standard pressure of the dry-sump oiling system. And, like other 2006 Corvettes, the Z06 has a new, smaller-diameter three-spoke steering wheel that provides a more agile, performance-oriented feel. The seats feature two-tone leathering surfaces, with Z06-logo embroidery and contrasting stitching.

Z06 options include a Bose audio system with an in-dash six-CD changer, polished wheels, a telescoping steering wheel, heated seats, side air bags, a navigation system with GPS, Homelink and XM Satellite Radio.

But for all its comfort, engineers did sacrifice a few components in the quest for lower weight and higher performance:

• Side bolsters are fixed and more aggressive to better hold the driver when cornering and they weigh less than standard-model seats

• Passenger seat features manual controls, saving the weight of a power-adjust motor

• Acoustic package revised to reduce weight and allow more aural feedback of the powertrain

Production of the 2006 Corvette Z06 will begin in the second half of 2005 at the Bowling Green , Ky. , Assembly Plant.

SPECIFICATIONS

Overview

Models: Chevrolet Corvette coupe and 2006 Corvette Z06

Body styles / driveline: 2-door hatchback coupe with removable roof; rear-wheel drive (coupe);

2-door hatchback coupe with fixed roof; rear-drive (Z06)

Construction: composite body panels, hydroformed steel frame with aluminum and magnesium structural and chassis components (coupe);

composite and carbon-fiber body panels, hydroformed aluminum frame with aluminum and magnesium structural and chassis components (Z06)

Manufacturing location: Bowling Green , Kentucky

Engine 6.0L V-8 LS2 7.0L V-8 LS7

Displacement (cu in / cc): 364 / 5967 427 / 7011.3

Bore & stroke (in / mm): 4 x 3.62 / 101.6 x 92 4.125 x 4 / 104.8 x 101.6

Block material: cast aluminum cast aluminum

Cylinder head material: cast aluminum cast aluminum

Valvetrain: OHV, 2 valves per cylinder OHV, 2 valves per cylinder

Fuel delivery: SFI (sequential fuel injection) SFI (sequential fuel injection)

Compression ratio: 10.9:1 11:1

Horsepower

(hp / kw @ rpm): 400 / 298 @ 6000 500 / 373 @ 6200

Torque (lb-ft / Nm @ rpm): 400 / 542 @ 4400 475 / 657 @ 4800

Recommended fuel: 93 octane (recommended but not required) 93 octane

Estimated fuel economy

(mpg city / hwy / combined): automatic: 18 / 25 / 21

manual: 19 / 28 / 23 TBD

Transmission Corvette coupe Corvette Z06

Type: Hydra-Matic 4L65-E 4-speed auto.; Tremec 6-speed manual Tremec 6-speed manual

Chassis / Suspension

Front: short/long arm ( SLA ) double wishbone, cast aluminum upper & lower control arms, transverse-mounted composite leaf spring, monotube shock absorber short/long arm ( SLA ) double wishbone, cast aluminum upper & lower control arms, transverse-mounted composite leaf spring, monotube shock absorber

Rear: short/long arm ( SLA ) double wishbone, cast aluminum upper & lower control arms, transverse-mounted composite leaf spring, monotube shock absorber short/long arm ( SLA ) double wishbone, cast aluminum upper & lower control arms, transverse-mounted composite leaf spring, monotube shock absorber

Traction control: electronic traction control; Active Handling electronic traction control; Active Handling

Brakes Corvette coupe Corvette Z06

Type: front and rear power-assisted disc with ABS; cross-drilled rotors with Z51 Performance Package front and rear power-assisted disc with ABS with 6-piston front and 4-piston rear calipers, cross-drilled rotors

Rotor diameter x thickness (in / mm): front: 12.8 x 1.26 / 325 x 32

rear: 12 x 1 / 305 x 26;

Z51 Performance Package:

front: 13.4 x 1.26 / 340 x 32

rear: 13 x 1 / 330 x 26 front: 14 x 1.3 / 355 x 32

rear: 13.4 x 1 / 340 x 26

Wheels & Tires

Wheel size: front: 18 inch x 8.5 inch

rear: 19 inch x 10 inch front: 18 inch x 9.5 inch

rear: 19 inch x 12 inch

Tires: Goodyear Eagle F1 GS

Extended Mobility

front: P245/40ZR18

rear: P285/35ZR19 Goodyear Eagle F1 Supercar Extended Mobility

front: P275/35ZR18

rear: P325/30ZR19

Dimensions

Wheelbase (in / mm): 106 / 2629 106 / 2629

Overall length (in / mm): 175 / 4445 175 / 4445

Overall width (in / mm): 73 / 1854 76 / 1930

Overall height (in / mm): 49 / 1244 49 / 1244

Curb weight (lb / kg): 3179 / 1442 3130 / 1419.7

Good info on Z06/C6 differentials:

http://forums.corvetteforum.com/show....php?t=1586766

LS7 weight.

From micro:

Hello,

I did some more research on the new LS7.

The following is from the January 2006 issue of Sports Car International on page 35:

"The net result is a fully trimmed engine that weighs 458 pounds, only 10 more than the 6.0-liter LS2."

Also, BMW's M5 Product Information Guide says that the 5.0 liter 500 hp (SAE net) V-10 weighs 240 kg/529 lbs.

Some aerodynamic info on your Z06.

From: "The Chevrolet Corvette: New Vehicle Engineering and Technical History" published by Society of Automotive Engineers, Inc. It's a collection of SAE and other papers.

2005-01-1943 2006 Chevrolet Corvette C6 Z06 Aerodynamic Development pages 328-333.

"...develop the 2006 Z06 to provide it with improved high speed stability, increased cooling capability and equivalent drag compared to the 2004 C5 Z06."

"...improve front brake flow by 400%." "...200% of the previous flow rate to cool the rear brakes."

Breakdown of lift reduction @ 300 kph

Total 138 kg

Splitter 92 kg 66.7 % of total

Front wheel opening leading edge extensions 10 kg 7.4 % of total

CHMSL spoiler 36 kg 25.9 % of total

CD is the same as the C5 Z06 at .342

and the thread

http://forums.corvetteforum.com/show...2&forum_id=100

Corvette Z06 adds carbon fiber fenders

http://www.compositesworld.com/hpc/i...ovember/1087/1

Molder meets GM's performance, weight-reduction goals and achieves 14,000-part production target with autoclave-cured prepreg.

By Jared Nelson | November 2005

Page: 1 2 3

Since its introduction in 1953, the General Motor's Chevrolet Corvette has been a trendsetter, with its fiberglass body, distinctive body styling and high-horsepower engines. It's also served as a test bed for new GM technologies, particularly in the areas of braking, engine development and new materials. In keeping with that tradition, the 2004 Z06 Corvette Coupe, the version equipped for highest performance, was selected as the test base to determine the feasibility of carbon fiber exterior body parts in a production scenario.

Source: Karl Reque

Corvette Z06 Carbon Fiber Fender

Carbon fiber has had a difficult time breaking into the OEM automotive market. Hot among the tuner crowd, carbon parts sell well in the auto aftermarket, but few have the quality necessary to qualify as original equipment says Donald Lasell, project engineer for composite manufacturer Vermont Composites (Bennington, Vt.). Although DaimlerChrysler and Ford were working carbon into support structures -- the 2003 Dodge Viper's 3,000 pairs of front fender supports (HPC April 2003, p. 32) and the 2004 Ford GT's 4,500 rear decklid inner structures (HPC January 2004, p. 16), Corvette's 2004 LeMans Commemorative Edition Z06 marked the first attempt by a U.S. automaker to produce a carbon exterior body panel. Until that time, carbon parts with Class-A finishes had been the exclusive preserve of Italy's Lamborghini, Britain's McClaren and other hand-built sports cars produced in quantities of a few hundred.

When Tier 1 manufacturer MacLean Quality Composites (West Jordan, Utah) successfully molded, autoclave-cured and delivered 2,100 carbon/epoxy prepreg exterior hood panels for the Z06 LeMans (see HPC, March 2004, p. 33), the landmark achievement spurred GM engineers to pursue more carbon on a future model. A Z06 was not built for model-year 2005, but 7,000 were slated for 2006, offering an ideal platform for pushing the production envelope for autoclaved prepreg.

Equipped with a 505-hp 7.0-liter (427 cubic inch) engine, the 2006 Z06 delivers 23 percent greater power and has a higher top speed (198 mph/319 kmh) than the 2004 model (171 mph/275 kmh), says Dave Hill, Corvette's chief engineer. To maximize the car's power-to-weight ratio, Hill and fellow Corvette engineers sought ways to trim additional pounds from the car's body weight.

Page: 1 2 3

More carbon up front

To determine whether a part is feasible, GM considers five factors in its Part Selection Process: cost per kilogram of mass saved; location on the vehicle; tooling cost; ability to meet or exceed all base vehicle requirements; and paintability at GM's Bowling Green Assembly Plant without paint process modification. The location on the vehicle is critical to vehicle performance and forward locations are preferred. By reducing the weight at the front of the car, the center of gravity is moved further back, away from the engine mass. In addition, reducing the weight at the sides of the car decreases the energy needed to change vehicle direction, thereby reducing rolling moment (the tendency for the car to lean in the direction of the turn) through turns. The change in the center of gravity and reduced rolling moment enable the driver to comfortably maintain higher speeds through corners.

Since it was cost prohibitive to use carbon in both the hood and additional exterior body panels, the front fenders offered the best opportunity to further reduce vehicle mass and improve its performance. GM specified that carbon parts for the 2006 Z06 be made with T600-24K carbon from Toray Composites America Inc. (Tacoma, Wash.), the same fiber used in the Toray P3831C-190 carbon fiber/epoxy prepreg for the 2004 hood. Therefore, there was little doubt that the part could meet performance or paintability requirements. However, the fenders were much more complex parts than the hood, and part variation had to be held to within ±0.75 mm (±0.030 inch). Therefore, the key challenges Vermont faced were in the area of tooling and processing speed.

During the hood project, Lasell was the R&D product engineer at GM responsible for its design and validation. As the hood was moved forward into production, Lasell began development of a carbon fender, but shortly thereafter returned to his home state of Vermont and went back to work with former employer Vermont Composites. GM approached him there and asked Vermont to validate the fender production. Before bidding on the fender contract, however, Vermont had to prove not only to GM but to itself as well, that production of 7,000 sets of fenders was feasible.

Source: Typical Z06 front fender mold, showing removable inserts.

Vermont Composites

Retooling the tools

To do so, Vermont enlisted the help of Models & Tools Inc. (Troy, Mich.) for tool design. The fenders' complex shapes made tooling cost and the potential for die lock primary concerns. Since the Z06 would feature an 35-mm/1.38-inch increase in tire track width over the base model C06, the need for new tooling gave Vermont the opportunity to select more advantageous tooling material than the Invar used for the hood. To reduce the tool's thermal resistance and, as a result, reduce heat-ing and cooling times during the cure cycle, single-sided tools were made from P20 steel, which has a thermal conductivity three times greater than Invar -- 10.8 W/m-°C (225 BTU/in- hr-°F) compared to 32.5 W/m-°C (75 BTU/in-hr-°F), respectively. P20 steel is also much easier to machine than, thus reducing cost.

Source: GM

Close-up of carbon fiber fender in place on the 2006 Corvette Z06

The new P20 steel molds, however, have a CTE of 12.8x10-6 mm/mm-°C (7.1x10-6 in/in-°F) resulting in a greater shrinkage of the tool during the cool-down process. For the hood, heavier Invar tools had been used to take advantage of the almost negligible difference in the coefficient of thermal expansion (CTE) between the carbon and the mold of 5.4x10-6 mm/mm-°C (3x10-6 in/in-°F). To account for the different CTE between the part and the P20 steel tool and avoid die lock, each tool was designed with a main shell and five removable inserts, positioned accurately within the shell by means of tongue-and-groove locators and held in place by vacuum. After cure, the vacuum is released, and inserts can be removed from the shell and part individually to facilitate demolding. The tongue-groove locators permit the inserts to move slightly -- less than 1.6 mm/0.063 inch -- during the cool-down, to accommodate tool shrinkage.

Source: Vermont Composites

A thermal profile model of the airflow inside of Vermont Composite's autoclave as created by Quartus Engineering using IDEAS-ESC.

Each insert is geometrically stable and weighs less than 11.3 kg/25 lb, making it easy for technicians to handle. In addition, each 318 kg/700 lb tool can be made from a single 9,525 kg/21,000 lb forged P20 billet. To minimize post-mold paint prep, the was engineered to strategically place the small, resin-rich flash lines, called "lifter lines," which occur at insert/shell seams, where they could be easily sanded manually during the finishing operation to achieve the necessary Class-A paint surface. To accommodate the almost three-fold increase in part production over the hood, Models & Tools constructed five sets of left-and-right fender tools.

Remodeling the cure cycle

MacLean's greatest challenge in producing the hood had been minimizing the autoclave cure cycle -- a challenge Vermont Composites revisited in the attempt to produce nearly seven times as many fenders. The company contracted with Quartus Engineering (San Diego, Calif.) to model the air flow characteristics in its 1.8m/6 ft by 6.1m/20 ft electrically heated autoclave. Quartus created a virtual 3-D model of Vermont's autoclave, in which four virtual fender tools could be placed and oriented in various ways to determine the ideal position for uniform heating, using I-DEAS finite element analysis software developed by MAYA Heat Transfer Technologies Ltd. (Montreal, Quebec. Canada), a supplier of advanced thermal and fluid flow analysis software. The ESC Flow add-on for the I-DEAS suite is designed to simulate 3-D airflow and thermal behavior, enabling engineers to resolve thermal engineering problems. Once the ideal tool position was established, it was determined analytically that the cure cycle time could be held under 90 minutes, which Vermont Composites validated in subsequent testing. Vermont is currently producing fenders using this positioning with four tools in each cure and maximum capacity of six tools.

Designing a load-worthy layup

Vermont Composites spent a significant amount of time developing what was intended to be a balanced six-ply layup, using unidirectional T600 24K tape impregnated with Toray's G83 quick-cure epoxy resin. But the six-ply schedule lacked sufficient stiffness, resulting in "oil canning," term used when a part tends to retain deflection that results after a load is applied and then removed, rather than springing back to its original shape. To eliminate this problem, two additional plies of prepreg were added to the layup schedule, both in 0° orientation (parallel to the car's length), to increase the part's nominal thickness from 0.8 mm to 1.2 mm (0.031 inch to 0.047 inch). The result was a balanced eight-ply lay-up (0°, 90°, 0°, 0°, 0°, 0°, 90°, 0°). Additional "spot" plies were placed in several select areas where greater stiffness was required.

Ultimately, GM expended $500,000 on the tooling design and modifications, to achieve a weight reduction of 12 kg/26.5 lb per car, meet all part performance and appearance specifications, and was able to manufacture the required 7,000 pairs within production time constraints, making the fender project a big win, notes GM design release engineer Mark Voss.

Looking forward

Vermont Composites has a commit-ment from Toray for enough material to produce the 14,000 fenders per year through 2006, and its contract with GM runs through 2010. However, both GM and Vermont Composites are looking at lower-cost fiber options for the 2007 model year and beyond, working with Toray and other prepreggers. In order for new materials to be used, however, the validation process would have to be repeated to make sure they attain the properties set forth in the GM specification for the material Toray currently supplies. In addition, a new prepreg would have to meet requirements for dimensional stability, surface finish and paint adhesion. Additional cost reductions, however, could help GM justify using the fender on the base Corvette C06, at 160 cars per day, Lasell notes, acknowledging that further improvement will be needed to abbreviate processing time and increase the production rate.

What is torque management?

http://forums.corvetteforum.com/show....php?t=1614438

Changes for 2007:

It’s Official! – Changes for 2007 Corvettes

--------------------------------------------------------------------------------

Just in from Chevrolet… 4/18/06

Exterior Color:

83U Atomic Orange Metallic Tintcoat (a bright chromatic orange), replaces Daytona Sunset Orange Metallic

GM mailed every dealer the new color selection with an actual chip of the new color. It is MUCH brighter and lighter than Daytona Sunset Orange Metallic!!!

Interior:

Two-tone Modified Seats (perforated leather seating surface) with crossed flag embroidery and contrasting stiching.

Available in 026 Red, 316 Cashmere, 846 Titanium

Available on Coupe and Convertible with 2LT or 3LT equipment packages

UK3 Steering-wheel mounted audio controls included with Bose premium audio systems (US9/U3U)

Larger glovebox storage space

UE1 OnStar now available on Z06 with 2LZ equipment group

Enhanced acoustic package reduces road noise and is included with Z06 2LZ equipment group

Bose audio enhancements

New keyless access transmitter with integrated mechanical key

CM7 Power convertible top is now included with Convertible 3LT equipment group

Cross-drilled brake rotors now included with F55 Magnetic Selective Ride Control

New Dealer Accessories Available for 2007:

Racing spoiler

Body side moldings

Racing stripe package

Z06 sillplates

Z06 427 hood badge

Hood blanket with color logo

2007 Order Guide Information

Three models:

1YY07 Corvette Coupe

1YY67 Corvette Convertible

1YY87 Corvette Z06 Coupe

1YY07 Coupe Information:

3 Packages; 1LT, 2LT, 3LT

2 Transmissions: MX0 Automatic, MN6 6 Speed

Options:

F55 Suspension Package

Z51 Suspension Package

QG7 Polished Wheels

QX1 Competition Gray Wheels

QX3 Chrome Wheels

R8C Museum Delivery

U3U Navigation with Single CD

VK3 Front License Plate Bracket

CC3 Transparent Top

C2L Transparent and Painted Top

Interior:

023 Cobalt Red

193 Ebony

313 Cashmere

843 Titanium

026 Cobalt Red Two Tone

316 Cashmere Two Tone

846 Titanium Two Tone

Colors:

10U Arctic White

19U LeMans Blue Metallic

41U Black

45U Velocity Yellow Tintcoat

67U Machine Silver Metallic

74U Victory Red

80U Monterey Red Metallic

83U Atomic Orange Metallic Tintcoat

1YY67 Convertible Information:

2 Packages; 2LT, 3LT

2 Transmissions: MX0 Automatic, MN6 6 Speed

Options:

CM7 Power Convertible Top

F55 Suspension Package

Z51 Suspension Package

QG7 Polished Wheels

QX1 Competition Gray Wheels

QX3 Chrome Wheels

R8C Museum Delivery

U3U Navigation with Single CD

VK3 Front License Plate Bracket

Interior:

023 Cobalt Red

193 Ebony

313 Cashmere

843 Titanium

026 Cobalt Red Two Tone

316 Cashmere Two Tone

846 Titanium Two Tone

Colors:

10U Arctic White

19U LeMans Blue Metallic

41U Black

45U Velocity Yellow Tintcoat

67U Machine Silver Metallic

74U Victory Red

80U Monterey Red Metallic

83U Atomic Orange Metallic Tintcoat

Top Colors:

29T Storm Gray

35T Beige

41T Black

1YY87 Z06 Coupe Information:

2 Packages; 1LZ, 2LZ

1 Transmissions: MN6 6 Speed

Options:

QL9 Polished Wheels

Q44 Competition Gray Wheels

R8C Museum Delivery

U3U Navigation with Single CD

VK3 Front License Plate Bracket

Interior:

023 Cobalt Red

193 Ebony

843 Titanium

Colors:

19U LeMans Blue Metallic

41U Black

45U Velocity Yellow Tintcoat

67U Machine Silver Metallic

74U Victory Red

83U Atomic Orange Metallic Tintcoat

Quick word search: Press control F and you will get a find box. Type in whatever you are looking for ie: brakes and zip right to the next mention of that keyword.

Table of Contents:

Post #1 General technical info and specs; 07 Changes

Post #2 Corvetteforum acronyms

Post #3 Z06 vs. other cars

Post #4 Info about the aluminum frame

Post #5 The dry sump & how to change the oil

Post #6 FAQ on the C5 Z06

Post #7 How to read tire info & what it means

Post #8 Magnuson Moss warranty act

Post #9 Transmission gear ratios

Post #10 Cell phone mounting

Post #11 Weight difference between 1LZ & 2LZ option pkgs

Post #12 Explanations of spoilers and wings

Post #13/14/15 LS7 cam specs & heads and flow #s

Post #16 Z06 problems

Post #17 The history of Corvette name and symbol

Post #18 How to take better pics of your Corvette

Post #19/20 C6 Z06 Nurburgring test pics

Post #21 Nurburgring info, vids, threads

Post #22 Scanned Car&Driver and Motor Trend articles

Post #23 Is it Z oh 6 or Z zero 6?

Post #24 The 2006 C6/Z06 manual

Post #25 Dyno runs

Post #26 Octane discussion and explanation

Post #27 C6 Z06 brake discussions.

Post #28 Convertible discussions

Post #29 Track Reviews, harness bars, suspension discussions, etc.

Post #30 Z06 specific part numbers

Post #31 Wheel and Tire section

Post #32 How to install a switch for muffler valve activation

Post #33 Sound reduction for the C6 Z06

Post #34 LS1 vs. LS7 crank pics

Post #35 Bolt torque specs

Post #36 Weight reduction

Post #37 Tire Pressure Sensor Reset

Post #38 iPod your car

Post #39 Front license plate mounting

Post #40 Do you need a Cold Air Intake on the C6 Z06?

Post #41 & 42 & 43 Jacking procedures

Post #44 Drag racing discussions

Post #45 Emissions control pads in the intake snorkel

Post #46 The Official "Top Gear/Fifth Gear" Video Library

Post #47 How to modify your stock muffler

Post #48 How to clean your clutch reservoir.

Post #49 Xeon fog lights

Post #50 DIY – Rear Axle / Differential oil change, with pics

Post #51 Katech How-To: Check lifter preload

Post #52 Our own Congaman's videos!

Post #53 How to find who built your engine.

Post #54 Skip shift eliminator (CAGS)

Post #55 Summary of the Axle Shaft Issue for FAQ

How to post pics, etc. our Help section.

http://forums.corvetteforum.com/forumdisplay.php?f=31

Check out the C6 Gen FAQ sticky

http://forums.corvetteforum.com/show...81&forum_id=74

It will answer many questions that the C6 and Z06 have in common like Nav and radio questions, etc.

23 Page Z06 fact book.

http://forums.corvetteforum.com/show...1&forum_id=100

Originally Posted by Another Yellow

The official final total build for the 2006 Z06 is 6,257.

Of the 6,257 Z06 built for 2006, 309 went to Canada and 361 to Europe.

The color breakdown for the Z06 only:

Black 27%

Yellow 22%

Red 19%

Silver 16%

Blue 11%

Orange 5%

89% were 2LZ

In addition to the 6,257 Z06, there were 16,588 coupes and 11,147 verts built for a total production of 33,992 for model year 2006.

Frank

Of the 6,257 Z06 built for 2006, 309 went to Canada and 361 to Europe.

The color breakdown for the Z06 only:

Black 27%

Yellow 22%

Red 19%

Silver 16%

Blue 11%

Orange 5%

89% were 2LZ

In addition to the 6,257 Z06, there were 16,588 coupes and 11,147 verts built for a total production of 33,992 for model year 2006.

Frank

Originally Posted by MONTVALEGOLF

Final 2006 Corvette production numbers:::

Total '06 build .. 34,021

Total '06 Z06 production .. 6,272 .. 18.4%

Total: Lemans Blue Z06 Build amount---671.. 10.7%

Black 1,672.. 26.7%

Machine Silver 978 .. 15.6%

DSOrange M 282.. 4.5%

VRed 1,205.. 19.2%

VYellow 1,464.. 23.3%

Regards, Mike Thanks JDogg for all your help!

Total '06 build .. 34,021

Total '06 Z06 production .. 6,272 .. 18.4%

Total: Lemans Blue Z06 Build amount---671.. 10.7%

Black 1,672.. 26.7%

Machine Silver 978 .. 15.6%

DSOrange M 282.. 4.5%

VRed 1,205.. 19.2%

VYellow 1,464.. 23.3%

Regards, Mike Thanks JDogg for all your help!

INFORMATION PROVIDED BY GENERAL MOTORS

2006 specs are up:

http://www.chevrolet.com/corvette/

CORVETTE Z06: RACING SUCCESS HELPS BREED THE FASTEST, MOST POWERFUL PRODUCTION CORVETTE EVER BUILT

DETROIT – By winning every race in the 2004 season, the Corvette C5-R racing team wrapped up the most successful era in Corvette’s 50-year racing history. In its five years, the C5-R racing program took 35 victories in 55 races, four American Le Mans Series championships and three double victories at the 24 Hours of Le Mans .

The Z06 sparked the second half of the C5’s life span with a Corvette model for the extreme performance enthusiast. Now, Team Corvette combines the numerous attributes of the sixth-generation Corvette with the technology and winning determination from the C5-R program to take the new Z06 to the next level in total performance.

Chevrolet introduced the 2006 Corvette Z06 at the North American International Auto Show. It is the fastest, most powerful car ever offered by Chevrolet and General Motors. It is comprised of an unprecedented level of capability and technology, making it one of the greatest performance values on the market. And with an unmistakably muscular appearance, the ’06 Z06 has a visual attitude that always looks ready to demonstrate Corvette’s winning attitude to any challenger around the globe.

“The new Z06 is the dividend from competing so successfully in endurance racing,” said Dave Hill, Corvette’s chief engineer. “It combines the strong attributes of the new, sixth-generation Corvette with the spirit, technology and know-how from the race program to form an American supercar with outstanding credentials.”

The new Z06 achieves 500 horsepower in an approximately 3130-pound (1419.7 kg) package and is expected to deliver 0-60 performance of less than 4 seconds, eclipse the quarter-mile in less than 12 seconds and deliver a top speed of more than 190 mph on a race track.

The links between racing and the production Z06 are both direct and indirect, as the vehicle was developed in conjunction with the forthcoming C6-R racecar, but they boil down to the application of lessons that could only have been learned after countless laps of endurance racing – everything from suspension geometry to aerodynamics. What the engineers developed was a totally unique vehicle that has its own powertrain, body structure and chassis system which are distinct from other Corvette models.

Previous Z06 models, from the original 1963 model to the 2001-04 editions, incorporated suspension and/or engine upgrades that complemented existing Corvette systems. Not surprisingly, the specs for the ’06 read like the blueprint of a champion. They include:

• LS7 7.0-liter/427-cubic-inch Gen IV V-8 with lightweight reciprocating components

• 500 horsepower (373 kw) at6200 rpm

• 475 lb.-ft. of torque (657 Nm) at 4800 rpm

• 7000 rpm redline

• Titanium connecting rods and intake valves

• Dry-sump engine lubrication system

• Engine hand-built at GM’s new Performance Build Center

• Aluminum body structure with one-piece hydroformed perimeter rails frame and magnesium front cradle

• Fixed roof design optimizes body rigidity and aerodynamics

• Carbon-fiber composite front fenders and front wheelhouses

• Unique front fascia incorporating a larger grille, cold-air scoop and lower air splitter

• Wide-body rear fenders and a unique rear spoiler incorporated with the CHMSL

• Huge 14-inch (355-mm) cross-drilled front disc brakes with six-piston calipers and 13.4-inch (340-mm) cross-drilled rear rotors with four-piston calipers

• 18 x 9.5-inch front wheels with 275/35ZR18 tires and 19 x 12-inch rear wheels with 325/30ZR19 tires

• 3-inch-diameter exhaust with bi-mode mufflers and larger polished stainless steel tips

• Engine, transmission and differential oil coolers; and steering cooler

• Rear-mounted battery to improve weight distribution

• Unique interior features including revised gauge cluster and lightweight two-tone seats with more aggressive bolsters

• Curb weight of 3130 pounds / 1419.7 kg (estimated)

• 3 inches (76.2 mm) wider than other Corvette models

• Vehicle developed simultaneously with C6-R racecar.

The features above are merely the highline points of the comprehensively designed Z06. What follows is a closer look at the vehicle’s unique attributes.

LS7 engine

The all-new LS7 of the ’06 Z06 reintroduces the 427-cubic-inch engine to the Corvette lineup. Unlike the previous 427 engine, which was a big-block design, the new 7.0-liter LS7 is a small-block V-8 – the largest-displacement small-block ever produced by GM and a tribute to its 50 years as a performance icon.

With 500 horsepower and 475 lb.-ft. of torque, it also is the most powerful passenger car engine ever produced by Chevrolet and GM. The LS7 is easily identified under the hood by red engine covers with black lettering.

The LS7 shares the same basic Gen IV V-8 architecture as the Corvette’s 6.0-liter LS2, but the LS7 uses a different cylinder block casting with pressed-in steel cylinder liners to accommodate the engine’s wide, 104.8-mm-wide cylinder bores; the LS2 has 101.6-mm bores. And when compared to the LS2, the LS7 also has a different front cover, oil pan, exhaust manifolds and cylinder heads.

Internally, the LS7’s reciprocating components make use of racing-derived lightweight technology, including titanium connecting rods and intake valves, to help boost horsepower and rpm capability. The rpm fuel shut-off limit is 7000 rpm.

The LS7’s specifications include:

• Unique cylinder block casting with large, 104.8-mm bores and pressed-in cylinder liners

• Forged steel main bearing caps

• Forged steel crankshaft

• Titanium connecting rods with 101.6-mm stroke

• Cast aluminum flat-top pistons

• 11.0:1 compression

• Dry-sump oiling system

• Camshaft with .591-inch lift

• Racing-derived CNC-ported aluminum cylinder heads with titanium intake valves and sodium-filled exhaust valves

• Titanium pushrods and valve springs

• Low-restriction air intake system

• Hydroformed exhaust headers with unique “quad flow” collector flanges.

“In many ways, the LS7 is a racing engine in a street car,” said Dave Muscaro, assistant chief engineer of small-block V-8 for passenger cars. “We’ve taken much of what we’ve learned over the years from the 7.0-liter C5-R racing program and instilled it here. There really has been nothing else like it offered in a GM production vehicle.”

One of the clearest examples of the LS7’s race-bred technology is its use of titanium connecting rods. They weigh just 480 grams apiece, almost 30 percent less than the rods in the LS2 V-8. Besides being lightweight, which enhances high-rpm performance and rpm range, titanium makes the rods extremely durable.

The LS7’s CNC-ported aluminum cylinder heads are all-new and designed to meet the high airflow demands of the engine’s 7.0-liter displacement, as it ingests approximately 100 cubic feet more air per minute than the Corvette’s 6.0-liter LS2 V-8 – an 18-percent increase in airflow. Consequently, a hydraulic roller camshaft with .591/.591-inch valve lift is used to allow plenty of air to circulate in and out of the engine.

To ensure optimal, uninterrupted airflow, the LS7’s heads have straight, tunnel-like intake runners. Very large by production-vehicle standards – even racing standards – they are designed to maintain fast airflow velocity, providing excellent torque at low rpm and exhilarating horsepower at high rpm. The heads feature 70-cc combustion chambers which are fed by huge, 56-mm-diameter titanium intake valves. The lightweight titanium valves weigh 21grams less than the stainless steel valves used in the LS2, despite the valve head having 22 percent more area. They are complemented by 41-mm sodium-filled exhaust valves, vs. 39.4-mm valves in the LS2. To accommodate the large valve face diameters, the heads’ valve seats are siamesed; and, taken from experience with the engines of C5-R racecars, the LS7’s valve angles are held at 12 degrees – versus 15 degrees for the LS2 – to enhance airflow through the ports.

All LS7 engines are assembled by hand at GM Powertrain’s new Performance Build Center in Wixom , Mich. The exacting standards to which they are built include deck-plate honing of the cylinders – a procedure normally associated with the building of racing engines and almost unheard of in a production-vehicle engine.

Dry sump oiling system

The LS7 has a dry-sump oiling system designed to keep the engine fully lubricated during the high cornering loads the Corvette Z06 is capable of producing. An engine compartment-mounted 8-quart reservoir delivers oil at a constant pressure to a conventional-style oil pump pick-up at the bottom of the engine. The pressurized oil feed keeps the oil pick-up continually immersed in oil at cornering loads exceeding 1 g.

Oil circulates through the engine and down to the oil pan, where it is sent back to the reservoir via a scavenge pump. The large-capacity reservoir, combined with a high efficiency air-to-oil cooler, provides necessary engine oil cooling under the demands of the engine’s power output. With the dry-sump system, oil is added to the engine via the reservoir tank – which includes the oil level dipstick.

The LS7’s dry-sump system was developed and tested on racetracks in the United States and Europe , including Germany ’s famed Nürburgring. And while common in racing cars, the Corvette Z06 is one of just a handful of production vehicles – and the only production Corvette – to ever incorporate such a high-performance oiling system.

Drivetrain

The Corvette Z06’s powertrain and drivetrain systems are matched to the LS7’s performance capability. The light, four-into-one headers discharge in to new, close-coupled catalytic converters and through to new “bi-modal” mufflers. The mufflers each feature a vacuum-actuated outlet valve, which controls exhaust noise during low-load operation but opens for maximum power.

At the rear of the LS7 engine, a single-mass flywheel and lightweight, high-capacity clutch channel torque to the rear transaxle. The six-speed manual transmission has been strengthened to handle the LS7’s increased torque load. The transmission includes a pump which sends transmission fluid to the front radiator for cooling. Upon its return, the fluid removes additional heat from the differential lube before returning to the transmission.

The M6 transmission connects to a limited-slip differential, with enlarged ring and pinion gears. Stronger axle half-shafts with tougher universal joints transmit power to the rear wheels.

Body structure

The Z06 has a unique aluminum body structure for optimum stiffness and light weight for the fixed-roof bodystyle. Perimeter rails are one-piece hydroformed members featuring cast suspension nodes, which replace many welded steel components on other Corvette models. Other castings, stampings and extrusions are combined into the innovative structure with state-of-the-art manufacturing technologies.

Advanced structural composites featuring carbon fiber are bonded to the aluminum structure. The wider front wheelhouses, for example, are carbon composites and the passenger compartment floors combine carbon-fiber skins with an ultra-lightweight balsa wood core.

Chassis system

The 2006 Corvette Z06 has a new magnesium cradle that serves as the attachment point for the engine and some front suspension components. Magnesium is lighter than aluminum yet incredibly strong. The magnesium cradle helps improve the front-to-rear weight distribution, as do carbon-fiber front fenders and wheelhouses. Engineers also moved the battery from underhood to a position in the rear cargo area, behind one of the rear wheels.

“This is an instance where the street car uses more advanced material than the racecar,” said Hill. “We’re constrained by rules to run the steel frame in the racecars, but we stretched to bring even more performance technology to the street for out customers.”

The mass reductions are offset by some added performance enablers, including dry-sump lubrication, 3-inch (76.2-mm) exhaust with outlet valves, larger wheels and tires, more power brake and stiffer roll stabilizers.

Suspension, brakes, wheels and tires

The Z06 retains the 106-inch (2686-mm) wheelbase of other Corvette models, as well as the short-long arm suspension and transverse leaf spring design, but it rides on all-new wheels, tires, brakes, as well as its own rear spring and roll stabilizer.

The firmer suspension works harmoniously with large 18 x 9.5-inch cast-spun aluminum wheels and 275/35ZR18 tires in the front, and 19 x 12-inch cast-spun aluminum wheels with 325/30ZR19 tires in the rear – the largest wheel-and-tire combination ever offered on a Corvette. The tires use the latest extended-mobility technology from Goodyear to provide a satisfactory ride, but still allow the vehicle to achieve lateral acceleration of more than 1 g. The extended-mobility tires eliminate the need – and weight – for a spare tire and jack or inflator kit, and reduce the chance of a sudden loss of handling capability.

“The Z06 enables the driver to turn excellent track lap times, but it also is quick to learn and is very forgiving for its performance level,” said Hill. “We tested its capability around the world to ensure it will feel at home on any road or race track.”

Complementing the suspension system and large rolling stock is an equally capable four-wheel disc brake system, consisting of 14-inch (355-mm) vented and cross-drilled front rotors and 13.4-inch (340-mm) vented and cross-drilled rear rotors. For comparison, the ’05 Corvette has 12.8-inch (325-mm) front and 12-inch (305-mm) rear rotors, while the ’05 Corvette with the Z51 has 13.4-inch (340-mm) and 13-inch (330-mm) rotors.

The front rotors are acted upon by huge, red-painted six-piston calipers that use six individual brake pads. Individual brake pads are used because they deliver more equalized wear compared to what would otherwise be a pair of very long single-piece pads. For the rear brakes, four-piston calipers with four individual brake pads are used. A Delphi four-channel ABS system is used, as is a very competent active handling system – complete with a Competitive Driving mode.

The large brakes bring an excellent level of stopping capability with the Z06, and with their four-wheel brake cooling, they provide excellent fade resistance and lining life during track duties.

Distinct design

The new Z06 has an unmistakable and aggressive appearance, with design cues that include:

• A wide front fascia with a large, forward-facing grille opening, a splitter along the bottom and “Gurney lips” along the sides to provide aerodynamic downforce

• A cold air scoop in front of the hood that integrates an air inlet system for the engine

• The trailing edge of the front wheel opening is radiused to achieve improved drag, but protects the body finish with a tough molding, and a large air extractor is located behind the wheel

• A fixed-roof bodystyle optimizes body rigidity and aerodynamics

• Wider rear fenders with flares cover the massive rear tires and a brake cooling scoop in front of the wheels visually balances the fender extractor

• A tall rear spoiler houses the CHMSL on the top of the rear fascia

• 10-spoke wheels

• Four larger stainless steel exhaust outlets

• New-design Z06 badging on the front fenders

While the function of the Z06’s design is to move air efficiently over the body and reduce lift, the net effect is a car that looks like a weight lifter whose muscles are straining the seams of his shirt.

“The Z06 has been sculpted very carefully, with every element in its design serving a performance function,” said Hill. “It also has a purposeful, menacing resemblance to the C6-R.”

The aerodynamics of the Z06’s exterior were shaped by the experiences of the Corvette racing program, where high-speed stability and cornering capability are paramount. And while the racecars use large rear wings, the Z06’s elevated spoiler provides sufficient downforce to balance the road-worthy front splitter without adversely affecting aerodynamic drag. The Z06’s Cd is .342.

Uncompromising amenities

For all its race-inspired functionality, the Z06 is designed to be a daily drivable high-performance vehicle. To that end, comfort and convenience are held to a very high standard. HID lighting, fog lamps, leather seating, dual-zone air conditioning, cabin air filtration and Head-Up Display (HUD) with track mode and g-meter are standard.

The Z06 also has a revised gauge cluster that displays the Z06 logo on the 7000-redline tachometer and has a new readout on the oil pressure gauge to reflect the higher standard pressure of the dry-sump oiling system. And, like other 2006 Corvettes, the Z06 has a new, smaller-diameter three-spoke steering wheel that provides a more agile, performance-oriented feel. The seats feature two-tone leathering surfaces, with Z06-logo embroidery and contrasting stitching.

Z06 options include a Bose audio system with an in-dash six-CD changer, polished wheels, a telescoping steering wheel, heated seats, side air bags, a navigation system with GPS, Homelink and XM Satellite Radio.

But for all its comfort, engineers did sacrifice a few components in the quest for lower weight and higher performance:

• Side bolsters are fixed and more aggressive to better hold the driver when cornering and they weigh less than standard-model seats

• Passenger seat features manual controls, saving the weight of a power-adjust motor

• Acoustic package revised to reduce weight and allow more aural feedback of the powertrain

Production of the 2006 Corvette Z06 will begin in the second half of 2005 at the Bowling Green , Ky. , Assembly Plant.

SPECIFICATIONS

Overview

Models: Chevrolet Corvette coupe and 2006 Corvette Z06

Body styles / driveline: 2-door hatchback coupe with removable roof; rear-wheel drive (coupe);

2-door hatchback coupe with fixed roof; rear-drive (Z06)

Construction: composite body panels, hydroformed steel frame with aluminum and magnesium structural and chassis components (coupe);

composite and carbon-fiber body panels, hydroformed aluminum frame with aluminum and magnesium structural and chassis components (Z06)

Manufacturing location: Bowling Green , Kentucky

Engine 6.0L V-8 LS2 7.0L V-8 LS7

Displacement (cu in / cc): 364 / 5967 427 / 7011.3

Bore & stroke (in / mm): 4 x 3.62 / 101.6 x 92 4.125 x 4 / 104.8 x 101.6

Block material: cast aluminum cast aluminum

Cylinder head material: cast aluminum cast aluminum

Valvetrain: OHV, 2 valves per cylinder OHV, 2 valves per cylinder

Fuel delivery: SFI (sequential fuel injection) SFI (sequential fuel injection)

Compression ratio: 10.9:1 11:1

Horsepower

(hp / kw @ rpm): 400 / 298 @ 6000 500 / 373 @ 6200

Torque (lb-ft / Nm @ rpm): 400 / 542 @ 4400 475 / 657 @ 4800

Recommended fuel: 93 octane (recommended but not required) 93 octane

Estimated fuel economy

(mpg city / hwy / combined): automatic: 18 / 25 / 21

manual: 19 / 28 / 23 TBD

Transmission Corvette coupe Corvette Z06

Type: Hydra-Matic 4L65-E 4-speed auto.; Tremec 6-speed manual Tremec 6-speed manual

Chassis / Suspension

Front: short/long arm ( SLA ) double wishbone, cast aluminum upper & lower control arms, transverse-mounted composite leaf spring, monotube shock absorber short/long arm ( SLA ) double wishbone, cast aluminum upper & lower control arms, transverse-mounted composite leaf spring, monotube shock absorber

Rear: short/long arm ( SLA ) double wishbone, cast aluminum upper & lower control arms, transverse-mounted composite leaf spring, monotube shock absorber short/long arm ( SLA ) double wishbone, cast aluminum upper & lower control arms, transverse-mounted composite leaf spring, monotube shock absorber

Traction control: electronic traction control; Active Handling electronic traction control; Active Handling

Brakes Corvette coupe Corvette Z06

Type: front and rear power-assisted disc with ABS; cross-drilled rotors with Z51 Performance Package front and rear power-assisted disc with ABS with 6-piston front and 4-piston rear calipers, cross-drilled rotors

Rotor diameter x thickness (in / mm): front: 12.8 x 1.26 / 325 x 32

rear: 12 x 1 / 305 x 26;

Z51 Performance Package:

front: 13.4 x 1.26 / 340 x 32

rear: 13 x 1 / 330 x 26 front: 14 x 1.3 / 355 x 32

rear: 13.4 x 1 / 340 x 26

Wheels & Tires

Wheel size: front: 18 inch x 8.5 inch

rear: 19 inch x 10 inch front: 18 inch x 9.5 inch

rear: 19 inch x 12 inch

Tires: Goodyear Eagle F1 GS

Extended Mobility

front: P245/40ZR18

rear: P285/35ZR19 Goodyear Eagle F1 Supercar Extended Mobility

front: P275/35ZR18

rear: P325/30ZR19

Dimensions

Wheelbase (in / mm): 106 / 2629 106 / 2629

Overall length (in / mm): 175 / 4445 175 / 4445

Overall width (in / mm): 73 / 1854 76 / 1930

Overall height (in / mm): 49 / 1244 49 / 1244

Curb weight (lb / kg): 3179 / 1442 3130 / 1419.7

Good info on Z06/C6 differentials:

http://forums.corvetteforum.com/show....php?t=1586766

LS7 weight.

From micro:

Hello,

I did some more research on the new LS7.

The following is from the January 2006 issue of Sports Car International on page 35:

"The net result is a fully trimmed engine that weighs 458 pounds, only 10 more than the 6.0-liter LS2."

Also, BMW's M5 Product Information Guide says that the 5.0 liter 500 hp (SAE net) V-10 weighs 240 kg/529 lbs.

Some aerodynamic info on your Z06.

From: "The Chevrolet Corvette: New Vehicle Engineering and Technical History" published by Society of Automotive Engineers, Inc. It's a collection of SAE and other papers.

2005-01-1943 2006 Chevrolet Corvette C6 Z06 Aerodynamic Development pages 328-333.

"...develop the 2006 Z06 to provide it with improved high speed stability, increased cooling capability and equivalent drag compared to the 2004 C5 Z06."

"...improve front brake flow by 400%." "...200% of the previous flow rate to cool the rear brakes."

Breakdown of lift reduction @ 300 kph

Total 138 kg

Splitter 92 kg 66.7 % of total

Front wheel opening leading edge extensions 10 kg 7.4 % of total

CHMSL spoiler 36 kg 25.9 % of total

CD is the same as the C5 Z06 at .342

and the thread

http://forums.corvetteforum.com/show...2&forum_id=100

Corvette Z06 adds carbon fiber fenders

http://www.compositesworld.com/hpc/i...ovember/1087/1

Molder meets GM's performance, weight-reduction goals and achieves 14,000-part production target with autoclave-cured prepreg.

By Jared Nelson | November 2005

Page: 1 2 3

Since its introduction in 1953, the General Motor's Chevrolet Corvette has been a trendsetter, with its fiberglass body, distinctive body styling and high-horsepower engines. It's also served as a test bed for new GM technologies, particularly in the areas of braking, engine development and new materials. In keeping with that tradition, the 2004 Z06 Corvette Coupe, the version equipped for highest performance, was selected as the test base to determine the feasibility of carbon fiber exterior body parts in a production scenario.

Source: Karl Reque

Corvette Z06 Carbon Fiber Fender

Carbon fiber has had a difficult time breaking into the OEM automotive market. Hot among the tuner crowd, carbon parts sell well in the auto aftermarket, but few have the quality necessary to qualify as original equipment says Donald Lasell, project engineer for composite manufacturer Vermont Composites (Bennington, Vt.). Although DaimlerChrysler and Ford were working carbon into support structures -- the 2003 Dodge Viper's 3,000 pairs of front fender supports (HPC April 2003, p. 32) and the 2004 Ford GT's 4,500 rear decklid inner structures (HPC January 2004, p. 16), Corvette's 2004 LeMans Commemorative Edition Z06 marked the first attempt by a U.S. automaker to produce a carbon exterior body panel. Until that time, carbon parts with Class-A finishes had been the exclusive preserve of Italy's Lamborghini, Britain's McClaren and other hand-built sports cars produced in quantities of a few hundred.

When Tier 1 manufacturer MacLean Quality Composites (West Jordan, Utah) successfully molded, autoclave-cured and delivered 2,100 carbon/epoxy prepreg exterior hood panels for the Z06 LeMans (see HPC, March 2004, p. 33), the landmark achievement spurred GM engineers to pursue more carbon on a future model. A Z06 was not built for model-year 2005, but 7,000 were slated for 2006, offering an ideal platform for pushing the production envelope for autoclaved prepreg.

Equipped with a 505-hp 7.0-liter (427 cubic inch) engine, the 2006 Z06 delivers 23 percent greater power and has a higher top speed (198 mph/319 kmh) than the 2004 model (171 mph/275 kmh), says Dave Hill, Corvette's chief engineer. To maximize the car's power-to-weight ratio, Hill and fellow Corvette engineers sought ways to trim additional pounds from the car's body weight.

Page: 1 2 3

More carbon up front

To determine whether a part is feasible, GM considers five factors in its Part Selection Process: cost per kilogram of mass saved; location on the vehicle; tooling cost; ability to meet or exceed all base vehicle requirements; and paintability at GM's Bowling Green Assembly Plant without paint process modification. The location on the vehicle is critical to vehicle performance and forward locations are preferred. By reducing the weight at the front of the car, the center of gravity is moved further back, away from the engine mass. In addition, reducing the weight at the sides of the car decreases the energy needed to change vehicle direction, thereby reducing rolling moment (the tendency for the car to lean in the direction of the turn) through turns. The change in the center of gravity and reduced rolling moment enable the driver to comfortably maintain higher speeds through corners.

Since it was cost prohibitive to use carbon in both the hood and additional exterior body panels, the front fenders offered the best opportunity to further reduce vehicle mass and improve its performance. GM specified that carbon parts for the 2006 Z06 be made with T600-24K carbon from Toray Composites America Inc. (Tacoma, Wash.), the same fiber used in the Toray P3831C-190 carbon fiber/epoxy prepreg for the 2004 hood. Therefore, there was little doubt that the part could meet performance or paintability requirements. However, the fenders were much more complex parts than the hood, and part variation had to be held to within ±0.75 mm (±0.030 inch). Therefore, the key challenges Vermont faced were in the area of tooling and processing speed.

During the hood project, Lasell was the R&D product engineer at GM responsible for its design and validation. As the hood was moved forward into production, Lasell began development of a carbon fender, but shortly thereafter returned to his home state of Vermont and went back to work with former employer Vermont Composites. GM approached him there and asked Vermont to validate the fender production. Before bidding on the fender contract, however, Vermont had to prove not only to GM but to itself as well, that production of 7,000 sets of fenders was feasible.

Source: Typical Z06 front fender mold, showing removable inserts.

Vermont Composites

Retooling the tools

To do so, Vermont enlisted the help of Models & Tools Inc. (Troy, Mich.) for tool design. The fenders' complex shapes made tooling cost and the potential for die lock primary concerns. Since the Z06 would feature an 35-mm/1.38-inch increase in tire track width over the base model C06, the need for new tooling gave Vermont the opportunity to select more advantageous tooling material than the Invar used for the hood. To reduce the tool's thermal resistance and, as a result, reduce heat-ing and cooling times during the cure cycle, single-sided tools were made from P20 steel, which has a thermal conductivity three times greater than Invar -- 10.8 W/m-°C (225 BTU/in- hr-°F) compared to 32.5 W/m-°C (75 BTU/in-hr-°F), respectively. P20 steel is also much easier to machine than, thus reducing cost.

Source: GM

Close-up of carbon fiber fender in place on the 2006 Corvette Z06

The new P20 steel molds, however, have a CTE of 12.8x10-6 mm/mm-°C (7.1x10-6 in/in-°F) resulting in a greater shrinkage of the tool during the cool-down process. For the hood, heavier Invar tools had been used to take advantage of the almost negligible difference in the coefficient of thermal expansion (CTE) between the carbon and the mold of 5.4x10-6 mm/mm-°C (3x10-6 in/in-°F). To account for the different CTE between the part and the P20 steel tool and avoid die lock, each tool was designed with a main shell and five removable inserts, positioned accurately within the shell by means of tongue-and-groove locators and held in place by vacuum. After cure, the vacuum is released, and inserts can be removed from the shell and part individually to facilitate demolding. The tongue-groove locators permit the inserts to move slightly -- less than 1.6 mm/0.063 inch -- during the cool-down, to accommodate tool shrinkage.

Source: Vermont Composites

A thermal profile model of the airflow inside of Vermont Composite's autoclave as created by Quartus Engineering using IDEAS-ESC.

Each insert is geometrically stable and weighs less than 11.3 kg/25 lb, making it easy for technicians to handle. In addition, each 318 kg/700 lb tool can be made from a single 9,525 kg/21,000 lb forged P20 billet. To minimize post-mold paint prep, the was engineered to strategically place the small, resin-rich flash lines, called "lifter lines," which occur at insert/shell seams, where they could be easily sanded manually during the finishing operation to achieve the necessary Class-A paint surface. To accommodate the almost three-fold increase in part production over the hood, Models & Tools constructed five sets of left-and-right fender tools.

Remodeling the cure cycle

MacLean's greatest challenge in producing the hood had been minimizing the autoclave cure cycle -- a challenge Vermont Composites revisited in the attempt to produce nearly seven times as many fenders. The company contracted with Quartus Engineering (San Diego, Calif.) to model the air flow characteristics in its 1.8m/6 ft by 6.1m/20 ft electrically heated autoclave. Quartus created a virtual 3-D model of Vermont's autoclave, in which four virtual fender tools could be placed and oriented in various ways to determine the ideal position for uniform heating, using I-DEAS finite element analysis software developed by MAYA Heat Transfer Technologies Ltd. (Montreal, Quebec. Canada), a supplier of advanced thermal and fluid flow analysis software. The ESC Flow add-on for the I-DEAS suite is designed to simulate 3-D airflow and thermal behavior, enabling engineers to resolve thermal engineering problems. Once the ideal tool position was established, it was determined analytically that the cure cycle time could be held under 90 minutes, which Vermont Composites validated in subsequent testing. Vermont is currently producing fenders using this positioning with four tools in each cure and maximum capacity of six tools.

Designing a load-worthy layup

Vermont Composites spent a significant amount of time developing what was intended to be a balanced six-ply layup, using unidirectional T600 24K tape impregnated with Toray's G83 quick-cure epoxy resin. But the six-ply schedule lacked sufficient stiffness, resulting in "oil canning," term used when a part tends to retain deflection that results after a load is applied and then removed, rather than springing back to its original shape. To eliminate this problem, two additional plies of prepreg were added to the layup schedule, both in 0° orientation (parallel to the car's length), to increase the part's nominal thickness from 0.8 mm to 1.2 mm (0.031 inch to 0.047 inch). The result was a balanced eight-ply lay-up (0°, 90°, 0°, 0°, 0°, 0°, 90°, 0°). Additional "spot" plies were placed in several select areas where greater stiffness was required.

Ultimately, GM expended $500,000 on the tooling design and modifications, to achieve a weight reduction of 12 kg/26.5 lb per car, meet all part performance and appearance specifications, and was able to manufacture the required 7,000 pairs within production time constraints, making the fender project a big win, notes GM design release engineer Mark Voss.

Looking forward