If you still have stock wires in your c6 you should watch this video.

The following users liked this post:

Ruouthere (09-14-2018)

#2

You pretty much hit the nail on the head, with some sort of grease used (not dielectric grease) when the plug wires where put back on. Hence we can tell this by the layer that has not only burnt on to the connector in the coil, but the plastic ID of the coil socket as well.

Note, OEM wire connectors do not have an added ceramic layer, and are just plated metal connectors alone.

But lets back it up, and the real problem was the where the wires were pulled after bowling green instead them. Hence the spray lube that the plant uses, it like a old product call "ASK" Lube. Hence after a short time, the lube will dry up and will glue the boots in place. So the first time the wires are removed, you have to be gently removing them, or you end up killing the connectors inside them. With the damage that I can see to the spark plug wires, pretty much the wired where distroyed when they where removed the first time around.

Now lets cover the "Lube" that was used to put the wired back on, and as you can tell, it's not silicone dielectric grease. So as the lube (my guess is some type of lithium grease), not only dried up from the motor heat, but created a barrier as well.

So coils wise, the electrical contact cleaner alone is not going to cut it, being that the hard baked/burnt on layer needs to be abrasively removed. So from the start, would pull every coil off the car, take it over the bead blast cabinet loaded with 400 glass bead, pressure around 40lbs, and clean the electrical posts in the every coil to remove the baked on burnt mystery grease coating, and to get the metal back down to it raw surface to allow them to make a good contact to the wire connectors.

On the spark plugs, which the the 41-104 are the correct plug, would glass bead blast them as well to clean them up (end posts too, to remove the mystery lube that I can see was applied on them and baked as well), since still look fine. Now with the coils connectors and spark plugs 400 bead blasted to clean them up (which will not remove the iridium plating on the plugs) now give them a good shot of electrical contact cleaner to final clean the parts, and coat the spark plug threads with a light coat of anti-seaze since you will be pulling the plugs say every 30K to give then a quick cleaning again, and to reset the gaps to .040".

Note, new plugs come with a thread coating, but since we will be pulling the plugs say every 30K to clean and reset the gaps, we need to add the antiseaze so we don't sleaze a plug up before it next removal.

As for spark plug wires, they are toasted between the mystery grease, and the fact they where manhandled when pulled the first time, and no real saving them isntead. So with a new set of spark plug wires (Oems are fine) and just give them a quick shot of spray cleaner to clean any thing on the contacts, and then dielectric grease them before putting them on the car. As for pulling them the next time around to clean the plugs up again and reset the gaps, again, do not man handle the wires, or you going to kill the connectors on them again yourself.

As for dielectric grease on the plug wire connectors, with you being in Ca near the ocean (hence salt in the air), would apply a very light coat to the metal parts, to keep them from environmental corroding up, or at least a quick shot of WD-40 and wipe down, since it was designed for just that purpose. Hence look at the amount of rust on your exhaust manifold bolts, and it telling the tail of high percentage of salt in air of where the car has been kept.

Note, OEM wire connectors do not have an added ceramic layer, and are just plated metal connectors alone.

But lets back it up, and the real problem was the where the wires were pulled after bowling green instead them. Hence the spray lube that the plant uses, it like a old product call "ASK" Lube. Hence after a short time, the lube will dry up and will glue the boots in place. So the first time the wires are removed, you have to be gently removing them, or you end up killing the connectors inside them. With the damage that I can see to the spark plug wires, pretty much the wired where distroyed when they where removed the first time around.

Now lets cover the "Lube" that was used to put the wired back on, and as you can tell, it's not silicone dielectric grease. So as the lube (my guess is some type of lithium grease), not only dried up from the motor heat, but created a barrier as well.

So coils wise, the electrical contact cleaner alone is not going to cut it, being that the hard baked/burnt on layer needs to be abrasively removed. So from the start, would pull every coil off the car, take it over the bead blast cabinet loaded with 400 glass bead, pressure around 40lbs, and clean the electrical posts in the every coil to remove the baked on burnt mystery grease coating, and to get the metal back down to it raw surface to allow them to make a good contact to the wire connectors.

On the spark plugs, which the the 41-104 are the correct plug, would glass bead blast them as well to clean them up (end posts too, to remove the mystery lube that I can see was applied on them and baked as well), since still look fine. Now with the coils connectors and spark plugs 400 bead blasted to clean them up (which will not remove the iridium plating on the plugs) now give them a good shot of electrical contact cleaner to final clean the parts, and coat the spark plug threads with a light coat of anti-seaze since you will be pulling the plugs say every 30K to give then a quick cleaning again, and to reset the gaps to .040".

Note, new plugs come with a thread coating, but since we will be pulling the plugs say every 30K to clean and reset the gaps, we need to add the antiseaze so we don't sleaze a plug up before it next removal.

As for spark plug wires, they are toasted between the mystery grease, and the fact they where manhandled when pulled the first time, and no real saving them isntead. So with a new set of spark plug wires (Oems are fine) and just give them a quick shot of spray cleaner to clean any thing on the contacts, and then dielectric grease them before putting them on the car. As for pulling them the next time around to clean the plugs up again and reset the gaps, again, do not man handle the wires, or you going to kill the connectors on them again yourself.

As for dielectric grease on the plug wire connectors, with you being in Ca near the ocean (hence salt in the air), would apply a very light coat to the metal parts, to keep them from environmental corroding up, or at least a quick shot of WD-40 and wipe down, since it was designed for just that purpose. Hence look at the amount of rust on your exhaust manifold bolts, and it telling the tail of high percentage of salt in air of where the car has been kept.

The following users liked this post:

joliett (09-15-2018)

#3

Race Director

Thread Starter

Thanks for the thoughtful reply always enjoy your points. Small disagreements.

I think the WD as I can spray that on & get better coverage.

The wires came off easy using the tool I showed & pull/wiggle/pull.... so I know I did not damage anything, been there done it before.

THANKS!

You pretty much hit the nail on the head, with some sort of grease used (not dielectric grease) when the plug wires where put back on. Hence we can tell this by the layer that has not only burnt on to the connector in the coil, but the plastic ID of the coil socket as well.

Note, OEM wire connectors do not have an added ceramic layer, and are just plated metal connectors alone.

But lets back it up, and the real problem was the where the wires were pulled after bowling green instead them. Hence the spray lube that the plant uses, it like a old product call "ASK" Lube. Hence after a short time, the lube will dry up and will glue the boots in place. So the first time the wires are removed, you have to be gently removing them, or you end up killing the connectors inside them. With the damage that I can see to the spark plug wires, pretty much the wired where distroyed when they where removed the first time around.

Yep.

Now lets cover the "Lube" that was used to put the wired back on, and as you can tell, it's not silicone dielectric grease. So as the lube (my guess is some type of lithium grease), not only dried up from the motor heat, but created a barrier as well.

I guess they were previously pulled by a gorilla, not sure why at 9k miles.

So coils wise, the electrical contact cleaner alone is not going to cut it, being that the hard baked/burnt on layer needs to be abrasively removed. So from the start, would pull every coil off the car, take it over the bead blast cabinet loaded with 400 glass bead, pressure around 40lbs, and clean the electrical posts in the every coil to remove the baked on burnt mystery grease coating, and to get the metal back down to it raw surface to allow them to make a good contact to the wire connectors.

Once the post on the coil is "eroded" by the arcing, I am just tossing it & replace, a good blasting "may" be enough, but under "race" conditions I want full metal/metal contact.

On the spark plugs, which the the 41-104 are the correct plug, would glass bead blast them as well to clean them up (end posts too, to remove the mystery lube that I can see was applied on them and baked as well), since still look fine. Now with the coils connectors and spark plugs 400 bead blasted to clean them up (which will not remove the iridium plating on the plugs) now give them a good shot of electrical contact cleaner to final clean the parts, and coat the spark plug threads with a light coat of anti-seaze since you will be pulling the plugs say every 30K to give then a quick cleaning again, and to reset the gaps to .040".

Note, new plugs come with a thread coating, but since we will be pulling the plugs say every 30K to clean and reset the gaps, we need to add the antiseaze so we don't sleaze a plug up before it next removal.

I ordered some aluminum type antisieze to have along with my regular antisieze, they have copper also.

As for spark plug wires, they are toasted between the mystery grease, and the fact they where manhandled when pulled the first time, and no real saving them isntead. So with a new set of spark plug wires (Oems are fine) and just give them a quick shot of spray cleaner to clean any thing on the contacts, and then dielectric grease them before putting them on the car. As for pulling them the next time around to clean the plugs up again and reset the gaps, again, do not man handle the wires, or you going to kill the connectors on them again yourself.

IMO the OEM are way underbuilt, that flimsy bit of "C" shaped metal fell apart in my hands, I cannot see wires that cheaply made holding up to many heat cycles & a getting pulled off/pushed on to check plugs. I will see if the GM Performance Parts wires are any better, calling Texas Speed for a set. I have some insulation sleeves to slide over the wires too.

As for dielectric grease on the plug wire connectors, with you being in Ca near the ocean (hence salt in the air), would apply a very light coat to the metal parts, to keep them from environmental corroding up, or at least a quick shot of WD-40 and wipe down, since it was designed for just that purpose. Hence look at the amount of rust on your exhaust manifold bolts, and it telling the tail of high percentage of salt in air of where the car has been kept.

Note, OEM wire connectors do not have an added ceramic layer, and are just plated metal connectors alone.

But lets back it up, and the real problem was the where the wires were pulled after bowling green instead them. Hence the spray lube that the plant uses, it like a old product call "ASK" Lube. Hence after a short time, the lube will dry up and will glue the boots in place. So the first time the wires are removed, you have to be gently removing them, or you end up killing the connectors inside them. With the damage that I can see to the spark plug wires, pretty much the wired where distroyed when they where removed the first time around.

Yep.

Now lets cover the "Lube" that was used to put the wired back on, and as you can tell, it's not silicone dielectric grease. So as the lube (my guess is some type of lithium grease), not only dried up from the motor heat, but created a barrier as well.

I guess they were previously pulled by a gorilla, not sure why at 9k miles.

So coils wise, the electrical contact cleaner alone is not going to cut it, being that the hard baked/burnt on layer needs to be abrasively removed. So from the start, would pull every coil off the car, take it over the bead blast cabinet loaded with 400 glass bead, pressure around 40lbs, and clean the electrical posts in the every coil to remove the baked on burnt mystery grease coating, and to get the metal back down to it raw surface to allow them to make a good contact to the wire connectors.

Once the post on the coil is "eroded" by the arcing, I am just tossing it & replace, a good blasting "may" be enough, but under "race" conditions I want full metal/metal contact.

On the spark plugs, which the the 41-104 are the correct plug, would glass bead blast them as well to clean them up (end posts too, to remove the mystery lube that I can see was applied on them and baked as well), since still look fine. Now with the coils connectors and spark plugs 400 bead blasted to clean them up (which will not remove the iridium plating on the plugs) now give them a good shot of electrical contact cleaner to final clean the parts, and coat the spark plug threads with a light coat of anti-seaze since you will be pulling the plugs say every 30K to give then a quick cleaning again, and to reset the gaps to .040".

Note, new plugs come with a thread coating, but since we will be pulling the plugs say every 30K to clean and reset the gaps, we need to add the antiseaze so we don't sleaze a plug up before it next removal.

I ordered some aluminum type antisieze to have along with my regular antisieze, they have copper also.

As for spark plug wires, they are toasted between the mystery grease, and the fact they where manhandled when pulled the first time, and no real saving them isntead. So with a new set of spark plug wires (Oems are fine) and just give them a quick shot of spray cleaner to clean any thing on the contacts, and then dielectric grease them before putting them on the car. As for pulling them the next time around to clean the plugs up again and reset the gaps, again, do not man handle the wires, or you going to kill the connectors on them again yourself.

IMO the OEM are way underbuilt, that flimsy bit of "C" shaped metal fell apart in my hands, I cannot see wires that cheaply made holding up to many heat cycles & a getting pulled off/pushed on to check plugs. I will see if the GM Performance Parts wires are any better, calling Texas Speed for a set. I have some insulation sleeves to slide over the wires too.

As for dielectric grease on the plug wire connectors, with you being in Ca near the ocean (hence salt in the air), would apply a very light coat to the metal parts, to keep them from environmental corroding up, or at least a quick shot of WD-40 and wipe down, since it was designed for just that purpose. Hence look at the amount of rust on your exhaust manifold bolts, and it telling the tail of high percentage of salt in air of where the car has been kept.

The wires came off easy using the tool I showed & pull/wiggle/pull.... so I know I did not damage anything, been there done it before.

THANKS!

Last edited by froggy47; 09-13-2018 at 01:02 PM.

#4

Race Director

Thread Starter

For sliding the rubber over the coils/plugs I like a dielectric as the whole design of it is to prevent arcing and/or environmental ingress. I have read differing opinions on whether to actually coat the metal/metal contact point with the grease or just the rubber cover contact area. What do you all think?

#5

Race Director

Member Since: Sep 2007

Location: Peoria/Phoenix AZ

Posts: 16,555

Received 2,060 Likes

on

1,505 Posts

C6 of Year Finalist (performance mods) 2019

I'm not a fan of dis-assembling things to see how well they are working, unless there is a reason to believe they are a cause or contributor of a problem. A WOT scan can identify a loss of performance fairly well when compared with previous scans. A few years ago, I failed to record a scan prior to traveling 800 miles for some dragstrip fun. I would have easily recognized I had several bad plugs (missing iridium tips) that only showed up as a problem under WOT. It sure took the fun out of that weekend.

BTW, 154 K miles and still on the original wires.

BTW, 154 K miles and still on the original wires.

#6

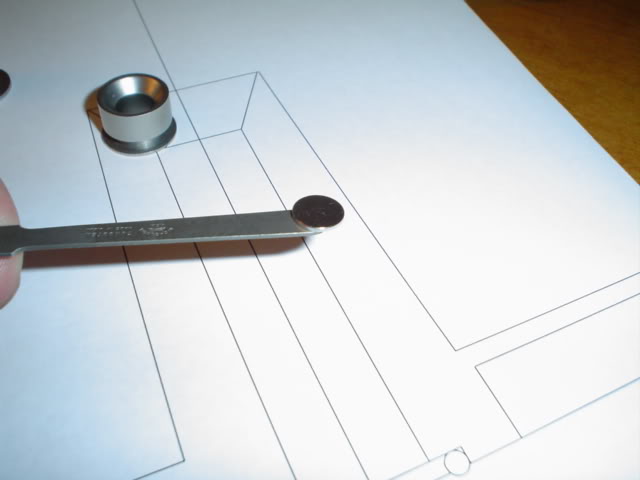

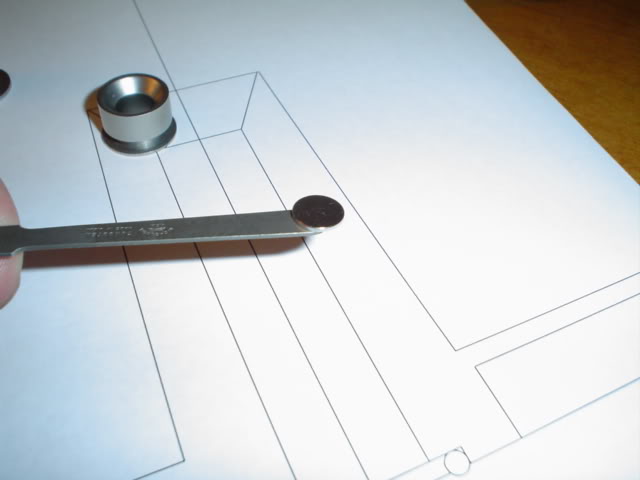

Spark plug off the 2 stroke weed eater is since it's the most fouled plug I could just find to do a quick 400 glass bleed cleaning on it, re-gapped to .030" for another years use.

So before you throw the coils away, give the spark plug connector tabs on them a quick 400 glass bead cleaning and they will right as rain to keep using; metal to metal contact and all!

As for the new spark plug wires, you dielectric grease the boots, and when you have to pull them for say a re-clean and gapping again, will not distroy them when you go to remove them. Hence not saying that you kill the OEM wires, but the lad that pulled them off the first time around did instead (and used the mystery lube when putting the wires back on to cause the coils build up as well)..

Part in the back ground is raw 7075, and 400 glass bead blasted after lathing. So as you can see, 400 glass bead does a great job at cleaning, without removing metal/plating/pitting so long as you don't lean into hard with air pressure. Hence glass bed peens to remove the fouling, and does not cut like oxide media does removing metal instead. So cleans up metal parts very well to remove fouling; even on softer aluminum.

So before you throw the coils away, give the spark plug connector tabs on them a quick 400 glass bead cleaning and they will right as rain to keep using; metal to metal contact and all!

As for the new spark plug wires, you dielectric grease the boots, and when you have to pull them for say a re-clean and gapping again, will not distroy them when you go to remove them. Hence not saying that you kill the OEM wires, but the lad that pulled them off the first time around did instead (and used the mystery lube when putting the wires back on to cause the coils build up as well)..

Part in the back ground is raw 7075, and 400 glass bead blasted after lathing. So as you can see, 400 glass bead does a great job at cleaning, without removing metal/plating/pitting so long as you don't lean into hard with air pressure. Hence glass bed peens to remove the fouling, and does not cut like oxide media does removing metal instead. So cleans up metal parts very well to remove fouling; even on softer aluminum.

Last edited by Dano523; 09-13-2018 at 06:07 PM.

#7

Race Director

Thread Starter

Spark plug off the 2 stroke weed eater is since it's the most fouled plug I could just find to do a quick 400 glass bleed cleaning on it, re-gapped to .030" for another years use.

So before you throw the coils away, give the spark plug connector tabs on them a quick 400 glass bead cleaning and they will right as rain to keep using; metal to metal contact and all!

As for the new spark plug wires, you dielectric grease the boots, and when you have to pull them for say a re-clean and gapping again, will not distroy them when you go to remove them. Hence not saying that you kill the OEM wires, but the lad that pulled them off the first time around did instead (and used the mystery lube when putting the wires back on to cause the coils build up as well)..

Part in the back ground is raw 7075, and 400 glass bead blasted after lathing. So as you can see, 400 glass bead does a great job at cleaning, without removing metal/plating/pitting so long as you don't lean into hard with air pressure. Hence glass bed peens to remove the fouling, and does not cut like oxide media does removing metal instead. So cleans up metal parts very well to remove fouling; even on softer aluminum.

So before you throw the coils away, give the spark plug connector tabs on them a quick 400 glass bead cleaning and they will right as rain to keep using; metal to metal contact and all!

As for the new spark plug wires, you dielectric grease the boots, and when you have to pull them for say a re-clean and gapping again, will not distroy them when you go to remove them. Hence not saying that you kill the OEM wires, but the lad that pulled them off the first time around did instead (and used the mystery lube when putting the wires back on to cause the coils build up as well)..

Part in the back ground is raw 7075, and 400 glass bead blasted after lathing. So as you can see, 400 glass bead does a great job at cleaning, without removing metal/plating/pitting so long as you don't lean into hard with air pressure. Hence glass bed peens to remove the fouling, and does not cut like oxide media does removing metal instead. So cleans up metal parts very well to remove fouling; even on softer aluminum.

So losing the sharp edges is ok?

Last edited by froggy47; 09-13-2018 at 06:52 PM.

#8