Anyone have any thoughts on my motor issue?

#1

Safety Car

Thread Starter

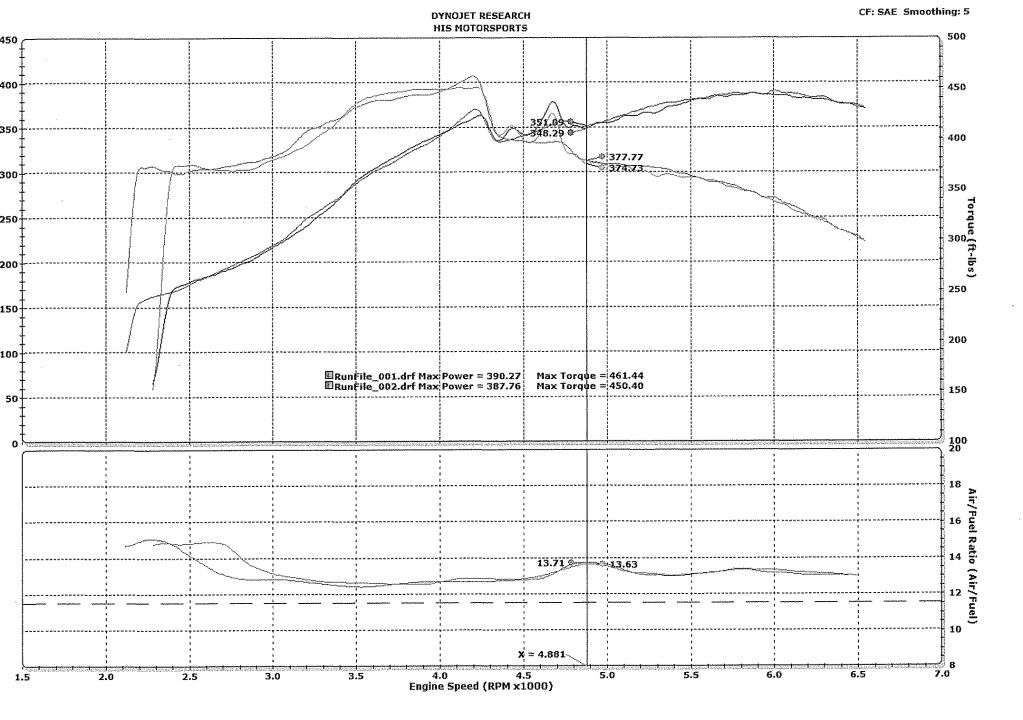

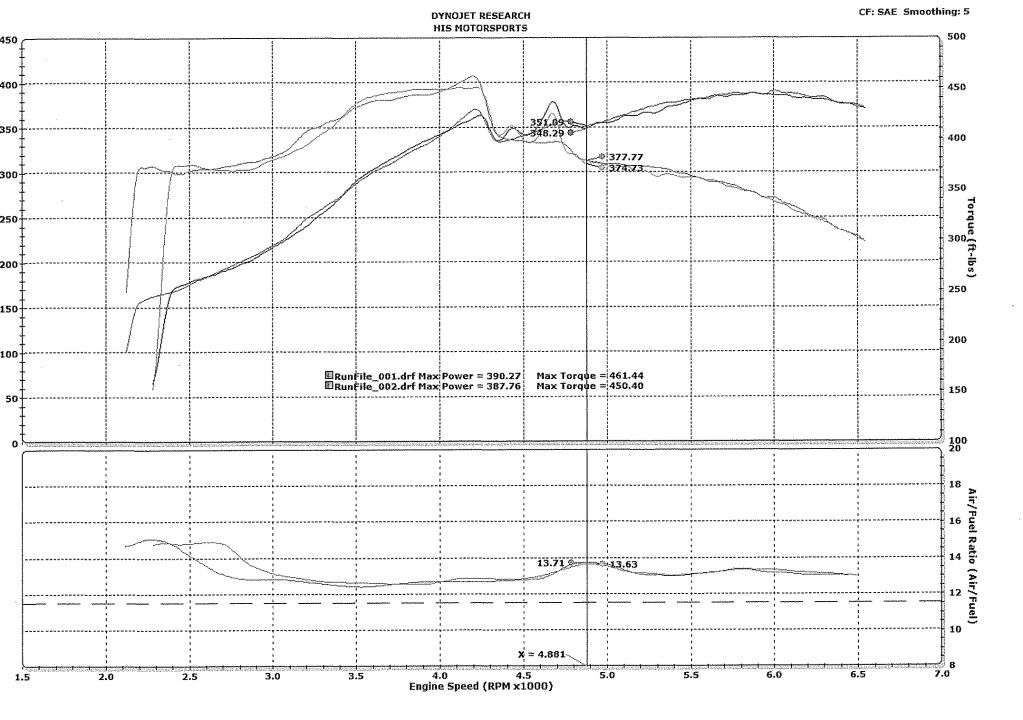

Severe power drop after 4200 rpms. Dyno from today:

[IMG] [/IMG]

[/IMG]

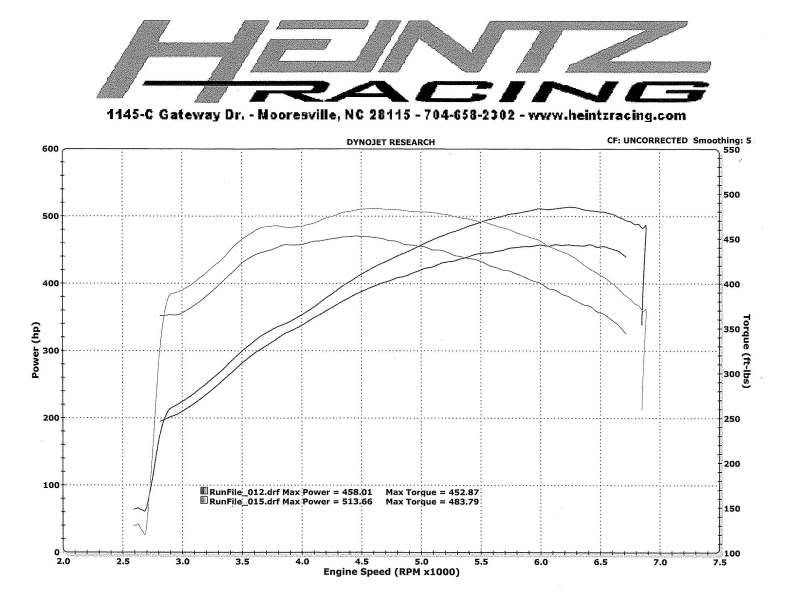

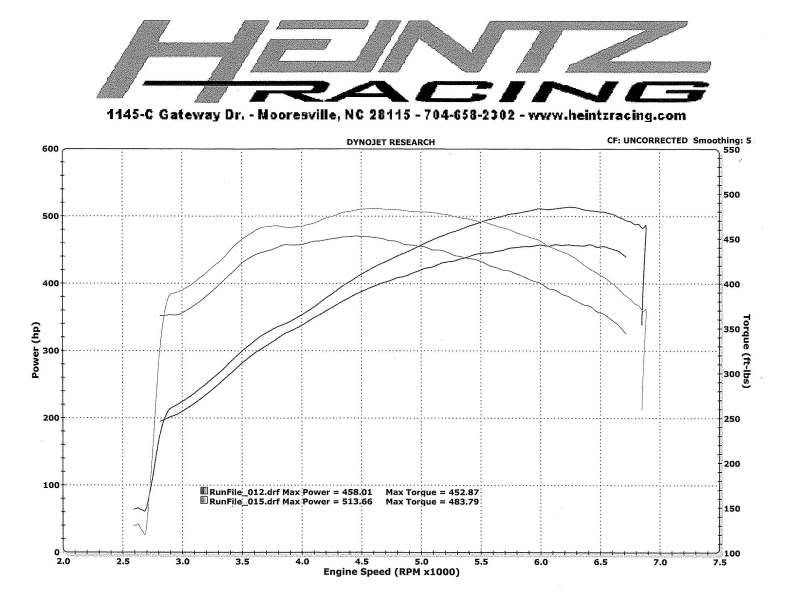

Dyno from 1 1/2 yrs ago:

[IMG] [/IMG]

[/IMG]

I have the GoPoint BT1 diagnostic app but it does not show anything out of the ordinary. No valve train rattle and car runs perfectly fine under the 4200 rpms. Any simple things to check before I haul it off to Heintz Racing?

All my mods are in signature.

[IMG]

[/IMG]

[/IMG]Dyno from 1 1/2 yrs ago:

[IMG]

[/IMG]

[/IMG]I have the GoPoint BT1 diagnostic app but it does not show anything out of the ordinary. No valve train rattle and car runs perfectly fine under the 4200 rpms. Any simple things to check before I haul it off to Heintz Racing?

All my mods are in signature.

#4

Safety Car

Thread Starter

All I have changed on the engine is I put a breather on the valve cover port that was previously plugged, and repl oil cap breather with stock oil cap. My ac is not hooked up due to a leak and I had my radiator top cover on backwards most of the year, so I installed it correctly. And I changed from Amsoil 10w40 to Mobil 10w40. That is it. The GoPoint OBDII reader app shows my O2 sensors are within range, MAP pressure rise with rpms, MAF #s incr with throttle. I may try to check my fuel pressure tonite. It has an LPE fuel pump, a Racetronic boost a pump and 42# inj from when it was previously supercharged. I wish I would have left the fp guage installed.

#5

Safety Car

Thread Starter

IIRC, according to my GoPoint app, the timing was 30* right before he went WOT on dyno and it pretty much flat lined at 24* thru the pull. Don't know if that is good or bad. Could the knock sensors go bad? They are the ones from my original LS6 that were relocated from valley cover to side of block.

#6

Safety Car

It looks like it is pulling timing. I assume you don't have HPTuners/EFI Live to log a few other parameters?

Look at that AFR curve. My guess is that is a fuel issue (not enough) and then the PCM is pulling timing. I had this happen to me when I ran low on fuel and cooked my fuel pump at VIR. You may want to go with the easy stuff first (injectors, fpr (if external), fuel filter) and then worry about the pump, unless you ran low at the track recently.

The oem filter also functions as the fpr. I would start there since it is easiest.

Look at that AFR curve. My guess is that is a fuel issue (not enough) and then the PCM is pulling timing. I had this happen to me when I ran low on fuel and cooked my fuel pump at VIR. You may want to go with the easy stuff first (injectors, fpr (if external), fuel filter) and then worry about the pump, unless you ran low at the track recently.

The oem filter also functions as the fpr. I would start there since it is easiest.

#7

Melting Slicks

I would start by replacing plugs and plug wires. I've had bad plug wires cause loss of power at high rpm. Other than that, you can log some runs with hp tuners and see if timing is being pulled. A fuel pressure gauge would also be nice to see.

#8

Safety Car

Thread Starter

My fuel rail has a schrader valve on the end. Can I attach my screw on tire gauge to that and measure fuel pressure? Would it have to be under load to measure correctly, or will be accurate running thru rpms with car not moving. Would like to check this before tearing down valve train. Springs have me worried because of my cam.

#9

Le Mans Master

I'd use a screw on fuel pressure gage.

IIRC the one I got to diagnose my cars was less than $30 at Harbor Freight

IIRC the one I got to diagnose my cars was less than $30 at Harbor Freight

#10

Drifting

1st question I'd ask is how does the car feel? Meaning did you know there was a problem and that is why you did the new dyno run?

You really need the AFR to see if it is fuel. Looks more like timing was pulled or you have a valve issue cropping up.

You can check the fuel pressure on the rail sitting but that doesn't mean much. You could have the pressure but not the flow -- need the AFR again.

Have you done a leak down test?

You really need the AFR to see if it is fuel. Looks more like timing was pulled or you have a valve issue cropping up.

You can check the fuel pressure on the rail sitting but that doesn't mean much. You could have the pressure but not the flow -- need the AFR again.

Have you done a leak down test?

#11

Safety Car

Thread Starter

Car feels perfectly normal below 4k rpms. At VIR, on the backstretch, normally I can get 151-155mph, but this time it was struggling to get to 145mph. I could feel it bog down around the 4500 rpms (which I never get close to on the highway). Other than that, it was running fine. The dyno graph from yesterday has the AFR at the bottom. It starts at 12.4 and stays there until right after the power drops and then it spiked to 13.71 and then came down. Not sure what that means.

By leak down, if you mean a compression check, my friend has offered me his testing equip. Would than confirm or rule out a spring/rocker issue? If so, I will do that tonite. Have to go out of town tomorrow, but I will be going by HF so I can get the proper fuel pressure tester if it will tell me anything.

Thanks to all for the help so far.

By leak down, if you mean a compression check, my friend has offered me his testing equip. Would than confirm or rule out a spring/rocker issue? If so, I will do that tonite. Have to go out of town tomorrow, but I will be going by HF so I can get the proper fuel pressure tester if it will tell me anything.

Thanks to all for the help so far.

#12

Suckin' gas, haulin' ass.

Member Since: Apr 2010

Location: Newport News Virginia

Posts: 1,100

Likes: 0

Received 8 Likes

on

7 Posts

I would definitely get the fuel pressure and timing checked. It's weird though because the power drop is a full 750-800 RPM before the AFR climbs to ~13.5. It looks like it throws the timing in again, but then takes it back out and then slowly puts it back in, but by then the power curve is on its way down.

Spark knock due to lean would definitely make it pull timing. See if you can get your tuner (or yourself) to log FP, Timing, and knock events. I don't think you have a valve/lifter problem. If something wasn't opening enough, you would know it through the RPM range, and it would tend to go away as RPM and oil pressure increase. At least that's how it would work in my mind. (Collapsed lifter then higher oil pressure pumps it up at higher RPM)

Spark knock due to lean would definitely make it pull timing. See if you can get your tuner (or yourself) to log FP, Timing, and knock events. I don't think you have a valve/lifter problem. If something wasn't opening enough, you would know it through the RPM range, and it would tend to go away as RPM and oil pressure increase. At least that's how it would work in my mind. (Collapsed lifter then higher oil pressure pumps it up at higher RPM)

#13

Drifting

A compression test probably won't tell much. A leak-down will give a little more information and tell you if you have a burnt valve, stuck open, broken, ring issue, etc. With 100 psi I'd look for no more than 8% in a healthy engine. It is also called a differential pressure test ... harbor freight has a cheap kit too. You apply a steady state pressure and see what the cyl. will hold. Tester

3.7 with WOT is really lean but it looks like that didn't occur until 400 RPM or so after the breakdown. (could be delay in the reading as well). 12.4-12.7 is where I'd want to be. I don't think pulling timing will cause the lean condition but others may verify. I'd lean to the fuel since the car works OK below 4K. Still could be a valve train issue breaking down at the higher RPM but sure sounds like fuel. Harbor freight has a pretty good fuel tester too but you need to be on the dyno so you can get the engine up to 80-90% load.

3.7 with WOT is really lean but it looks like that didn't occur until 400 RPM or so after the breakdown. (could be delay in the reading as well). 12.4-12.7 is where I'd want to be. I don't think pulling timing will cause the lean condition but others may verify. I'd lean to the fuel since the car works OK below 4K. Still could be a valve train issue breaking down at the higher RPM but sure sounds like fuel. Harbor freight has a pretty good fuel tester too but you need to be on the dyno so you can get the engine up to 80-90% load.

#14

Safety Car

lean, then knock, then pulled timing as a result

If this was a carb'd setup you would have at least one hole in your block.

It could be plugs or wires, but this is a huge dropoff so I doubt it. You would feel if the car was misfiring at high rpm and the CEL would flash (though no code).

If this was a carb'd setup you would have at least one hole in your block.

It could be plugs or wires, but this is a huge dropoff so I doubt it. You would feel if the car was misfiring at high rpm and the CEL would flash (though no code).

#16

Safety Car

Thread Starter

My GoPoint says the MAF is around 4# at idle and goes up to 8#s with throttle. No clue what it should be. Cats are less than 2 yrs old as are plugs and plug wires. Getting fuel pressure gauge tomorrow at HF. Borrowing friends leak down tester and doing that Sat. May pull the valve covers just to look at springs and rocker arms. If nothing quickly obvious, then off to shop.

#18

Drifting

Not sure how your MAF works but most return a voltage (generally 0-5v) that is related to a table correlated to Kg of air flowing through it per minute of possibly Grams/Sec. The ECU uses that information and the RPM to calculate the load. WOT in 4th at 4200 RPM would be in the high 90% load I would think. Based on the load the ECU then calculates the pulse width for the fuel. Your problem starts at 4K so it again looks like fuel. Remote possibility the MAF has an issue and you can clean it pretty easily.

#19

Safety Car

And to follow-up on the above, b/c inj pulse is based on engine load, you won't find anything if you are checking the fuel press at anything other than the load conditions encountered on the dyno, and you will want some decent datalogging rates, and see some other engine variables as well, to confirm the issue.

Save some time and head to the shop.

Save some time and head to the shop.

#20

Drifting

Member Since: Dec 2005

Location: Dayton, OH

Posts: 1,822

Likes: 0

Received 0 Likes

on

0 Posts

I would definitely get the fuel pressure and timing checked. It's weird though because the power drop is a full 750-800 RPM before the AFR climbs to ~13.5. It looks like it throws the timing in again, but then takes it back out and then slowly puts it back in, but by then the power curve is on its way down.

Spark knock due to lean would definitely make it pull timing. See if you can get your tuner (or yourself) to log FP, Timing, and knock events. I don't think you have a valve/lifter problem. If something wasn't opening enough, you would know it through the RPM range, and it would tend to go away as RPM and oil pressure increase. At least that's how it would work in my mind. (Collapsed lifter then higher oil pressure pumps it up at higher RPM)

Spark knock due to lean would definitely make it pull timing. See if you can get your tuner (or yourself) to log FP, Timing, and knock events. I don't think you have a valve/lifter problem. If something wasn't opening enough, you would know it through the RPM range, and it would tend to go away as RPM and oil pressure increase. At least that's how it would work in my mind. (Collapsed lifter then higher oil pressure pumps it up at higher RPM)

My first thoughts when I looked at your dyno sheet where VALVE TRAIN.

Springs or lifters.

The speculation that it can't be lifters due to recovery at higher rpm's is false.

I have seen this before. Lifters work fine until XYZ load/rpm then they start to collapse and may or may not recover at higher rpm.

Two likely causes,

air sucked into the oil distribution path due to vibration/harmonics at certain frequencies causing separation of connections or gaskets. The lifters are the first thing fed by the oil pump after the filter so the air would more than likely cause issues with #7 and possible #5 lifters but not likely to go much further. This would explain the smaller loss of over all power after the big dip. There's still air in the oil but the pressure/volume is high enough that the valves still get some lift. The initial collapse is the first surge of air.

Or,

Oil pump cavitation at xyz RPM due to wear, miss alignment, poor porting job, improperly torqued cover bolts or mounting bolts or a bad/failing harmonic crank damper.

Things I would look at:

Is oil pump getting starved?

Oil not flowing back to pan for some reason?

Oil pickup not aligned with bottom of pan properly?

Air leak in or around the oil filter?

Do you have an external/ auxiliary oil cooler that connects at or before the oil filter? then check all fittings etc.

There are a few other less likely possibilities....have you had the motor out or the torque tube and clutch and flywheel off/out recently?