What have you done for the starter heat soak problem, z06/427 motor

#1

Race Director

Thread Starter

Interested only in posts where the problem was successfully resolved.

Please don't post links to stuff that vendors "claim" fix the problem. I have already seen all those.

I would just like to hear about a fix the WORKED.

Mine is a 2013 z battery is new & fine 9k miles.

Cold starts are fine.

THX

Please don't post links to stuff that vendors "claim" fix the problem. I have already seen all those.

I would just like to hear about a fix the WORKED.

Mine is a 2013 z battery is new & fine 9k miles.

Cold starts are fine.

THX

Last edited by froggy47; 08-18-2018 at 03:04 PM.

#2

Last edited by Dano523; 08-18-2018 at 03:10 PM.

The following 4 users liked this post by Dano523:

#3

If the question is slow cranking since you have increased the compression or displacement on the motor, then the solution there is High torque starter with heat shield isntead.

As for the starter solenoid, over time its contact disc is going to get spot burnt, so even if you don't end up cracking the terminals of the bakelite end piece from heat, you may still have to replace the solenoid. When that happens, its a Delco 10503939.

https://www.amazon.com/DB-Electrical-Solenoid-Starters-10-DE263S/dp/B06X6JF3CL/ref=sr_1_1/141-2263505-3243834?ie=UTF8&qid=1513596083&sr=8-1&keywords=10503939

https://www.amazon.com/DB-Electrical-Solenoid-Starters-10-DE263S/dp/B06X6JF3CL/ref=sr_1_1/141-2263505-3243834?ie=UTF8&qid=1513596083&sr=8-1&keywords=10503939

Hence on the older solenoid, you could pull them apart to reface the disc contact points to clean the back up, but since the C6 unit is sealed, then you just replace the sealed unit instead.

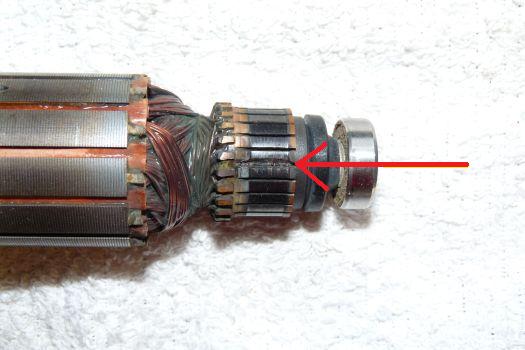

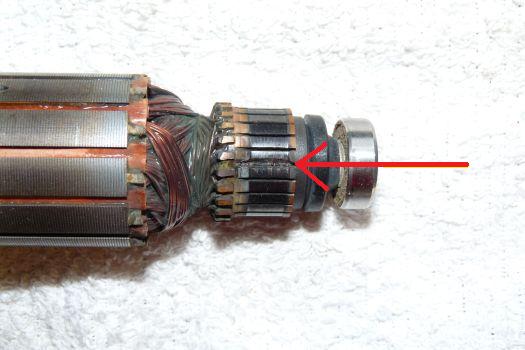

Older types that you could pull apart to clean the contact discs.

As for the starter (motor) itself, the only time you really do damage to them, is in the case that you should be using a High torque starter to begin with, and what happens on the base units is that the slower chugging of the motor ends up with the armature winding coil wire shield coating ends and bushing contact surfaces melting from the increase amperage heat, to take out the armature instead. So it really not a exhaust heat problem, but an amperage problem with the starter motor not spinning fast enough, and the coil loop sections on the armature each seeing too long of amperage before turning to energize the next set of coils as the starter motor turns isntead.

So what the high torque starters really are, is they have a higher reduction gear drive in them, which allows the motor to turn faster per flywheel rotation, keeping the starter motor turning faster at crank so you don't burn up is winding.

As for backing it up on solenoid replacements, if its the Contact ring on the unit that is spot burnt and the reason that you are replacing it, Not a bad idea to pull the starter motor apart to clean up its commutator bars, and blow out the bushing dust that has accumulated as well. Ball bearings on the starter should last the life of the starter motor, and having a heat shield in place helps to keep the grease in the bearings, instead of it just being melted out of them.

Also, keep in mind that the ground to the starter is it bolting contact area to the bell housing, so loose starter bolts ends up with less than stellar ground when the motor is hot. I bring this up, since as you are bolting the starter back in place, clean up the body to bell housing mating surfaces, and a touch of dielectric grease between the two to make sure that the connections surfaces of the aluminum parts do not oxidized over time (same goes for alternator to bracket as well).

P.S, let me know I you want to go deeper down the rabbit hole, since the OEM valeo starter does not like to be over spun, since it ends up with the armature coil cages cracking, and this causes problems with the unit itself. Hence spun to 6.2K is fine, but spun to 7K, and GM should have used a different alternator on the LS7 isntead.

So basic primer on pulling the valeo apart to clean it contact points so it putting out full charge,

https://www.corvetteforum.com/forums...nator-fix.html

And to check a unit that once you do have it cleaned up, should be working correcty, but is not, how to dig deeper in it to see if the coil cage is cracked.

Skip to 12.40,

And quick write up on checking the charging system, but just think rear battery in your case since you have longer battery cables isntead, and less than stellar contacts of these longer cables to their contact points just makes the problem worse isntead.

https://www.corvetteforum.com/forums...intenance.html

As for the starter solenoid, over time its contact disc is going to get spot burnt, so even if you don't end up cracking the terminals of the bakelite end piece from heat, you may still have to replace the solenoid. When that happens, its a Delco 10503939.

Hence on the older solenoid, you could pull them apart to reface the disc contact points to clean the back up, but since the C6 unit is sealed, then you just replace the sealed unit instead.

Older types that you could pull apart to clean the contact discs.

As for the starter (motor) itself, the only time you really do damage to them, is in the case that you should be using a High torque starter to begin with, and what happens on the base units is that the slower chugging of the motor ends up with the armature winding coil wire shield coating ends and bushing contact surfaces melting from the increase amperage heat, to take out the armature instead. So it really not a exhaust heat problem, but an amperage problem with the starter motor not spinning fast enough, and the coil loop sections on the armature each seeing too long of amperage before turning to energize the next set of coils as the starter motor turns isntead.

So what the high torque starters really are, is they have a higher reduction gear drive in them, which allows the motor to turn faster per flywheel rotation, keeping the starter motor turning faster at crank so you don't burn up is winding.

As for backing it up on solenoid replacements, if its the Contact ring on the unit that is spot burnt and the reason that you are replacing it, Not a bad idea to pull the starter motor apart to clean up its commutator bars, and blow out the bushing dust that has accumulated as well. Ball bearings on the starter should last the life of the starter motor, and having a heat shield in place helps to keep the grease in the bearings, instead of it just being melted out of them.

Also, keep in mind that the ground to the starter is it bolting contact area to the bell housing, so loose starter bolts ends up with less than stellar ground when the motor is hot. I bring this up, since as you are bolting the starter back in place, clean up the body to bell housing mating surfaces, and a touch of dielectric grease between the two to make sure that the connections surfaces of the aluminum parts do not oxidized over time (same goes for alternator to bracket as well).

P.S, let me know I you want to go deeper down the rabbit hole, since the OEM valeo starter does not like to be over spun, since it ends up with the armature coil cages cracking, and this causes problems with the unit itself. Hence spun to 6.2K is fine, but spun to 7K, and GM should have used a different alternator on the LS7 isntead.

So basic primer on pulling the valeo apart to clean it contact points so it putting out full charge,

https://www.corvetteforum.com/forums...nator-fix.html

And to check a unit that once you do have it cleaned up, should be working correcty, but is not, how to dig deeper in it to see if the coil cage is cracked.

Skip to 12.40,

And quick write up on checking the charging system, but just think rear battery in your case since you have longer battery cables isntead, and less than stellar contacts of these longer cables to their contact points just makes the problem worse isntead.

https://www.corvetteforum.com/forums...intenance.html

Last edited by Dano523; 08-18-2018 at 03:49 PM.

The following users liked this post:

CorvetteBrent (09-25-2018)

#4

Race Director

Thread Starter

I saw this video but the guy did it b4 headers so he doesn't really say if it worked with the headers. I have stock headers but I think they get plenty hot.

anyone else?

thx

#5

Drifting

I’ve had good luck so far with the DEI heatshield from O’Reilley. I have about 2500 miles on this starter without it failing. I periodically look at the solenoid to see if ithe plastic is cracking or failing in. So far so good.

The following 2 users liked this post by Turbo2L:

CorvetteBrent (09-25-2018),

DEITIM (08-20-2018)

#7

Note, Picked a spark plug that your going to do the compression test on, then loosen that plug with the motor cold, and then only hand tighten the plug so you can remove it without stripping the head threads when the heads are hot.

So would start with pulling the starter, cleaning up the contact point of the starter to bell housing with some 400 sandpaper, dap of dielectric grease, then re-bolt the starter back in place. Also, ground point to the motor above the starter is also a good place to clean/grease, and re-tighten the nut since it can become loose as the block heats up as well.

Short of of a ground/charge problem to the starter, and due to the increase in engine compression as the motor heats up, High torque starter is about your best choice if the OEM starter is having a hell of a time cranking the engine hot to begin with. Hence the problem does not get better, but worse as the starter's armature commuter contact points to bushing just get burnt up more and more isntead.

#8

Melting Slicks

Member Since: Jun 2005

Location: Rochester NY

Posts: 2,734

Received 1,678 Likes

on

878 Posts

2018 C6 of Year Finalist

St. Jude Donor '10, '17

froggy, all of the questions you post on here have been asked no less than 1000 times and resolved a decade ago, and then re-resolved virtually every week. You ask all of these questions, demand only the exact solutions (when every scenario is different) and then never take the advice. You aren't a newbie so I am a tad perplexed. Replace the solenoid, wrap the starter with a heat shield and be done with it. If it continues to give you a problem then replace the starter itself and still wrap with a heat shield. If the starter fails again and you have headers then coat the headers and find a more robust heat shield. This isn't rocket science and a bit of common sense is needed. It is getting hot, so you must protect it. Some things are trial and error and so you start with the simplest/cheapest solution first (solenoid and heat shield). Do you think there is some magic pixie dust us old timers sprinkle on our starters to stop them from failing? We all deal with this to one extent or another.

The following users liked this post:

CorvetteBrent (09-25-2018)

#9

Race Director

Thread Starter

froggy, all of the questions you post on here have been asked no less than 1000 times and resolved a decade ago, and then re-resolved virtually every week. You ask all of these questions, demand only the exact solutions (when every scenario is different) and then never take the advice. You aren't a newbie so I am a tad perplexed. Replace the solenoid, wrap the starter with a heat shield and be done with it. If it continues to give you a problem then replace the starter itself and still wrap with a heat shield. If the starter fails again and you have headers then coat the headers and find a more robust heat shield. This isn't rocket science and a bit of common sense is needed. It is getting hot, so you must protect it. Some things are trial and error and so you start with the simplest/cheapest solution first (solenoid and heat shield). Do you think there is some magic pixie dust us old timers sprinkle on our starters to stop them from failing? We all deal with this to one extent or another.

You should know the forum search engine is not that great, right?

And if, by chance you are referring to the tpms project, well so what if I want to try it my self? Anyway, no offense, just chill.

There are "one or two" guys on the forum that are helped by my videos, oh and 15,000 subscribers on YT.

#10

Race Director

Thread Starter

Short of a bad ground between the starter and the bell housing caused by heat as the starter bolts grow a touch the hotter they get, it really easy to see the difference in compression on the motor cold and hot instead.

Note, Picked a spark plug that your going to do the compression test on, then loosen that plug with the motor cold, and then only hand tighten the plug so you can remove it without stripping the head threads when the heads are hot.

So would start with pulling the starter, cleaning up the contact point of the starter to bell housing with some 400 sandpaper, dap of dielectric grease, then re-bolt the starter back in place. Also, ground point to the motor above the starter is also a good place to clean/grease, and re-tighten the nut since it can become loose as the block heats up as well.

Short of of a ground/charge problem to the starter, and due to the increase in engine compression as the motor heats up, High torque starter is about your best choice if the OEM starter is having a hell of a time cranking the engine hot to begin with. Hence the problem does not get better, but worse as the starter's armature commuter contact points to bushing just get burnt up more and more isntead.

Note, Picked a spark plug that your going to do the compression test on, then loosen that plug with the motor cold, and then only hand tighten the plug so you can remove it without stripping the head threads when the heads are hot.

So would start with pulling the starter, cleaning up the contact point of the starter to bell housing with some 400 sandpaper, dap of dielectric grease, then re-bolt the starter back in place. Also, ground point to the motor above the starter is also a good place to clean/grease, and re-tighten the nut since it can become loose as the block heats up as well.

Short of of a ground/charge problem to the starter, and due to the increase in engine compression as the motor heats up, High torque starter is about your best choice if the OEM starter is having a hell of a time cranking the engine hot to begin with. Hence the problem does not get better, but worse as the starter's armature commuter contact points to bushing just get burnt up more and more isntead.

#11

So if the solenoid "wheel/plate" is pitted bad enough, could be half the problem of the less electric amperage to the starter when the solenoid is hot; if the ground points/positive terminal to the starter is not the problem, or the increased compression on the motor is hot.

Myself, would pull the starter to clean the ground point of it to the bell housing, spend the $20 to install a new solenoid, as well pull the starter motor apart to blow out the bushing dust out, clean the commutator on the armature, and maybe even re-grease the bearings if they need it.

Note, older gen starter, but they are pretty much same basic design through the different gens of the vets.

This would solve any question if its the starter or volt amperage problem to the hot starter to begin with, or just the increased compression of the motor hot the reason for the starter slow cranking then isntead.

Hell, worst case and you do need to buy a high torque starter, should be no problems selling your rebuilt starter to recoup some of the money.

Note, when recondition a commutator, I cheat and just chuck the armature up in the lathe to spin clean it, or it bad enough, will make a light pass with a sharp fine tip HSS tool to clean and re-square its surfaces, polish it back up afterwards, then run a razor down the slots to remove any derbies from them in the end.

Hell, who knows, and it may just be a loose bushing plate contact to the body ground point of the case for the bushing plate ground side that is causing all the problems with the starter/motor hot to begin with.

Last edited by Dano523; 08-20-2018 at 03:07 AM.

The following users liked this post:

CorvetteBrent (09-25-2018)

#12

Former Vendor

Hello Everyone,

Tim from DEI here. We get his question a lot. While every application and engine is just a little bit different, typically we see great results with our Universal starter shields. Check out our Versa shield for the original standard GM starter (the big one). We also offer a smaller version for the high torque mini starters or new OE styles. P# 010384 for the bigger shield http://designengineering.com/versa-s...tarter-shield/ and P# 010384 for the smaller shield http://designengineering.com/mini-versa-shield/ . Also depending on how your header tubes run we also like to recommend wrapping your headers or at least the area by the starter. We also offer a pipe shield that clamps on over the pipe to shield heat away from the desired area you want to protect. http://designengineering.com/titanium-pipe-shield/ all of these products are available from Corvette Central or Zip Products. Feel free to contact me with any questions.

Thanks, Tim

Tim from DEI here. We get his question a lot. While every application and engine is just a little bit different, typically we see great results with our Universal starter shields. Check out our Versa shield for the original standard GM starter (the big one). We also offer a smaller version for the high torque mini starters or new OE styles. P# 010384 for the bigger shield http://designengineering.com/versa-s...tarter-shield/ and P# 010384 for the smaller shield http://designengineering.com/mini-versa-shield/ . Also depending on how your header tubes run we also like to recommend wrapping your headers or at least the area by the starter. We also offer a pipe shield that clamps on over the pipe to shield heat away from the desired area you want to protect. http://designengineering.com/titanium-pipe-shield/ all of these products are available from Corvette Central or Zip Products. Feel free to contact me with any questions.

Thanks, Tim

Last edited by DEITIM; 08-20-2018 at 01:52 PM.

The following users liked this post:

CorvetteBrent (09-25-2018)

#13

Race Director

Thread Starter

Hello Everyone,

Tim from DEI here. We get his question a lot. While every application and engine is just a little bit different, typically we see great results with our Universal starter shields. Check out our Versa shield for the original standard GM starter (the big one). We also offer a smaller version for the high torque mini starters or new OE styles. P# 010402 for the bigger shield http://designengineering.com/versa-s...tarter-shield/ and P# 010384 for the smaller shield http://designengineering.com/mini-versa-shield/ . Also depending on how your header tubes run we also like to recommend wrapping your headers or at least the area by the starter. We also offer a pipe shield that clamps on over the pipe to shield heat away from the desired area you want to protect. http://designengineering.com/titanium-pipe-shield/ all of these products are available from Corvette Central or Zip Products. Feel free to contact me with any questions.

Thanks, Tim

Tim from DEI here. We get his question a lot. While every application and engine is just a little bit different, typically we see great results with our Universal starter shields. Check out our Versa shield for the original standard GM starter (the big one). We also offer a smaller version for the high torque mini starters or new OE styles. P# 010402 for the bigger shield http://designengineering.com/versa-s...tarter-shield/ and P# 010384 for the smaller shield http://designengineering.com/mini-versa-shield/ . Also depending on how your header tubes run we also like to recommend wrapping your headers or at least the area by the starter. We also offer a pipe shield that clamps on over the pipe to shield heat away from the desired area you want to protect. http://designengineering.com/titanium-pipe-shield/ all of these products are available from Corvette Central or Zip Products. Feel free to contact me with any questions.

Thanks, Tim

#14

Former Vendor

Thanks again,

Tim

The following users liked this post:

CorvetteBrent (09-25-2018)

#15

Race Director

Thread Starter

Wrapping the section of pipe near the starter is a great starting point. No pun intended. This will cut down a lot of heat getting to the starter. If you still have heat soak issues then the next step would be a starter shield. Check out our pipe wrap and tie kit. http://designengineering.com/titaniu...cking-tie-kit/ . It comes with 2"x 25' roll of our Titanium wrap and locking ties. Should be the perfect amount for section wrapping.

Thanks again,

Tim

Thanks again,

Tim

The following users liked this post:

DEITIM (08-20-2018)

#16

Team Owner

$15 and your heat problem is solved.

https://youtu.be/DukuTN0rTcI

https://www.speedwaymotors.com/Alumi...ters,5745.html

https://youtu.be/DukuTN0rTcI

https://www.speedwaymotors.com/Alumi...ters,5745.html

#17

Froggy, thought you have the Oem exhaust system still on the car, and would not be in a rush to wrap the titanium system pipes to start trapping moisture on the pipes. Hell, on the stock system, your biggest source of heat is the cats themselves by the starter as part of the flex down pipe part, and wrapping the cats to hold their heat is in not gong to end well with the life of the cats.

Last edited by Dano523; 08-21-2018 at 06:51 PM.

#18

Former Vendor

Froggy, through you have the Oem exhaust system still on the car, and would not be in a rush to wrap the titanium system pipes to start trapping moisture on the pipes. Hell, on the stock system, your biggest source of heat is the cats themselves by the starter as part of the flex down pipe part, and wrapping the cats to hold their heat is in not gong to end well with the life of the cats.

Also, as Dano523 mentioned we do not recommend wrapping catalytic converters as you can trap too much heat in the converters and shorten their lifespan. We offer a catalytic converter shield that has stand offs built into them to allow for an air gap so the converter can still "breathe" but act as a heat barrier. Check out http://designengineering.com/corvett...verter-shield/ . I know this was designed specifically for the C7 but it has many other fitments.

Please let me know if anyone has any questions.

Thank you, Tim

Last edited by DEITIM; 08-21-2018 at 10:44 AM.

#19

Race Director

Thread Starter

Froggy, through you have the Oem exhaust system still on the car, and would not be in a rush to wrap the titanium system pipes to start trapping moisture on the pipes. Hell, on the stock system, your biggest source of heat is the cats themselves by the starter as part of the flex down pipe part, and wrapping the cats to hold their heat is in not gong to end well with the life of the cats.

#20

Race Director

Thread Starter

I just want to let everyone know that wrapping pipes with exhaust wrap does not trap or hold moisture. Especially when the wrap is designed keep heat in the pipes (hot surface). Typically any moisture that comes in contact with wrap burns off immediately. Just like an un-wrapped pipe once moisture touches the pipe it will burn or steam off. The only time the wrap will hold moisture is if you purposely saturate the wrap with water while the engine is not up to temperature and walk away. But even if you did this, the wrap itself does not promote rusting. I will say if you are running a bare steel pipe we will recommend that you coat it with our HT silicone spray or some type of header paint before wrapping as bare steel will rust a lot quicker versus and un-coated pipe.

Also, as Dano523 mentioned we do not recommend wrapping catalytic converters as you can trap too much heat in the converters and shorten their lifespan. We offer a catalytic converter shield that has stand offs built into them to allow for an air gap so the converter can still "breathe" but act as a heat barrier. Check out http://designengineering.com/corvett...verter-shield/ . I know this was designed specifically for the C7 but it has many other fitments.

Please let me know if anyone has any questions.

Thank you, Tim

Also, as Dano523 mentioned we do not recommend wrapping catalytic converters as you can trap too much heat in the converters and shorten their lifespan. We offer a catalytic converter shield that has stand offs built into them to allow for an air gap so the converter can still "breathe" but act as a heat barrier. Check out http://designengineering.com/corvett...verter-shield/ . I know this was designed specifically for the C7 but it has many other fitments.

Please let me know if anyone has any questions.

Thank you, Tim

Sample

HD at not extra charge (I work for free).