Help with launch- Z06

#1

Pro

Thread Starter

My first time drag racing this weekend at LS Fest did not go well. Running a Carbon Edition Z06 with Lingenfelter upgraded motor. Making about 600hp at rear wheels, car was on Hoosier DR2 tires and was dead hooking. No matter what I did at launch car would dead hook then drop on its nose and then take off again. My 60 ft times were mostly in the 2.6 - 2.8 second range but overall runs were in the 12.3 second at 120 mph +. What would cause the car to bog so bad at the launch ? I tried different launch RPM's , tire pressure, slipping the clutch, dumping the clutch , etc. Any advice from someone who has done this more than me would be greatly appreciated. Due to massive amount of rain on Sunday were we not able to get into eliminations so was not able to see if I could hit my dial in of 12.25.

When I did some test passes on local 1/8 mile track car did not have the problem of bogging down but the track was not as prepped as Beech Bend. I was doing 1.5 - 1.7 60ft on the un-prepped track.

When I did some test passes on local 1/8 mile track car did not have the problem of bogging down but the track was not as prepped as Beech Bend. I was doing 1.5 - 1.7 60ft on the un-prepped track.

#2

Race Director

If you were dead hooking and bogging, you either needed more rpm or more clutch slippage or both. You can't dump the clutch on these cars without either spinning, bogging or breaking. Probably the unprepped track allowed the tires to spin somewhat eliminating the bog.

Last edited by 383vett; 09-10-2018 at 11:42 AM.

#3

By far, the most important AND most overlooked part of hooking up any manual trans car on radials is how hard the clutch hits. It's just not possible for any combination of springs/shocks or chassis adjustments to fix the actual problem.

Here's why it's hard to make radials work at the dragstrip with a manual trans...

Radials basically need to dead hook, as they will tolerate very little wheelspeed. Lets imagine launching with no clutch slip at all, engine rpm with a dead hook on the starting line would equal "0". For simplicity, lets say a car has a constant acceleration rate in 1st gear and the potential to reach it's 1/2 shift point of 7000 rpm at about 2 seconds into the run. If starting line rpm equals "0", and rpm 2.0 seconds in equals 7000 and acceleration rate is constant, at 0.5 seconds engine rpm would be 1750, at 1 second in engine rpm would equal 3500, and at 1.5 seconds 5250 with the tires dead hooked and no clutch slip at all. Obviously dead hooking alone is not the answer, as our engines don't make any power at zero rpm. You NEED some controlled clutch slipping to keep those radials dead hooked without dragging the engine down too far, as there's just no way any combination of spring rate and/or suspension adjustments can possibly absorb enough engine rpm over a long enough time frame to make the radials work.

Here's what controlled clutch slip can do for you-

To a point the longer a clutch slips, the more time the car/engine has to gain speed/rpm before that clutch locks up, which in turn means engine rpm does not get dragged down as far. Lets apply the above example to a magical engine that has a completely flat torque curve of 500 ftlbs from 1500 to 5500 rpm. If that engine's clutch only slips for 0.5 second, rpm gets dragged down to 1750 after launch and that engine is only making 166.6 hp at the low point of the bog. If the clutch were to slip for a full second, rpm only dips to 3500rpm which effectively doubles it's power production to 333.2 hp thru the low point of the bog. In the real world the difference would be even more dramatic, as it's pretty unlikely the engine would be making 500 ftlbs at 1750.

When it comes time to shift, the problem for radials then becomes the fact that the rotating assembly must almost instantly shed about half of it's stored inertia energy due to the ratio change. If that excess energy is dumped into the chassis/tires all at once, there's a good chance that extra energy will be enough to knock the radials loose, resulting in far less productive instant spin rather than effectively propelling the car forward. Adding a hit controller makes it possible to spread that inevitable energy transfer over a longer time period, reducing it's peak to a level that doesn't knock the radials loose. Also because the car is gaining speed during those periods of controlled clutch slip, the overall amount of energy that must be dumped due to the ratio change is also reduced.

A hit controller like my ClutchTamer makes it practical to choose a clutch with plenty of torque capacity for the application, one that might otherwise grab too aggressively for a radial, then allows "dialing in" longer clutch slip as needed to raise the bog rpm without reducing that clutch's overall holding ability. You might try to accomplish the same thing with your foot, but you will find it impossible to achieve the same degree of precision no matter how well trained the foot.

Going to a bias slick is an alternative solution, but radials are way more fun on a street/strip car as you can drive thru the gate and make passes without the hassle of swapping tires. There may be other ways to make a radial work with a manual trans, but my way works pretty good.

Grant

Here's why it's hard to make radials work at the dragstrip with a manual trans...

Radials basically need to dead hook, as they will tolerate very little wheelspeed. Lets imagine launching with no clutch slip at all, engine rpm with a dead hook on the starting line would equal "0". For simplicity, lets say a car has a constant acceleration rate in 1st gear and the potential to reach it's 1/2 shift point of 7000 rpm at about 2 seconds into the run. If starting line rpm equals "0", and rpm 2.0 seconds in equals 7000 and acceleration rate is constant, at 0.5 seconds engine rpm would be 1750, at 1 second in engine rpm would equal 3500, and at 1.5 seconds 5250 with the tires dead hooked and no clutch slip at all. Obviously dead hooking alone is not the answer, as our engines don't make any power at zero rpm. You NEED some controlled clutch slipping to keep those radials dead hooked without dragging the engine down too far, as there's just no way any combination of spring rate and/or suspension adjustments can possibly absorb enough engine rpm over a long enough time frame to make the radials work.

Here's what controlled clutch slip can do for you-

To a point the longer a clutch slips, the more time the car/engine has to gain speed/rpm before that clutch locks up, which in turn means engine rpm does not get dragged down as far. Lets apply the above example to a magical engine that has a completely flat torque curve of 500 ftlbs from 1500 to 5500 rpm. If that engine's clutch only slips for 0.5 second, rpm gets dragged down to 1750 after launch and that engine is only making 166.6 hp at the low point of the bog. If the clutch were to slip for a full second, rpm only dips to 3500rpm which effectively doubles it's power production to 333.2 hp thru the low point of the bog. In the real world the difference would be even more dramatic, as it's pretty unlikely the engine would be making 500 ftlbs at 1750.

When it comes time to shift, the problem for radials then becomes the fact that the rotating assembly must almost instantly shed about half of it's stored inertia energy due to the ratio change. If that excess energy is dumped into the chassis/tires all at once, there's a good chance that extra energy will be enough to knock the radials loose, resulting in far less productive instant spin rather than effectively propelling the car forward. Adding a hit controller makes it possible to spread that inevitable energy transfer over a longer time period, reducing it's peak to a level that doesn't knock the radials loose. Also because the car is gaining speed during those periods of controlled clutch slip, the overall amount of energy that must be dumped due to the ratio change is also reduced.

A hit controller like my ClutchTamer makes it practical to choose a clutch with plenty of torque capacity for the application, one that might otherwise grab too aggressively for a radial, then allows "dialing in" longer clutch slip as needed to raise the bog rpm without reducing that clutch's overall holding ability. You might try to accomplish the same thing with your foot, but you will find it impossible to achieve the same degree of precision no matter how well trained the foot.

Going to a bias slick is an alternative solution, but radials are way more fun on a street/strip car as you can drive thru the gate and make passes without the hassle of swapping tires. There may be other ways to make a radial work with a manual trans, but my way works pretty good.

Grant

#4

Race Director

#6

Le Mans Master

Yes but you also need someone helping you as well because your numbers and experiences are all over the place. Best to stick with one person who can go to the track with you or follow a consistent plan from one person who is experienced and recommended with a 6 speed corvette.

It sounds like you are launching too low and dumping the clutch too much but need more info.

It sounds like you are launching too low and dumping the clutch too much but need more info.

Last edited by robz; 09-11-2018 at 03:08 PM.

#7

Le Mans Master

I can give you some general info here but need to know your goals on the drag strip specifically.

Also need to know:

what clutch

what rwhp

what tires exactly

what rims

C6?

n/a?

You will need a detailed launch plan and written list of all factors to be consistent.

It will include:

launch rpm

tire pressure cold

launch technique

burnout type

suspension setup if any

track conditions

atmospheric conditions

Write all down on each slip. If you get video or even audio I can help you adjust each pass based on the previous one.

Also need to know:

what clutch

what rwhp

what tires exactly

what rims

C6?

n/a?

You will need a detailed launch plan and written list of all factors to be consistent.

It will include:

launch rpm

tire pressure cold

launch technique

burnout type

suspension setup if any

track conditions

atmospheric conditions

Write all down on each slip. If you get video or even audio I can help you adjust each pass based on the previous one.

Last edited by robz; 09-11-2018 at 03:05 PM.

#8

Some think a clutch hit controller is a cheat, but it's simple tech that can save a lot of wear/tear to your car. There is not a version currently being made specifically for any Corvette, but if you are serious about drag racing a diy install could be well worth the effort.

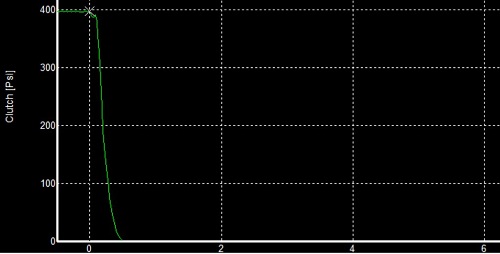

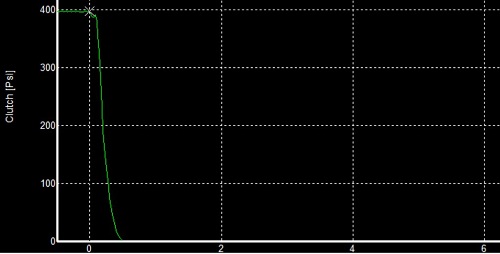

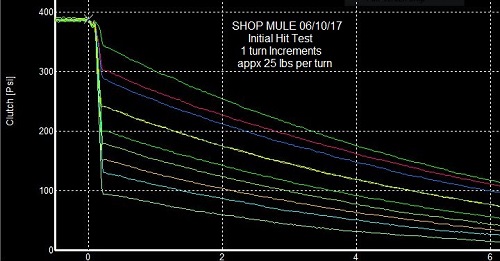

To help illustrate the concept, here's a graph showing hydraulic throwout bearing Psi change during an uncontrolled clutch pedal release cycle (clutch dump)…

In these Clutch Psi graphs, any pressure in the throwout bearing basically represents a reduction of the clutch's overall clamp pressure. The above graph shows the pressure in the throwout bearing near 400 Psi with the clutch pedal fully depressed at the zero second mark (time is marked along the bottom edge of the graph), then when the pedal was "dumped" and t-brg pressure quickly fell from 400 Psi to "0" within a couple tenths of a second. This represents a typical clutch dump where the clutch reached it's maximum clamp pressure and torque holding ability very quickly after pedal release, with a minimal amount of slipping. The likely result of the above uncontrolled release curve is either severe engine bog, instant wheel spin, or broken parts. The typical cure for this is the "driver mod", which comes down to the simultaneous application of throttle combined with a limited release of the clutch pedal. Basically you are using your left foot to make the clutch slip a little longer than it wants to, when done right it softens engagement long enough to prevent wheelspin and broken parts while minimizing engine bog. The trick to making this work is practice / practice / practice, as that's what is required to consistently apply just the right amount of clutch pedal release to go along with just the right amount of throttle squeeze.

The "sweet spot" in a clutch pedal's travel is that range where the clutch is grabbing not too hard or too soft, but just the right amount to keep the tires stuck with a minimum amount of engine bog. For a drag race launch, you want to instantly release the clutch pedal into that sweet spot range to get the car moving as quickly/efficiently as possible. But from that point on the pedal needs to move much slower, which effectively extends the dwell time within that sweet spot pressure range. This produces a firm/quick/efficient "hit" of the clutch, but the added dwell time within that sweet spot range allows the clutch to slip a little longer, which effectively reduces engine bog.

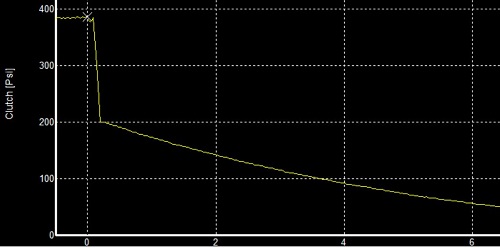

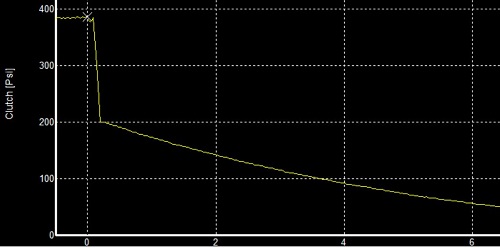

To help explain the concept, lets say this clutch's "sweet spot" for a good launch is a T-brg pressure range between 200 and 100 Psi. Below is a T-brg Psi graph showing what the perfect clutch pedal release curve might look like. Notice that Psi suddenly drops almost instantly to 200 Psi, then instantly transitions to a much more gradual decline of Psi from that point on. That gradual decline is what extends the period of time that the clutch spends in it's sweet spot, while also ensuring that the clutch still reaches it's full clamp pressure to eliminate any clutch slippage after that short delay...

An ideal dump/transition/curve with a sharp transition like the above graph is pretty much impossible to produce with your foot alone, but it's easy to produce graphs like this with the help of a clutch hit controller like the ClutchTamer.

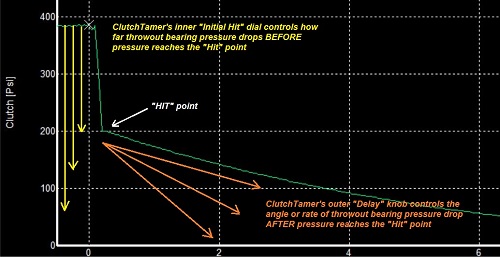

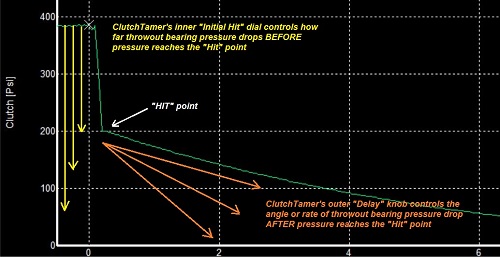

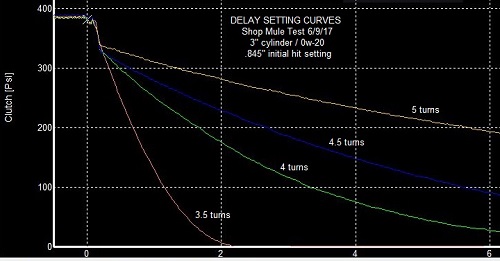

Below is a graph explaining how the ClutchTamer's adjustments can affect the shape of the graph...

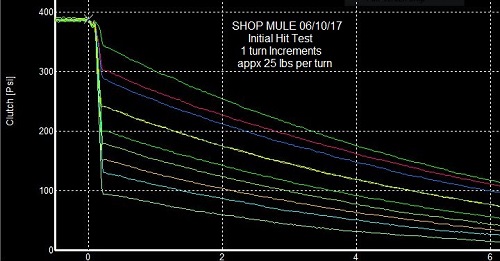

T-brg Psi of the "hit" point can be changed to suit the application. This is essentially like being able to almost instantly release the clutch pedal to a certain point in it's travel. Here's a composite graph showing a range of different "hit" adjustments...

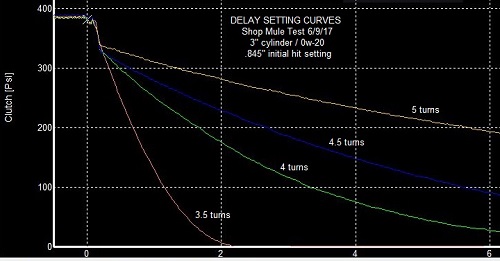

The rate of throwout bearing Psi loss after the "hit" point can also be changed, this adjustment basically controls how long the clutch slips AFTER T-brg pressure reaches the "hit" point. This composite graph shows a range of T-brg pressure loss rates...

When using a clutch hit controller, you will also find there's very little need to compromise launch rpm.

Grant

To help illustrate the concept, here's a graph showing hydraulic throwout bearing Psi change during an uncontrolled clutch pedal release cycle (clutch dump)…

In these Clutch Psi graphs, any pressure in the throwout bearing basically represents a reduction of the clutch's overall clamp pressure. The above graph shows the pressure in the throwout bearing near 400 Psi with the clutch pedal fully depressed at the zero second mark (time is marked along the bottom edge of the graph), then when the pedal was "dumped" and t-brg pressure quickly fell from 400 Psi to "0" within a couple tenths of a second. This represents a typical clutch dump where the clutch reached it's maximum clamp pressure and torque holding ability very quickly after pedal release, with a minimal amount of slipping. The likely result of the above uncontrolled release curve is either severe engine bog, instant wheel spin, or broken parts. The typical cure for this is the "driver mod", which comes down to the simultaneous application of throttle combined with a limited release of the clutch pedal. Basically you are using your left foot to make the clutch slip a little longer than it wants to, when done right it softens engagement long enough to prevent wheelspin and broken parts while minimizing engine bog. The trick to making this work is practice / practice / practice, as that's what is required to consistently apply just the right amount of clutch pedal release to go along with just the right amount of throttle squeeze.

The "sweet spot" in a clutch pedal's travel is that range where the clutch is grabbing not too hard or too soft, but just the right amount to keep the tires stuck with a minimum amount of engine bog. For a drag race launch, you want to instantly release the clutch pedal into that sweet spot range to get the car moving as quickly/efficiently as possible. But from that point on the pedal needs to move much slower, which effectively extends the dwell time within that sweet spot pressure range. This produces a firm/quick/efficient "hit" of the clutch, but the added dwell time within that sweet spot range allows the clutch to slip a little longer, which effectively reduces engine bog.

To help explain the concept, lets say this clutch's "sweet spot" for a good launch is a T-brg pressure range between 200 and 100 Psi. Below is a T-brg Psi graph showing what the perfect clutch pedal release curve might look like. Notice that Psi suddenly drops almost instantly to 200 Psi, then instantly transitions to a much more gradual decline of Psi from that point on. That gradual decline is what extends the period of time that the clutch spends in it's sweet spot, while also ensuring that the clutch still reaches it's full clamp pressure to eliminate any clutch slippage after that short delay...

An ideal dump/transition/curve with a sharp transition like the above graph is pretty much impossible to produce with your foot alone, but it's easy to produce graphs like this with the help of a clutch hit controller like the ClutchTamer.

Below is a graph explaining how the ClutchTamer's adjustments can affect the shape of the graph...

T-brg Psi of the "hit" point can be changed to suit the application. This is essentially like being able to almost instantly release the clutch pedal to a certain point in it's travel. Here's a composite graph showing a range of different "hit" adjustments...

The rate of throwout bearing Psi loss after the "hit" point can also be changed, this adjustment basically controls how long the clutch slips AFTER T-brg pressure reaches the "hit" point. This composite graph shows a range of T-brg pressure loss rates...

When using a clutch hit controller, you will also find there's very little need to compromise launch rpm.

Grant

#9

Instructor

My first time drag racing this weekend at LS Fest did not go well. Running a Carbon Edition Z06 with Lingenfelter upgraded motor. Making about 600hp at rear wheels, car was on Hoosier DR2 tires and was dead hooking. No matter what I did at launch car would dead hook then drop on its nose and then take off again. My 60 ft times were mostly in the 2.6 - 2.8 second range but overall runs were in the 12.3 second at 120 mph +. What would cause the car to bog so bad at the launch ? I tried different launch RPM's , tire pressure, slipping the clutch, dumping the clutch , etc. Any advice from someone who has done this more than me would be greatly appreciated. Due to massive amount of rain on Sunday were we not able to get into eliminations so was not able to see if I could hit my dial in of 12.25.

When I did some test passes on local 1/8 mile track car did not have the problem of bogging down but the track was not as prepped as Beech Bend. I was doing 1.5 - 1.7 60ft on the un-prepped track.

When I did some test passes on local 1/8 mile track car did not have the problem of bogging down but the track was not as prepped as Beech Bend. I was doing 1.5 - 1.7 60ft on the un-prepped track.