[Z06] More bad guides *video inside*

#201

Though one may never be able to prove that it did in fact happen, it has been said all over the internet that; the absence of evidence is not the evidence of absence.

That means that a brand new Z06 might have out of spec guides, even if there is no evidence of such. So anyone buying a new Z06 today, might want to go ahead and do a wiggle test on it, because the absence of evidence, is not the evidence of absence.

But knowing that the possibility that GM may have handed this off to the lowest bidder, and seeing talk of this machining issue with the guides, then it is certainly within reason to entertain the prospect that GM may have selected the lowest bidder, or whomever got the contract may have cut corners as well.

I earlier pointed out these two builds which ended up with worn stock guides.

http://forums.corvetteforum.com/c6-z...ours-hpde.html

http://forums.corvetteforum.com/c6-z...post1585223049

I figure that if these guys can have guides wear out in their builds, well then nobody is immune to this.

The more I look at that, the more chilling it is. Shocking. Maybe I just might take your advice and do a wiggle test at 10K miles…..

I'm only somewhere between 2K-3K on my build now, so I have another 2-3 years or so to make up my mind.

Maybe I'll get myself some of those PSI 1511 beehive springs too while I'm at it.

Last edited by '06 Quicksilver Z06; 12-14-2013 at 11:44 AM.

#202

Pro Mechanic

Pro Mechanic

While the video footage in the OP clearly shows some valve guide clearance, the method of measurement is faulty in that the geometry used exaggerates the problem.

The right way to do the "wiggle" test is the manner in which the Factory Service Manual suggests–with the dial indicator pintle on the valve stem just above the top of the guide. Admittedly, that's very difficult so an alternative is to take the measurement farther up the stem or as shown in the video but figure the actual stem/guide clearance using trig. The results from that will show clearance but it will likely be less than shown in the video. Also, since that head was off the engine, the best way to measure stem-to-guide clearance would be to remove the valve, measure the ID of the guide and the OD of the stem and subtract the two.

As for "valve bounce" when replacing hollow stem valves with solid stem valves and using the stock valve springs, know that increasing exhaust valve mass by 18% lowers the engine speed at which the valve train becomes unstable. You'd have to test to find out at what speed that is, but suffice to say there's a good change heavier exhausts with stock springs will cause problems with engines which are run over 6500 rpm on a regular basis.

As to what you'll see on the parts from an engine which has been floating or bouncing the exhausts valves? To the untrained observer, probably not much–unless the exhaust valvetrain fails. If your engine is floating or bouncing the exhaust valve, you'll clearly see it on the dyno.

Keep in mind that when you run the engine to a speed where the valvetrain is unstable–ie valve closing is not well-controlled–you weaken the valve springs. If the engine is frequently in valve float, the springs wear out quickly.

If you're going to replace the stock valves with sold stem exhausts, change the exhaust valve springs to something with more tension.

The right way to do the "wiggle" test is the manner in which the Factory Service Manual suggests–with the dial indicator pintle on the valve stem just above the top of the guide. Admittedly, that's very difficult so an alternative is to take the measurement farther up the stem or as shown in the video but figure the actual stem/guide clearance using trig. The results from that will show clearance but it will likely be less than shown in the video. Also, since that head was off the engine, the best way to measure stem-to-guide clearance would be to remove the valve, measure the ID of the guide and the OD of the stem and subtract the two.

As for "valve bounce" when replacing hollow stem valves with solid stem valves and using the stock valve springs, know that increasing exhaust valve mass by 18% lowers the engine speed at which the valve train becomes unstable. You'd have to test to find out at what speed that is, but suffice to say there's a good change heavier exhausts with stock springs will cause problems with engines which are run over 6500 rpm on a regular basis.

As to what you'll see on the parts from an engine which has been floating or bouncing the exhausts valves? To the untrained observer, probably not much–unless the exhaust valvetrain fails. If your engine is floating or bouncing the exhaust valve, you'll clearly see it on the dyno.

Keep in mind that when you run the engine to a speed where the valvetrain is unstable–ie valve closing is not well-controlled–you weaken the valve springs. If the engine is frequently in valve float, the springs wear out quickly.

If you're going to replace the stock valves with sold stem exhausts, change the exhaust valve springs to something with more tension.

Last edited by Hib Halverson; 12-14-2013 at 12:05 PM.

#203

While the video footage in the OP clearly shows some valve guide clearance, the method of measurement is faulty in that the geometry used exaggerates the problem.

The right way to do the "wiggle" test is the manner in which the Factory Service Manual suggests–with the dial indicator pintle on the valve stem just above the top of the guide. The results from that will show clearance but it will likely be less than shown in the video. Also, since that head was off the engine, the best way to measure stem-to-guide clearance would be to remove the valve, measure the ID of the guide and the OD of the stem and subtract the two.

The right way to do the "wiggle" test is the manner in which the Factory Service Manual suggests–with the dial indicator pintle on the valve stem just above the top of the guide. The results from that will show clearance but it will likely be less than shown in the video. Also, since that head was off the engine, the best way to measure stem-to-guide clearance would be to remove the valve, measure the ID of the guide and the OD of the stem and subtract the two.

However this technique, and similar techniques with or without measuring devices are sometimes used in video reports of valve guide wear.

As for "valve bounce" when replacing hollow stem valves with solid stem valves and using the stock valve springs, know that increasing exhaust valve mass by 18% lowers the engine speed at which the valve train becomes unstable. You'd have to test to find out at what speed that is, but suffice to say there's a good change heavier exhausts with stock springs will cause problems with engines which are run over 6500 rpm on a regular basis.

As to what you'll see on the parts from an engine which has been floating or bouncing the exhausts valves? To the untrained observer, probably not much–unless the exhaust valvetrain fails. If your engine is floating or bouncing the exhaust valve, you'll clearly see it on the dyno.

As to what you'll see on the parts from an engine which has been floating or bouncing the exhausts valves? To the untrained observer, probably not much–unless the exhaust valvetrain fails. If your engine is floating or bouncing the exhaust valve, you'll clearly see it on the dyno.

Keep in mind that when you run the engine to a speed where the valvetrain is unstable–ie valve closing is not well-controlled–you weaken the valve springs. If the engine is frequently in valve float, the springs wear out quickly.

If you're going to replace the stock valves with sold stem exhausts, change the exhaust valve springs to something with more tension.

If you're going to replace the stock valves with sold stem exhausts, change the exhaust valve springs to something with more tension.

While it is bandied about a lot in here, I have seen no confirmed or definite instance of an engine failure due to valve bounce in anyone's car on this forum.

Last edited by '06 Quicksilver Z06; 12-14-2013 at 11:57 AM.

#204

Instructor

Question:

From what I'm reading here, it appears that getting closer to a "fix" might

involve replacing the stock rocker arms with a roller tip rocker arm (not necessarily Yella for those who don't like them) and use the bronze guides. The bronze guides seem to have some advantage over the PM via inherent lubricating properties, the ability to affect a tighter clearance with the valve stem, and availability. So, by employing roller tip rockers it sounds like side-loading is decreased to an acceptable range for durability; which, it sounds to me from reading here, eliminates the main problem of using bronze guides.

What am I missing ? Is it just that owners don't want to do valve lash adjustments periodically ? Would that even be necessary - i.e., is there a fixed 1:8 ratio roller tip rocker on the market that fits our pedestal ? Wouldn't that be closer to "problem solved" ?

I honestly don't know and I'm just asking from what I'm gathering here. Thanks for all the info guys and please clue me in if I'm thinking correctly or if I'm way off base ...

From what I'm reading here, it appears that getting closer to a "fix" might

involve replacing the stock rocker arms with a roller tip rocker arm (not necessarily Yella for those who don't like them) and use the bronze guides. The bronze guides seem to have some advantage over the PM via inherent lubricating properties, the ability to affect a tighter clearance with the valve stem, and availability. So, by employing roller tip rockers it sounds like side-loading is decreased to an acceptable range for durability; which, it sounds to me from reading here, eliminates the main problem of using bronze guides.

What am I missing ? Is it just that owners don't want to do valve lash adjustments periodically ? Would that even be necessary - i.e., is there a fixed 1:8 ratio roller tip rocker on the market that fits our pedestal ? Wouldn't that be closer to "problem solved" ?

I honestly don't know and I'm just asking from what I'm gathering here. Thanks for all the info guys and please clue me in if I'm thinking correctly or if I'm way off base ...

#205

If that is OK for them with valve bounce being considered, then an 86g such as the Ferrea Semi-Hollow F2042P valve should be an even better choice if keeping stock valve springs and stock cam. Consider the intake valves are 80g themselves with the same lift. At ~6% heavier than the intake valves it should be a manageable weight increase.

Without a significant increase in weight and no change in cam, I don't see a need to change the stock springs out if you go with a 86g valve. I'm considering that as an option for my 17k mile car.

#206

Melting Slicks

Question:

From what I'm reading here, it appears that getting closer to a "fix" might

involve replacing the stock rocker arms with a roller tip rocker arm (not necessarily Yella for those who don't like them) and use the bronze guides. The bronze guides seem to have some advantage over the PM via inherent lubricating properties, the ability to affect a tighter clearance with the valve stem, and availability. So, by employing roller tip rockers it sounds like side-loading is decreased to an acceptable range for durability; which, it sounds to me from reading here, eliminates the main problem of using bronze guides.

What am I missing ? Is it just that owners don't want to do valve lash adjustments periodically ? Would that even be necessary - i.e., is there a fixed 1:8 ratio roller tip rocker on the market that fits our pedestal ? Wouldn't that be closer to "problem solved" ?

I honestly don't know and I'm just asking from what I'm gathering here. Thanks for all the info guys and please clue me in if I'm thinking correctly or if I'm way off base ...

From what I'm reading here, it appears that getting closer to a "fix" might

involve replacing the stock rocker arms with a roller tip rocker arm (not necessarily Yella for those who don't like them) and use the bronze guides. The bronze guides seem to have some advantage over the PM via inherent lubricating properties, the ability to affect a tighter clearance with the valve stem, and availability. So, by employing roller tip rockers it sounds like side-loading is decreased to an acceptable range for durability; which, it sounds to me from reading here, eliminates the main problem of using bronze guides.

What am I missing ? Is it just that owners don't want to do valve lash adjustments periodically ? Would that even be necessary - i.e., is there a fixed 1:8 ratio roller tip rocker on the market that fits our pedestal ? Wouldn't that be closer to "problem solved" ?

I honestly don't know and I'm just asking from what I'm gathering here. Thanks for all the info guys and please clue me in if I'm thinking correctly or if I'm way off base ...

PM guides also have self lubricating properties and are a stronger material. If your looking to correct any issues with the LS7 head I see nothing wrong with going with PM guides. Up till recently the problem is most shops weren't offering PM guides. WCCH included which is why I believe Katech and others went with bronze.

Now that PM guides are being more widely used I would bet WCCH will start to as well.

You should also look into the Trick Flow heads coming out in Feb 2014 for the LS7. They will have PM guides.

Last edited by propain; 12-14-2013 at 12:19 PM.

#207

Pro Mechanic

Pro Mechanic

It's likely you have not seen reports from dyno runs with engines floating valves because no one has tested–or at least someone who has test data showing it has not posted here.

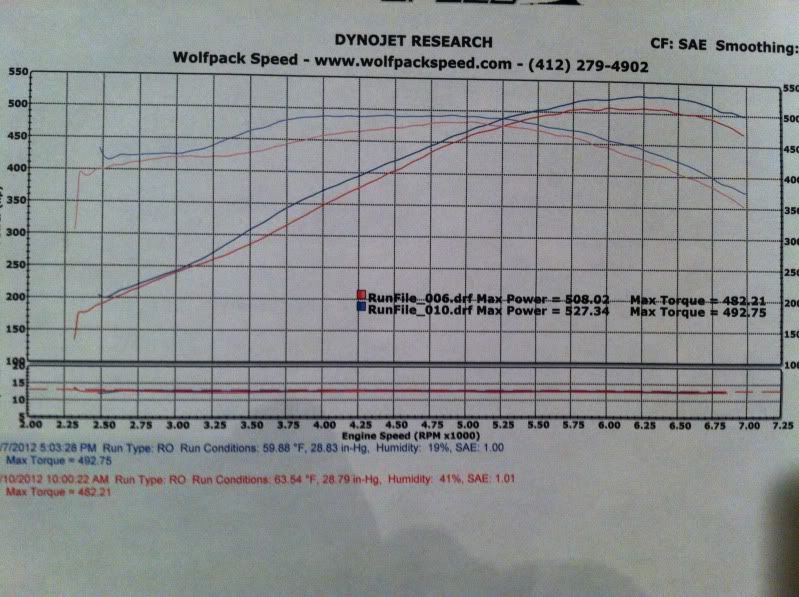

I did a project engine build a few years ago on a 3.8L V6. Now, admittedly, that's got little in common with an LS7 other than it uses the same valve springs, but the effect of valve float or seat bounce on dyno results would look the same.

The engine was originally built with a COMP cam and the COMP springs which came with the came. Every time we ran it on the chassis dyno about 400 rpm short of the rev limit, there was this funny "dip" in the torque curve.

The dyno operator's boss told me that was valve float.

We swapped the COMP springs for a set of the same Katech PSI springs recommended for LS7s and the problem was gone.

The root cause was the cam profile combined with our valve train mass and the too-weak COMP spring. What was interesting is the change in spring pressure was not great, but it was just enough to keep the valve train stable to the engine's 6200 rpm limiter.

I did a project engine build a few years ago on a 3.8L V6. Now, admittedly, that's got little in common with an LS7 other than it uses the same valve springs, but the effect of valve float or seat bounce on dyno results would look the same.

The engine was originally built with a COMP cam and the COMP springs which came with the came. Every time we ran it on the chassis dyno about 400 rpm short of the rev limit, there was this funny "dip" in the torque curve.

The dyno operator's boss told me that was valve float.

We swapped the COMP springs for a set of the same Katech PSI springs recommended for LS7s and the problem was gone.

The root cause was the cam profile combined with our valve train mass and the too-weak COMP spring. What was interesting is the change in spring pressure was not great, but it was just enough to keep the valve train stable to the engine's 6200 rpm limiter.

#208

What am I missing ? Is it just that owners don't want to do valve lash adjustments periodically ? Would that even be necessary - [...]

i.e., is there a fixed 1:8 ratio roller tip rocker on the market that fits our pedestal ?

#209

After valvetrain dynamics testing with a STOCK CAM, Katech made a recommendation that the stock springs are OK on a street car running the REV valves if rpm limiter is set to 7000. Those valves are actually more like 32% heavier than the stock valves or ~22% heavier than the intake valves.

If that is OK for them with valve bounce being considered, then an 86g such as the Ferrea Semi-Hollow F2042P valve should be an even better choice if keeping stock valve springs and stock cam. Consider the intake valves are 80g themselves with the same lift. At ~6% heavier than the intake valves it should be a manageable weight increase.

Without a significant increase in weight and no change in cam, I don't see a need to change the stock springs out if you go with a 86g valve. I'm considering that as an option for my 17k mile car.

If that is OK for them with valve bounce being considered, then an 86g such as the Ferrea Semi-Hollow F2042P valve should be an even better choice if keeping stock valve springs and stock cam. Consider the intake valves are 80g themselves with the same lift. At ~6% heavier than the intake valves it should be a manageable weight increase.

Without a significant increase in weight and no change in cam, I don't see a need to change the stock springs out if you go with a 86g valve. I'm considering that as an option for my 17k mile car.

I don't blame you. Move forward and I wish you the best.

It's likely you have not seen reports from dyno runs with engines floating valves because no one has tested–or at least someone who has test data showing it has not posted here.

I did a project engine build a few years ago on a 3.8L V6. Now, admittedly, that's got little in common with an LS7 other than it uses the same valve springs, but the effect of valve float or seat bounce on dyno results would look the same.

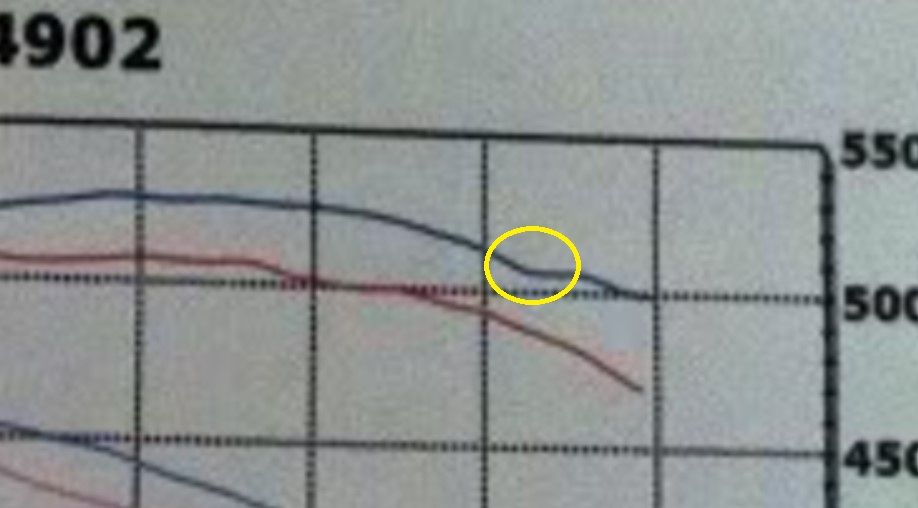

The engine was originally built with a COMP cam and the COMP springs which came with the came. Every time we ran it on the chassis dyno about 400 rpm short of the rev limit, there was this funny "dip" in the torque curve.

The dyno operator's boss told me that was valve float.

We swapped the COMP springs for a set of the same Katech PSI springs recommended for LS7s and the problem was gone.

The root cause was the cam profile combined with our valve train mass and the too-weak COMP spring. What was interesting is the change in spring pressure was not great, but it was just enough to keep the valve train stable to the engine's 6200 rpm limiter.

I did a project engine build a few years ago on a 3.8L V6. Now, admittedly, that's got little in common with an LS7 other than it uses the same valve springs, but the effect of valve float or seat bounce on dyno results would look the same.

The engine was originally built with a COMP cam and the COMP springs which came with the came. Every time we ran it on the chassis dyno about 400 rpm short of the rev limit, there was this funny "dip" in the torque curve.

The dyno operator's boss told me that was valve float.

We swapped the COMP springs for a set of the same Katech PSI springs recommended for LS7s and the problem was gone.

The root cause was the cam profile combined with our valve train mass and the too-weak COMP spring. What was interesting is the change in spring pressure was not great, but it was just enough to keep the valve train stable to the engine's 6200 rpm limiter.

According to that testing, my setup and others like it, should have been a disaster.

It was run to 7K. The torque curve is nice, flat and steady. No funny dips in the torque curve. The blue line was after the headers were added to it. Several have seen it, and I've never heard of any signs on it indicating severe valve bounce.

Last edited by '06 Quicksilver Z06; 12-15-2013 at 12:43 AM.

#210

Pro

While the video footage in the OP clearly shows some valve guide clearance, the method of measurement is faulty in that the geometry used exaggerates the problem.

The right way to do the "wiggle" test is the manner in which the Factory Service Manual suggests–with the dial indicator pintle on the valve stem just above the top of the guide. Admittedly, that's very difficult so an alternative is to take the measurement farther up the stem or as shown in the video but figure the actual stem/guide clearance using trig. The results from that will show clearance but it will likely be less than shown in the video. Also, since that head was off the engine, the best way to measure stem-to-guide clearance would be to remove the valve, measure the ID of the guide and the OD of the stem and subtract the two.

As for "valve bounce" when replacing hollow stem valves with solid stem valves and using the stock valve springs, know that increasing exhaust valve mass by 18% lowers the engine speed at which the valve train becomes unstable. You'd have to test to find out at what speed that is, but suffice to say there's a good change heavier exhausts with stock springs will cause problems with engines which are run over 6500 rpm on a regular basis.

As to what you'll see on the parts from an engine which has been floating or bouncing the exhausts valves? To the untrained observer, probably not much–unless the exhaust valvetrain fails. If your engine is floating or bouncing the exhaust valve, you'll clearly see it on the dyno.

Keep in mind that when you run the engine to a speed where the valvetrain is unstable–ie valve closing is not well-controlled–you weaken the valve springs. If the engine is frequently in valve float, the springs wear out quickly.

If you're going to replace the stock valves with sold stem exhausts, change the exhaust valve springs to something with more tension.

The right way to do the "wiggle" test is the manner in which the Factory Service Manual suggests–with the dial indicator pintle on the valve stem just above the top of the guide. Admittedly, that's very difficult so an alternative is to take the measurement farther up the stem or as shown in the video but figure the actual stem/guide clearance using trig. The results from that will show clearance but it will likely be less than shown in the video. Also, since that head was off the engine, the best way to measure stem-to-guide clearance would be to remove the valve, measure the ID of the guide and the OD of the stem and subtract the two.

As for "valve bounce" when replacing hollow stem valves with solid stem valves and using the stock valve springs, know that increasing exhaust valve mass by 18% lowers the engine speed at which the valve train becomes unstable. You'd have to test to find out at what speed that is, but suffice to say there's a good change heavier exhausts with stock springs will cause problems with engines which are run over 6500 rpm on a regular basis.

As to what you'll see on the parts from an engine which has been floating or bouncing the exhausts valves? To the untrained observer, probably not much–unless the exhaust valvetrain fails. If your engine is floating or bouncing the exhaust valve, you'll clearly see it on the dyno.

Keep in mind that when you run the engine to a speed where the valvetrain is unstable–ie valve closing is not well-controlled–you weaken the valve springs. If the engine is frequently in valve float, the springs wear out quickly.

If you're going to replace the stock valves with sold stem exhausts, change the exhaust valve springs to something with more tension.

Another thing that I noticed, was taking the same valve and putting it in multiple guides.

With the above said, those videos still pretty much demonstrate those heads being shot.

I do honestly believe the poster of those videos has the best intentions and has done a lot to bring awareness to this issue.

#211

Pro

There is the very real possibility that this happened.

Though one may never be able to prove that it did in fact happen, it has been said all over the internet that; the absence of evidence is not the evidence of absence.

That means that a brand new Z06 might have out of spec guides, even if there is no evidence of such. So anyone buying a new Z06 today, might want to go ahead and do a wiggle test on it, because the absence of evidence, is not the evidence of absence.

But knowing that the possibility that GM may have handed this off to the lowest bidder, and seeing talk of this machining issue with the guides, then it is certainly within reason to entertain the prospect that GM may have selected the lowest bidder, or whomever got the contract may have cut corners as well.

Though one may never be able to prove that it did in fact happen, it has been said all over the internet that; the absence of evidence is not the evidence of absence.

That means that a brand new Z06 might have out of spec guides, even if there is no evidence of such. So anyone buying a new Z06 today, might want to go ahead and do a wiggle test on it, because the absence of evidence, is not the evidence of absence.

But knowing that the possibility that GM may have handed this off to the lowest bidder, and seeing talk of this machining issue with the guides, then it is certainly within reason to entertain the prospect that GM may have selected the lowest bidder, or whomever got the contract may have cut corners as well.

One might want to look around, or ask around as to if any Lingenfelter builds have shown up with worn stock guides.

I earlier pointed out these two builds which ended up with worn stock guides.

http://forums.corvetteforum.com/c6-z...ours-hpde.html

http://forums.corvetteforum.com/c6-z...post1585223049

I figure that if these guys can have guides wear out in their builds, well then nobody is immune to this.

I earlier pointed out these two builds which ended up with worn stock guides.

http://forums.corvetteforum.com/c6-z...ours-hpde.html

http://forums.corvetteforum.com/c6-z...post1585223049

I figure that if these guys can have guides wear out in their builds, well then nobody is immune to this.

The more I look at that, the more chilling it is. Shocking. Maybe I just might take your advice and do a wiggle test at 10K miles…..

I'm only somewhere between 2K-3K on my build now, so I have another 2-3 years or so to make up my mind.

Maybe I'll get myself some of those PSI 1511 beehive springs too while I'm at it.

I'm only somewhere between 2K-3K on my build now, so I have another 2-3 years or so to make up my mind.

Maybe I'll get myself some of those PSI 1511 beehive springs too while I'm at it.

Being aware is wise but it's unfortunate that we have to look over our shoulder.

If you are not racking up a lot miles that will give you some reprieve for a while.

You know I've mentioned PSI 1511 beehive springs quite a bit in this discussion as I really am a fan of beehives, especially those.

But... when the times comes for new valve springs it would be best to stay with the dual springs on your particular set-up for all the right reasons... Heavier exhaust valves, installed spring height, correctly machined pocket for your particular valve springs. Since you have the WCCH, I would go by their recommendations.

Do you have the stock cam ? Edit: Never mind I see the answer above after I posted this.

.

Last edited by bearcatt; 12-14-2013 at 01:49 PM.

#212

Pro

After valvetrain dynamics testing with a STOCK CAM, Katech made a recommendation that the stock springs are OK on a street car running the REV valves if rpm limiter is set to 7000. Those valves are actually more like 32% heavier than the stock valves or ~22% heavier than the intake valves.

If that is OK for them with valve bounce being considered, then an 86g such as the Ferrea Semi-Hollow F2042P valve should be an even better choice if keeping stock valve springs and stock cam. Consider the intake valves are 80g themselves with the same lift. At ~6% heavier than the intake valves it should be a manageable weight increase.

Without a significant increase in weight and no change in cam, I don't see a need to change the stock springs out if you go with a 86g valve. I'm considering that as an option for my 17k mile car.

If that is OK for them with valve bounce being considered, then an 86g such as the Ferrea Semi-Hollow F2042P valve should be an even better choice if keeping stock valve springs and stock cam. Consider the intake valves are 80g themselves with the same lift. At ~6% heavier than the intake valves it should be a manageable weight increase.

Without a significant increase in weight and no change in cam, I don't see a need to change the stock springs out if you go with a 86g valve. I'm considering that as an option for my 17k mile car.

With some PSI 1511 beehives and Ti-retainers.

.

#213

Pro

Thread.

http://forums.corvetteforum.com/c6-z...upersnake.html

ZO6's specs in that video.

WCCH stg2 heads, CMS spec cam, fast102, halltech 107r, kooks headers/xpipe, corsa exhaust.

Not very scientific but I doubt valve float is a problem.

Airstrip Attack: C6 Z06 vs Porsche GTR Mustangs, SuperSnake.

.

http://forums.corvetteforum.com/c6-z...upersnake.html

ZO6's specs in that video.

WCCH stg2 heads, CMS spec cam, fast102, halltech 107r, kooks headers/xpipe, corsa exhaust.

Not very scientific but I doubt valve float is a problem.

Airstrip Attack: C6 Z06 vs Porsche GTR Mustangs, SuperSnake.

.

Last edited by bearcatt; 12-14-2013 at 01:58 PM.

#214

Pro Mechanic

Pro Mechanic

I was only pointing out that method would not result in the accurate results.

Obviously, with that much clearance, the guide being measured is toasted, but...if you were using that set-up, and measured, say .004, which is just outside the acceptable range, the inaccuracy of the set-up would affect a decision on whether or not to replaced guides.

For the re-editing of the LS7 story on the CAC we have a sectioned LS7 head which was new before it was cut. I, also, have some valves. I'll use that stuff to properly illustrate how the wiggle test should be done with the heads on the car.

#216

I agree.

I was only pointing out that method would not result in the accurate results.

Obviously, with that much clearance, the guide being measured is toasted, but...if you were using that set-up, and measured, say .004, which is just outside the acceptable range, the inaccuracy of the set-up would affect a decision on whether or not to replaced guides.

For the re-editing of the LS7 story on the CAC we have a sectioned LS7 head which was new before it was cut. I, also, have some valves. I'll use that stuff to properly illustrate how the wiggle test should be done with the heads on the car.

I was only pointing out that method would not result in the accurate results.

Obviously, with that much clearance, the guide being measured is toasted, but...if you were using that set-up, and measured, say .004, which is just outside the acceptable range, the inaccuracy of the set-up would affect a decision on whether or not to replaced guides.

For the re-editing of the LS7 story on the CAC we have a sectioned LS7 head which was new before it was cut. I, also, have some valves. I'll use that stuff to properly illustrate how the wiggle test should be done with the heads on the car.

I was saying just yesterday, that variation in how the wiggle test is actually performed by those doing it, can make a difference in a guide to stem clearance being reported as in spec, or out of spec.

Some of these guides which have been reported as out of spec, be they stock guides or "bronze" guides, might not actually have been out of spec, depending upon the technique of the operator doing the test.

Thank you for pointing the above out, as the tendency amongst us, myself included, has been to accept at face value, the actual accuracy of the numbers presented.

Probably not the best approach to take considering the variability in technique amongst any group doing these measurements.

Last edited by '06 Quicksilver Z06; 12-14-2013 at 03:54 PM.

#217

As to your dip, which could be masked to some extent by the cropped smoothing setting on your graph (most seem to use 5, the maximum)...

#218

Supporting Vendor

Member Since: Sep 2013

Location: Harbor City California

Posts: 2,817

Received 1,012 Likes

on

533 Posts

If I were considering PM guides, well then I certainly would have a hard time even considering the stock ones, taking into account how many of them we have seen wear out in a short period of time, and in cars which were supposedly well outside of the 2008-2011 guide machining issue window referenced in the sticky thread.

Of course these and other parts may have worked in prior LS engines, but this does not necessarily mean that the same parts will enjoy the same success in other LS engines.

Of course, if one is a real stickler they would want to know how well those guides referred to above have held up, how many years they have been in use and how many miles.

All legitimate questions.

Very important observations.

I am unsure if the LS7 OEM PM guides are the exact same guides that were used in previous LS motors.

Very well. We have been using the proprietary aftermarket PM guides for 3 years in both street and some serious all out race application. Some of our heads are going on 35,000+ miles with no warranty's.

Last edited by American Heritage; 12-14-2013 at 05:14 PM.

#219

Pro Mechanic

Pro Mechanic

As for "valve bounce" we need to be careful about use of that term because, any valve bounces on closing. It's the degree of bouncing that is important.

#220

Melting Slicks

If you are going to use bronze guides I would say you should run roller tipped rockers for sure. The softer metal and the side loading of the 1.8 rocker is not a good combination.

PM guides also have self lubricating properties and are a stronger material. If your looking to correct any issues with the LS7 head I see nothing wrong with going with PM guides. Up till recently the problem is most shops weren't offering PM guides. WCCH included which is why I believe Katech and others went with bronze.

Now that PM guides are being more widely used I would bet WCCH will start to as well.

You should also look into the Trick Flow heads coming out in Feb 2014 for the LS7. They will have PM guides.

PM guides also have self lubricating properties and are a stronger material. If your looking to correct any issues with the LS7 head I see nothing wrong with going with PM guides. Up till recently the problem is most shops weren't offering PM guides. WCCH included which is why I believe Katech and others went with bronze.

Now that PM guides are being more widely used I would bet WCCH will start to as well.

You should also look into the Trick Flow heads coming out in Feb 2014 for the LS7. They will have PM guides.

Without going into detail I can pretty well guarantee you that the bolt-on full roller systems for the LS7 effectively result in one step forward and two steps backward.

If the price of running bronze guides is getting roller tipped rockers you better have a very thick wallet, otherwise just go with PM thus saving money and the potential of additional issues.

Cheers, Paul.