DIY: Add NPP Switch - True Manual On/Off Valve Control

#21

Race Director

Member Since: Feb 2014

Location: Center of the Universe, Alabama

Posts: 12,243

Received 95 Likes

on

41 Posts

Theta,

Please see my attached .jpg scan of my thoughts on using the "add a circuit" for your solderless idea.

You would not need to fabricate the "double" jumper piece. Simply put the original 20 amp NPP fuse in the top slots of the "add a circuit" and plug your single plug lead into the bottom, right side slot of the "add a circuit".

What do you think. I have not purchased an "add a circuit" so I have not verified its' internal wiring.

Please see my attached .jpg scan of my thoughts on using the "add a circuit" for your solderless idea.

You would not need to fabricate the "double" jumper piece. Simply put the original 20 amp NPP fuse in the top slots of the "add a circuit" and plug your single plug lead into the bottom, right side slot of the "add a circuit".

What do you think. I have not purchased an "add a circuit" so I have not verified its' internal wiring.

#22

Tech Contributor

Thread Starter

Member Since: Jan 2006

Location: Saint Louis MO

Posts: 4,761

Likes: 0

Received 218 Likes

on

110 Posts

St. Jude Donor '14-'15

Great info...great write up.

I had similar thoughts but with one difference, I wanted to keep the relocated 20 amp NPP fuse under the hood and on the +12v side of the wiring coming from the fuse panel. I'm a little **** and my reason being that if the wiring coming into the cabin ever chaffed enough to short to ground, that it would be protected. I'll explain what I mean by "+12v side of the wiring coming from the fuse panel". With the NPP fuse removed and with the car running, you take a volt meter and check each of the two fuse socket pin holes, one of them will measure +12 volts to ground. That's the wire I'd want the new fuse socket to be on.

Again kudos.

I had similar thoughts but with one difference, I wanted to keep the relocated 20 amp NPP fuse under the hood and on the +12v side of the wiring coming from the fuse panel. I'm a little **** and my reason being that if the wiring coming into the cabin ever chaffed enough to short to ground, that it would be protected. I'll explain what I mean by "+12v side of the wiring coming from the fuse panel". With the NPP fuse removed and with the car running, you take a volt meter and check each of the two fuse socket pin holes, one of them will measure +12 volts to ground. That's the wire I'd want the new fuse socket to be on.

Again kudos.

I understand what you mean, though - I placed the AGC (or ATM - I will give the choice based on preference) right before the switch for the ease of diagnosis. You're suggesting putting the fuse on the +12v hot from the box before it enters the cabin (and preferably inside the box). This is a very good idea, and as I've not put the fuse info up yet, I believe I will do this for the sake of safety.

Reading your other post now - good stuff.

.

Last edited by Theta; 03-31-2015 at 02:33 PM.

#23

Tech Contributor

Thread Starter

Member Since: Jan 2006

Location: Saint Louis MO

Posts: 4,761

Likes: 0

Received 218 Likes

on

110 Posts

St. Jude Donor '14-'15

Theta,

Please see my attached .jpg scan of my thoughts on using the "add a circuit" for your solderless idea.

You would not need to fabricate the "double" jumper piece. Simply put the original 20 amp NPP fuse in the top slots of the "add a circuit" and plug your single plug lead into the bottom, right side slot of the "add a circuit".

What do you think. I have not purchased an "add a circuit" so I have not verified its' internal wiring.

Please see my attached .jpg scan of my thoughts on using the "add a circuit" for your solderless idea.

You would not need to fabricate the "double" jumper piece. Simply put the original 20 amp NPP fuse in the top slots of the "add a circuit" and plug your single plug lead into the bottom, right side slot of the "add a circuit".

What do you think. I have not purchased an "add a circuit" so I have not verified its' internal wiring.

#24

Tech Contributor

Thread Starter

Member Since: Jan 2006

Location: Saint Louis MO

Posts: 4,761

Likes: 0

Received 218 Likes

on

110 Posts

St. Jude Donor '14-'15

Now that I've found an additional two sources for the Micro2 Add-A-Fuse, I may eliminate the solder method - it requires more work, tools, and time. In addition, since the fuse will now be located within the box, it actually becomes a bigger pain-in-the-butt than the Add-A-Fuse.

Anyone have thoughts on this? Everyone always wanted soldered connections, but now with Micro2 tap options out there, that route sure looks a lot better...

Anyone have thoughts on this? Everyone always wanted soldered connections, but now with Micro2 tap options out there, that route sure looks a lot better...

#25

Race Director

Member Since: Feb 2014

Location: Center of the Universe, Alabama

Posts: 12,243

Received 95 Likes

on

41 Posts

Now that I've found an additional two sources for the Micro2 Add-A-Fuse, I may eliminate the solder method - it requires more work, tools, and time. In addition, since the fuse will now be located within the box, it actually becomes a bigger pain-in-the-butt than the Add-A-Fuse.

Anyone have thoughts on this? Everyone always wanted soldered connections, but now with Micro2 tap options out there, that route sure looks a lot better...

Anyone have thoughts on this? Everyone always wanted soldered connections, but now with Micro2 tap options out there, that route sure looks a lot better...

I like the lighted switch and the location you chose for it. Looking forward to your final tutorial.

#26

Tech Contributor

Thread Starter

Member Since: Jan 2006

Location: Saint Louis MO

Posts: 4,761

Likes: 0

Received 218 Likes

on

110 Posts

St. Jude Donor '14-'15

AutoZone is just rolling out the Bussmann Micro Add-A-Circuits (not in all stores yet), so it's easier to pick either one or 3 up from Amazon with Prime shipping.

I got caught up in having the switch inside (my gauge fuses are AGC, but a pain to get to), and forgot how easily the existing 20A would be to use. Thanks for taking the time to draw that up - it's always easier for us to draw than it is to write out an explanation... Well, unless it's an equation - though I still normally take a photo of my scribbles, as well.

This has to be the weirdest tutorial for people watching, in that it's changed so much. Thought about bringing it down and re-tooling, but input like this is very much welcome and appreciated.

#28

Tech Contributor

Thread Starter

Member Since: Jan 2006

Location: Saint Louis MO

Posts: 4,761

Likes: 0

Received 218 Likes

on

110 Posts

St. Jude Donor '14-'15

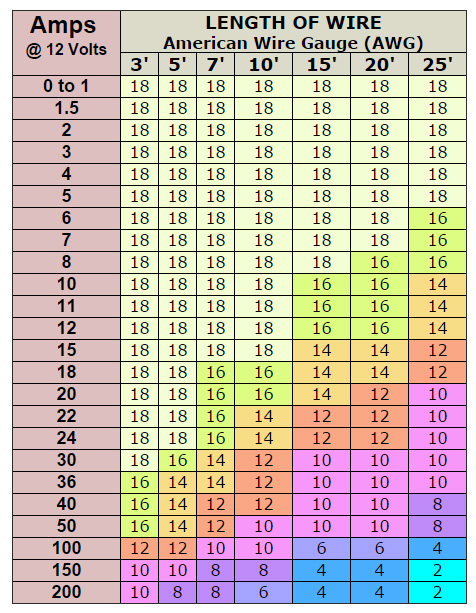

Checked with Bussmann, and then looked at the other taps online. 25A is the actual maximum. The lead attached is a 16AWG, and 16AWG is rated for 20A at up to 10 feet in 12V circuits (25A @ 6ft). Past that, it drops to 15A at 16ft, etc. We'll be using 6-7 feet of wire after the cutting (starting out with 10, and trimming way down), so we're well within the guidelines of safety.

Since they didn't use 14ga, this was a liability limiter. Additional fun fact is that the 2A designation is silly, since a 1A is perfectly fine.

And even more odd is that GM used a 20A fuse on the valves, as the measured current is around 4A during actuation. Sometimes engineering teams baffle me.

#29

Tech Contributor

Thread Starter

Member Since: Jan 2006

Location: Saint Louis MO

Posts: 4,761

Likes: 0

Received 218 Likes

on

110 Posts

St. Jude Donor '14-'15

Funny enough, I just saw that this (nearly exact) mod was done on the C6 8 years ago. Nothing new here, just a different set of part numbers and a new section for everyone.

More pictures, though.

More pictures, though.

#30

Race Director

Member Since: Feb 2014

Location: Center of the Universe, Alabama

Posts: 12,243

Received 95 Likes

on

41 Posts

In all reality the 10 amp "tap a fuse" will probably be okay but now I've played the paranoia card. Will a 20 or 25 amp rated "tap a fuse" fit under the closed fuse box lid?

#31

Tech Contributor

Thread Starter

Member Since: Jan 2006

Location: Saint Louis MO

Posts: 4,761

Likes: 0

Received 218 Likes

on

110 Posts

St. Jude Donor '14-'15

My guess is that while the motors pull 4 amps, they probably have an 8 to 10 amp start up surge. Add some extra so it's not accidentally blown & ya need a 20 amp fuse.

In all reality the 10 amp "tap a fuse" will probably be okay but now I've played the paranoia card. Will a 20 or 25 amp rated "tap a fuse" fit under the closed fuse box lid?

In all reality the 10 amp "tap a fuse" will probably be okay but now I've played the paranoia card. Will a 20 or 25 amp rated "tap a fuse" fit under the closed fuse box lid?

A 20-Amp rated tap is identical to this one - just a branding and spec difference. To give you an idea of marketing on the Add-a-Fuse, here's the exact setup on Amazon with a 20A rating:

Note that it uses the same 16ga 5" lead. The cheaper Chinese clones are rated at 30A, but I'm guessing that's just because they saw that you can shove a 30A in the socket. Don't mix 30A with 16ga wire, folks.

We're good on terminal material (it's not thin like a maimed circuit would be), and the lengths noted before assume a 20% margin of error. You can actually use 18ga with 20A for up to 5ft runs, but I personally wouldn't.

Here's an AWG chart summary @ 12 Volts:

#34

Drifting

Awesome work as always Theta!

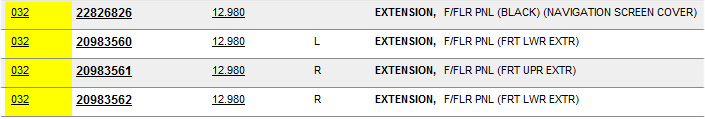

If you are able to find out, can you add the part number for the trim piece drilled for the switch? I will eventually do this and I always like buying replacement OEM parts for the ones I modify.

If you are able to find out, can you add the part number for the trim piece drilled for the switch? I will eventually do this and I always like buying replacement OEM parts for the ones I modify.

Last edited by xp800; 03-31-2015 at 10:04 PM.

#35

Safety Car

Looking / sounding good so far.

I hate crimp connectors, though, so I'll either solder them or use Posi-Locks where butt connectors are needed. Posi-Locks inside the fuse box will also make it really easy to disconnect everything in the fuse box and set back to stock before a trip to the dealer.

Thanks. Look forward to seeing the rest.

I hate crimp connectors, though, so I'll either solder them or use Posi-Locks where butt connectors are needed. Posi-Locks inside the fuse box will also make it really easy to disconnect everything in the fuse box and set back to stock before a trip to the dealer.

Thanks. Look forward to seeing the rest.

#36

Tech Contributor

Thread Starter

Member Since: Jan 2006

Location: Saint Louis MO

Posts: 4,761

Likes: 0

Received 218 Likes

on

110 Posts

St. Jude Donor '14-'15

Looking / sounding good so far.

I hate crimp connectors, though, so I'll either solder them or use Posi-Locks where butt connectors are needed. Posi-Locks inside the fuse box will also make it really easy to disconnect everything in the fuse box and set back to stock before a trip to the dealer.

Thanks. Look forward to seeing the rest.

I hate crimp connectors, though, so I'll either solder them or use Posi-Locks where butt connectors are needed. Posi-Locks inside the fuse box will also make it really easy to disconnect everything in the fuse box and set back to stock before a trip to the dealer.

Thanks. Look forward to seeing the rest.

#38

Tech Contributor

Thread Starter

Member Since: Jan 2006

Location: Saint Louis MO

Posts: 4,761

Likes: 0

Received 218 Likes

on

110 Posts

St. Jude Donor '14-'15

#39

Tech Contributor

Thread Starter

Member Since: Jan 2006

Location: Saint Louis MO

Posts: 4,761

Likes: 0

Received 218 Likes

on

110 Posts

St. Jude Donor '14-'15

I'm not sure if the non-NPP cars have Fuse 41/42 actually leading anywhere, assuming it has a pinned slot in the first place.

I tried to figure that one out a while ago, but it will come down to a PWM converter and a switched relay to bypass the CCM - pretty positive of that.

#40

I'm Batman..

Pro Mechanic

Member Since: Apr 2014

Location: Lehigh Acres FL

Posts: 6,130

Received 908 Likes

on

561 Posts

Tech Contributor

This would only be for factory-NPP cars. If the NPP conversions end up getting figured out with regard to the PWM and CCM, then you could do something similar.

I'm not sure if the non-NPP cars have Fuse 41/42 actually leading anywhere, assuming it has a pinned slot in the first place.

I tried to figure that one out a while ago, but it will come down to a PWM converter and a switched relay to bypass the CCM - pretty positive of that.

I'm not sure if the non-NPP cars have Fuse 41/42 actually leading anywhere, assuming it has a pinned slot in the first place.

I tried to figure that one out a while ago, but it will come down to a PWM converter and a switched relay to bypass the CCM - pretty positive of that.

I was hoping that you had that figured out too as part of your DIY. oh wells..

I was hoping that you had that figured out too as part of your DIY. oh wells..