[Z06] why stainless valves?

#1

Safety Car

Thread Starter

new LS7 owner here. spent the last 9 months straight researching the C6Z. nearly everyday here on the CF. i understand the valve guide issue and its fix.

but one thing i havent been able to find any info on is why most everyone changes the valves (usually exhaust) to solid or hollow stainless steel valves?

if the issue was soft guides, what is the reason behind the stainless valves?

but one thing i havent been able to find any info on is why most everyone changes the valves (usually exhaust) to solid or hollow stainless steel valves?

if the issue was soft guides, what is the reason behind the stainless valves?

#2

Safety Car

The dropping valve problem is dynamic. It is not 100% a guide issue.

Why put a stock valve back in if they have any percentage of blame?

Why put a stock valve back in if they have any percentage of blame?

#3

Safety Car

I just went with what is recommended by WCCH. I think it is for cost and strength factors. Others, including Katech, stay with oem valves or one piece titanium I believe for weight and valve train stability concerns.

#4

Team Owner

These days, there's no reason to run solid...the Ferrea F2042p is a great 1-piece lightweight alternative to the two piece OEM valve. A few years back, it was chicken vs egg...is the OE valve the culprit, or is it the guides? So many opted for the strongest valve they could find...perhaps without researching things like valve bounce and valvetrain stability.

Now that we have a universal understanding of how/why the "dropped valve" failures were occurring (Linamar machining = substandard quality), I feel the OE exhaust valves are certainly fine to use. As for me, I just wanted something that I considered to be an upgrade over the two piece sodium filled OE valve. There were dissection experiments on the OE exhaust valves, and I recall seeing variances in the stem wall thickness along with variances in the amount of sodium fill from one valve to another. To me, that just says poor quality all over it...so I went in another direction.

Now that we have a universal understanding of how/why the "dropped valve" failures were occurring (Linamar machining = substandard quality), I feel the OE exhaust valves are certainly fine to use. As for me, I just wanted something that I considered to be an upgrade over the two piece sodium filled OE valve. There were dissection experiments on the OE exhaust valves, and I recall seeing variances in the stem wall thickness along with variances in the amount of sodium fill from one valve to another. To me, that just says poor quality all over it...so I went in another direction.

#5

Based on my research and from a person on here pm guides are mot the way to go I dis on my last heads and cam they were starting to wear but still ok, moldstar guides and bronze che guides are the way to go trust me I have done plenty of heads and have a strong source that def the moldstar guide is the strongest.....but yes you can still use hollow valves but I would get something better and stronger.....uograde....

#6

Team Owner

Based on my research and from a person on here pm guides are mot the way to go I dis on my last heads and cam they were starting to wear but still ok, moldstar guides and bronze che guides are the way to go trust me I have done plenty of heads and have a strong source that def the moldstar guide is the strongest.....but yes you can still use hollow valves but I would get something better and stronger.....uograde....

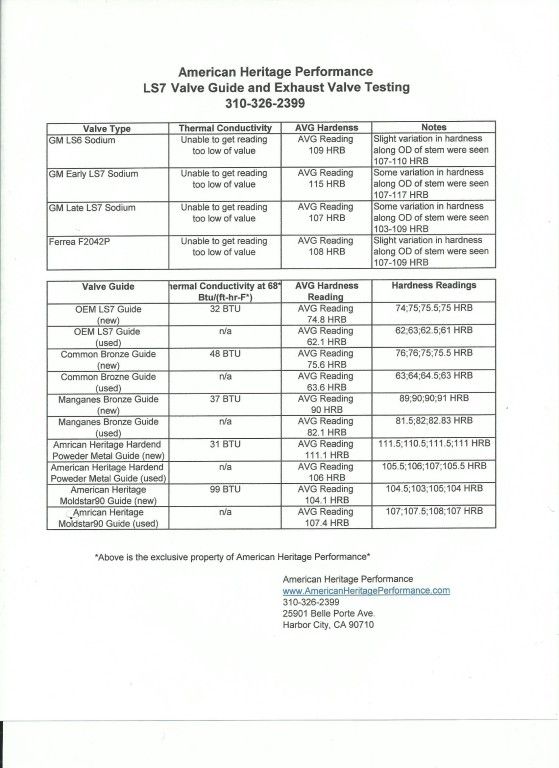

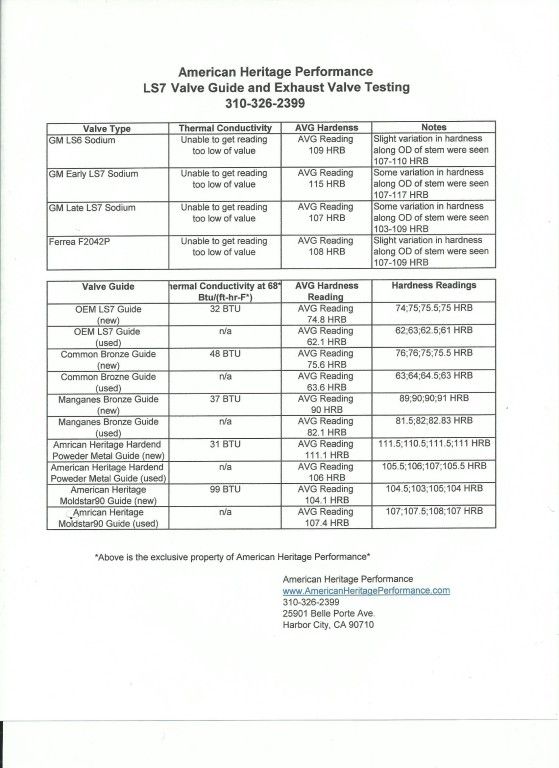

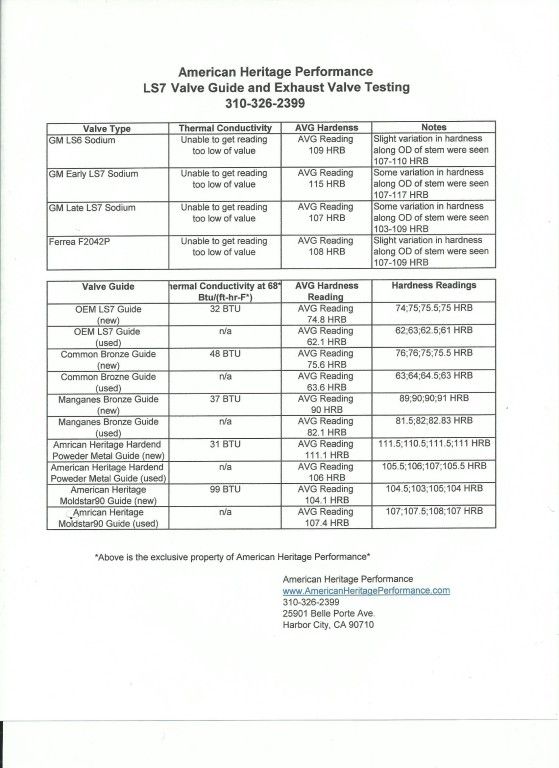

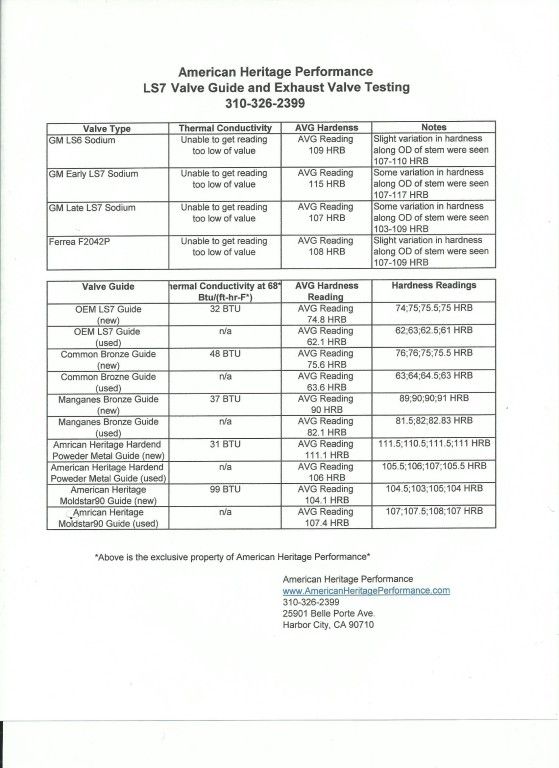

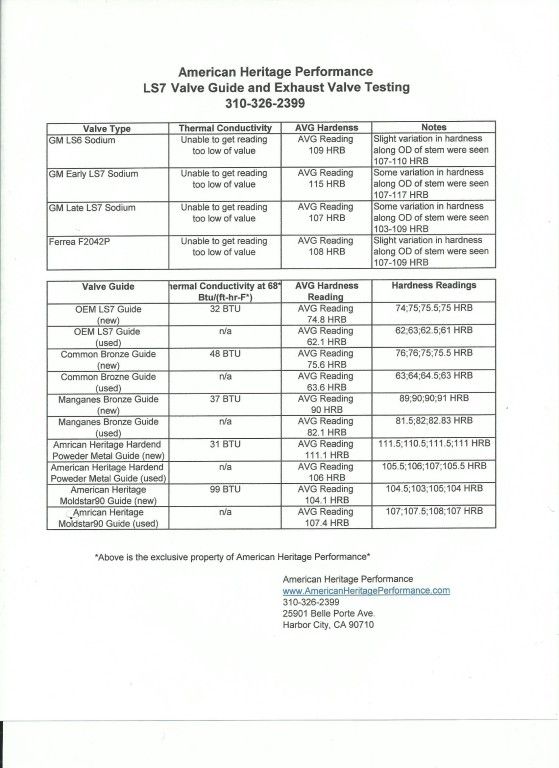

Here's AHP's independent guide hardness test for those who may not have seen it:

The following users liked this post:

Blackship (02-22-2021)

#7

Race Director

Angelo, I believe it had been determined that those PM guides were OE PM guides, correct? Not all PM material is the same...just like not all Bronze guides are the same. MoldStar90 (Best), CHE Bronze Manganese, and AHP's proprietary PM guides are probably the only three anyone should be considering these days when rebuilding LS7 heads.

Here's AHP's independent guide hardness test for those who may not have seen it:

Here's AHP's independent guide hardness test for those who may not have seen it:

#10

Burning Brakes

#11

Burning Brakes

new LS7 owner here. spent the last 9 months straight researching the C6Z. nearly everyday here on the CF. i understand the valve guide issue and its fix.

but one thing i havent been able to find any info on is why most everyone changes the valves (usually exhaust) to solid or hollow stainless steel valves?

if the issue was soft guides, what is the reason behind the stainless valves?

but one thing i havent been able to find any info on is why most everyone changes the valves (usually exhaust) to solid or hollow stainless steel valves?

if the issue was soft guides, what is the reason behind the stainless valves?

The following users liked this post:

Blackship (02-22-2021)

#12

Tech Contributor

Member Since: Oct 1999

Location: Charlotte, NC (formerly Endicott, NY)

Posts: 40,089

Received 8,928 Likes

on

5,333 Posts

new LS7 owner here. spent the last 9 months straight researching the C6Z. nearly everyday here on the CF. i understand the valve guide issue and its fix.

but one thing i havent been able to find any info on is why most everyone changes the valves (usually exhaust) to solid or hollow stainless steel valves?

if the issue was soft guides, what is the reason behind the stainless valves?

but one thing i havent been able to find any info on is why most everyone changes the valves (usually exhaust) to solid or hollow stainless steel valves?

if the issue was soft guides, what is the reason behind the stainless valves?

Search on dropped valves and look at the threads in 2011 when a number of cars had valves drop. You don't see a lot of mention of loose guides but you do see a lot of conjecture about the stock exhaust valve stem being weak and prone to breaking.

Bill

#13

Le Mans Master

new LS7 owner here. spent the last 9 months straight researching the C6Z. nearly everyday here on the CF. i understand the valve guide issue and its fix.

but one thing i havent been able to find any info on is why most everyone changes the valves (usually exhaust) to solid or hollow stainless steel valves?

if the issue was soft guides, what is the reason behind the stainless valves?

but one thing i havent been able to find any info on is why most everyone changes the valves (usually exhaust) to solid or hollow stainless steel valves?

if the issue was soft guides, what is the reason behind the stainless valves?

Katech builds plenty of engines with the stock GM hollow exhaust valves, call them and ask or do a search on the CF, see for yourself.

I currently run them in my car.

This design has a proven track record, in use since 2002 with the LS6 in the C5 Z06 - try to find exhaust valve failures in any volume from that time period.. Lot's of those engines were beat on at race tracks throughout this country (and abroad); we have a significant data set to draw conclusions from.

That said, there was an "updated" GM part, so if you do run the stock valves, run a new set. The other choice would be the hollow-stem Ferrea. Last choice would be a solid stem SS valve (but they also require you you run a stiffer spring, in-turn loading the lifters, rockers, more friction between the cam lobe and the lifter wheel, etc.).

Yes, of course, a solid stem valve will hold up longer (how long is "longer"?) in a badly worn valve guide. If you don't have worn valve guides, and the valve closes squarely on the seat, there is no issue - you aren't "solving a problem" with solid stem valves. If you address the core issue, you can leave them alone, enjoy the benefits of the design (light weight and superior heat dissipation), worry about the other dozen things that can go wrong.

Finally, there has never been ANY evidence of a failed exhaust valve that was running in an in-spec valve guide, period-end. ALL of the failed exhaust valve examples were found to be running in way out-of-spec guides - those are the FACTS, not conjecture or arm-chair engineering theories.

I know with certainty what causes exhaust valve failures in LS7 engines - poor initial machining of cylinder heads by Linamar, LLC. I don't wonder about it, nor do I need additional proof or evidence. The search is over, the verdict is in. And GM knows it to be true as well - that's one "reason" why there is no "fix" from GM - they haven't invented a time machine to send your cylinder heads somewhere else to be properly machined the first time around.

Last edited by Dan_the_C5_Man; 11-02-2016 at 03:21 AM.

#14

Team Owner

#15

Correct I mean you can run the stock stuff there's is nothing wrong with but on my new engine you want to keep things not as heavy but not to light....Darin Morgan even said a little oil on the guides help lubricate them...I will post pictures of all my new stuff that way people can go from there....heres a peak of my block ...

Say something about this photo

Say something about this photo

Last edited by RamAir972003; 11-02-2016 at 03:35 AM.

#16

Angelo, I believe it had been determined that those PM guides were OE PM guides, correct? Not all PM material is the same...just like not all Bronze guides are the same. MoldStar90 (Best), CHE Bronze Manganese, and AHP's proprietary PM guides are probably the only three anyone should be considering these days when rebuilding LS7 heads.

Here's AHP's independent guide hardness test for those who may not have seen it:

Here's AHP's independent guide hardness test for those who may not have seen it:

The following users liked this post:

Blackship (02-22-2021)

#17

I'm running the spec stage3 plus single disc good for 900hp I will let everyone know how it goes...thinking of running a methanol kit for safety...also.

Last edited by RamAir972003; 11-02-2016 at 03:33 AM.

#18

Supporting Vendor

Member Since: Sep 2013

Location: Harbor City California

Posts: 2,817

Received 1,012 Likes

on

533 Posts

OP: An answer to your question in post 1

The first generation of LS7 exhaust valves (06'-mid 08') had inconsistent wall thickness as well as thinner than what would be recommenced wall thickness. It was quickly blamed for most if not all the LS7 valve train failures (weather it was the direct cause or not).

The theory of the solid SS exhaust valve is pretty strait forward: Replace a thin walled valve with a heavy duty solid steel valve (heavy being the key word). Bigger is better right... As we all know that is not always the case.

That is a brief over view as to why the Solid SS exhaust valve became so popular and to a point it worked but only to a point. A thin walled valve is going to break faster in an out of spec guide than say a solid valve but eventually they both will break in an out of spec guide.

The point is the guide should not be out of spec. Period.

There is no reason to run a Heavy Solid SS valve in the LS7 valve train, none at all.

We use the Ferrea F2042p Hollow SS valve in most our builds but we also install the newer/late model gm sodium exhaust valves in some builds.

We like to build the lightest valve train possible

310-326-2399

http://www.americanheritageperformance.com/

The first generation of LS7 exhaust valves (06'-mid 08') had inconsistent wall thickness as well as thinner than what would be recommenced wall thickness. It was quickly blamed for most if not all the LS7 valve train failures (weather it was the direct cause or not).

The theory of the solid SS exhaust valve is pretty strait forward: Replace a thin walled valve with a heavy duty solid steel valve (heavy being the key word). Bigger is better right... As we all know that is not always the case.

That is a brief over view as to why the Solid SS exhaust valve became so popular and to a point it worked but only to a point. A thin walled valve is going to break faster in an out of spec guide than say a solid valve but eventually they both will break in an out of spec guide.

The point is the guide should not be out of spec. Period.

There is no reason to run a Heavy Solid SS valve in the LS7 valve train, none at all.

We use the Ferrea F2042p Hollow SS valve in most our builds but we also install the newer/late model gm sodium exhaust valves in some builds.

We like to build the lightest valve train possible

310-326-2399

http://www.americanheritageperformance.com/

Last edited by American Heritage; 11-02-2016 at 05:29 AM.

The following 2 users liked this post by American Heritage:

BigVette427 (11-03-2016),

Landru (11-02-2016)

#19

Safety Car

Thread Starter

Paranoia mainly, plus some good ol' fashion old-school thinking tossed in for good measure.

Katech builds plenty of engines with the stock GM hollow exhaust valves, call them and ask or do a search on the CF, see for yourself.

I currently run them in my car.

This design has a proven track record, in use since 2002 with the LS6 in the C5 Z06 - try to find exhaust valve failures in any volume from that time period.. Lot's of those engines were beat on at race tracks throughout this country (and abroad); we have a significant data set to draw conclusions from.

That said, there was an "updated" GM part, so if you do run the stock valves, run a new set. The other choice would be the hollow-stem Ferrea. Last choice would be a solid stem SS valve (but they also require you you run a stiffer spring, in-turn loading the lifters, rockers, more friction between the cam lobe and the lifter wheel, etc.).

Yes, of course, a solid stem valve will hold up longer (how long is "longer"?) in a badly worn valve guide. If you don't have worn valve guides, and the valve closes squarely on the seat, there is no issue - you aren't "solving a problem" with solid stem valves. If you address the core issue, you can leave them alone, enjoy the benefits of the design (light weight and superior heat dissipation), worry about the other dozen things that can go wrong.

Finally, there has never been ANY evidence of a failed exhaust valve that was running in an in-spec valve guide, period-end. ALL of the failed exhaust valve examples were found to be running in way out-of-spec guides - those are the FACTS, not conjecture or arm-chair engineering theories.

I know with certainty what causes exhaust valve failures in LS7 engines - poor initial machining of cylinder heads by Linamar, LLC. I don't wonder about it, nor do I need additional proof or evidence. The search is over, the verdict is in. And GM knows it to be true as well - that's one "reason" why there is no "fix" from GM - they haven't invented a time machine to send your cylinder heads somewhere else to be properly machined the first time around.

Katech builds plenty of engines with the stock GM hollow exhaust valves, call them and ask or do a search on the CF, see for yourself.

I currently run them in my car.

This design has a proven track record, in use since 2002 with the LS6 in the C5 Z06 - try to find exhaust valve failures in any volume from that time period.. Lot's of those engines were beat on at race tracks throughout this country (and abroad); we have a significant data set to draw conclusions from.

That said, there was an "updated" GM part, so if you do run the stock valves, run a new set. The other choice would be the hollow-stem Ferrea. Last choice would be a solid stem SS valve (but they also require you you run a stiffer spring, in-turn loading the lifters, rockers, more friction between the cam lobe and the lifter wheel, etc.).

Yes, of course, a solid stem valve will hold up longer (how long is "longer"?) in a badly worn valve guide. If you don't have worn valve guides, and the valve closes squarely on the seat, there is no issue - you aren't "solving a problem" with solid stem valves. If you address the core issue, you can leave them alone, enjoy the benefits of the design (light weight and superior heat dissipation), worry about the other dozen things that can go wrong.

Finally, there has never been ANY evidence of a failed exhaust valve that was running in an in-spec valve guide, period-end. ALL of the failed exhaust valve examples were found to be running in way out-of-spec guides - those are the FACTS, not conjecture or arm-chair engineering theories.

I know with certainty what causes exhaust valve failures in LS7 engines - poor initial machining of cylinder heads by Linamar, LLC. I don't wonder about it, nor do I need additional proof or evidence. The search is over, the verdict is in. And GM knows it to be true as well - that's one "reason" why there is no "fix" from GM - they haven't invented a time machine to send your cylinder heads somewhere else to be properly machined the first time around.

#20

Safety Car

Thread Starter

OP: An answer to your question in post 1

The first generation of LS7 exhaust valves (06'-mid 08') had inconsistent wall thickness as well as thinner than what would be recommenced wall thickness. It was quickly blamed for most if not all the LS7 valve train failures (weather it was the direct cause or not).

The theory of the solid SS exhaust valve is pretty strait forward: Replace a thin walled valve with a heavy duty solid steel valve (heavy being the key word). Bigger is better right... As we all know that is not always the case.

That is a brief over view as to why the Solid SS exhaust valve became so popular and to a point it worked but only to a point. A thin walled valve is going to break faster in an out of spec guide than say a solid valve but eventually they both will break in an out of spec guide.

The point is the guide should not be out of spec. Period.

There is no reason to run a Heavy Solid SS valve in the LS7 valve train, none at all.

We use the Ferrea F2042p Hollow SS valve in most our builds but we also install the newer/late model gm sodium exhaust valves in some builds.

We like to build the lightest valve train possible

310-326-2399

http://www.americanheritageperformance.com/

The first generation of LS7 exhaust valves (06'-mid 08') had inconsistent wall thickness as well as thinner than what would be recommenced wall thickness. It was quickly blamed for most if not all the LS7 valve train failures (weather it was the direct cause or not).

The theory of the solid SS exhaust valve is pretty strait forward: Replace a thin walled valve with a heavy duty solid steel valve (heavy being the key word). Bigger is better right... As we all know that is not always the case.

That is a brief over view as to why the Solid SS exhaust valve became so popular and to a point it worked but only to a point. A thin walled valve is going to break faster in an out of spec guide than say a solid valve but eventually they both will break in an out of spec guide.

The point is the guide should not be out of spec. Period.

There is no reason to run a Heavy Solid SS valve in the LS7 valve train, none at all.

We use the Ferrea F2042p Hollow SS valve in most our builds but we also install the newer/late model gm sodium exhaust valves in some builds.

We like to build the lightest valve train possible

310-326-2399

http://www.americanheritageperformance.com/

funny you posted, i decided a couple weeks ago ill be sending my heads to you. 2 reasons. i plan to keep this car for 15 years, and it will also be a road race car. spending 2-3 hours a weekend at redline. i will be getting the moldstar90 guides for an extra piece of mind and longevity. also you use hollow stem valves that are within just a few grams of the stock valves weight although i suspect with proper guides the stock valves would hold up just fine.

im pulling the heads off next week and will give you a call.

Last edited by STANG KILLA SS; 11-02-2016 at 12:20 PM.

I like the stainless cause they are shiny. I like shiny stuff.

I like the stainless cause they are shiny. I like shiny stuff.