*** Special on Magnuson Heartbeat this Fall **

#1261

Le Mans Master

You will get more boost out of the bigger throttle body. No doubt. I don't know for sure that more boost will create more load on your belt system....but, I suspect it will. Better up your anti belt slip game another notch or two.

#1262

I will get another 97.5" RPM belt and I'll try running that with the standard Magnuson 81mm pulley, as you suggested. I don't think it's the Griptech pulley that's the problem though. That thing has got to grip the belt better than a standard pulley.

However, consider this: In this scenario, boost would be increased by reducing vacuum on the intake side of the rotors, thereby allowing more airflow through the rotors, not by increasing rotor speed. So, whilst the increase in boost by itself would increase load on the belt, will this not be offset by reducing vacuum on the intake side, which must decrease load to some extent as well? Put another way, isn't the vacuum on the intake side of the rotors creating some load on the belt right now?

Basically, what would be happening here is that I would making my airpump more efficient at pumping air.

#1263

Le Mans Master

However, consider this: In this scenario, boost would be increased by reducing vacuum on the intake side of the rotors, thereby allowing more airflow through the rotors, not by increasing rotor speed. So, whilst the increase in boost by itself would increase load on the belt, will this not be offset by reducing vacuum on the intake side, which must decrease load to some extent as well? Put another way, isn't the vacuum on the intake side of the rotors creating some load on the belt right now?

Basically, what would be happening here is that I would making my airpump more efficient at pumping air.

I have a plaque on my desk that states, "I don't need Google...My wife knows everything." I ran this by her and she agrees with me. End of argument.

#1264

Yeah, I thought about that. And your argument definitely has warrant. I just think the increase in boost has more influence on the belt load vs the decrease in vacuum.

I have a plaque on my desk that states, "I don't need Google...My wife knows everything." I ran this by her and she agrees with me. End of argument.

I have a plaque on my desk that states, "I don't need Google...My wife knows everything." I ran this by her and she agrees with me. End of argument.

#1265

So, my thinking for right now is to explore the possibility of modifying the stock 90mm HBeat throttle body inlet to utilize a 102mm. I know they have the same bolt pattern/spacing, and I recall that at least one person (monsta1) had installed a NW102 before, with no real success, but simply bolting the larger throttle body on, without opening the inlet up to 102+mm, will gain nothing, and there's no way to port the inlet to 102mm, because the casting is very narrow behind the mounting flange (see pic below).

The following users liked this post:

CI GS (07-27-2017)

#1266

Drifting

I'd say yes also, FWIW. Less Delta P = lower load.

HOWEVER if you conquer this belt issue, I bet you machine a 70mm upper just for the challenge...

HOWEVER if you conquer this belt issue, I bet you machine a 70mm upper just for the challenge...

However, consider this: In this scenario, boost would be increased by reducing vacuum on the intake side of the rotors, thereby allowing more airflow through the rotors, not by increasing rotor speed. So, whilst the increase in boost by itself would increase load on the belt, will this not be offset by reducing vacuum on the intake side, which must decrease load to some extent as well? Put another way, isn't the vacuum on the intake side of the rotors creating some load on the belt right now?

Basically, what would be happening here is that I would making my airpump more efficient at pumping air.

Basically, what would be happening here is that I would making my airpump more efficient at pumping air.

#1267

However, consider this: In this scenario, boost would be increased by reducing vacuum on the intake side of the rotors, thereby allowing more airflow through the rotors, not by increasing rotor speed. So, whilst the increase in boost by itself would increase load on the belt, will this not be offset by reducing vacuum on the intake side, which must decrease load to some extent as well? Put another way, isn't the vacuum on the intake side of the rotors creating some load on the belt right now?

Basically, what would be happening here is that I would making my airpump more efficient at pumping air.

Basically, what would be happening here is that I would making my airpump more efficient at pumping air.

The input power required by the SC is composed of:

Pressure Ratio

Mass Flow

Frictional Losses

Frictional losses on a TVS SC (which dosen't require any type of step-up gearing system) are pretty small, they can be mostly neglected under boost.

Mass Flow and Pressure Ratio remain the dominating factors here. As discussed - the inlet depression causes an increased Pressure Ratio (increased power requirement) but at a lower mass flow (less power) because of the throttle restriction. With the larger throttle the opposite is true - which might have the higher input power requirement - but will result in a higher engine power output - which is the desired outcome.

I second the nomination for a 70 mm pulley...

The following users liked this post:

CI GS (07-27-2017)

#1268

That's exactly how we modded the adapter for the Camaro. Welded up the inlet adapter with 5356 filler rod and opened up the inlet to 103mm (its an LT1). At the 700 RWHP level the throttle the TB change added about 13 RWHP and is pretty much the minimum TB size required if you plan to explore the full capability of the TVS2300 SC.

Attachment 48117864

Attachment 48117865

Attachment 48117864

Attachment 48117865

Did you check to see what kind of vacuum you were getting behind the TB before the inlet adaptor was opened up?

What are you using for an air inlet in front of the TB.

What pulley ratio are you using at that power level?

The ZR1 and LS Camaro guys with the Hbeat blowers seem to be picking up a lot of HP from going to the 102 or 108mm TBs.

You certainly seem to have a thing for those Heartbeat blowers, lol!

Thanks again for your very valuable input.

#1269

The problem is that it is physically impossible to fit a pulley over the drive snout of the Hbeat blower that's smaller than 81mm

The caddy/commodore/Camaro Hbeat blowers benefit from the fact that their pulleys are offset forward of the snout, so they can go down to a 75mm, I believe. And, of course, they can also use a much larger drive pulley (9"+ dia.), so they can significantly increase rotor speeds far above the Vette. In terms of a lower C6 is limited to what I'm running - a 3.2" (or 81mm) upper pulley and a 9.00" pullied balancer (which actually measures 9.25" overall diameter) for a total drive ratio of 2.5:1.

Hence my search for alternative ways to gain boost and power...

The following users liked this post:

Chiselchst (07-27-2017)

#1270

This is correct.

The input power required by the SC is composed of:

Pressure Ratio

Mass Flow

Frictional Losses

Frictional losses on a TVS SC (which dosen't require any type of step-up gearing system) are pretty small, they can be mostly neglected under boost.

Mass Flow and Pressure Ratio remain the dominating factors here. As discussed - the inlet depression causes an increased Pressure Ratio (increased power requirement) but at a lower mass flow (less power) because of the throttle restriction. With the larger throttle the opposite is true - which might have the higher input power requirement - but will result in a higher engine power output - which is the desired outcome.

I second the nomination for a 70 mm pulley...

The input power required by the SC is composed of:

Pressure Ratio

Mass Flow

Frictional Losses

Frictional losses on a TVS SC (which dosen't require any type of step-up gearing system) are pretty small, they can be mostly neglected under boost.

Mass Flow and Pressure Ratio remain the dominating factors here. As discussed - the inlet depression causes an increased Pressure Ratio (increased power requirement) but at a lower mass flow (less power) because of the throttle restriction. With the larger throttle the opposite is true - which might have the higher input power requirement - but will result in a higher engine power output - which is the desired outcome.

I second the nomination for a 70 mm pulley...

I will try this mod to see how this works out in actuality.

But before I do, the first thing I'm going to do is document the amount of vacuum in the TB inlet behind the throttle body and in the intake tract ahead of the throttle body at WOT.

#1271

Thanks once more for sharing the knowledge.

I will try this mod to see how this works out in actuality.

But before I do, the first thing I'm going to do is document the amount of vacuum in the TB inlet behind the throttle body and in the intake tract ahead of the throttle body at WOT.

I will try this mod to see how this works out in actuality.

But before I do, the first thing I'm going to do is document the amount of vacuum in the TB inlet behind the throttle body and in the intake tract ahead of the throttle body at WOT.

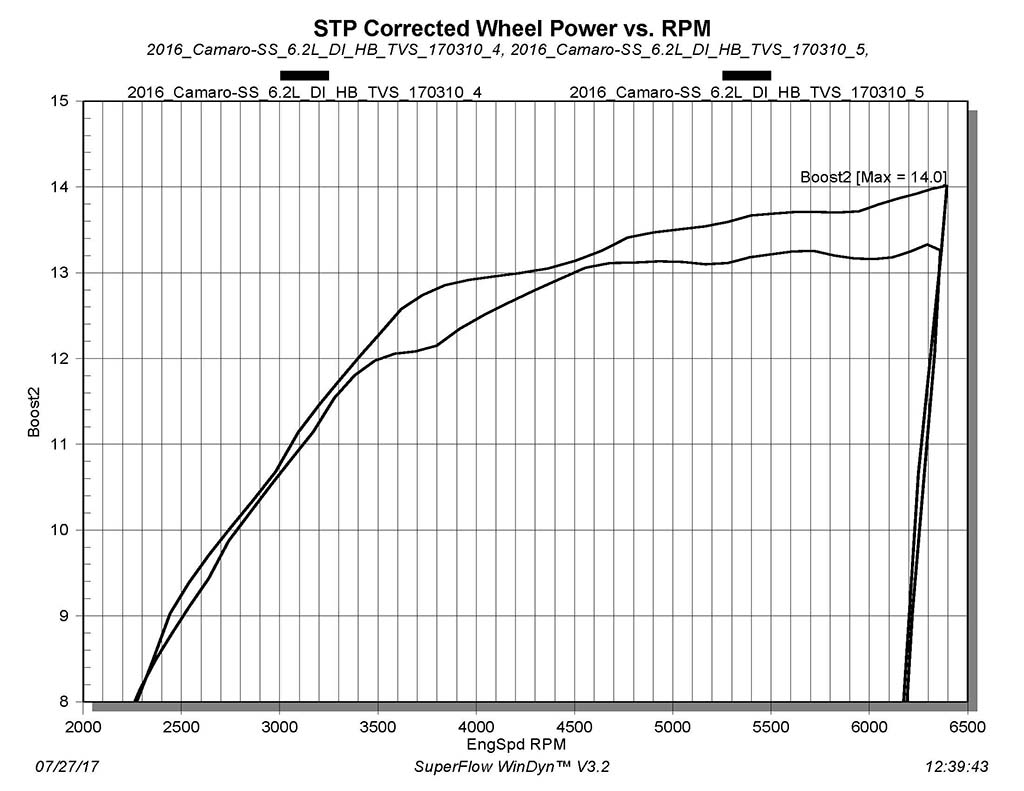

I did find the boost plots of the pull before (90mm throttle) and just after (103mm throttle) install. The car was running a 204mm crank pulley and a 75mm blower pulley making right about 690 RWHP in the plot below:

The following users liked this post:

CI GS (07-28-2017)

#1272

I looked to see if I had a log of Inlet Pressure before and after TB install - I did not. I'll be sure to record it on my Z06 when I add the 103mm TB in the near future.

I did find the boost plots of the pull before (90mm throttle) and just after (103mm throttle) install. The car was running a 204mm crank pulley and a 75mm blower pulley making right about 690 RWHP in the plot below:

Attachment 48120069

I did find the boost plots of the pull before (90mm throttle) and just after (103mm throttle) install. The car was running a 204mm crank pulley and a 75mm blower pulley making right about 690 RWHP in the plot below:

Attachment 48120069

But wait, you're making 730whp on a stock engine LT2 Camaro??? Is that with the stock cam too?? Holy **** dude. That is seriously impressive!

I'm seriously starting to wonder if I'm not wasting my time with this LS platform...

I'm seriously starting to wonder if I'm not wasting my time with this LS platform...

#1273

Le Mans Master

Thanks once more for sharing the knowledge.

I will try this mod to see how this works out in actuality.

But before I do, the first thing I'm going to do is document the amount of vacuum in the TB inlet behind the throttle body and in the intake tract ahead of the throttle body at WOT.

I will try this mod to see how this works out in actuality.

But before I do, the first thing I'm going to do is document the amount of vacuum in the TB inlet behind the throttle body and in the intake tract ahead of the throttle body at WOT.

The following users liked this post:

CI GS (07-28-2017)

#1274

I didn't get any vacuum between the air filter and throttle body. 3 or 4" between the throttle body and blower. Never thought to check that rubber flex hose connected to the throttle body. How are you going to check that? Drill a hole in the front of the throttle body? That 3 or 4" I found behind the throttle body could have come from that flex hose.

It also occurs to me that if there's enough vacuum generated behind the throttle body, this could possibly affect the bypass valve. I don't know what the chances are of that happening on the Hbeat though, since the bypass vacuum orifice is not located on the inlet snout, but on the blower housing, right in front of the rotors?

#1275

Burning Brakes

Interesting....I have been playing around with a Hurricane CAI I had on my C6 prior to the Heartbeat install. It doesn't line up well with the throttle body now, has to make a bit of a turn, and I always thought that bellows was a restriction. I am playing around with cutting into the Hurricane, and building a fiberglass transistion to smooth out the air flow with a small flex connection to take up engine movement. If I get a bit of time, I'll finish this project and take some before and after readings to see if I wasted my time.

#1276

Drifting

I think you're on to something. FWIW, I imagine that at a minimum the turbulence created (from the corrugated tube) will disrupt flow and cause turbulence, and additionally any distortion in ID the same. I like the centri set ups, they have those straight - long low restriction smooth tubes and dongles...

Perhaps you can boost the TVS2300 suction pressure by just throwing in a small single turbo...

Perhaps you can boost the TVS2300 suction pressure by just throwing in a small single turbo...

That damn bellows has got to be a restriction at some point though, being twisted like that with all of those corrugations. Mine certainly was at one point, because I had over-tightened the clamp that holds it onto the air cleaner assembly, and it had actually squashed the plastic housing and had the hose collapsed as well.

#1277

Interesting....I have been playing around with a Hurricane CAI I had on my C6 prior to the Heartbeat install. It doesn't line up well with the throttle body now, has to make a bit of a turn, and I always thought that bellows was a restriction. I am playing around with cutting into the Hurricane, and building a fiberglass transistion to smooth out the air flow with a small flex connection to take up engine movement. If I get a bit of time, I'll finish this project and take some before and after readings to see if I wasted my time.

Im currently considering using the K&N ZR1 intake, which I would have to cut a bit off of to get it to fit the Hbeat. It's expensive (like $900.00) though, since it's carbon fiber, so the idea of buying it without knowing if it can work and then cutting it up has me a little worried, to tell you the truth.

But I see that Vengeance is using that K&N intake nowadays with the NW 102mm TB and a ported stock ZR1 snout with very good results. I may give them a call and see what they think about me getting it to work on the HB.

#1278

I think you're on to something. FWIW, I imagine that at a minimum the turbulence created (from the corrugated tube) will disrupt flow and cause turbulence, and additionally any distortion in ID the same. I like the centri set ups, they have those straight - long low restriction smooth tubes and dongles...

Perhaps you can boost the TVS2300 suction pressure by just throwing in a small single turbo...

Perhaps you can boost the TVS2300 suction pressure by just throwing in a small single turbo...

Too bad Magnuson didn't do a "dongle" for the Heartbeat, instead of a "ribbed rubber" hose!

BTW: I'm planning on going there on Monday. Hopefully they won't throw me out the door...

#1279

So, I dropped in at Magnuson yesterday and spoke to one of their tech guys, and he gave me some very useful info. I've decided I'm going to order another inlet from them (along with the Camaro lid) and I'll weld up one of the inlets (and keep the other as a spare) and cut it out to about 108-110mm and bolt a 102mm NW boosted TB on that.

I've also been doing some digging on the benefits of opening up the throttle body and it looks like the C7 boys are also switched on to the benefits of larger throttle bodies and the ford guys are running 5" inlet tubes and really big throttle bodies and making serious power with the 2300 rotor pack. That tells me there's more to be gained from this.

If VCM picked up 90hp from switching from a 90mm to 108mm on a built motor, then I would think that I should be able to pick up at least a couple of pounds of boost and another 40hp or so, no?

Now I just need to figure out what to do for an air intake system...

I will also do some testing for vacuum in the inlet system to see if I can identify where the restriction is, and report back on here.

I've also been doing some digging on the benefits of opening up the throttle body and it looks like the C7 boys are also switched on to the benefits of larger throttle bodies and the ford guys are running 5" inlet tubes and really big throttle bodies and making serious power with the 2300 rotor pack. That tells me there's more to be gained from this.

If VCM picked up 90hp from switching from a 90mm to 108mm on a built motor, then I would think that I should be able to pick up at least a couple of pounds of boost and another 40hp or so, no?

Now I just need to figure out what to do for an air intake system...

I will also do some testing for vacuum in the inlet system to see if I can identify where the restriction is, and report back on here.

#1280

Melting Slicks

Member Since: Mar 2007

Location: Santa Barbara CA

Posts: 2,391

Likes: 0

Received 23 Likes

on

23 Posts

Hey Sammy,

Have you tried using a vacuum pump (like a mityvac) to test the bypass valve? I'm just wondering what vacuum level is required to start closing it. Then you could compare that to what you read with a vacuum gauge while in boost.

I was also thinking about what you said about connecting the bypass valve to the boost pressure port on the blower. If that port has vacuum at idle, it should work. I remember my old 122 blower having some port at the rear that only read boost. Or maybe it was only vacuum. I can't remember now.

Reducing the vacuum in the intake at WOT is really the best solution though. A custom intake and that inlet/throttle body should do it.

Have you tried using a vacuum pump (like a mityvac) to test the bypass valve? I'm just wondering what vacuum level is required to start closing it. Then you could compare that to what you read with a vacuum gauge while in boost.

I was also thinking about what you said about connecting the bypass valve to the boost pressure port on the blower. If that port has vacuum at idle, it should work. I remember my old 122 blower having some port at the rear that only read boost. Or maybe it was only vacuum. I can't remember now.

Reducing the vacuum in the intake at WOT is really the best solution though. A custom intake and that inlet/throttle body should do it.