Brake problem won't go away- need help

#41

Instructor

Thread Starter

Member Since: Sep 2007

Location: Philadelphia PA

Posts: 224

Likes: 0

Received 0 Likes

on

0 Posts

I don't appreciate all the people trying to thread jack. You don't go and say "I don't mean to thread jack, but...." that's just plain rude.

GM Power 4 Life, at least you have the same issue, so you're not thread jacking.

It's cold now, can't drive the car at all, but the last time the weather was nice a few weeks ago, I took some advice, took the console apart and put some weatherstripping foam in between the yaw sensor and the sheetmetal, screwed it back down tight. I also removed the ipod adapter I had in there, in case that was banging against the yaw sensor and causing a problem.

I took the car for a decently long (20 min) test drive, activated active handling a couple times in corners as well as activating traction control by punching it in first gear- no issues. ABS worked fine as well.

I don't know if that solved the issue, because I have not been able to drive the car for a decent distance to see if the problem reappears- I probably won't be able to do that until the spring.

For GM Power4Life- your tires are not the stock size- the difference in rolling circumference might be enough to cause the problem- if you're running stock tire sizes, you should have any issue and the fact that it only happens above a certain speed should clue you in that this is the cause of your problem. Why that shows up as only one wheel speed sensor creating a fault, I have no idea.

I wish there was someone at GM that could explain this- nothing in the service manual says that if you run aftermarket tires/wheels that a difference in wheel circumference will cause the right front wheel sensor fault, even if that is what happens.

My local dealership wanted a little over $2000 to fix the problem as they diagnosed- I spend about $800 plus $200 diagnostics and didn't fix the problem, although I'm running the ZR1 spec SKF hubs now as a side benefit, which would not be the case if I used the dealership to install $150 OE hubs.

GM Power 4 Life, at least you have the same issue, so you're not thread jacking.

It's cold now, can't drive the car at all, but the last time the weather was nice a few weeks ago, I took some advice, took the console apart and put some weatherstripping foam in between the yaw sensor and the sheetmetal, screwed it back down tight. I also removed the ipod adapter I had in there, in case that was banging against the yaw sensor and causing a problem.

I took the car for a decently long (20 min) test drive, activated active handling a couple times in corners as well as activating traction control by punching it in first gear- no issues. ABS worked fine as well.

I don't know if that solved the issue, because I have not been able to drive the car for a decent distance to see if the problem reappears- I probably won't be able to do that until the spring.

For GM Power4Life- your tires are not the stock size- the difference in rolling circumference might be enough to cause the problem- if you're running stock tire sizes, you should have any issue and the fact that it only happens above a certain speed should clue you in that this is the cause of your problem. Why that shows up as only one wheel speed sensor creating a fault, I have no idea.

I wish there was someone at GM that could explain this- nothing in the service manual says that if you run aftermarket tires/wheels that a difference in wheel circumference will cause the right front wheel sensor fault, even if that is what happens.

My local dealership wanted a little over $2000 to fix the problem as they diagnosed- I spend about $800 plus $200 diagnostics and didn't fix the problem, although I'm running the ZR1 spec SKF hubs now as a side benefit, which would not be the case if I used the dealership to install $150 OE hubs.

#42

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

Ok boys,,, I will add some stuff that I figured out for the C5s. Its pretty much the same for the C6.

The Wheel Hub speed sensors are pretty much bullet proof. There NOT very complicated when you take them apart.. These are C5 units but the C6s are not that much different and work the exact same way:

Its just a coil of wire around a plastic spool a small circuit board to connect the coil to the harness and the harness/plug assy.

Another fact that you need to know, the sensor output is an AC signal. Its a pulsed DC but the AC setting reads it better.

All the years that I have been dealing with wheel speed sensor issues (since 97) I have NEVER seen ANY wheel speed sensors FAIL.

What does fail and they fail a LOT are the crappy female pins inside the connectors on the main wheel speed sensor harness connector on the frame and the female plug in the sensor jumper harness

Heres an example of a NEW Female connector vs a BAD used female connector. The one on the RIGHT is BAD!!!!:

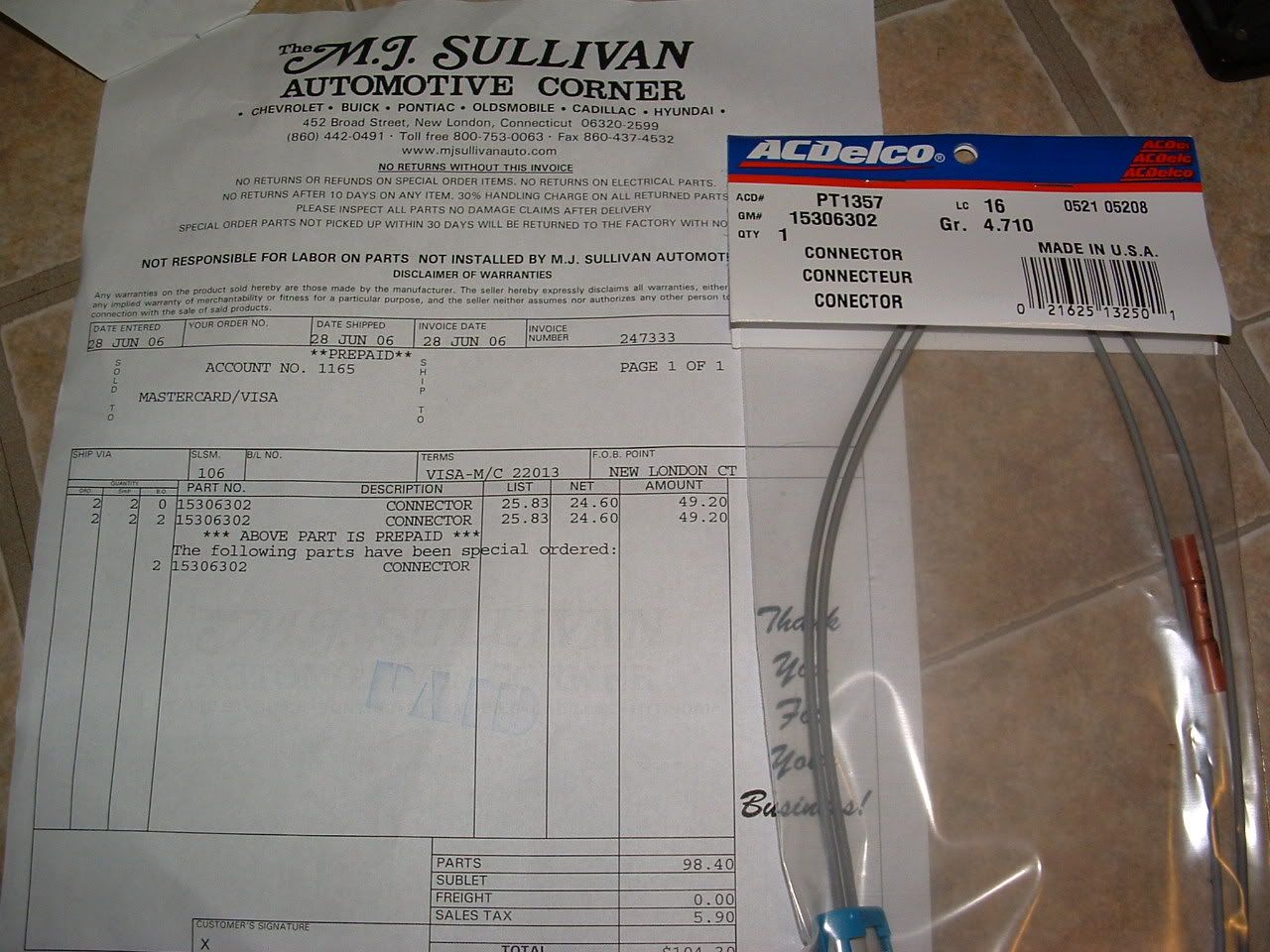

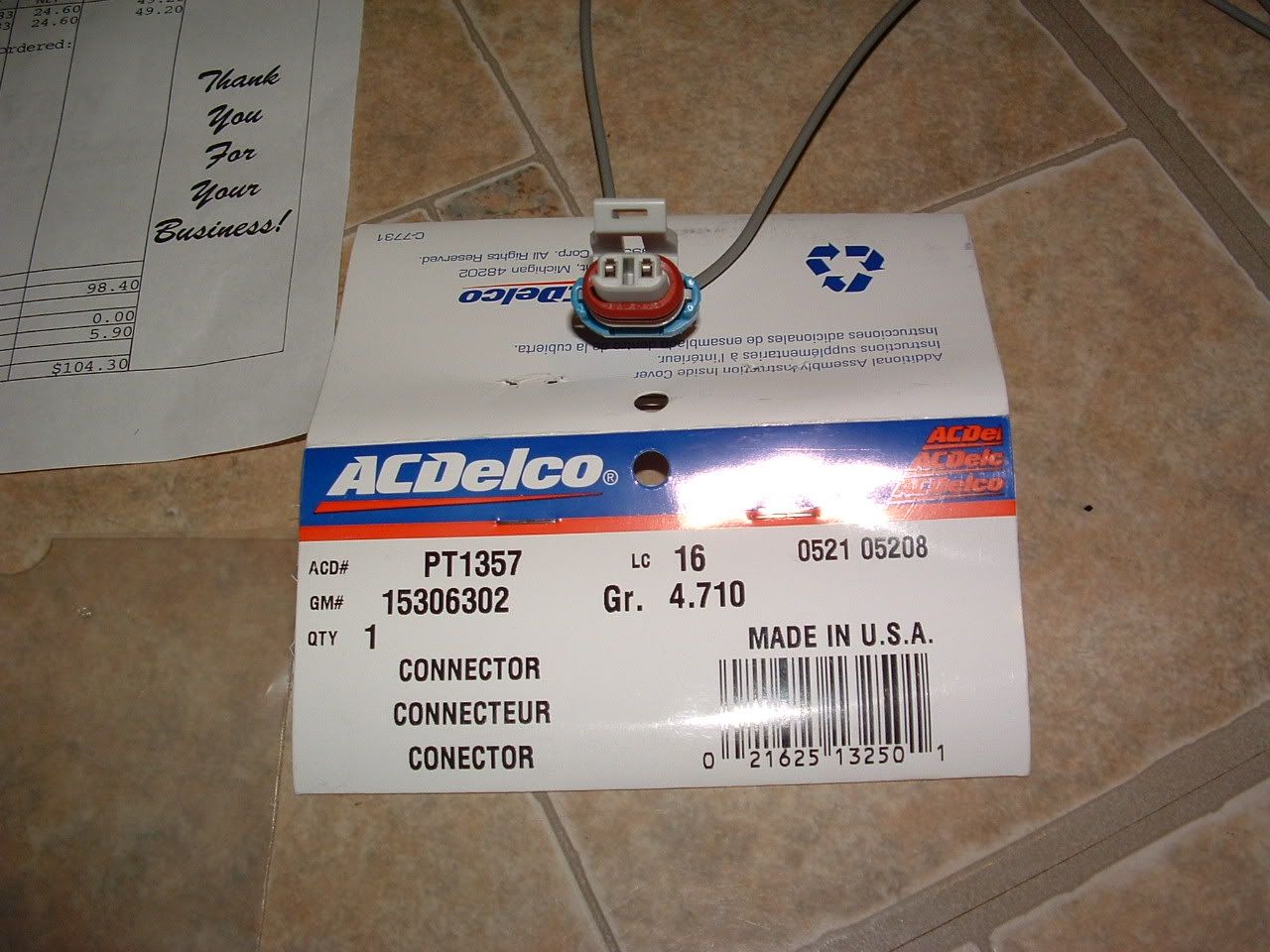

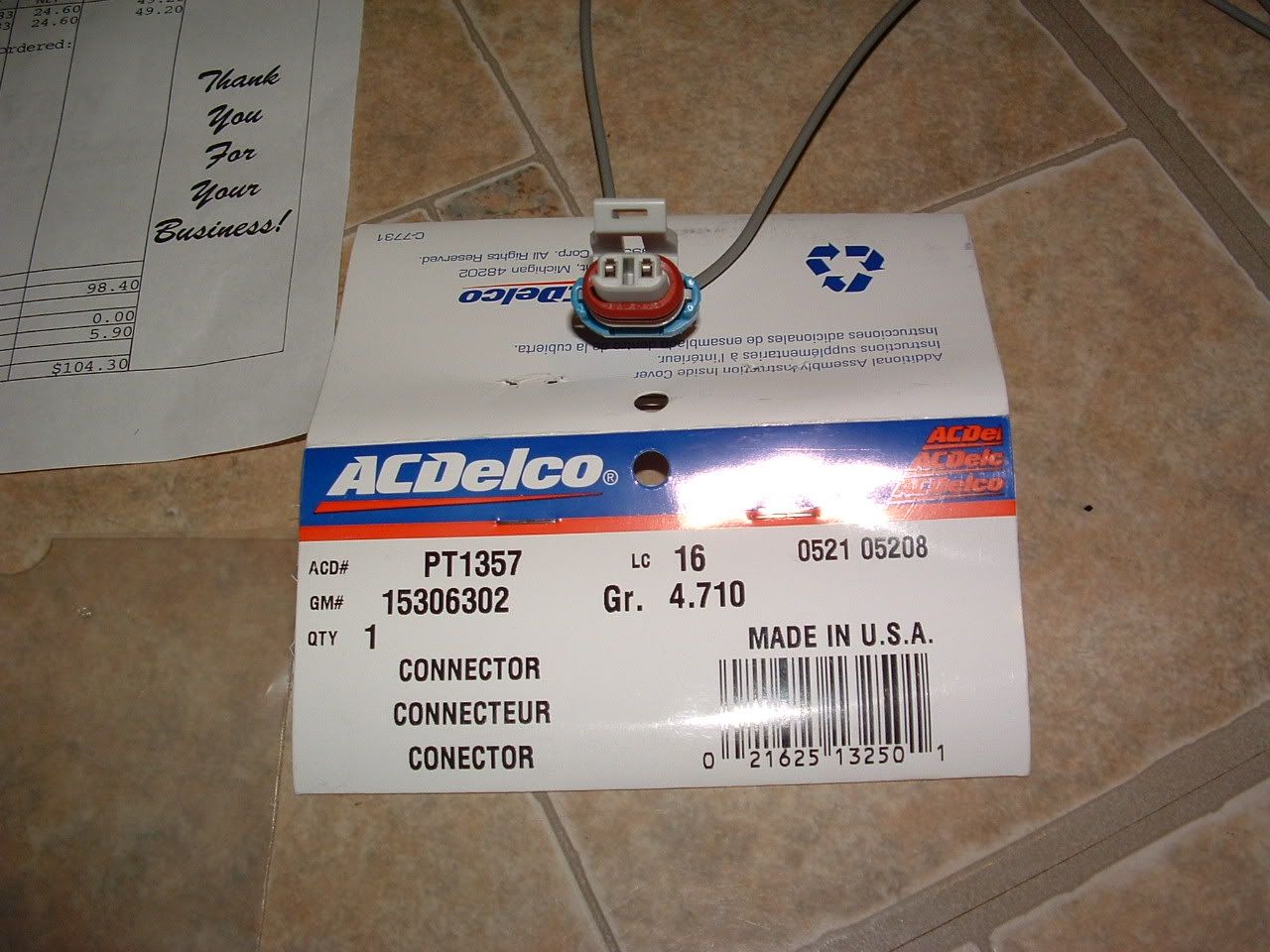

If you use a metal pick, you can reshape the little metal tung and make the proper connection. You can also purchase a new female connector pigtail. DO NOT get if from the stealership. There $26 each!!! Ask me how I know! Get them from the local parts store or Gene Culley www.gmpartshouse.com for a whole lot less!!

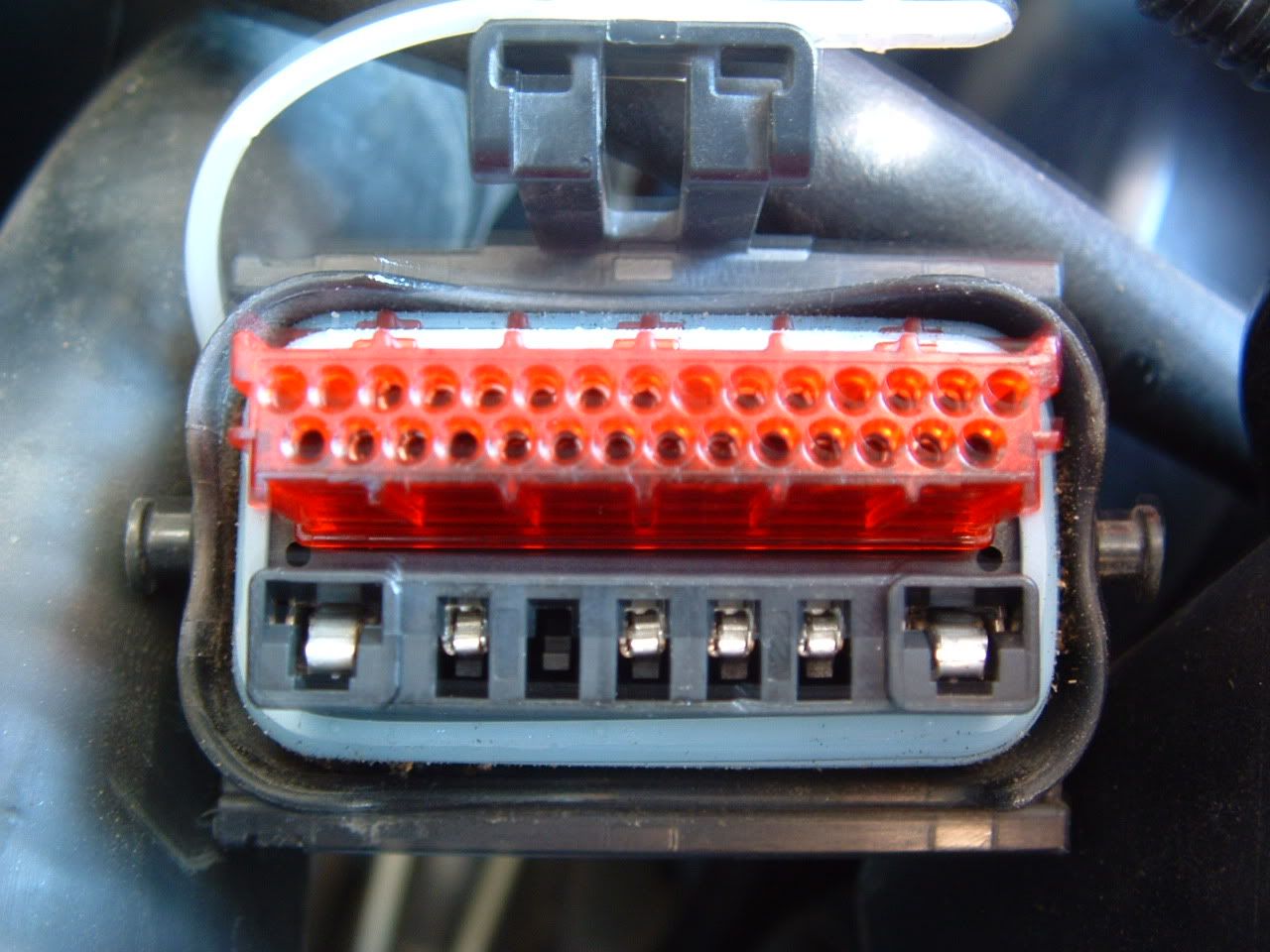

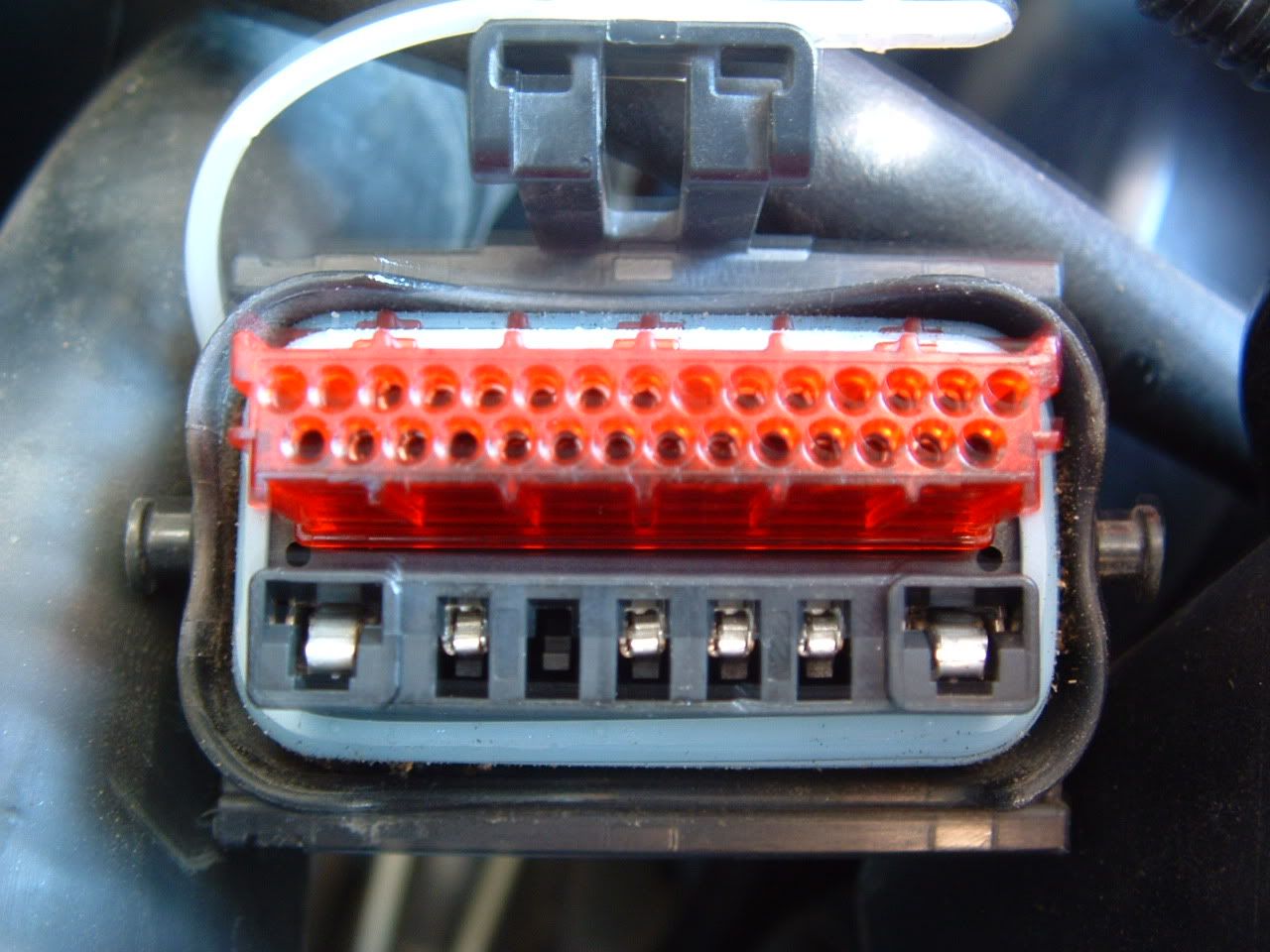

For easy troubleshooting,, you can read the wheel sensor resistances and voltages (when you rotate the wheel right from the EBTCM main connector:

2001+ shown

Long Story made short, there are TWO female connectors on EACH front wheel and ONE on each rear wheel harness connector that need to be checked for proper female pin grip. If the female pin is all spread open,, it is most likely part of the problem. I use an old MALE pin to check for proper female pin grip/connection.

If you slide the male pin into the female pin, there should be a nice tight fit and it should take a little effort to extract it and insert it.

Yea,,,,, I know what that sounds like!

Hope this helps!

BC

The Wheel Hub speed sensors are pretty much bullet proof. There NOT very complicated when you take them apart.. These are C5 units but the C6s are not that much different and work the exact same way:

Its just a coil of wire around a plastic spool a small circuit board to connect the coil to the harness and the harness/plug assy.

Another fact that you need to know, the sensor output is an AC signal. Its a pulsed DC but the AC setting reads it better.

All the years that I have been dealing with wheel speed sensor issues (since 97) I have NEVER seen ANY wheel speed sensors FAIL.

What does fail and they fail a LOT are the crappy female pins inside the connectors on the main wheel speed sensor harness connector on the frame and the female plug in the sensor jumper harness

Heres an example of a NEW Female connector vs a BAD used female connector. The one on the RIGHT is BAD!!!!:

If you use a metal pick, you can reshape the little metal tung and make the proper connection. You can also purchase a new female connector pigtail. DO NOT get if from the stealership. There $26 each!!! Ask me how I know! Get them from the local parts store or Gene Culley www.gmpartshouse.com for a whole lot less!!

For easy troubleshooting,, you can read the wheel sensor resistances and voltages (when you rotate the wheel right from the EBTCM main connector:

2001+ shown

Long Story made short, there are TWO female connectors on EACH front wheel and ONE on each rear wheel harness connector that need to be checked for proper female pin grip. If the female pin is all spread open,, it is most likely part of the problem. I use an old MALE pin to check for proper female pin grip/connection.

If you slide the male pin into the female pin, there should be a nice tight fit and it should take a little effort to extract it and insert it.

Yea,,,,, I know what that sounds like!

Hope this helps!

BC

Last edited by Bill Curlee; 01-21-2012 at 12:19 PM.

#44

Instructor

Thread Starter

Member Since: Sep 2007

Location: Philadelphia PA

Posts: 224

Likes: 0

Received 0 Likes

on

0 Posts

Bill- thank you for the information and the photos! When the weather gets nicer (I've currently got 3" of snow on the ground and 25F weather), I will pull the wheel and check the harness again, look for bent pins.

#45

My connectors and pins look good. I didn't unplug the big plug from the EBCM tho. It looked like a PITA. I don't have a multimeter but if I can get one what do I test?

BTW Texas weather is beautiful right now.

BTW Texas weather is beautiful right now.

#46

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

WISE GUY!

7" and rising

7" and rising

Thats OK,, we can snow ski and you cant!

Heres the C6 EBTCM schematic for all the WSS:

#47

Thanks for the diagram. So I'm not familiar with a multimeter but the .35 or whatever the decimal is, what reading am I shooting for? So I contact at the ebcm then spin the wheel and look for the correct reading?

#48

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

DTC C0035-C0050

Circuit Description

As the wheel spins, the wheel speed sensor produces an A/C signal. The electronic brake control module (EBCM) uses the frequency of the A/C signal to calculate the wheel speed.

DTC Descriptors

This diagnostic procedure supports the following DTCs:

DTC C0035 LF Wheel Speed Sensor Circuit

DTC C0040 RF Wheel Speed Sensor Circuit

DTC C0045 LR Wheel Speed Sensor Circuit

DTC C0050 RR Wheel Speed Sensor Circuit

This vehicle has DTCs which include DTC Symptoms. For more information on DTC Symptoms, refer to DTC Symptom Description in Vehicle DTC Information.

DTC Symptom

DTC Symptom Descriptor

18

Signal Amplitude Less Than Minimum

0F

Signal Erratic

00

No Additional Information

Conditions for Running the DTC

C0035 - C0050 00 and 0F

The ignition is ON.

The ignition voltage is greater than 8 volts.

C0035 - C0050 18

The ignition is ON.

The ignition voltage is greater than 8 volts.

The brake pedal is not pressed.

The ABS is not active.

Conditions for Setting the DTC

C0035 - C0050 00

One of the following conditions exists for 0.02 seconds:

A short to voltage - the wheel speed sensor signal circuit and wheel speed sensor return circuit voltages are both greater than 4.25 volts.

A short to ground - the wheel speed sensor signal circuit and wheel speed sensor return circuit voltages are both less than 0.75 volts.

An open - the wheel speed sensor signal circuit voltage is greater than 4.25 volts and wheel speed sensor return circuit voltage is less than 0.75 volts.

C0035 - C0050 0F

The EBCM detects a rapid variation in the wheel speed. The wheel speed changes by 20 km/h (12 mph) or more in 0.01 second. The change must occur 3 times with no more than 0.2 seconds between occurrences.

C0035 - C0050 18

All of the following conditions exists for 0.2 seconds:

The suspect wheel speed equals zero.

The other wheel speeds are greater than 8 km/h (5 mph).

The other wheel speeds are within 11 km/h (7 mph) of each other.

Action Taken When the DTC Sets

If equipped, the following actions occur:

The EBCM disables the antilock brake system (ABS) / engine drag control (EDC) / traction control system (TCS) / tire pressure monitor (TPM) / vehicle stability enhancement system (VSES) for the duration of the ignition cycle.

The adaptive cruise control (ACC) braking function is disabled.

The DRP does not function optimally.

The ABS indicator turns ON.

The traction control indicator turns ON.

The drive information center (DIC) displays the Service Stability System message.

Conditions for Clearing the DTC

The condition for the DTC is no longer present and the DTC is cleared with a scan tool.

The EBCM automatically clears the history DTC when a current DTC is not detected in 100 consecutive drive cycles.

Diagnostic Aids

C0035 - C0050 00

If the customer comments that the ABS indicator is ON only during moist environmental conditions (rain, snow, vehicle wash, etc.), inspect the wheel speed sensor wiring for signs of water intrusion. If the DTC is not current, clear all DTCs and simulate the effects of water intrusion by using the following procedure:

Spray the suspected area with a 5 percent saltwater solution. To create a 5 percent saltwater solution, add 2 teaspoons (9.9 ml) of salt to 354 ml (12 oz) of water.

Test drive the vehicle over various road surfaces (bumps, turns, etc.) above 40 km/h (25 mph) for at least 30 seconds.

If the DTC returns, replace the suspected wheel speed sensor or repair the wheel speed sensor wiring.

Rinse the area thoroughly when completed.

C0035 - C0050 0F

A possible cause of this DTC is electrical noise on the wheel speed sensor harness wiring. Electrical noise could result from the wheel speed sensor wires being routed to close to high energy ignition system components, such as spark plug wires.

C0035 - C0050 18

Under the following conditions, DTCs are set:

The 2 suspect wheel speeds equal zero for 60 seconds.

The other wheel speeds are greater than 16 km/h (10 mph).

The other wheel speeds are within 11 km/h (7 mph) of each other.

Diagnose each wheel speed sensor individually.

Test Description

The numbers below refer to the step numbers on the diagnostic table.

Measure the resistance of the wheel speed sensor in order to determine if the sensor has a valid resistance value.

Ensures that the wheel speed sensor is generating a valid A/C voltage output.

Step

Action

Values

Yes

No

Schematic Reference: ABS Schematics

Connector End View Reference: ABS Connector End Views

1

Did you perform the Diagnostic System Check - Vehicle?

--

Go to Step 2

Go to Diagnostic System Check - Vehicle in Vehicle DTC Information

2

Install a scan tool.

Turn ON the ignition.

Set up the scan tool snap shot feature to trigger for this DTC.

Drive the vehicle at a speed greater than the specified value.

Does the scan tool indicate that this wheel speed DTC set?

8 km/h (5 mph)

Go to Step 3

Go to Diagnostic Aids

3

Raise and support the vehicle. Refer to Lifting and Jacking the Vehicle in General Information.

Disconnect the wheel speed sensor connector.

Measure the resistance across the wheel speed sensor.

Does the resistance measure within the specified range?

850-1350 ohms

Go to Step 4

Go to Step 8

4

Spin the wheel.

Measure the A/C voltage across the wheel speed sensor.

Does the A/C voltage measure greater than the specified value?

100 mV

Go to Step 5

Go to Step 8

5

Inspect for poor connections at the harness connector of the wheel speed sensor. Refer to Testing for Intermittent Conditions and Poor Connections and Connector Repairs in Wiring Systems.

Did you find and correct the condition?

--

Go to Step 10

Go to Step 6

6

Test the wheel speed sensor circuits of the electronic brake control module (EBCM) for the following conditions:

An open

A short to ground

A short to voltage

Shorted together

Refer to Circuit Testing and Wiring Repairs in Wiring Systems.

Did you find and correct the condition?

--

Go to Step 10

Go to Step 7

7

Inspect for poor connections at the harness connector for the EBCM. Refer to Testing for Intermittent Conditions and Poor Connections and Connector Repairs in Wiring Systems.

Did you find and correct the condition?

--

Go to Step 10

Go to Step 9

8

Replace the wheel speed sensor. Refer to Wheel Bearing/Hub Replacement - Front in Front Suspension or Wheel Bearing/Hub Replacement - Rear in Rear Suspension.

Did you complete the replacement?

--

Go to Step 10

--

9

Replace the EBCM. Refer to Control Module References in Computer/Integrating Systems for replacement, setup, and programming.

Did you complete the repair?

--

Go to Step 10

--

10

Use the scan tool in order to clear the DTCs.

Operate the vehicle within the Conditions for Running the DTC as specified in the supporting text.

Does the DTC reset?

--

Go to Step 2

System OK

--------------------------------------------------------------------------------

Document ID# 1460367

2005 Chevrolet Corvette

Circuit Description

As the wheel spins, the wheel speed sensor produces an A/C signal. The electronic brake control module (EBCM) uses the frequency of the A/C signal to calculate the wheel speed.

DTC Descriptors

This diagnostic procedure supports the following DTCs:

DTC C0035 LF Wheel Speed Sensor Circuit

DTC C0040 RF Wheel Speed Sensor Circuit

DTC C0045 LR Wheel Speed Sensor Circuit

DTC C0050 RR Wheel Speed Sensor Circuit

This vehicle has DTCs which include DTC Symptoms. For more information on DTC Symptoms, refer to DTC Symptom Description in Vehicle DTC Information.

DTC Symptom

DTC Symptom Descriptor

18

Signal Amplitude Less Than Minimum

0F

Signal Erratic

00

No Additional Information

Conditions for Running the DTC

C0035 - C0050 00 and 0F

The ignition is ON.

The ignition voltage is greater than 8 volts.

C0035 - C0050 18

The ignition is ON.

The ignition voltage is greater than 8 volts.

The brake pedal is not pressed.

The ABS is not active.

Conditions for Setting the DTC

C0035 - C0050 00

One of the following conditions exists for 0.02 seconds:

A short to voltage - the wheel speed sensor signal circuit and wheel speed sensor return circuit voltages are both greater than 4.25 volts.

A short to ground - the wheel speed sensor signal circuit and wheel speed sensor return circuit voltages are both less than 0.75 volts.

An open - the wheel speed sensor signal circuit voltage is greater than 4.25 volts and wheel speed sensor return circuit voltage is less than 0.75 volts.

C0035 - C0050 0F

The EBCM detects a rapid variation in the wheel speed. The wheel speed changes by 20 km/h (12 mph) or more in 0.01 second. The change must occur 3 times with no more than 0.2 seconds between occurrences.

C0035 - C0050 18

All of the following conditions exists for 0.2 seconds:

The suspect wheel speed equals zero.

The other wheel speeds are greater than 8 km/h (5 mph).

The other wheel speeds are within 11 km/h (7 mph) of each other.

Action Taken When the DTC Sets

If equipped, the following actions occur:

The EBCM disables the antilock brake system (ABS) / engine drag control (EDC) / traction control system (TCS) / tire pressure monitor (TPM) / vehicle stability enhancement system (VSES) for the duration of the ignition cycle.

The adaptive cruise control (ACC) braking function is disabled.

The DRP does not function optimally.

The ABS indicator turns ON.

The traction control indicator turns ON.

The drive information center (DIC) displays the Service Stability System message.

Conditions for Clearing the DTC

The condition for the DTC is no longer present and the DTC is cleared with a scan tool.

The EBCM automatically clears the history DTC when a current DTC is not detected in 100 consecutive drive cycles.

Diagnostic Aids

C0035 - C0050 00

If the customer comments that the ABS indicator is ON only during moist environmental conditions (rain, snow, vehicle wash, etc.), inspect the wheel speed sensor wiring for signs of water intrusion. If the DTC is not current, clear all DTCs and simulate the effects of water intrusion by using the following procedure:

Spray the suspected area with a 5 percent saltwater solution. To create a 5 percent saltwater solution, add 2 teaspoons (9.9 ml) of salt to 354 ml (12 oz) of water.

Test drive the vehicle over various road surfaces (bumps, turns, etc.) above 40 km/h (25 mph) for at least 30 seconds.

If the DTC returns, replace the suspected wheel speed sensor or repair the wheel speed sensor wiring.

Rinse the area thoroughly when completed.

C0035 - C0050 0F

A possible cause of this DTC is electrical noise on the wheel speed sensor harness wiring. Electrical noise could result from the wheel speed sensor wires being routed to close to high energy ignition system components, such as spark plug wires.

C0035 - C0050 18

Under the following conditions, DTCs are set:

The 2 suspect wheel speeds equal zero for 60 seconds.

The other wheel speeds are greater than 16 km/h (10 mph).

The other wheel speeds are within 11 km/h (7 mph) of each other.

Diagnose each wheel speed sensor individually.

Test Description

The numbers below refer to the step numbers on the diagnostic table.

Measure the resistance of the wheel speed sensor in order to determine if the sensor has a valid resistance value.

Ensures that the wheel speed sensor is generating a valid A/C voltage output.

Step

Action

Values

Yes

No

Schematic Reference: ABS Schematics

Connector End View Reference: ABS Connector End Views

1

Did you perform the Diagnostic System Check - Vehicle?

--

Go to Step 2

Go to Diagnostic System Check - Vehicle in Vehicle DTC Information

2

Install a scan tool.

Turn ON the ignition.

Set up the scan tool snap shot feature to trigger for this DTC.

Drive the vehicle at a speed greater than the specified value.

Does the scan tool indicate that this wheel speed DTC set?

8 km/h (5 mph)

Go to Step 3

Go to Diagnostic Aids

3

Raise and support the vehicle. Refer to Lifting and Jacking the Vehicle in General Information.

Disconnect the wheel speed sensor connector.

Measure the resistance across the wheel speed sensor.

Does the resistance measure within the specified range?

850-1350 ohms

Go to Step 4

Go to Step 8

4

Spin the wheel.

Measure the A/C voltage across the wheel speed sensor.

Does the A/C voltage measure greater than the specified value?

100 mV

Go to Step 5

Go to Step 8

5

Inspect for poor connections at the harness connector of the wheel speed sensor. Refer to Testing for Intermittent Conditions and Poor Connections and Connector Repairs in Wiring Systems.

Did you find and correct the condition?

--

Go to Step 10

Go to Step 6

6

Test the wheel speed sensor circuits of the electronic brake control module (EBCM) for the following conditions:

An open

A short to ground

A short to voltage

Shorted together

Refer to Circuit Testing and Wiring Repairs in Wiring Systems.

Did you find and correct the condition?

--

Go to Step 10

Go to Step 7

7

Inspect for poor connections at the harness connector for the EBCM. Refer to Testing for Intermittent Conditions and Poor Connections and Connector Repairs in Wiring Systems.

Did you find and correct the condition?

--

Go to Step 10

Go to Step 9

8

Replace the wheel speed sensor. Refer to Wheel Bearing/Hub Replacement - Front in Front Suspension or Wheel Bearing/Hub Replacement - Rear in Rear Suspension.

Did you complete the replacement?

--

Go to Step 10

--

9

Replace the EBCM. Refer to Control Module References in Computer/Integrating Systems for replacement, setup, and programming.

Did you complete the repair?

--

Go to Step 10

--

10

Use the scan tool in order to clear the DTCs.

Operate the vehicle within the Conditions for Running the DTC as specified in the supporting text.

Does the DTC reset?

--

Go to Step 2

System OK

--------------------------------------------------------------------------------

Document ID# 1460367

2005 Chevrolet Corvette

#49

Track Junky

Bill, as always, great info. Your detailed posts will save people hours of diagnostics and research.

BTW, I grew ip in Groton... Small world!

BTW, I grew ip in Groton... Small world!

#50

Tech Contributor

Member Since: Oct 1999

Location: Charlotte, NC (formerly Endicott, NY)

Posts: 40,089

Received 8,928 Likes

on

5,333 Posts

I don't appreciate all the people trying to thread jack. You don't go and say "I don't mean to thread jack, but...." that's just plain rude.

GM Power 4 Life, at least you have the same issue, so you're not thread jacking.

It's cold now, can't drive the car at all, but the last time the weather was nice a few weeks ago, I took some advice, took the console apart and put some weatherstripping foam in between the yaw sensor and the sheetmetal, screwed it back down tight. I also removed the ipod adapter I had in there, in case that was banging against the yaw sensor and causing a problem.

I took the car for a decently long (20 min) test drive, activated active handling a couple times in corners as well as activating traction control by punching it in first gear- no issues. ABS worked fine as well.

I don't know if that solved the issue, because I have not been able to drive the car for a decent distance to see if the problem reappears- I probably won't be able to do that until the spring.

For GM Power4Life- your tires are not the stock size- the difference in rolling circumference might be enough to cause the problem- if you're running stock tire sizes, you should have any issue and the fact that it only happens above a certain speed should clue you in that this is the cause of your problem. Why that shows up as only one wheel speed sensor creating a fault, I have no idea.

I wish there was someone at GM that could explain this- nothing in the service manual says that if you run aftermarket tires/wheels that a difference in wheel circumference will cause the right front wheel sensor fault, even if that is what happens.

My local dealership wanted a little over $2000 to fix the problem as they diagnosed- I spend about $800 plus $200 diagnostics and didn't fix the problem, although I'm running the ZR1 spec SKF hubs now as a side benefit, which would not be the case if I used the dealership to install $150 OE hubs.

GM Power 4 Life, at least you have the same issue, so you're not thread jacking.

It's cold now, can't drive the car at all, but the last time the weather was nice a few weeks ago, I took some advice, took the console apart and put some weatherstripping foam in between the yaw sensor and the sheetmetal, screwed it back down tight. I also removed the ipod adapter I had in there, in case that was banging against the yaw sensor and causing a problem.

I took the car for a decently long (20 min) test drive, activated active handling a couple times in corners as well as activating traction control by punching it in first gear- no issues. ABS worked fine as well.

I don't know if that solved the issue, because I have not been able to drive the car for a decent distance to see if the problem reappears- I probably won't be able to do that until the spring.

For GM Power4Life- your tires are not the stock size- the difference in rolling circumference might be enough to cause the problem- if you're running stock tire sizes, you should have any issue and the fact that it only happens above a certain speed should clue you in that this is the cause of your problem. Why that shows up as only one wheel speed sensor creating a fault, I have no idea.

I wish there was someone at GM that could explain this- nothing in the service manual says that if you run aftermarket tires/wheels that a difference in wheel circumference will cause the right front wheel sensor fault, even if that is what happens.

My local dealership wanted a little over $2000 to fix the problem as they diagnosed- I spend about $800 plus $200 diagnostics and didn't fix the problem, although I'm running the ZR1 spec SKF hubs now as a side benefit, which would not be the case if I used the dealership to install $150 OE hubs.

DTC C0040 00 : Right Front Wheel Speed Sensor Circuit

DTC C0040 0F : Right Front Wheel Speed Sensor Circuit Erratic Signal

DTC C0040 18 : Right Front Wheel Speed Sensor Circuit Signal Amplitude Less Than Minimum

You need a scanner that can read the last two characters of the code. They help tell you what the problem is. I am assuming that you don't have a sensor issue since you just replaced them with top notch parts.

If you have a 0F that may mean you have a poor connection between the sensor connector and the harness connector or a bad connection at the other end of the harness. Same goes for 18. Check the connectors for corrosion or poor fit between male and female pins. Bill C has several pictures of what to look for when checking the connectors and how to fix them so you get good contact. The fact the problem seems to start happening as the speed gets up to highway speeds sort of indicates a high resistance connection.

Bill

#51

Instructor

Thread Starter

Member Since: Sep 2007

Location: Philadelphia PA

Posts: 224

Likes: 0

Received 0 Likes

on

0 Posts

Bills Curlee and Dearborn- again, I wanted to thank you for your contributions and help.

Right now I can't really do much diagnosis because of the winter conditions- when I get some consistently warm weather, I can drive the car for long enough to see if there are any error messages- I don't get them now with a short (20 min.) drive, so maybe I did have a bad connection somewhere.

I will pull the connectors and check the fit of the pins- I also have to get the car up to highway speeds to see if there are any issues- the last time I took the car out for a test drive, I got it to 80mph for a brief period without issues- before I did the harness and wheel bearing, it would do it a lot more often.

I'll update this thread with more info once I get a chance to do more diagnosis. I also have to buy some diagnostic software for the laptop so I can do more detailed diagnosis- I can't read those last two characters like you mentioned.

Right now I can't really do much diagnosis because of the winter conditions- when I get some consistently warm weather, I can drive the car for long enough to see if there are any error messages- I don't get them now with a short (20 min.) drive, so maybe I did have a bad connection somewhere.

I will pull the connectors and check the fit of the pins- I also have to get the car up to highway speeds to see if there are any issues- the last time I took the car out for a test drive, I got it to 80mph for a brief period without issues- before I did the harness and wheel bearing, it would do it a lot more often.

I'll update this thread with more info once I get a chance to do more diagnosis. I also have to buy some diagnostic software for the laptop so I can do more detailed diagnosis- I can't read those last two characters like you mentioned.

#52

Safety Car

My C5 would throw abs and Trac lights at any big bump for the first two years I had it. Then I had an intermittent start issue. Turn key and nothing. No click, just silence. Turn off and back on several times and it would fire up strongly.

What I found was a battery cable that was corroded inside.

After fixing that, no more start issues. And four years later? Not one instance of a Trac/abs light.

So it could be any loose connection, even the battery.

What I found was a battery cable that was corroded inside.

After fixing that, no more start issues. And four years later? Not one instance of a Trac/abs light.

So it could be any loose connection, even the battery.

#57

Instructor

Thread Starter

Member Since: Sep 2007

Location: Philadelphia PA

Posts: 224

Likes: 0

Received 0 Likes

on

0 Posts

Now that it is warmer, time to resurrect this thread......

In order to check the female pins in the harness and if necessary, fix them, what is the best way to bend the female pins for better contact?

Bill Curlee (sp?) mentioned using a pick- any pointers on how this is done? I can't quite picture it in my head.

I still haven't gotten the diagnostic software, but I will this spring for sure.

In order to check the female pins in the harness and if necessary, fix them, what is the best way to bend the female pins for better contact?

Bill Curlee (sp?) mentioned using a pick- any pointers on how this is done? I can't quite picture it in my head.

I still haven't gotten the diagnostic software, but I will this spring for sure.

#58

Le Mans Master

Member Since: Jun 2003

Location: CFOTHQlikeaMofoForums.com

Posts: 7,452

Likes: 0

Received 2 Likes

on

2 Posts

St. Jude Donor '09

Bump, my mom's 05 has just started popping up the Service ABS, TC, and Active Handling messages as well. Started after hitting a massive pothole in OK, a quick scan at an O'Reilly's produced C0050 and C0253 codes, the former for the right wheel speed sensor and a centering error for the latter. Car is bone stock. I checked the plug at the wheel hub and it seemed ok, but I don't have the tools here to get under the car and check the other connections.

#59

Intermediate

Member Since: May 2012

Location: Miami Beach Florida

Posts: 39

Received 0 Likes

on

0 Posts

I'm experiencing this exact same problem with my recently purchased 2007 C6  .

.

At any given time after starting to drive my car (usually within 1-2 minutes) the AH, ABS and Traction Control all light up saying they need service.

Also usually during my first braking after starting the car I get physical push-back from the ABS system (but never again during that time driivng).

Every Now and then the Red Brake Indicator Light also comes on.

Car is at Dealer, but they don't seem to have Clear indication of the problem. Apparently the previous owner disassemble the wheel assembly, I'm assuming trying to correct this problem. According to the Dealer they routed the Wheel Speed Sensor Cable incorrectly and failed to install the bracket that holds the connector in place.. The Dealer is now insisting they have to take it apart to bring the cable down the designated path. Even though I don't see how this might be the cause of the problem, I can't argue with the Dealer to bring the car to factory condition in spite this being a $800 dollar rewire. The dealer is also replacing the wire harness.

They are also replacing the steering positioning sensor, based on an error code, but say that has nothing to do with the warnings i'm getting.

Any insight will be greatly appreciated

I'll post after getting the car back from the Dealer.

.

.At any given time after starting to drive my car (usually within 1-2 minutes) the AH, ABS and Traction Control all light up saying they need service.

Also usually during my first braking after starting the car I get physical push-back from the ABS system (but never again during that time driivng).

Every Now and then the Red Brake Indicator Light also comes on.

Car is at Dealer, but they don't seem to have Clear indication of the problem. Apparently the previous owner disassemble the wheel assembly, I'm assuming trying to correct this problem. According to the Dealer they routed the Wheel Speed Sensor Cable incorrectly and failed to install the bracket that holds the connector in place.. The Dealer is now insisting they have to take it apart to bring the cable down the designated path. Even though I don't see how this might be the cause of the problem, I can't argue with the Dealer to bring the car to factory condition in spite this being a $800 dollar rewire. The dealer is also replacing the wire harness.

They are also replacing the steering positioning sensor, based on an error code, but say that has nothing to do with the warnings i'm getting.

Any insight will be greatly appreciated

I'll post after getting the car back from the Dealer.

#60

Instructor

Thread Starter

Member Since: Sep 2007

Location: Philadelphia PA

Posts: 224

Likes: 0

Received 0 Likes

on

0 Posts

Update- problem solved!

I have to admit that I'm terrible with electrical stuff. To make things worse, I don't have a Tech 2, so it's not exactly easy to diagnose stuff with this car.

That said, I took the car to Phoenix Performance in Phoenixville, PA. They are a well-respected Corvette race car shop.

The same code popped up- C0040. They told me that they couldn't find anything wrong with my car, they cleaned all of the connections and did all of the fault checks that Bill Dearborn outlined:

Test the wheel sensor resistance and voltage output when spun.

Tested wire continuity for all sections of the harness- the wiring out of the wheel sensor, the sub-harness that connects to the main harness and finally, the wiring in the main harness from the sub-harness to the EBCM.

Everything checked out fine, until I got back to the shop and test-drove it myself. For whatever reason, the problem only shows up with regularity when you get the car warmed up (oil temp above 180F) and exceed 90 mph. So the first thing I did (the shop already had the car warm for me) was to seek out an open section of road, made sure there was no traffic and no cross-traffic, accelerated hard and like clockwork, the "Service ABS, Service Traction Control and Service Active Handling" warnings all came on as I've described before.

I drove the car back to Phoenix, where I left it running and the car was hooked up to the GM Tech 2 scanner. The odd thing was that when the car was scanned for codes, no codes showed, even though these service lights were lit. More oddly, only historical codes were shown when the EBCM was polled.

A week passed, due to my schedule and their work schedule (they are pretty busy racing cars in Grand-Am). They called me back and I found out that they determined that I have a bad EBCM. They replaced the EBCM, made sure it was updated to the latest software and then gave the car back to me. I test-drove it again, made sure that everything was warmed up and repeatedly took the car to 90 mph to make sure everything worked fine. No error lights! No error messages!

I think that fixed the problem- apparently, C6 EBCMs are no better than C5 EBCMs when it comes to reliability- they go bad. The shop manager Kurt speculated that it was a bad solder joint in the circuit board, which is the common failure in the C5 part. They are going to hold on to my original EBCM for a few months to make sure that the problem is fixed for good, then I think they might take my old unit apart to see what went wrong.

I hope this doesn't happen commonly, nor to a lot of people, but that was the rather expensive solution to my problem which has been ongoing for quite a while due to my procrastination.

I have to admit that I'm terrible with electrical stuff. To make things worse, I don't have a Tech 2, so it's not exactly easy to diagnose stuff with this car.

That said, I took the car to Phoenix Performance in Phoenixville, PA. They are a well-respected Corvette race car shop.

The same code popped up- C0040. They told me that they couldn't find anything wrong with my car, they cleaned all of the connections and did all of the fault checks that Bill Dearborn outlined:

Test the wheel sensor resistance and voltage output when spun.

Tested wire continuity for all sections of the harness- the wiring out of the wheel sensor, the sub-harness that connects to the main harness and finally, the wiring in the main harness from the sub-harness to the EBCM.

Everything checked out fine, until I got back to the shop and test-drove it myself. For whatever reason, the problem only shows up with regularity when you get the car warmed up (oil temp above 180F) and exceed 90 mph. So the first thing I did (the shop already had the car warm for me) was to seek out an open section of road, made sure there was no traffic and no cross-traffic, accelerated hard and like clockwork, the "Service ABS, Service Traction Control and Service Active Handling" warnings all came on as I've described before.

I drove the car back to Phoenix, where I left it running and the car was hooked up to the GM Tech 2 scanner. The odd thing was that when the car was scanned for codes, no codes showed, even though these service lights were lit. More oddly, only historical codes were shown when the EBCM was polled.

A week passed, due to my schedule and their work schedule (they are pretty busy racing cars in Grand-Am). They called me back and I found out that they determined that I have a bad EBCM. They replaced the EBCM, made sure it was updated to the latest software and then gave the car back to me. I test-drove it again, made sure that everything was warmed up and repeatedly took the car to 90 mph to make sure everything worked fine. No error lights! No error messages!

I think that fixed the problem- apparently, C6 EBCMs are no better than C5 EBCMs when it comes to reliability- they go bad. The shop manager Kurt speculated that it was a bad solder joint in the circuit board, which is the common failure in the C5 part. They are going to hold on to my original EBCM for a few months to make sure that the problem is fixed for good, then I think they might take my old unit apart to see what went wrong.

I hope this doesn't happen commonly, nor to a lot of people, but that was the rather expensive solution to my problem which has been ongoing for quite a while due to my procrastination.