Max lift for stock rockers?

#1

Burning Brakes

Thread Starter

What is the maximum recommended safe lift for the stock rockers? I currently have the BTR Stage 2 cam. Lift is .644/.630. My builder said power came in late (past 4k) due to what he called "high lift." I love the power and how it drives but I am not ruling out going bigger someday. It is currently 100% street driven and I would be ok sacrificing a bit more drivability for faster street characteristics.

Also, another guy on here recently finished a build by DRM with Mamo heads and made 598hp. He expected to make more and pulled the tune and it was supposedly extremely conservative. I think he is working with Pat G on a re-tune. I'm wondering if mine is quite conservative as well. I made 543/487 with all the supporting mods minus a 102tb.

Thanks, Jesse

Also, another guy on here recently finished a build by DRM with Mamo heads and made 598hp. He expected to make more and pulled the tune and it was supposedly extremely conservative. I think he is working with Pat G on a re-tune. I'm wondering if mine is quite conservative as well. I made 543/487 with all the supporting mods minus a 102tb.

Thanks, Jesse

#2

Le Mans Master

Your power level seems in line with the output from the BTR Stage 2. I made ~40 more whp with their Stage 3 cam and my car drives great (IMO). Power is fantastic but does leave a craving for more top end pull.

As far as max lift on stock rockers, I've seen a wide variety of opinions. Most say .650 is the highest they go. A lot of the off-the-shelf cams are in the .655-.660 range. I've even seen some say they are running in the .680ish range on stock rockers.

As far as max lift on stock rockers, I've seen a wide variety of opinions. Most say .650 is the highest they go. A lot of the off-the-shelf cams are in the .655-.660 range. I've even seen some say they are running in the .680ish range on stock rockers.

#3

Burning Brakes

Thread Starter

Your power level seems in line with the output from the BTR Stage 2. I made ~40 more whp with their Stage 3 cam and my car drives great (IMO). Power is fantastic but does leave a craving for more top end pull.

As far as max lift on stock rockers, I've seen a wide variety of opinions. Most say .650 is the highest they go. A lot of the off-the-shelf cams are in the .655-.660 range. I've even seen some say they are running in the .680ish range on stock rockers.

As far as max lift on stock rockers, I've seen a wide variety of opinions. Most say .650 is the highest they go. A lot of the off-the-shelf cams are in the .655-.660 range. I've even seen some say they are running in the .680ish range on stock rockers.

Thanks Jay. What would you do to accomplish more top end? More duration or more narrow LSA? I suppose you would lose some low and midrange...

#4

Racer

I believe someone a while back did some calculations based on the degrees of rotation/pivot the stock rocker allows and came up with .700" or something like that

But, that doesn't include any kind of harmonic motions and only accounts for a completely rigid system being absolutely maxed out. Never heard of anyone running .680 on stock rockers without also having done the trunnion "upgrade", but I don't see why you couldn't run to the .660 range at least on completely stock rockers.

I'm sure you'll get as many different answers as there are people willing to answer though, given that everyone has there own comfort zones

But, that doesn't include any kind of harmonic motions and only accounts for a completely rigid system being absolutely maxed out. Never heard of anyone running .680 on stock rockers without also having done the trunnion "upgrade", but I don't see why you couldn't run to the .660 range at least on completely stock rockers.

I'm sure you'll get as many different answers as there are people willing to answer though, given that everyone has there own comfort zones

#5

Team Owner

Without a trunion rebuild to something like the all the bushed systems out there (CHE, Smith Bros, etc.), the OE trunions will bind in high lift situations. Purely going off memory, but I believe they bind somewhere at or above the .675 range...meaning; if you held an OE rocker in your hand, it would not rotate 360 degrees unless you've installed an aftermarket trunion kit.

Wipe pattern is the concern here on high lift with OE rockers regardless of your trunion type. An ideal wipe pattern in a nutshell means that the rocker arm tip never leaves the center ~1/3 of the valve stem tip throughout the entire range of motion. Getting above ~.630 lift, the rocker tip starts to leave that center ~1/3...which contributes to side-loading and premature guide wear. Plenty of guys running between .630 and .650 on OE rockers...just be aware that periodic guide inspections goes with the territory if that's what you run. For me, anything above .630, I'd be running a roller tip setup.

Wipe pattern is the concern here on high lift with OE rockers regardless of your trunion type. An ideal wipe pattern in a nutshell means that the rocker arm tip never leaves the center ~1/3 of the valve stem tip throughout the entire range of motion. Getting above ~.630 lift, the rocker tip starts to leave that center ~1/3...which contributes to side-loading and premature guide wear. Plenty of guys running between .630 and .650 on OE rockers...just be aware that periodic guide inspections goes with the territory if that's what you run. For me, anything above .630, I'd be running a roller tip setup.

#6

Le Mans Master

This is a new world for me. Trying to learn as much as I can. That being said, I don't know what is needed to accomplish what I want. I know there will be some trade-off to drive-ability and down low power. I'll leave my next camshaft selection up to a professional. Most likely Tony Mamo. His stuff has been making some excellent power lately.

#8

Burning Brakes

Previously had. 660 lift aggressive cam. Guides were all shot in about 3k miles on new WCCH heads. Joe@CPR recommends staying .650 or lower I believe with stock rockers. My new cam is lessthan .650 lift. Costly mistake going with that high of lift for me. If you go really big, check your heads often.

The following users liked this post:

MTPZ06 (07-27-2017)

#10

Melting Slicks

Member Since: Jun 2005

Location: Rochester NY

Posts: 2,734

Received 1,678 Likes

on

878 Posts

2018 C6 of Year Finalist

St. Jude Donor '10, '17

I run a high lift cam. 227/239 duration 678/.688 lift 114 CL. I know all of the issues with high lift cams, but it doesn't scare me. With the right set-up and some routine maintenance/inspection the cam runs great, produces a metric **** ton of power everywhere, drives awesome, is raced regularly (weekly) and sounds like a beast. Cam has been spintron tested to 8500 RPMs. Very little surging, nice aggressive lope and makes power EVERYWHERE. These motors love more lift, assuming you can deal with the issues that come with it.

Higher average power under the usable RPM curve beats peak hp everytime in an ACTUAL RACE. For guys lugging around town flashing their peak hp manufactured dyno graphs that don't want to deal with regular head inspection - stick with a lower lift cam spec'd properly for your usage and setup.

Springs are PAC1209X, installed at correct height. Upgraded rockers/trunnions, stock lifters, correct length pushrods, M90 guides, new valves etc. Wipe pattern on the rockers are great. Lifters are in good shape. Cam lobes are perfect.

Higher average power under the usable RPM curve beats peak hp everytime in an ACTUAL RACE. For guys lugging around town flashing their peak hp manufactured dyno graphs that don't want to deal with regular head inspection - stick with a lower lift cam spec'd properly for your usage and setup.

Springs are PAC1209X, installed at correct height. Upgraded rockers/trunnions, stock lifters, correct length pushrods, M90 guides, new valves etc. Wipe pattern on the rockers are great. Lifters are in good shape. Cam lobes are perfect.

Last edited by Mordeth; 07-27-2017 at 07:11 AM.

#11

I run a high lift cam. 227/239 duration 678/.688 lift 114 CL. I know all of the issues with high lift cams, but it doesn't scare me. With the right set-up and some routine maintenance/inspection the cam runs great, produces a metric **** ton of power everywhere, drives awesome, is raced regularly (weekly) and sounds like a beast. Cam has been spintron tested to 8500 RPMs. Very little surging, nice aggressive lope and makes power EVERYWHERE. These motors love more lift, assuming you can deal with the issues that come with it.

Higher average power under the usable RPM curve beats peak hp everytime in an ACTUAL RACE. For guys lugging around town flashing their peak hp manufactured dyno graphs that don't want to deal with regular head inspection - stick with a lower lift cam spec'd properly for your usage and setup.

Springs are PAC1209X, installed at correct height. Upgraded rockers/trunnions, stock lifters, correct length pushrods, M90 guides, new valves etc. Wipe pattern on the rockers are great. Lifters are in good shape. Cam lobes are perfect.

Higher average power under the usable RPM curve beats peak hp everytime in an ACTUAL RACE. For guys lugging around town flashing their peak hp manufactured dyno graphs that don't want to deal with regular head inspection - stick with a lower lift cam spec'd properly for your usage and setup.

Springs are PAC1209X, installed at correct height. Upgraded rockers/trunnions, stock lifters, correct length pushrods, M90 guides, new valves etc. Wipe pattern on the rockers are great. Lifters are in good shape. Cam lobes are perfect.

The following users liked this post:

MTPZ06 (07-27-2017)

#13

That cam is not big, especially for an LS7 with valve reliefs. It just has a lot of lift and spring pressure. I would not use stock rockers there. Plenty of P2V though since that has nothing to do with lift.

Last edited by lt1z; 07-27-2017 at 11:45 AM.

#14

Melting Slicks

Member Since: Jun 2005

Location: Rochester NY

Posts: 2,734

Received 1,678 Likes

on

878 Posts

2018 C6 of Year Finalist

St. Jude Donor '10, '17

Plenty. When I put my strip of clay on top of the piston and rotated the engine a few times there was zero resistance. When I took it back apart and cut the clay back off the thinnest part was around .100" or so on both sides according to my dial caliper. I honestly didn't even need to check, as I know this cam doesn't create a problem like this. It creates other problems though, which I am equipped to deal with.

#15

Racer

Ran stock rockers with comp trunnions with a .675 lift(I&E) cam with no issues for about 8k miles. 1k+ of those miles included Drag Week. Comp trunnions were recently removed for the typical trunnion wear that many people have seen and I'm now running Smith Bros bushed trunnions.

#16

I run a high lift cam. 227/239 duration 678/.688 lift 114 CL. I know all of the issues with high lift cams, but it doesn't scare me. With the right set-up and some routine maintenance/inspection the cam runs great, produces a metric **** ton of power everywhere, drives awesome, is raced regularly (weekly) and sounds like a beast. Cam has been spintron tested to 8500 RPMs. Very little surging, nice aggressive lope and makes power EVERYWHERE. These motors love more lift, assuming you can deal with the issues that come with it.

Higher average power under the usable RPM curve beats peak hp everytime in an ACTUAL RACE. For guys lugging around town flashing their peak hp manufactured dyno graphs that don't want to deal with regular head inspection - stick with a lower lift cam spec'd properly for your usage and setup.

Springs are PAC1209X, installed at correct height. Upgraded rockers/trunnions, stock lifters, correct length pushrods, M90 guides, new valves etc. Wipe pattern on the rockers are great. Lifters are in good shape. Cam lobes are perfect.

Higher average power under the usable RPM curve beats peak hp everytime in an ACTUAL RACE. For guys lugging around town flashing their peak hp manufactured dyno graphs that don't want to deal with regular head inspection - stick with a lower lift cam spec'd properly for your usage and setup.

Springs are PAC1209X, installed at correct height. Upgraded rockers/trunnions, stock lifters, correct length pushrods, M90 guides, new valves etc. Wipe pattern on the rockers are great. Lifters are in good shape. Cam lobes are perfect.

that's a whole different story!

that's a whole different story!Last edited by MikeOC; 07-27-2017 at 01:49 PM.

#17

Team Owner

#18

Previously had. 660 lift aggressive cam. Guides were all shot in about 3k miles on new WCCH heads. Joe@CPR recommends staying .650 or lower I believe with stock rockers. My new cam is lessthan .650 lift. Costly mistake going with that high of lift for me. If you go really big, check your heads often.

"Fixed heads" only reset the clock of the failure and problems associated with ported OEM castings and stock rockers....the problems and issues are going to resurface again.....you have to change some of the players (valvetrain components) if you expect to have different end results.

It's just one of the reasons I always advocate getting away from stock rockers. I don't know why so many people are intent on running them. They were designed to operate with half the spring pressure (seat and open pressure) most of us run, SOFT gentle OEM cam lobes/ramps, and .100 or more less lift. That's the application they were designed for....they are out of their element on most of the aftermarket builds and will take out the guides of your heads due to all the side loading imparted on the stem of the valve and the guide as the flat arced pad of the rocker scrubs and see-saws across the tip of your valve. You end up with an hour glassed shape valve guide and oil consumption issues once you have achieved that shape which is vastly accelerated with aftermarket cams and alot more spring pressure....not to mention a loss of performance from your valves not properly sealing when your guides are worn.

ALL the engines I build and spec are equipped with Yella Terra Ultralites built specifically for the castings Im using but you can buy them for stock heads also....much more affordable than the other big names in the rocker arm business and more importantly they are better designed for an HR system most of us are running (they are lightweight which is crucial to valve control).

I don't understand the love affair with OEM rockers when your upgrading all the other areas pertinent to building a real performance engine, not to mention some guys investing more money in them with trunion upgrades etc.....its silly because you still haven't addressed their major design flaw regarding not having the proper geometry for much more lift and not having a roller wheel which reduces contact patch by a large margin and reduces side loading dramatically as well. Also a roller will offer reduced friction and that will free up a small bit of power also....a nice perk from the upgrade to a roller.

I stock this stuff guys so if you would like to discuss in more detail feel free to contact me. Not a single engine I build (or help spec for a customer by providing them with all the parts) includes OEM rockers. You leave them to collect dust on the shelf with all the other OEM parts you removed when you decided to upgrade and mod your engine in search of more power. The engine is a tuned system.....when you upgrade the valvetrain in other areas (springs, camshaft lift and profile, etc.) you have to also upgrade the rockers as well to better compliment the other changes....this gives you a more reliable piece and a harder running one as well

Those paying attention have seen some of the numbers my combinations keep putting up....its all part of the program and none of it happens by accident.

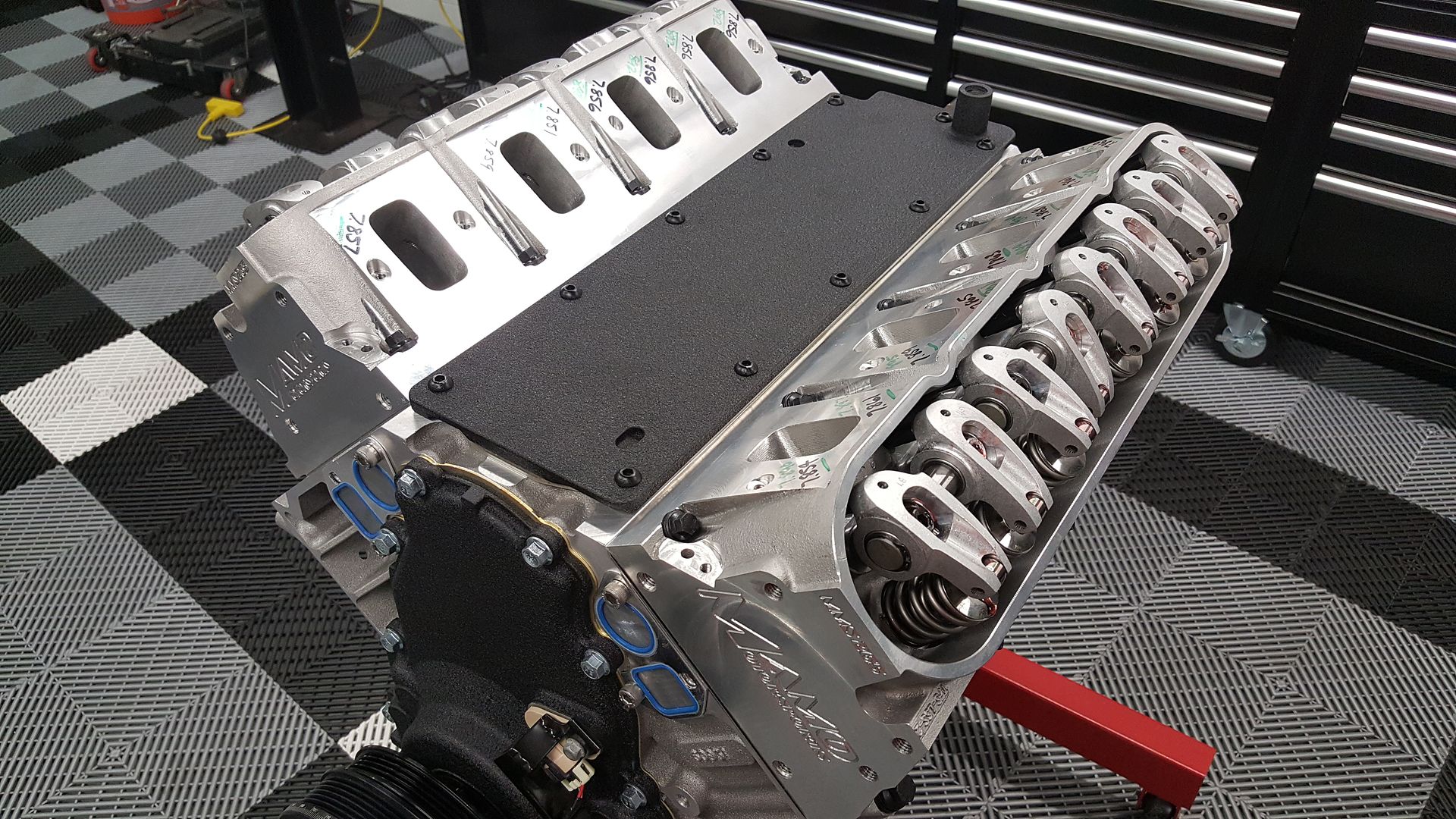

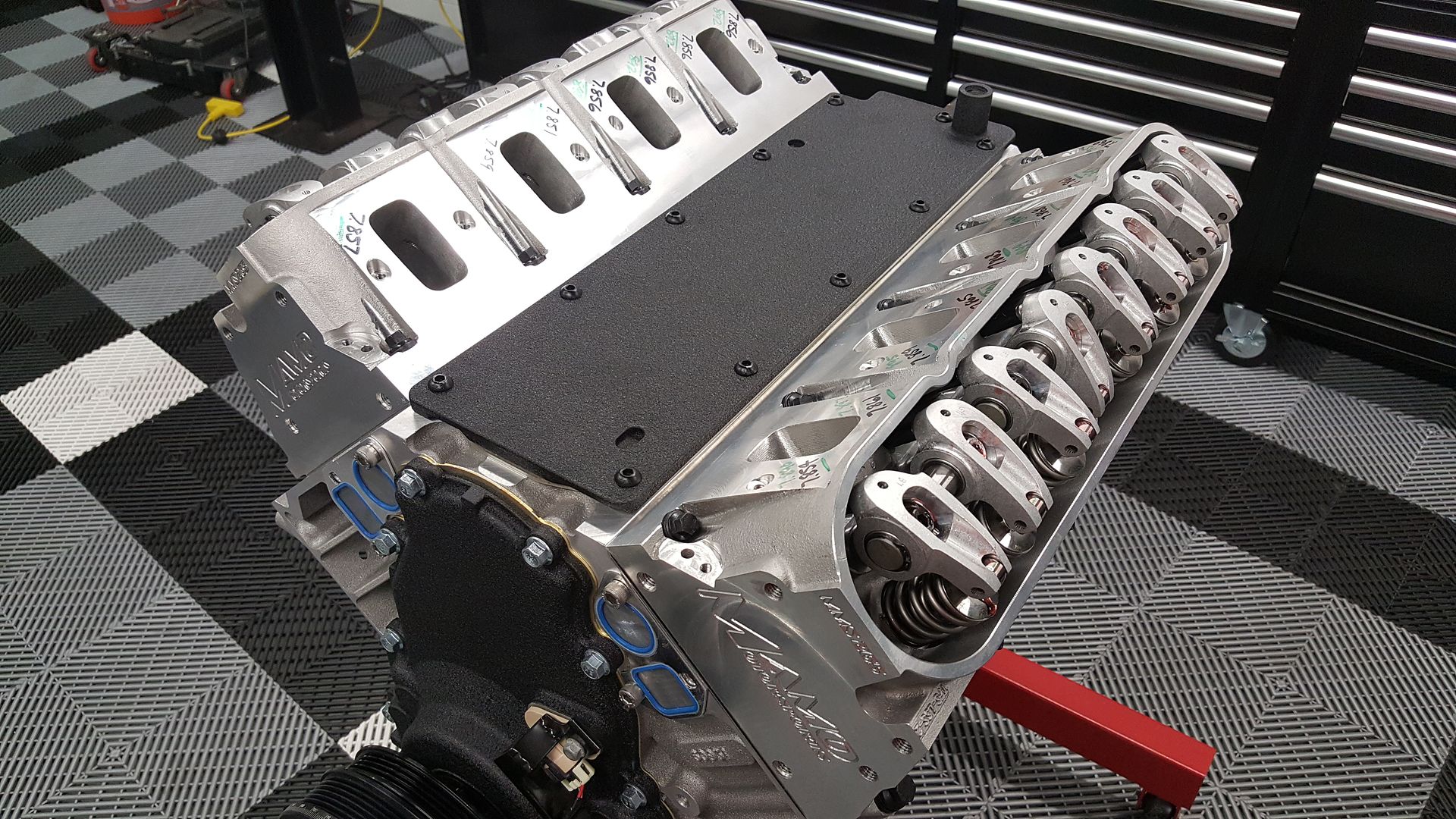

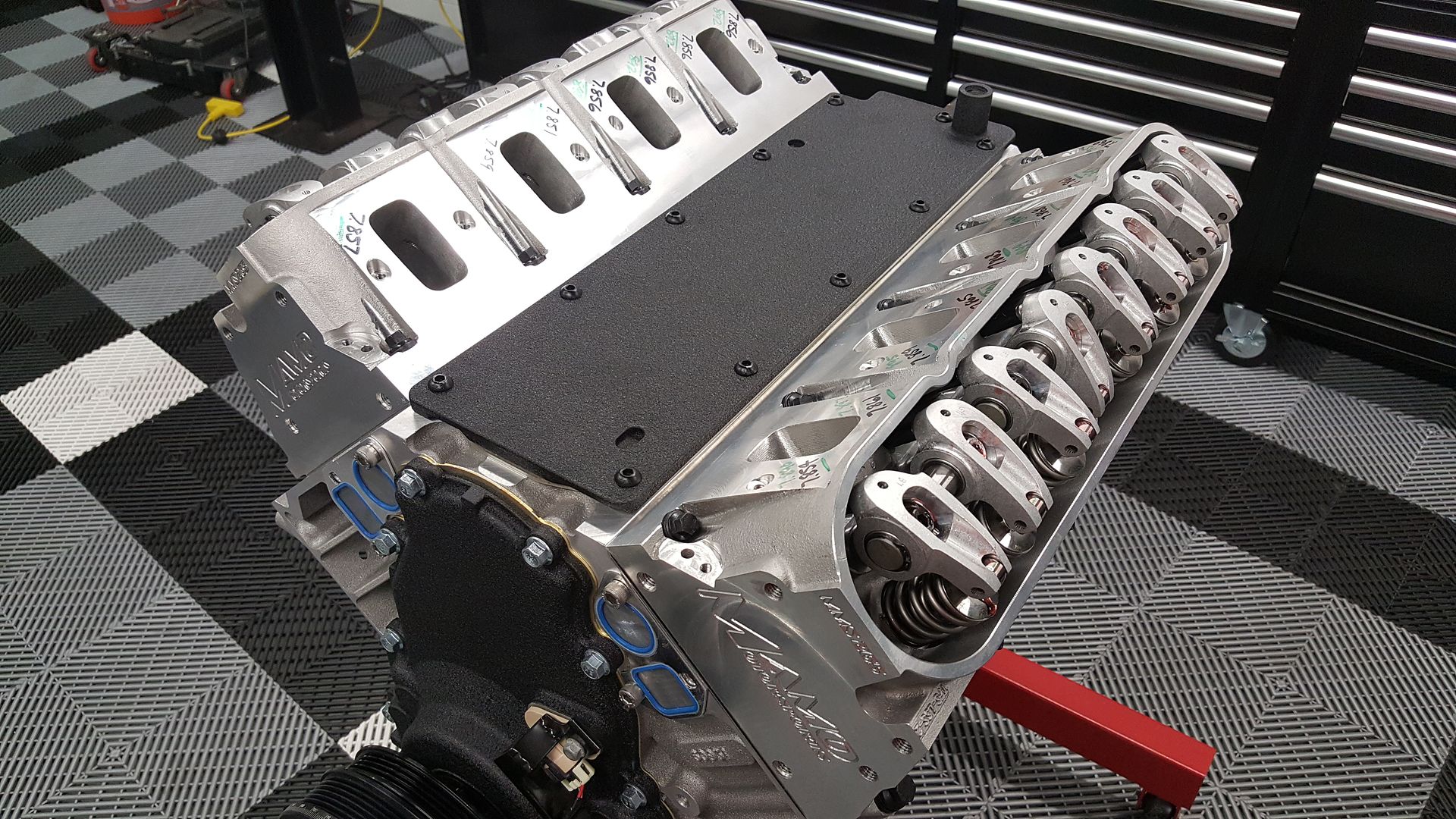

Here is an engine Im just wrapping up and taking to the dyno next Tuesday....no OEM rockers on this badboy (454 CID....sleeved OEM block....MMS 265 LS7 heads.....hoping for 725 - 750 HP at the crank)

-Tony

Last edited by Tony @ Mamo Motorsports; 07-27-2017 at 11:38 PM.

#19

Melting Slicks

The BTR 2 cam sounds "ok" for use with stock rockers for awhile. Like so many have mentioned here, Tony Mamo in particular, the stock rockers were designed for use with stock geometries and loads.

I run the Mamo Yella Terra adjustable rockers on my 454 with .734"/.728" lift figures. Very high quality especially given their cost...as little as half of what you will pay for a Crower shaft rocker system that is overkill on most engines. I'm a believer in replacing the stock rockers on any heads/cam builds I do in my shop. We might never find the one, single smoking gun that causes valve guide issues in the LS7 but it certainly helps to minimize issues where we can. Preventing the side loading caused by the stock rocker with >.650" lift camshafts is a great place to start.

As to the dyno question. 550rwhp doesn't sound "low" per se, we would need to know more about which exact mods and know more about the dyno in question. Very hard to answer definitively. Track results seem to be a better indicator.

I run the Mamo Yella Terra adjustable rockers on my 454 with .734"/.728" lift figures. Very high quality especially given their cost...as little as half of what you will pay for a Crower shaft rocker system that is overkill on most engines. I'm a believer in replacing the stock rockers on any heads/cam builds I do in my shop. We might never find the one, single smoking gun that causes valve guide issues in the LS7 but it certainly helps to minimize issues where we can. Preventing the side loading caused by the stock rocker with >.650" lift camshafts is a great place to start.

As to the dyno question. 550rwhp doesn't sound "low" per se, we would need to know more about which exact mods and know more about the dyno in question. Very hard to answer definitively. Track results seem to be a better indicator.

#20

Melting Slicks

THIS ^^^^^

"Fixed heads" only reset the clock of the failure and problems associated with ported OEM castings and stock rockers....the problems and issues are going to resurface again.....you have to change some of the players (valvetrain components) if you expect to have different end results.

It's just one of the reasons I always advocate getting away from stock rockers. I don't know why so many people are intent on running them. They were designed to operate with half the spring pressure (seat and open pressure) most of us run, SOFT gentle OEM cam lobes/ramps, and .100 or more less lift. That's the application they were designed for....they are out of their element on most of the aftermarket builds and will take out the guides of your heads due to all the side loading imparted on the stem of the valve and the guide as the flat arced pad of the rocker scrubs and see-saws across the tip of your valve. You end up with an hour glassed shape valve guide and oil consumption issues once you have achieved that shape which is vastly accelerated with aftermarket cams and alot more spring pressure....not to mention a loss of performance from your valves not properly sealing when your guides are worn.

ALL the engines I build and spec are equipped with Yella Terra Ultralites built specifically for the castings Im using but you can buy them for stock heads also....much more affordable than the other big names in the rocker arm business and more importantly they are better designed for an HR system most of us are running (they are lightweight which is crucial to valve control).

I don't understand the love affair with OEM rockers when your upgrading all the other areas pertinent to building a real performance engine, not to mention some guys investing more money in them with trunion upgrades etc.....its silly because you still haven't addressed their major design flaw regarding not having the proper geometry for much more lift and not having a roller wheel which reduces contact patch by a large margin and reduces side loading dramatically as well. Also a roller will offer reduced friction and that will free up a small bit of power also....a nice perk from the upgrade to a roller.

I stock this stuff guys so if you would like to discuss in more detail feel free to contact me. Not a single engine I build (or help spec for a customer by providing them with all the parts) includes OEM rockers. You leave them to collect dust on the shelf with all the other OEM parts you removed when you decided to upgrade and mod your engine in search of more power. The engine is a tuned system.....when you upgrade the valvetrain in other areas (springs, camshaft lift and profile, etc.) you have to also upgrade the rockers as well to better compliment the other changes....this gives you a more reliable piece and a harder running one as well

Those paying attention have seen some of the numbers my combinations keep putting up....its all part of the program and none of it happens by accident.

Here is an engine Im just wrapping up and taking to the dyno next Tuesday....no OEM rockers on this badboy (454 CID....sleeved OEM block....MMS 265 LS7 heads.....hoping for 725 - 750 HP at the crank)

-Tony

"Fixed heads" only reset the clock of the failure and problems associated with ported OEM castings and stock rockers....the problems and issues are going to resurface again.....you have to change some of the players (valvetrain components) if you expect to have different end results.

It's just one of the reasons I always advocate getting away from stock rockers. I don't know why so many people are intent on running them. They were designed to operate with half the spring pressure (seat and open pressure) most of us run, SOFT gentle OEM cam lobes/ramps, and .100 or more less lift. That's the application they were designed for....they are out of their element on most of the aftermarket builds and will take out the guides of your heads due to all the side loading imparted on the stem of the valve and the guide as the flat arced pad of the rocker scrubs and see-saws across the tip of your valve. You end up with an hour glassed shape valve guide and oil consumption issues once you have achieved that shape which is vastly accelerated with aftermarket cams and alot more spring pressure....not to mention a loss of performance from your valves not properly sealing when your guides are worn.

ALL the engines I build and spec are equipped with Yella Terra Ultralites built specifically for the castings Im using but you can buy them for stock heads also....much more affordable than the other big names in the rocker arm business and more importantly they are better designed for an HR system most of us are running (they are lightweight which is crucial to valve control).

I don't understand the love affair with OEM rockers when your upgrading all the other areas pertinent to building a real performance engine, not to mention some guys investing more money in them with trunion upgrades etc.....its silly because you still haven't addressed their major design flaw regarding not having the proper geometry for much more lift and not having a roller wheel which reduces contact patch by a large margin and reduces side loading dramatically as well. Also a roller will offer reduced friction and that will free up a small bit of power also....a nice perk from the upgrade to a roller.

I stock this stuff guys so if you would like to discuss in more detail feel free to contact me. Not a single engine I build (or help spec for a customer by providing them with all the parts) includes OEM rockers. You leave them to collect dust on the shelf with all the other OEM parts you removed when you decided to upgrade and mod your engine in search of more power. The engine is a tuned system.....when you upgrade the valvetrain in other areas (springs, camshaft lift and profile, etc.) you have to also upgrade the rockers as well to better compliment the other changes....this gives you a more reliable piece and a harder running one as well

Those paying attention have seen some of the numbers my combinations keep putting up....its all part of the program and none of it happens by accident.

Here is an engine Im just wrapping up and taking to the dyno next Tuesday....no OEM rockers on this badboy (454 CID....sleeved OEM block....MMS 265 LS7 heads.....hoping for 725 - 750 HP at the crank)

-Tony