[Z06] Wiggle Test vs Dial Bore Gauge comparision....results

#1

Pro

Thread Starter

If you haven't followed my thread here: http://forums.corvetteforum.com/c6-z...next-step.html

You may have not known I have been expecting actual dial bore gauge results back from WCCH to compare to my results of the wiggle test I did on my heads. They just completed my head work and shipped the heads out yesterday so I should see them back on Tuesday.

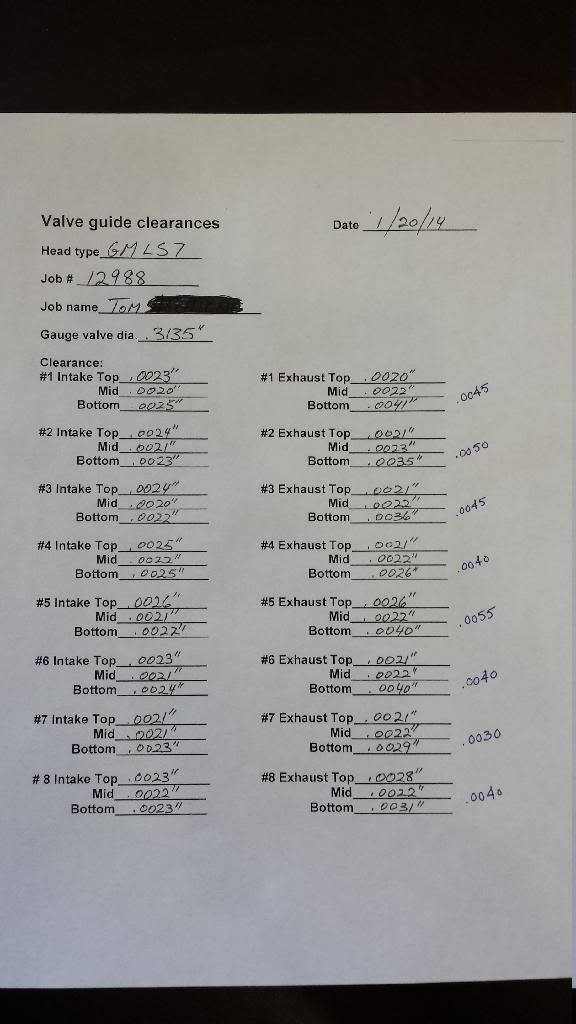

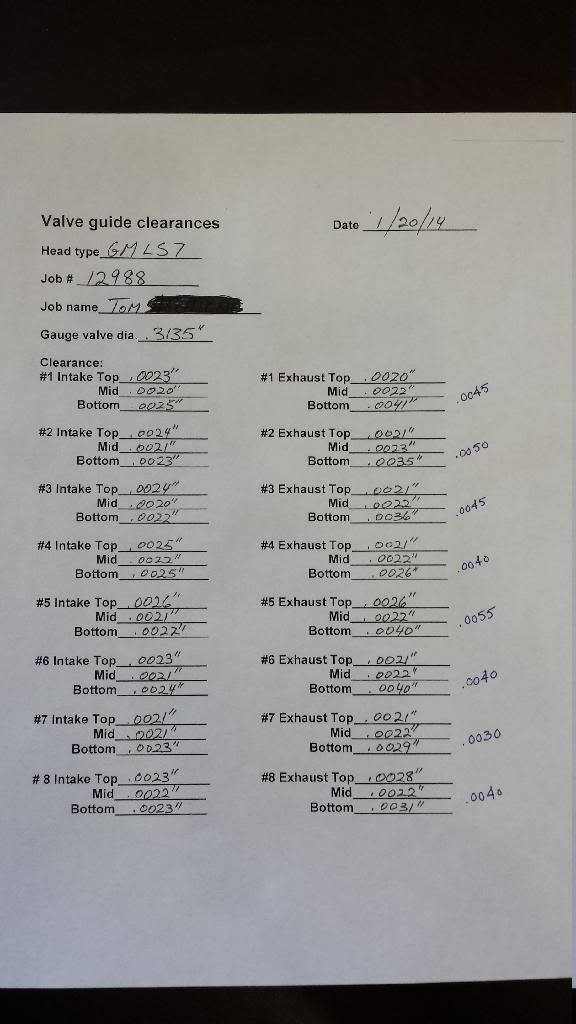

Here is the comparison of my calculated guide clearances based on the wiggle test versus what WCCH measured. The results are a shock to me and I have no explanation whatsoever for some of the large differences.

My measurements of the exhaust valves are written to the right in blue:

Here are my complete calculated measurements from the wiggle test. The intake valves measurements are not even close.

So I did have some exhaust guides just out of spec but not as bad as what I measured. The dial gauge was placed 3/4"-1" above the guide and no higher. I measured each valve guide several times to make sure I was getting the same measurement each time. I'm disappointed in the inaccuracy and at this point I really don't know what to say. Either I f---ed up or the wiggle test isn't as accurate as originally thought. I'd probably lean toward the I f----ed up

You may have not known I have been expecting actual dial bore gauge results back from WCCH to compare to my results of the wiggle test I did on my heads. They just completed my head work and shipped the heads out yesterday so I should see them back on Tuesday.

Here is the comparison of my calculated guide clearances based on the wiggle test versus what WCCH measured. The results are a shock to me and I have no explanation whatsoever for some of the large differences.

My measurements of the exhaust valves are written to the right in blue:

Here are my complete calculated measurements from the wiggle test. The intake valves measurements are not even close.

Originally Posted by ctsv510

Based on the calculation from wiggle test measurements to actual clearances (/2):

1- .0050 - .0045

2- .0050 - .0050

3- .0050 - .0045

4- .0045 - .0040

5- .0050 - .0055

6- .0040 - .0040

7- .0035 - .0030

8- .0050 - .0040

1- .0050 - .0045

2- .0050 - .0050

3- .0050 - .0045

4- .0045 - .0040

5- .0050 - .0055

6- .0040 - .0040

7- .0035 - .0030

8- .0050 - .0040

#2

Melting Slicks

Thanks for the update.

Wow... way off.

Good of you to man up and post this info I bet some would just tuck it away and not admit it.

Either the wiggle test is crap or you messed up. You seem like a smart guy, I cant imagine you messed up on all of these. Seems like the method might be flawed. It looks like from WCCH none of your intakes were even close to out of spec and only 3 of the exhausts were just out of spec. Did you measure your intakes? Is the bottom quote your intakes and your exhausts side my side?

I wonder how many others have measured and redone their heads while being completely in spec.

Wow... way off.

Good of you to man up and post this info I bet some would just tuck it away and not admit it.

Either the wiggle test is crap or you messed up. You seem like a smart guy, I cant imagine you messed up on all of these. Seems like the method might be flawed. It looks like from WCCH none of your intakes were even close to out of spec and only 3 of the exhausts were just out of spec. Did you measure your intakes? Is the bottom quote your intakes and your exhausts side my side?

I wonder how many others have measured and redone their heads while being completely in spec.

#3

Pro

Thread Starter

Yeah crazy huh? I definitely followed the test properly so I am at a loss as to how the results could be so bad. Maybe my tool was malfunctioning.

I did measure my intakes and they all had the movement I posted... The left side of that list is indeed the intake sides.

Who knows but I'm not one to sweep this under the carpet because it doesn't fall in line with my expectations. I have no problem owning up to the possibility that I screwed up the test somehow but either way the info needs to be shared. At the end of the day I did have out of spec guides just not as bad as I thought.

I did measure my intakes and they all had the movement I posted... The left side of that list is indeed the intake sides.

Who knows but I'm not one to sweep this under the carpet because it doesn't fall in line with my expectations. I have no problem owning up to the possibility that I screwed up the test somehow but either way the info needs to be shared. At the end of the day I did have out of spec guides just not as bad as I thought.

#4

Melting Slicks

Its really hard to get an accurate reading doing wiggle test. You have a round point to your dial gauge, with a round valve stem, on a fixture that isn't totally sturdy... then you are trying to measure things in the thousandths of an inch.

I wouldn't ever put a ton of faith in those numbers. If the valves rock when wiggling, then they are bad

I wouldn't ever put a ton of faith in those numbers. If the valves rock when wiggling, then they are bad

#5

Racer

Member Since: Aug 2011

Location: Houston Texas

Posts: 417

Likes: 0

Received 0 Likes

on

0 Posts

There seems to be a slight consistency in the differential between your measurements and WCCH's though. Almost like maybe your dial was out of calibration that much?

#6

Melting Slicks

Did you convert these measurements or are your actual measurements?

#7

Racer

Member Since: Aug 2011

Location: Houston Texas

Posts: 417

Likes: 0

Received 0 Likes

on

0 Posts

Hey, I'm subject to error, too, I'm an engineer and we all know how much we screw up lol. He's clearly a smart dude and I just had a hard time buying that he was the faulty variable. I converted the measurements and calculated in a +/-0.00018 degree of error in for surface imperfections we use for similar processes in the oilfield. The range of difference between his measurements and theirs, when you really look at it on a guage, seem like the equipment could have been at fault. That's all. Just a suggestion.

#8

Pro

Thread Starter

Those are calculated measurements (wiggle/2).

#9

Burning Brakes

Not really surprised by the results. Measuring 3/4'' -1'' above the guide represents a small angular error , however, we are trying to measure small displacements.

Interesting that a couple exhausts were right on?

Interesting that a couple exhausts were right on?

#10

Pro

Thread Starter

I would just say that anyone that is out of spec with the wiggle test, have your machine shop follow up with a dial bore test when they get your heads to verify your measurements.

WCCH only charged an extra $25 to measure them.

#11

Melting Slicks

Cheers, Paul.

#12

Wiggle test should just be an indicator that clearence is either OK, not OK, or trending to not OK. Your results told you what you needed to know, clearence was not OK. Actual mic'ed results verify that. The wiggle test worked.

Lot's of variables can give different results. Heck, you may have had some carbon on the stem throw off your results.

Lot's of variables can give different results. Heck, you may have had some carbon on the stem throw off your results.

#13

Team Owner

Yeah crazy huh? I definitely followed the test properly so I am at a loss as to how the results could be so bad. Maybe my tool was malfunctioning.

I did measure my intakes and they all had the movement I posted... The left side of that list is indeed the intake sides.

Who knows but I'm not one to sweep this under the carpet because it doesn't fall in line with my expectations. I have no problem owning up to the possibility that I screwed up the test somehow but either way the info needs to be shared. At the end of the day I did have out of spec guides just not as bad as I thought.

I did measure my intakes and they all had the movement I posted... The left side of that list is indeed the intake sides.

Who knows but I'm not one to sweep this under the carpet because it doesn't fall in line with my expectations. I have no problem owning up to the possibility that I screwed up the test somehow but either way the info needs to be shared. At the end of the day I did have out of spec guides just not as bad as I thought.

You were indeed out of spec but barely so. I personally would have been fine running my car with those specs at the track. But then again I have SS valves which certainly can withstand a higer threshold than the specs GM designed around their hollow ones.

And I personally watched an experienced GM tech do the wiggle test recently on a buddies car (which was way out of spec and heads replaced by GM), and its not THAT easy to do in my opinion. So I wouldn't be down on yourself if you were not precise and consistant in recording your data

DH

#14

Melting Slicks

Wiggle test should just be an indicator that clearence is either OK, not OK, or trending to not OK. Your results told you what you needed to know, clearence was not OK. Actual mic'ed results verify that. The wiggle test worked.

Lot's of variables can give different results. Heck, you may have had some carbon on the stem throw off your results.

Lot's of variables can give different results. Heck, you may have had some carbon on the stem throw off your results.

Those intake measurements have me perplexed the most.

When I measured my guides I stayed at a Holiday Inn the night before so I think that gave me an advantage.

#15

Race Director

The end result of the WCCH measurements is that you had out of spec exhaust valves on both heads. They may have been close, but still out of spec. Having it fixed with no failure is a plus.

Thanks for all the info.

Thanks for all the info.

#16

Based on the exhaust numbers alone, I don't think the accuracy is all that bad compared to the alternative (removing the heads to measure).

The error ranges from .0000 to .0015, with an average error of less than a thousandth of an inch (.00084). Average accuracy of less than a thousandth of an inch isn't bad at all for a shadetree test. In this case, since the guides weren't terribly worn, it seems like a lot. If the guides had been worn to .011, then there really wouldn't be any quibble over .001 here or .001 there.

On the intake side things clearly didn't turn out as well; dunno what happened there. Error ranges from .0012 (not terribly bad) to .0028 (pretty bad). Average error .00229, almost triple that of the exhaust side, not too good.

For reference, the bottom lip of the retainer groove is 1.105" above the top of the valve guide (not the top of the valve stem seal), with the valve fully seated.

The error ranges from .0000 to .0015, with an average error of less than a thousandth of an inch (.00084). Average accuracy of less than a thousandth of an inch isn't bad at all for a shadetree test. In this case, since the guides weren't terribly worn, it seems like a lot. If the guides had been worn to .011, then there really wouldn't be any quibble over .001 here or .001 there.

On the intake side things clearly didn't turn out as well; dunno what happened there. Error ranges from .0012 (not terribly bad) to .0028 (pretty bad). Average error .00229, almost triple that of the exhaust side, not too good.

For reference, the bottom lip of the retainer groove is 1.105" above the top of the valve guide (not the top of the valve stem seal), with the valve fully seated.

#17

Pro

Thread Starter

I understand some error here and there on the exhaust side, but the intakes don't make sense to me at all. I recall they on average felt the same or worse than the exhaust valves when I gave them a wiggle before even attaching the dial gauge. It's a mystery to me.

I would sure be nice to see some more of these comparisons. Oh well, heads are redone and on their way back to me with a little milling and porting. I can't wait to have this car back finally, thought the weather in PA has not been very corvette friendly.

I would sure be nice to see some more of these comparisons. Oh well, heads are redone and on their way back to me with a little milling and porting. I can't wait to have this car back finally, thought the weather in PA has not been very corvette friendly.

#18

Supporting Vendor

Member Since: Sep 2013

Location: Harbor City California

Posts: 2,817

Received 1,012 Likes

on

533 Posts

Thanks for the update.

Wow... way off.

Good of you to man up and post this info I bet some would just tuck it away and not admit it.

Either the wiggle test is crap or you messed up. You seem like a smart guy, I cant imagine you messed up on all of these. Seems like the method might be flawed. It looks like from WCCH none of your intakes were even close to out of spec and only 3 of the exhausts were just out of spec. Did you measure your intakes? Is the bottom quote your intakes and your exhausts side my side?

I wonder how many others have measured and redone their heads while being completely in spec.

Wow... way off.

Good of you to man up and post this info I bet some would just tuck it away and not admit it.

Either the wiggle test is crap or you messed up. You seem like a smart guy, I cant imagine you messed up on all of these. Seems like the method might be flawed. It looks like from WCCH none of your intakes were even close to out of spec and only 3 of the exhausts were just out of spec. Did you measure your intakes? Is the bottom quote your intakes and your exhausts side my side?

I wonder how many others have measured and redone their heads while being completely in spec.

#19

Melting Slicks

I understand some error here and there on the exhaust side, but the intakes don't make sense to me at all. I recall they on average felt the same or worse than the exhaust valves when I gave them a wiggle before even attaching the dial gauge. It's a mystery to me.

I would sure be nice to see some more of these comparisons. Oh well, heads are redone and on their way back to me with a little milling and porting. I can't wait to have this car back finally, thought the weather in PA has not been very corvette friendly.

I would sure be nice to see some more of these comparisons. Oh well, heads are redone and on their way back to me with a little milling and porting. I can't wait to have this car back finally, thought the weather in PA has not been very corvette friendly.

Strange indeed. Those intakes are very solid and what you came back with has some pretty good movement.

Either way they were out of spec and you got them done. You can at least rest easy for a while and start driving again.

#20

Burning Brakes

When doing a wiggle test you need to make sure you are measuring the valve at the correct location and at the correct lift or else you are multiplying things. Because of the geometry the wiggle test is often going to be "looser" than the actual bore gauge measurements. For example a head sitting here on the bench has a wiggle test measurement of .015" clearance and an actual bore gauge measurement of .011" clearance.