[ZR1] D3 Performance Engineering ZR1 HX System Development

#21

Former Vendor

Thread Starter

Morphin,

While I can understand where you're coming from, we could have bought a much cheaper core, pump, and other components with our kit, but please keep in mind our stated goals in the first post, mainly #5.

There is a reason many of you bought a ZR-1, and paid a premium for the finest, no compromise approach to Corvette, led by GM's finest engineers and racers. After much brutal real-world testing, trial and error, experimentation, and effort the ZR-1 was released to the public and brought technology previously beyond the realm of Corvette, and helped catapult our American Supercar into a World-Class competitor. People understood and appreciated this, and they supported it by spending their hard earned money to let the team that created this car know that they had accomplished the task in which they set out to acheive. Instead of buying a Z06, Base, or GS and letting your local tuning house go nuts on it, you wanted the best out of the box, you wanted no compromises, and you invested in achieving your goal with the purchase of the ZR-1.

We approached this project with that mind-set, we could have cut a lot of corners, and used inferior parts to offer a solution. We could have increased capacity, ran an ice tank in the trunk, and tested on a car with meth injection, to save costs and create a facade of a working system, but we didn't want to take a compromised approach and settle for anything less than the original goals our team set out for.

While we've seen other companies base all of their data eyeballing or using a GoPro pointed at factory temp sensors while doing pulls to 180 on public highways and nothing more, or using CAD and some testing. We invested weeks of intensive data testing, started with several different designs, and as the data was accrued the particulars of the design evolved as we learned which ideas worked in CAD and on paper, and which ideas worked in the real world, which led us to the system you see us sharing today.

Our kit is not for everyone, and our approach is not for everyone, there are a lot of great kits that fit the wide variance of needs and goals for the Corvette community, and there is plenty of room for many different kits. We did not want to compromise any single aspect of our package, much like GM's engineering teams' approach when designing the ZR-1. I think the information that we chose to share without giving away too much free information on how to design a product like this, speaks for itself. While we wish everyone was as tireless in their pursuit of perfection, we understand that this kit will only be for clients who will not tolerate any amount of compromise, and that community is a very elusive and unique part of the community. At the end of the day we are left with a product that we feel is unparalleled, and we can take a lot of pride in, and that is the place that we would like to be at the end of any dyno tune, fabrication project, turn-key build, horsepower package, or off-the-shelf product that we sell, and we've already had the pleasure of meeting several fellow Corvette enthusiasts who are like-minded in their pursuit for perfection, and we look forward to enhancing their cars performance with our system, which we feel is the best no-compromise system on the market.

While I can understand where you're coming from, we could have bought a much cheaper core, pump, and other components with our kit, but please keep in mind our stated goals in the first post, mainly #5.

There is a reason many of you bought a ZR-1, and paid a premium for the finest, no compromise approach to Corvette, led by GM's finest engineers and racers. After much brutal real-world testing, trial and error, experimentation, and effort the ZR-1 was released to the public and brought technology previously beyond the realm of Corvette, and helped catapult our American Supercar into a World-Class competitor. People understood and appreciated this, and they supported it by spending their hard earned money to let the team that created this car know that they had accomplished the task in which they set out to acheive. Instead of buying a Z06, Base, or GS and letting your local tuning house go nuts on it, you wanted the best out of the box, you wanted no compromises, and you invested in achieving your goal with the purchase of the ZR-1.

We approached this project with that mind-set, we could have cut a lot of corners, and used inferior parts to offer a solution. We could have increased capacity, ran an ice tank in the trunk, and tested on a car with meth injection, to save costs and create a facade of a working system, but we didn't want to take a compromised approach and settle for anything less than the original goals our team set out for.

While we've seen other companies base all of their data eyeballing or using a GoPro pointed at factory temp sensors while doing pulls to 180 on public highways and nothing more, or using CAD and some testing. We invested weeks of intensive data testing, started with several different designs, and as the data was accrued the particulars of the design evolved as we learned which ideas worked in CAD and on paper, and which ideas worked in the real world, which led us to the system you see us sharing today.

Our kit is not for everyone, and our approach is not for everyone, there are a lot of great kits that fit the wide variance of needs and goals for the Corvette community, and there is plenty of room for many different kits. We did not want to compromise any single aspect of our package, much like GM's engineering teams' approach when designing the ZR-1. I think the information that we chose to share without giving away too much free information on how to design a product like this, speaks for itself. While we wish everyone was as tireless in their pursuit of perfection, we understand that this kit will only be for clients who will not tolerate any amount of compromise, and that community is a very elusive and unique part of the community. At the end of the day we are left with a product that we feel is unparalleled, and we can take a lot of pride in, and that is the place that we would like to be at the end of any dyno tune, fabrication project, turn-key build, horsepower package, or off-the-shelf product that we sell, and we've already had the pleasure of meeting several fellow Corvette enthusiasts who are like-minded in their pursuit for perfection, and we look forward to enhancing their cars performance with our system, which we feel is the best no-compromise system on the market.

#22

Le Mans Master

D3 while I commend you for your level of research and we here in the ZR1 section are very into sharing research and helping each other I think I speak for all of us when I say THANK YOU.

That being said you can't redefine physics when it comes to air to water systems. Surface area is more important than thickness in this department.

Next I am tired of this corvette tax BS. Yes we bought ZR1s and most of us did that because we knew were were getting a great platform and knew we could do simple mods to upgrade from here. I know for a fact that ZBADDESTZ and a few others including myself are seeing equal if not better temps with the Magnuson setup. There is no way in hell you convince me to switch setups for the price that you guys have posted. You guys need to rethink that department.

That being said you can't redefine physics when it comes to air to water systems. Surface area is more important than thickness in this department.

Next I am tired of this corvette tax BS. Yes we bought ZR1s and most of us did that because we knew were were getting a great platform and knew we could do simple mods to upgrade from here. I know for a fact that ZBADDESTZ and a few others including myself are seeing equal if not better temps with the Magnuson setup. There is no way in hell you convince me to switch setups for the price that you guys have posted. You guys need to rethink that department.

#23

D3 while I commend you for your level of research and we here in the ZR1 section are very into sharing research and helping each other I think I speak for all of us when I say THANK YOU.

That being said you can't redefine physics when it comes to air to water systems. Surface area is more important than thickness in this department.

Next I am tired of this corvette tax BS. Yes we bought ZR1s and most of us did that because we knew were were getting a great platform and knew we could do simple mods to upgrade from here. I know for a fact that ZBADDESTZ and a few others including myself are seeing equal if not better temps with the Magnuson setup. There is no way in hell you convince me to switch setups for the price that you guys have posted. You guys need to rethink that department.

That being said you can't redefine physics when it comes to air to water systems. Surface area is more important than thickness in this department.

Next I am tired of this corvette tax BS. Yes we bought ZR1s and most of us did that because we knew were were getting a great platform and knew we could do simple mods to upgrade from here. I know for a fact that ZBADDESTZ and a few others including myself are seeing equal if not better temps with the Magnuson setup. There is no way in hell you convince me to switch setups for the price that you guys have posted. You guys need to rethink that department.

#24

Le Mans Master

on the contrary i think im running the best magnuson set up out of everyone right now and my temps are still questionable and hitting 165-173 on half mile pulls with meth still. thats magnuson heat ex 3/4" line through out the system with an icetank and straightline tank making a 6 gallon capacity in the system. it cools down very well but the temps during the pull are still climbing due to the ****** factory Y for the IC bricks. not going to get around that with out going up to 1" and getting better flow through each IC brick in the blower.

Edit just noticed Jim runs the 2.3 upper pulley

Last edited by whatcop?; 09-09-2014 at 12:38 AM.

#25

Melting Slicks

Member Since: Jun 2009

Location: Naperville/Palm Beach IL/FL

Posts: 3,109

Likes: 0

Received 3 Likes

on

3 Posts

on the contrary i think im running the best magnuson set up out of everyone right now and my temps are still questionable and hitting 165-173 on half mile pulls with meth still. thats magnuson heat ex 3/4" line through out the system with an icetank and straightline tank making a 6 gallon capacity in the system. it cools down very well but the temps during the pull are still climbing due to the ****** factory Y for the IC bricks. not going to get around that with out going up to 1" and getting better flow through each IC brick in the blower.

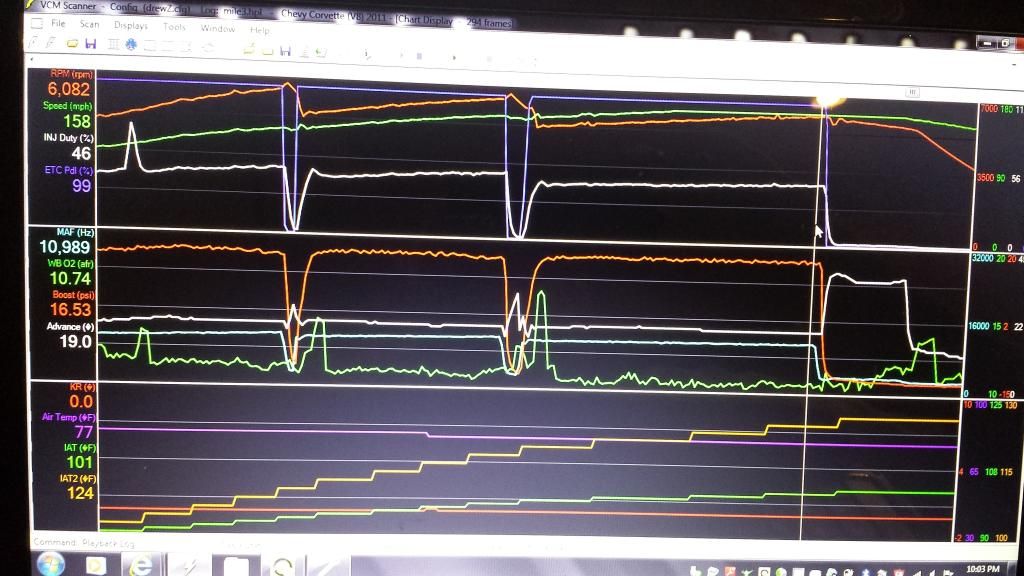

I just wanna see real data logs to be conveinced....

Like this halfmile log..

The more power you make the harder to keep it cool

Like D3 said theres only a large handful that push it too extreme and your 1

of them and let us know how it goes....

of them and let us know how it goes....I will share mine from the Texas Mile

#27

i was running a stock pump in mine aswell aswell as a mezeire pump to return it. i have no problem being the guinea pig here. looking to have them do my z06 up with some snails and other goodies so its a good test to see how there stuff does. you know me i always say it how it is

#28

Le Mans Master

i was running a stock pump in mine aswell aswell as a mezeire pump to return it. i have no problem being the guinea pig here. looking to have them do my z06 up with some snails and other goodies so its a good test to see how there stuff does. you know me i always say it how it is

#29

pressurized system and the stock pump and the mezire pumps by themselves werent flowing enough i tried it both ways. worked best with one inline with the set up i had but thats beside the point here. dont want to off topic the OP thread

#30

Melting Slicks

Member Since: Jun 2009

Location: Naperville/Palm Beach IL/FL

Posts: 3,109

Likes: 0

Received 3 Likes

on

3 Posts

i was running a stock pump in mine aswell aswell as a mezeire pump to return it. i have no problem being the guinea pig here. looking to have them do my z06 up with some snails and other goodies so its a good test to see how there stuff does. you know me i always say it how it is

Z06 is gonna be a monster.

I will just set this here to tease you.

I think the information that we chose to share without giving away too much free information on how to design a product like this

I thought that was what this forum was for to help each other out?

Like tell how and what to use to get gates green belt to work... etc...

Jim you selling the expansion tank you got from other vendor?

#31

When is shift sector?

Z06 is gonna be a monster.

I will just set this here to tease you.

I think the information that we chose to share without giving away too much free information on how to design a product like this

I thought that was what this forum was for to help each other out?

Like tell how and what to use to get gates green belt to work... etc...

Jim you selling the expansion tank you got from other vendor?

Z06 is gonna be a monster.

I will just set this here to tease you.

I think the information that we chose to share without giving away too much free information on how to design a product like this

I thought that was what this forum was for to help each other out?

Like tell how and what to use to get gates green belt to work... etc...

Jim you selling the expansion tank you got from other vendor?

#32

When is shift sector?

Z06 is gonna be a monster.

I will just set this here to tease you.

I think the information that we chose to share without giving away too much free information on how to design a product like this

I thought that was what this forum was for to help each other out?

Like tell how and what to use to get gates green belt to work... etc...

Jim you selling the expansion tank you got from other vendor?

Z06 is gonna be a monster.

I will just set this here to tease you.

I think the information that we chose to share without giving away too much free information on how to design a product like this

I thought that was what this forum was for to help each other out?

Like tell how and what to use to get gates green belt to work... etc...

Jim you selling the expansion tank you got from other vendor?

D3P can you confirm what the added weight of the kit it and how much additional water capacity you are adding to the system? My fear is the reducing in IATs is simply down to the added water volume in the system not due to the HE!

Also any plans on testing this at a road course session to really show all if its the end of high IATs.

#33

My honest feeling is these system that simply add water volume are just postponing the heat soak issue. Yes the system will take longer to get into heat soak but without a significantly larger HE (or better placed like the German car with the HEs mounted in the fog light area) you simply cant remove the heat from the system.

An example is an F1 engine. They run with approximately 5 ltr of water in the whole engine and rad setup. yet they manage to cool 800++bhp engines. Its not about the volume it about moving the heat to the environment.

#34

Le Mans Master

Stock pump shouldn't matter as long as flow is over approx 10lpm (that's the speed when you start to get a thicker boundary layer forming reducing cooling). Dont forget the longer the water is in the HE the lower the temp as it leaves.

My honest feeling is these system that simply add water volume are just postponing the heat soak issue. Yes the system will take longer to get into heat soak but without a significantly larger HE (or better placed like the German car with the HEs mounted in the fog light area) you simply cant remove the heat from the system.

An example is an F1 engine. They run with approximately 5 ltr of water in the whole engine and rad setup. yet they manage to cool 800++bhp engines. Its not about the volume it about moving the heat to the environment.

My honest feeling is these system that simply add water volume are just postponing the heat soak issue. Yes the system will take longer to get into heat soak but without a significantly larger HE (or better placed like the German car with the HEs mounted in the fog light area) you simply cant remove the heat from the system.

An example is an F1 engine. They run with approximately 5 ltr of water in the whole engine and rad setup. yet they manage to cool 800++bhp engines. Its not about the volume it about moving the heat to the environment.

Stock pump only flows 8gpm if I am correct. I am completely with you on wanting slow flow through the hx but I want the fastest flow possible through the intercooler. That's where our system is limited. You want the fastest flow as not to allow the water going through there to not get saturated with heat. The larger the differential area of temperature the greater the efficiency in extracting heat.

So ideally we need as much pump as possible, smallest diameter pipe, greatest surface area, and then a restriction post intercooler to slow the fluid through the heat exchangers.

And in case anyone isn't following my thoughts on this you have to remember that air-to-water systems function best went the water molecules can come in direct contact with the surface to exchange heat. Don't believe me? Go look at your radiator or oil coolers on any car and tell me how thick they are and then look at an air-to-air intercooler and how thick it is.

#35

Melting Slicks

Member Since: Jun 2009

Location: Naperville/Palm Beach IL/FL

Posts: 3,109

Likes: 0

Received 3 Likes

on

3 Posts

Yes. It's a motivator . Built by Redline motorsports

That's a lovely looking turbo kit! however isn't it for a Gen 5 Camaro?

D3P can you confirm what the added weight of the kit it and how much additional water capacity you are adding to the system? My fear is the reducing in IATs is simply down to the added water volume in the system not due to the HE!

Also any plans on testing this at a road course session to really show all if its the end of high IATs.

D3P can you confirm what the added weight of the kit it and how much additional water capacity you are adding to the system? My fear is the reducing in IATs is simply down to the added water volume in the system not due to the HE!

Also any plans on testing this at a road course session to really show all if its the end of high IATs.

#36

Not sure I buy that the Katech heat exchanger performed worse than stock. Filling these systems are tricky. How did the developer (D3P) prove the stock and Katech HX set ups were full?

The pump curve data that LPE did shows the stock pump can deliver quite a bit of water flow if some restrictions are removed. For example, the pump suction is too restrictive. I relocated my stock pump to take a direct straight inlet from the HX. Did the developer consider to retain the stock pump for cost savings and ease of installation?

The lack of HX divider plates in the stock and Katech HX tend to be mitigated by increase flow rate and a full system. If the system isn't completely full then expect air pockets in the HX and a huge drop in performance.

Not sure I like the idea of all the air to the LS9 going through a restrictive HX. What us the pressure drop of the HX at 100 mph, 150 mph and 200 mph? The LS9 needs air! Maybe modify the NACA duct to increase air flow to the air filter? Is this in development at D3P?

I already have sunk $2,000 in intercooler upgrades in an attempt to contend with south Texas heat! Do I have to scrap that investment or do you sell the HX and Y replacement fittings separately?

I really liked the development here but wonder if there isn't some optimization left on price vs performance.

The pump curve data that LPE did shows the stock pump can deliver quite a bit of water flow if some restrictions are removed. For example, the pump suction is too restrictive. I relocated my stock pump to take a direct straight inlet from the HX. Did the developer consider to retain the stock pump for cost savings and ease of installation?

The lack of HX divider plates in the stock and Katech HX tend to be mitigated by increase flow rate and a full system. If the system isn't completely full then expect air pockets in the HX and a huge drop in performance.

Not sure I like the idea of all the air to the LS9 going through a restrictive HX. What us the pressure drop of the HX at 100 mph, 150 mph and 200 mph? The LS9 needs air! Maybe modify the NACA duct to increase air flow to the air filter? Is this in development at D3P?

I already have sunk $2,000 in intercooler upgrades in an attempt to contend with south Texas heat! Do I have to scrap that investment or do you sell the HX and Y replacement fittings separately?

I really liked the development here but wonder if there isn't some optimization left on price vs performance.

Last edited by greenshark68; 09-09-2014 at 09:37 AM. Reason: Spelling

#37

For cooling purposes I am having great results with twin D04 nozzles from Devils Own, since my objective is to cool air I use 70% water 30% meth, water has been proven to cool down better than meth. I am at 850whp and temps are most of the time in the 130s range and after several runs it reaches 150s@5500rpms but when reaching 6500rpms its almost down to 130s again.

#38

Stock pump only flows 8gpm if I am correct. I am completely with you on wanting slow flow through the hx but I want the fastest flow possible through the intercooler. That's where our system is limited. You want the fastest flow as not to allow the water going through there to not get saturated with heat. The larger the differential area of temperature the greater the efficiency in extracting heat.

So ideally we need as much pump as possible, smallest diameter pipe, greatest surface area, and then a restriction post intercooler to slow the fluid through the heat exchangers.

And in case anyone isn't following my thoughts on this you have to remember that air-to-water systems function best went the water molecules can come in direct contact with the surface to exchange heat. Don't believe me? Go look at your radiator or oil coolers on any car and tell me how thick they are and then look at an air-to-air intercooler and how thick it is.

So ideally we need as much pump as possible, smallest diameter pipe, greatest surface area, and then a restriction post intercooler to slow the fluid through the heat exchangers.

And in case anyone isn't following my thoughts on this you have to remember that air-to-water systems function best went the water molecules can come in direct contact with the surface to exchange heat. Don't believe me? Go look at your radiator or oil coolers on any car and tell me how thick they are and then look at an air-to-air intercooler and how thick it is.

However if you use the car on a road course then all you are doing by increasing the speed of the water through the Intercooler bricks is reducing the temp of the water as it leaves the intercooler. This then results in a lower delta T at the HE end and thus less heat transfer.

Same goes for engine cooling. Everyone wants massive flow when actually it’s the radiator and the airflow over it that really matters. In fact in an engine you can actually increase the metal temps (internal engine temps) by increasing water flow rate. As the radiator becomes less efficient (due to lower Delta T values).

In an ideal world you would want the water leaving the intercooler (or engine) to be as hot as in coming air (or the metal in an engine). This would then mean that the water as removed as much heat as it can. This would also mean you have a decent delta T across the HE (or rad with an engine) and thus more heat transfer. To do this you want more intercooler rather than really slow speeds as you need to keep the water flowing fast enough to stop a thick boundary layer forming (form what I'm told that 10 lpm).

How would this look in reality? Like a massive intercooler on top of your engine with water flowing backwards and forwards through the brick(s). Like below

Air flow out

../\/\/\/\/\/\/\

|<<<<<<<<<<<|Water flow IN

|>>>>>>>>>>>|

|<<<<<<<<<<<|

|>>>>>>>>>>>|Water flow out

../\/\/\/\/\/\/\

Air flow in

Obviously this isn't practical but you get the idea.

Also how do you plan on slowing flow rater in a closed loop system? You cant do that as far as i am aware! you could have a HUGE HE which would take its time being pumped through but you cant slow the flow rate. Think of it like a river. The flow rate is the same but the water speed will increase in shallower sections and reduces in deeper ones. But the flow rate remains constant!

Last edited by chuntington101; 09-09-2014 at 11:56 AM.

#39

But thatís my point, why do you need such high flow rates unless you are suing the car solely for drag racing? I can see it helping when drag racing as you want as cold water in the Intercooler brick as you can. This maintains higher Delta T between the incoming air and the water and thus pulls more heat from the intake air.

However if you use the car on a road course then all you are doing by increasing the speed of the water through the Intercooler bricks is reducing the temp of the water as it leaves the intercooler. This then results in a lower delta T at the HE end and thus less heat transfer.

Same goes for engine cooling. Everyone wants massive flow when actually itís the radiator and the airflow over it that really matters. In fact in an engine you can actually increase the metal temps (internal engine temps) by increasing water flow rate. As the radiator becomes less efficient (due to lower Delta T values).

In an ideal world you would want the water leaving the intercooler (or engine) to be as hot as in coming air (or the metal in an engine). This would then mean that the water as removed as much heat as it can. This would also mean you have a decent delta T across the HE (or rad with an engine) and thus more heat transfer. To do this you want more intercooler rather than really slow speeds as you need to keep the water flowing fast enough to stop a thick boundary layer forming (form what I'm told that 10 lpm).

How would this look in reality? Like a massive intercooler on top of your engine with water flowing backwards and forwards through the brick(s). Like below

Air flow out

../\/\/\/\/\/\/\

|<<<<<<<<<<<|Water flow IN

|>>>>>>>>>>>|

|<<<<<<<<<<<|

|>>>>>>>>>>>|Water flow out

../\/\/\/\/\/\/\

Air flow in

Obviously this isn't practical but you get the idea.

However if you use the car on a road course then all you are doing by increasing the speed of the water through the Intercooler bricks is reducing the temp of the water as it leaves the intercooler. This then results in a lower delta T at the HE end and thus less heat transfer.

Same goes for engine cooling. Everyone wants massive flow when actually itís the radiator and the airflow over it that really matters. In fact in an engine you can actually increase the metal temps (internal engine temps) by increasing water flow rate. As the radiator becomes less efficient (due to lower Delta T values).

In an ideal world you would want the water leaving the intercooler (or engine) to be as hot as in coming air (or the metal in an engine). This would then mean that the water as removed as much heat as it can. This would also mean you have a decent delta T across the HE (or rad with an engine) and thus more heat transfer. To do this you want more intercooler rather than really slow speeds as you need to keep the water flowing fast enough to stop a thick boundary layer forming (form what I'm told that 10 lpm).

How would this look in reality? Like a massive intercooler on top of your engine with water flowing backwards and forwards through the brick(s). Like below

Air flow out

../\/\/\/\/\/\/\

|<<<<<<<<<<<|Water flow IN

|>>>>>>>>>>>|

|<<<<<<<<<<<|

|>>>>>>>>>>>|Water flow out

../\/\/\/\/\/\/\

Air flow in

Obviously this isn't practical but you get the idea.

im getting similar cool down rates with my current set up but my heat increase during a pull is alot higher than what they are getting with their kit which is what i want and why i decided to snag one.

#40

Former Vendor

Thread Starter

That's a lovely looking turbo kit! however isn't it for a Gen 5 Camaro?

D3P can you confirm what the added weight of the kit it and how much additional water capacity you are adding to the system? My fear is the reducing in IATs is simply down to the added water volume in the system not due to the HE!

Also any plans on testing this at a road course session to really show all if its the end of high IATs.

D3P can you confirm what the added weight of the kit it and how much additional water capacity you are adding to the system? My fear is the reducing in IATs is simply down to the added water volume in the system not due to the HE!

Also any plans on testing this at a road course session to really show all if its the end of high IATs.

Our data paints a very clear picture that our system works.

There are many systems on the market that do indeed band-aid the problem by adding sheer capacity and a trunk-mounted tank, that is not the approach we took to solve this problem. If you take time to truly review the real-world data in the first two posts of this thread it is pretty conclusive.

Anyone on Earth is more than welcome to test our product, I think our testing proceedure and documented results we openly posted are pretty clear. We did a lot more than some highway and dyno pulls using the stock IAT2 sensor...