Ls2 TT guys... need help with vent

#1

Burning Brakes

Thread Starter

Member Since: Jan 2010

Location: Orient Oh

Posts: 796

Likes: 0

Received 0 Likes

on

0 Posts

I recently finished the TT project. and noticed there's entirely to much crank case pressure.. so much that the valve cover gasket started leaking. I had a auto zone little vent oil filter on the valve cover and another on the crank case passenger side vent... so now I have to get new gasket's and really don't want another gasket blow again. So I thought about on the driver's side pulling off that little nipple and adding a filter there and doing something with hose that goes above the throttle body to the passenger side into a sensor and wraps back around to behind the throttle body... I'm just a back yard mech and learning as I go so any help would be well appreciated

#2

Melting Slicks

valve cover gaskets blew out? never heard that one before.

and you bought new ones?

did you happen to run way too much boost on accident or without fuel system / tune?

are you running boost from the charge pipe right into the crank case? if so don't do that.. relocate that line to before the turbo(s).

and you bought new ones?

did you happen to run way too much boost on accident or without fuel system / tune?

are you running boost from the charge pipe right into the crank case? if so don't do that.. relocate that line to before the turbo(s).

#3

Le Mans Master

Member Since: May 2011

Location: Tampa FL (formerly Justinjor)

Posts: 5,022

Likes: 0

Received 14 Likes

on

9 Posts

Tech Contributor

St. Jude Donor '11-'12-'13-'14

Have you contacted UPP? I have never heard of valve cover gaskets blowing out with their kit. Perhaps they have a suggestion or fix. IIRC, you did buy one of their kits

#4

Drifting

If you have that much crank case pressure without accidentally putting boost into one of the crank case ports via a vacuum hose routed wrong then it sounds like the motor has a ton of blow by! Make sure the vacuum fitting that runs to the valley under intake mani is open and not using a vacuum line that will see positive pressure!

#5

Burning Brakes

Thread Starter

Member Since: Jan 2010

Location: Orient Oh

Posts: 796

Likes: 0

Received 0 Likes

on

0 Posts

I can't find out what that darn hose is on the drivers side after throttle body... well I didn't blew a valve cover gasket after inspection.. it was loose. Here's a little issue. I follow the UPP instructions to a T... I have the wastegate's routed to the turbo compressor because I wanted a base tune of 8 psi (waste gate springs) I have my bov and fpr routed after the intercooler pre maf. My tuner told me to run the wastegates off of intake pressure. well I got it tuned... it has 19 degree timing a/f is good. The tuner has his boost thing hooked up with the bov & fpr line and it reads 8 psi max.. well my boost gauge (route from my brake booster) shows almost 5psi max while I was driving the car home... I think that mystery line has something to do with it.. car made 587rwhp 565rwtq.. also I had a bad drivers side 02 sensor, donut gasket ( pre turbo huge leak).. injectors was 60% dc.. I have plenty of fuel aeromotive eliminator and all supporting fuel system... tuner told me once I fix the exhuast leak, get new 02 sensors and route the wastegates off the intake pressure he's going to re-do my tune.. I should be getting my boost controller in soon as well...

Last edited by marine&hisvette; 11-20-2012 at 04:18 PM.

#6

Drifting

Your bov's need to see vacuum so you need to route the lines to them from the intake (after the trottle body) so they will see vacuum and close while not under boost. I have all my boost referenced items (fuel pump hobb switch, boost gauge, boost controller, Wastegates and BOV's) getting boos/vacuum from the large nipple in the intake manifold right after the throttle body! This used to run to the PCV which is eliminated with this setup.

The valley port and passenger side valve cover port should be left vented (open)

The valley port and passenger side valve cover port should be left vented (open)

#7

Instructor

Ya when i had my wastegates hooked directly to my turbos id only see 5-6 psi but as soon as i hooked my waste gates to my intake pipe right before my maf sensor id almost see 10psi.

#8

Burning Brakes

Thread Starter

Member Since: Jan 2010

Location: Orient Oh

Posts: 796

Likes: 0

Received 0 Likes

on

0 Posts

But what is that hard line hose set up? the one that goes behind the throttle body on the drivers side? it's hooked up to a sensor and then runs back to the line with a quick disconnect to the fuel line.. I could just cap that portion off and run the wastegates to that side of the intake? and use the other side for the bov?

Last edited by marine&hisvette; 11-20-2012 at 08:41 PM.

#9

Le Mans Master

Member Since: Jul 2005

Location: Think BEFORE hitting "Submit Reply"

Posts: 9,378

Received 708 Likes

on

391 Posts

If you have any hoses hooked up from the intake manifold back to the engine/crankcase, like with a catch can, you will need some type of check valve that closes under boost to keep from pressurizing the crankcase.

It sounds like that may be your problem.

Just a thought.

Hope this helps.

It sounds like that may be your problem.

Just a thought.

Hope this helps.

#10

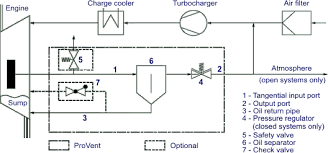

1) Get rid of the open breathers on the valve cover.

2) Buy a Mann & Hummel Provent200 (LPE sells them)

3) Install it exactly as per their directions:

A lot of turbo guys have been using these for years (myself included). It works 10x better than any kind of open vent, but you need to follow the directions and make sure it's plumbed correctly.

2) Buy a Mann & Hummel Provent200 (LPE sells them)

3) Install it exactly as per their directions:

A lot of turbo guys have been using these for years (myself included). It works 10x better than any kind of open vent, but you need to follow the directions and make sure it's plumbed correctly.

#11

Former Vendor

I recently finished the TT project. and noticed there's entirely to much crank case pressure.. so much that the valve cover gasket started leaking. I had a auto zone little vent oil filter on the valve cover and another on the crank case passenger side vent... so now I have to get new gasket's and really don't want another gasket blow again. So I thought about on the driver's side pulling off that little nipple and adding a filter there and doing something with hose that goes above the throttle body to the passenger side into a sensor and wraps back around to behind the throttle body... I'm just a back yard mech and learning as I go so any help would be well appreciated

There's only 2 ways to get pressure in the crank case, by blowing it in via vacuum line, or by excessive blow by.

So there's 3 ports or vents to open or route away from boost pressures.

The first is on the rear of the drivers side. From factory it's generally capped, so if you're not using a breather system, leave it alone and let it stay capped.

Next is on the Pass valve cover. It's a hard line that goes connect to the valve cover in the rear and then comes up along the front pointing forward. (see pic). This was connected to the intake BEFORE the TB. Disconnect it and let it vent. (you shouldn't have a way to connect it anyways with the IC piping replacing all of the vent ports).

*And that brings on another question as to how you're connecting the BOV's before the MAF, as there's no ports there to connect to?

The third port is in the valley below the plastic intake manifold. From factory it's routed a short "U" hose that connects to right AFTER the throttle body. Remove this hose completely. The bottom port in the valley will be a vent, the port on the plastic intake mani (where you just removed the other end of the "U" hose from) will be your port for measuring boost/vacuum. So this is where your Boost gauge gets plunged into as well as the BOV's, Meth injection boost source, KB BAPs, etc. All from this one port. We don't use the brake line at all as we don't want to touch the brake system, AND there is a check valve somewhere in that line. Putting things (like boost gauge) after that will screw with their readings.

As far as putting the WG source to the manifold, you can. There is generally a bit of a difference between the two due to IC pressure drop (but usually never as much as Greer is seeing). So the turbos will see 8psi before the intake mani, and therefore open the WG's sooner. We generally keep the lines connected at the WG's and just use a boost controller to hit our desired boost (whatever it may be).

Once you have all this corrected, if you still see a crank case pressures, it's because you have excessive blow by. This is generally due to worn/damaged piston rings (wear and tear, or detonation). Some blow by is normal, which is why we use catch cans with vents (or the Mann-Hummel) to eliminate the pressures. Some have even reused their secondary air injection pumps as vacuums for the crank case. If you manage to produce an actual vacuum in the crank case, that is the best as the piston rings will seal better, and generally produce more power.

Hope this helps, if not post back up, or just give me a call.

#12

Burning Brakes

Thread Starter

Member Since: Jan 2010

Location: Orient Oh

Posts: 796

Likes: 0

Received 0 Likes

on

0 Posts

Here's my set up I been running... I used my rx catch can for na car's because when I had a oil filter on the cap I thought the oil was blowing out of it.. well turns out the oil line that feeds into the oil cap has been leaking the whole time at the an fitting!! so I'm gonna use that tape to repair the line I put a cap on this side intake port behind the tb. I have the bov and fpr T off on the charge pipe before maf and after intercooler ( can't see here because I painted it black) I'm seeing 11psi now but the rubber intake thing has to go!!!!!

here's the other side.. I used the outlet after the tb for the wastegates vac/boost and took off that nipple and added a filter

here's the other side.. I used the outlet after the tb for the wastegates vac/boost and took off that nipple and added a filter

Last edited by marine&hisvette; 11-23-2012 at 07:15 PM.

#13

I had big issue with too much crank house pressure. I did put cats can with 3 inputs and too air breathers. I did drill bigger holes in to each valve cover for more air flow. I took those 2 in too cats can and the one from under the manifold as well in too the cats can. After this I have none issue and hardly any oil in to the cats can. I have gone up to 18 psi.