C7 owners that are mechanically inclined!!

#1

Melting Slicks

Thread Starter

Looking for C7 owners that are handy enough to take 15 minutes or so to remove their intake manifold (minimal tools, very easy, and all gaskets are reusable) and take close up pictures of the level of coking deposits already on your valves, and if over 20k miles and really handy to measure valve guide wear at this point. The more we can look at with different levels of miles already on (really want to see 10-20k miles engines) to help other judge the progression of this issue.

Here is a video at 5500 for reference:

Pause it at the beginning to examine these valves and note how these hard abrasive deposits are being drawn into the guide and wearing them with each cycle:

Many are under the mistaken belief that this is not happening with the new GM GDI V8's as publicly no automaker admits to it, so the more actual owners willing to perform this simple step and share it, the better to share what is actually occurring on individual owners cars.

Thanks in Advance!!

Jason

Here is a video at 5500 for reference:

Pause it at the beginning to examine these valves and note how these hard abrasive deposits are being drawn into the guide and wearing them with each cycle:

Many are under the mistaken belief that this is not happening with the new GM GDI V8's as publicly no automaker admits to it, so the more actual owners willing to perform this simple step and share it, the better to share what is actually occurring on individual owners cars.

Thanks in Advance!!

Jason

The following users liked this post:

blkvet6 (06-24-2017)

#2

I watched this video, but didn't understand the 'alarm' he was trying to convey. Do we have any proof of the cars losing 6-15 percent of their horsepower after 15k to 20k miles? This would seem to be a glaring issue, easily caught and seen during development.

Would a catch can from mile 0 eliminate this?

Would a catch can from mile 0 eliminate this?

#3

Le Mans Master

It is not clear to me either exactly how deposits on the stem can cause loss of power, or cause wear to the guides...

If the carbon only builds up in areas that are not being wiped by the guides, how does that cause wear?

Are they saying power loss is due to the deposits taking up volume that should be occupied by incoming air, or just that the irregular surface disrupts laminar flow of air into the chamber?

If the carbon only builds up in areas that are not being wiped by the guides, how does that cause wear?

Are they saying power loss is due to the deposits taking up volume that should be occupied by incoming air, or just that the irregular surface disrupts laminar flow of air into the chamber?

Last edited by TEXHAWK0; 10-21-2015 at 12:55 PM.

#5

It is not clear to me either exactly how deposits on the stem can cause loss of power, or cause wear to the guides...

If the carbon only builds up in areas that are not being wiped by the guides, how does that cause wear?

Are they saying power loss is due to the deposits taking up volume that should be occupied by incoming air, or just that the irregular surface disrupts laminar flow of air into the chamber?

If the carbon only builds up in areas that are not being wiped by the guides, how does that cause wear?

Are they saying power loss is due to the deposits taking up volume that should be occupied by incoming air, or just that the irregular surface disrupts laminar flow of air into the chamber?

I had the same thoughts.

I also just ran through all of the issues that sticking a drill-gun blender near my cylinders could cause. Especially if your doing it EVERY 5k MILES

What if you lose a bristle into the valve area? Chip/bend the valve?

#6

Race Director

The deposits might disrupt airflow slightly, question the percentage of power loss? Certainly not performing valve stem cleaning as depicted. Could be doing more harm if dirt finds it's way into combustion chamber.

#7

Ya know what, Looks like I for one am going to have to live with the power loss. (if any)

Last edited by Casey VP26; 10-21-2015 at 01:49 PM.

#9

Melting Slicks

I watched this video, but didn't understand the 'alarm' he was trying to convey. Do we have any proof of the cars losing 6-15 percent of their horsepower after 15k to 20k miles? This would seem to be a glaring issue, easily caught and seen during development.

Would a catch can from mile 0 eliminate this?

Would a catch can from mile 0 eliminate this?

#10

Melting Slicks

Thread Starter

I watched this video, but didn't understand the 'alarm' he was trying to convey. Do we have any proof of the cars losing 6-15 percent of their horsepower after 15k to 20k miles? This would seem to be a glaring issue, easily caught and seen during development.

Would a catch can from mile 0 eliminate this?

Would a catch can from mile 0 eliminate this?

No Automaker is more aware of this than BMW, one of the pioneers in today's GDI engines as this video shows:

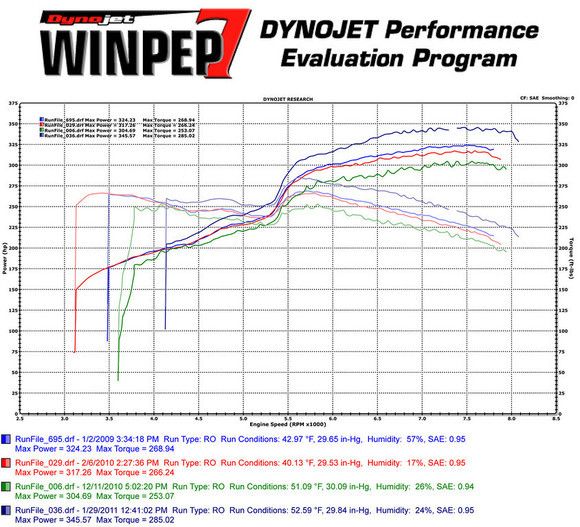

And this 3 year plus study done as these deposits built. This study was started at app 15k miles, and was then dynoed every year for 43 years as the owner (a tech for BMW) came back to the same dyno at app the same time of year trying to duplicate temp and weather for as accurate results as possible. Then he performed the crushed walnut shell media blasting cleaning and look at the final dyno run.

Also, one just has to look at the class action suite against GM right now for the worn valve guides at low miles and the broken valves/blown motors and this was caused by a very slight machining error over years that caused the valve guides to not be perfectly square with the seats to see the effect that had. These hard abrasive deposits from GDI on the valves are pulling into the guide with every cycle and it is not unusual to already see guides worn out of acceptable tolerances by 20-30k miles on these GDI engine today (look close at the stem where these deposits are pushed down into a "mushroom" like accumulation showing the stroke of the valve). The valve guide is made of a softer material (brass alloy) that the valve stem to prevent galling and metal transfer, but for the past 20-30 years other than the freak issues like the LS7 had, valve guide issues had disappeared from engines since port fuel injection was adopted that kept the valves spotless and deposit free for decades (used to be a common repair at 30-40k miles in the "old days" of carbureted engines).

So here is an intake valve and port from my personal C5 at 142,000 miles when we pulled it down for heads/cam:

Not a spec of build up, and on any port injection engine they can go several hundred thousand miles and experience none of this as the fuel was constantly sprayed on the valves to keep them cool and clean, deposit free for the life of the engine. But now that no fuel is being sprayed on these GDI valves, they run at far higher temps and these oil and other compounds are baking onto them and baking on in a hard crystalline abrasive deposit, or "coking" that causes the valve guide wear and quickly begins to disrupt the efficiency and flow characteristics of the post and valve/seat design.

It is not clear to me either exactly how deposits on the stem can cause loss of power, or cause wear to the guides...

If the carbon only builds up in areas that are not being wiped by the guides, how does that cause wear?

Are they saying power loss is due to the deposits taking up volume that should be occupied by incoming air, or just that the irregular surface disrupts laminar flow of air into the chamber?

If the carbon only builds up in areas that are not being wiped by the guides, how does that cause wear?

Are they saying power loss is due to the deposits taking up volume that should be occupied by incoming air, or just that the irregular surface disrupts laminar flow of air into the chamber?

Generally speaking, the intake valve stem-to guide clearance for most passenger cars ranges from .001 to .003 in., and .002 to .004 in. for exhaust guides (which generally require .0005 to .001 in. more clearance than the intakes for thermal expansion) and this clearance allows plenty of the hard abrasive coating to be drawn up into the guide and cause the premature wear. (Search on here LS7 intake valve guide wear and the "wiggle" test GM used to instruct techs to perform...they now got smart and do it with a dial indicator LOL).

So that should help you understand this better. Just ask any technical questions on any part not clear or if you need me to go into further detail and give more industry white paper links, etc.

Glen, I was warned ahead of time to watch for you to come into any of these threads and disrupt them and cause trouble. If that is not the case and you wish to have a civil technical discussion, then I am OK with that, but reading how you have attacked others trying to share this info and educate owners I suspect not. So, please do not post in this thread if that is the case as we are doing this as an educational service as well as refer members to ColoradoSPeeds and Elite Engineering's newly developed solutions designed just for the new GDI GM engines that have been proven to eliminate most all of this. So, I am not "selling" anything. I am tech support for ColoradoSpeed. To purchase these systems members must visit the web-store and order there.

#11

I made a DIY a couple weeks ago when I did the cleaning on my buddys C7:

https://www.corvetteforum.com/forums...3723336&page=2

He had under 15k, half of that time with a catch can. I didn't really worry about loosing a bristle, you don't need that much pressure and if you take the time to close each valve and to blow it out and vacuum it, its super hard to get debris in the port.

https://www.corvetteforum.com/forums...3723336&page=2

He had under 15k, half of that time with a catch can. I didn't really worry about loosing a bristle, you don't need that much pressure and if you take the time to close each valve and to blow it out and vacuum it, its super hard to get debris in the port.

#12

I am not what you call an ace auto tech by any means but I have started out with auto shop in high school and have taken many other mechanics classes since then. I have done lots of DIY jobs over the years and done all the normal maintenance on my vehicles. I agree with Nuclearranger and Larry/car and would NEVER clean valve deposits as depicted in the video.

#13

Le Mans Master

Member Since: Jul 2015

Location: Northern California

Posts: 6,223

Received 1,694 Likes

on

1,240 Posts

St. Jude Donor '15

I'm just an average joe car owner. I'm not gonna worry about it. If I hit 25, 30 or 40k miles and my car starts choking, I'll deal with it then. I'm certainly not going to stress about it, tear my engine apart or clean it myself. Thanks for the info though!

#14

Melting Slicks

Thread Starter

And this was only done right before installing a proper system to prevent having to ever do this again the next 50-100k miles.

Here is a picture of a valve where a chuck of the deposits broke loose and was trapped between the valve and seat during a solvent based service, and it resulted in a slightly bent valve. Car still ran decent, but the owner brought it in to the dealer under warranty complaining after they performed the cleaning service it "did not feel right or as peppy". They claimed each visit all was fine until they finally found low compression on one cylinder, and this is what was found when the valves were removed from the head. Look close, you can see where the large chunk broke loose and as he continued to drive while they claimed it was fine, you can see how additional deposits formed over it on the left side of where the tulip and stem meet:

The point of this is to have just the type of questions your posting. The only way to understand all of this is to learn, research, and look at your own. ANY deposits will have a effect on power, and the more the deposits, the more you see power loss and other issues.

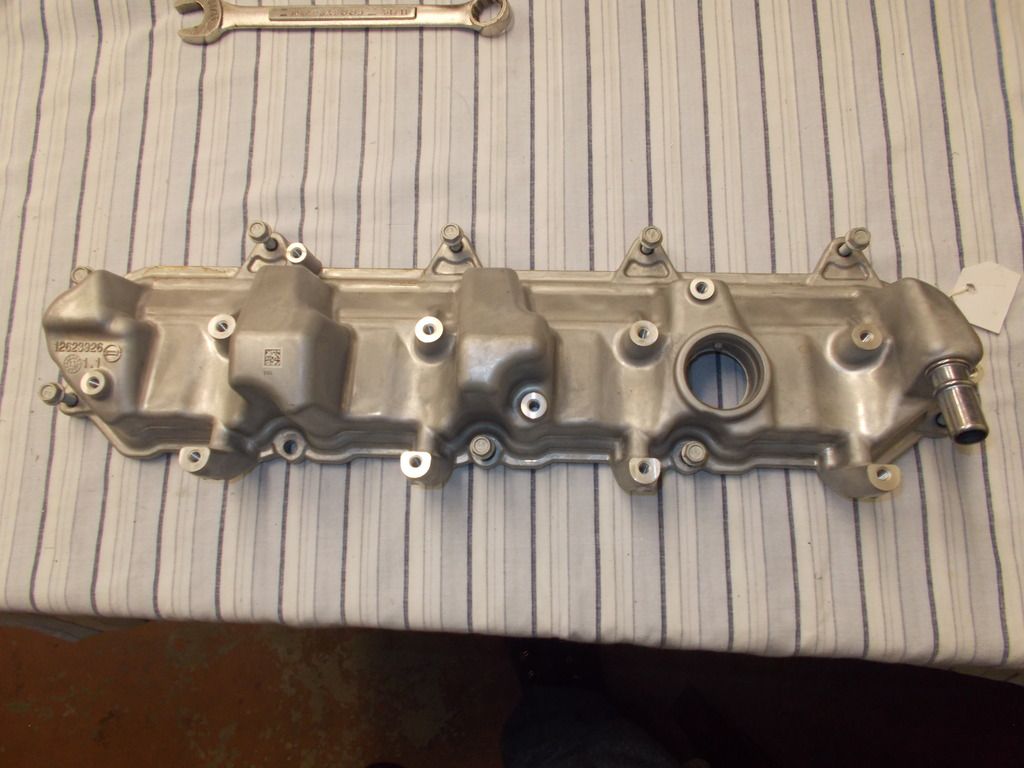

Take a look at the new LT1/LT4 valve cover. The vapors only enter the firewall end of the cover, and have to travel through 2 condensing towers with perforated baffles to slow the oil ingestion that causes all of this (these are on ALL LT based V8's, car and truck) and they have sealed the oil fill well so it is not part of the baffle system as well.

That is the best development to date, and you still have the severity you see if you remove your IM and see personally how bad yours is.:

Last edited by COSPEED; 10-21-2015 at 06:57 PM.

#15

Melting Slicks

Thread Starter

I made a DIY a couple weeks ago when I did the cleaning on my buddys C7:

https://www.corvetteforum.com/forums...3723336&page=2

He had under 15k, half of that time with a catch can. I didn't really worry about loosing a bristle, you don't need that much pressure and if you take the time to close each valve and to blow it out and vacuum it, its super hard to get debris in the port.

https://www.corvetteforum.com/forums...3723336&page=2

He had under 15k, half of that time with a catch can. I didn't really worry about loosing a bristle, you don't need that much pressure and if you take the time to close each valve and to blow it out and vacuum it, its super hard to get debris in the port.

Thanks for the post!

I am not what you call an ace auto tech by any means but I have started out with auto shop in high school and have taken many other mechanics classes since then. I have done lots of DIY jobs over the years and done all the normal maintenance on my vehicles. I agree with Nuclearranger and Larry/car and would NEVER clean valve deposits as depicted in the video.

Last edited by COSPEED; 10-21-2015 at 06:54 PM.

#16

Can you lease explain why? The valves are a very hard stainless alloy, and the brushes or walnut shells harm none of it. Please share you rational (I am an Automotive Engineer that used to work for GM and today work for an engineering firm that does PCV design work currently used on GM and other engines, and these procedures are both widely accepted and proven if done correctly at dealerships and independent shops alike even though I prefer the crushed walnut shell)

Sure. I would not worry about harming the valves. My worry would be getting debris or bristles into the cylinders. The procedure I did not like was the first one you showed. I like the BMW method you showed later a lot better although I would not attempt it myself. I am sure that there would not be a problem if done correctly by experienced personnel at a dealership or independent shop. Sloppy work by an inexperienced tech could be catastrophic.

#19

Pro

Are you saying that GM on the 15 and 16 models have this cured and any with a 14 are screwed and what can we do or ask GM to do under warranty ?? can we ask for them to clean and add a catch can at N/C under warranty nad if not what do you suggest Im at 7k miles on a 14.9 model z 51 thanks

#20

Melting Slicks

I think I got the UPR. It was $200ish. I have a non Z51 wet sump. Catches about 1.5 oz every 2000mi or so? Car already has 5k on it. I'm handy enough to take it apart but I'm also rather busy. I think my dad has the same brand on his Z51 that was installed early on too.