12-bolt Tom's Differential Conversion

#1

Drifting

Thread Starter

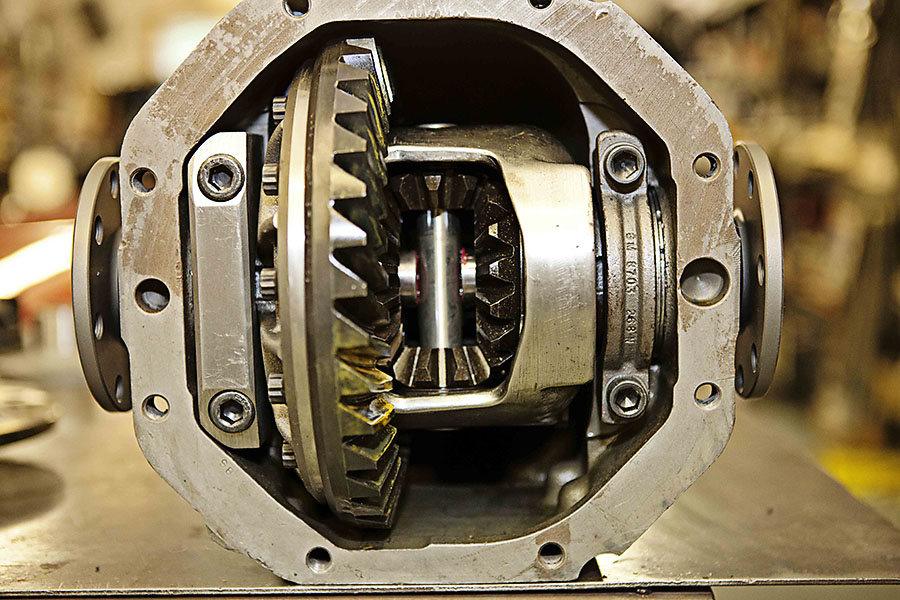

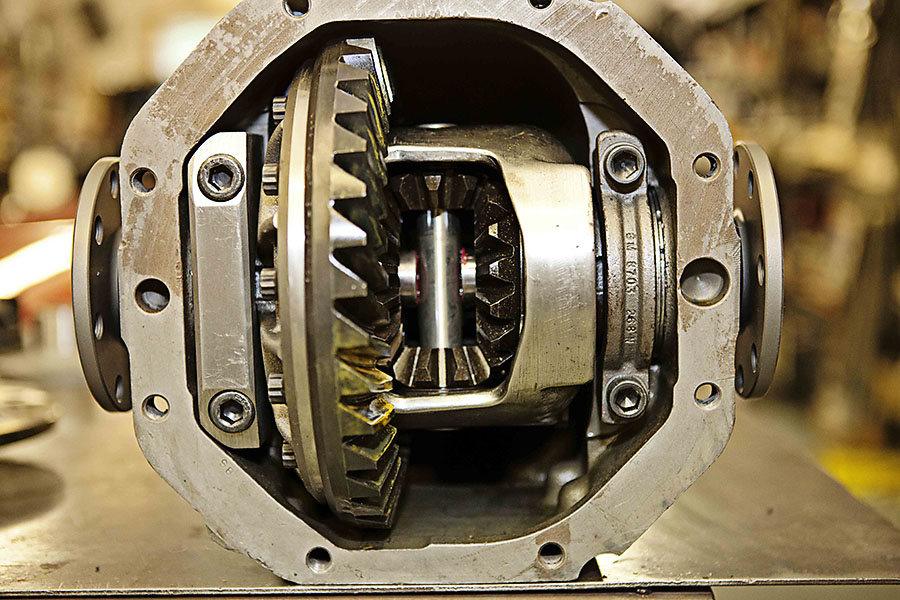

I recently got my 12-bolt differential conversion back from Mike Dyer(tracdogg2). This will be going in my red '67 convertible that I am putting a big block in. I was concerned about the strength of the factory diff so a Tom's was in order. I decided on the 1350 kit because I didn't want to have to cut the fiberglass on this car as you have to do with the 1480 kit that I currently have in my '67 632 car.

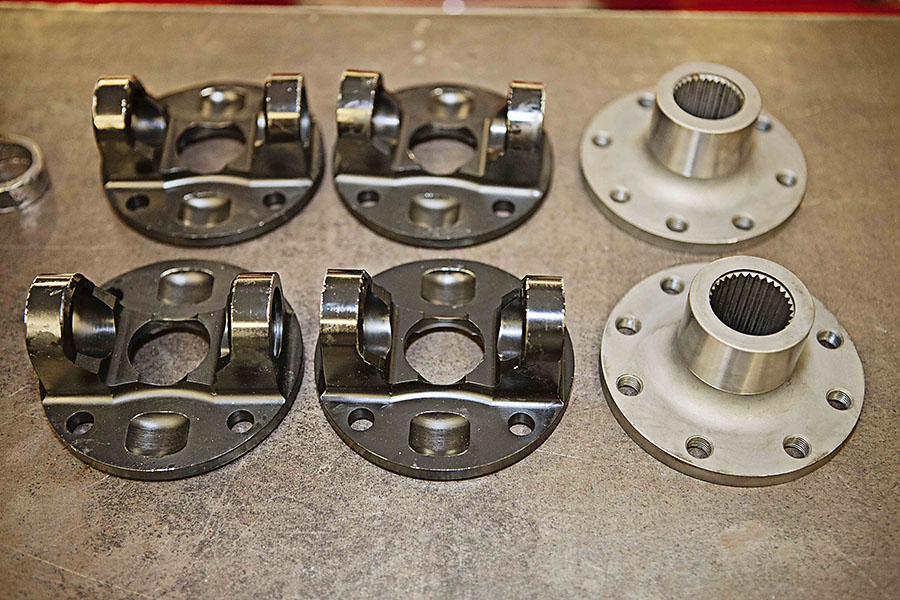

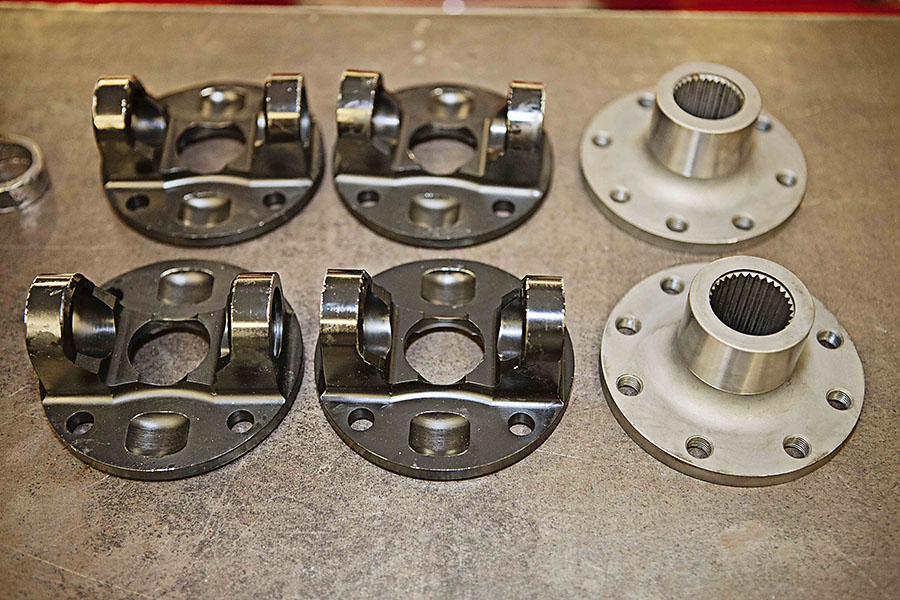

Tom recommended the HY-TUFF inner axles and Mike recommended the Billet Flanges.

I went with the following Tom's Differential components:

12V-KIT (12-bolt Corvette Conversion Parts Kit with 4.11 gears)

1350-VAK (1350 Vette Axle Kit with upgrade to HY-TUFF inner axles and Billet Flanges)

C10V-HDRC (H.D. Rear Cover)

Mike supplied his own custom left-side cap. At this point all of the work that Mike has performed is first class. Of course, the real test will be when I take it out to the drag strip.

I have included some pics:

Once I get the motor completed, my plan is to make a few DynoJet runs with the factory 3.70 rearend and then switch to this new 4.11 rearend and make a few more runs to see what the differences are.

Steve

Tom recommended the HY-TUFF inner axles and Mike recommended the Billet Flanges.

I went with the following Tom's Differential components:

12V-KIT (12-bolt Corvette Conversion Parts Kit with 4.11 gears)

1350-VAK (1350 Vette Axle Kit with upgrade to HY-TUFF inner axles and Billet Flanges)

C10V-HDRC (H.D. Rear Cover)

Mike supplied his own custom left-side cap. At this point all of the work that Mike has performed is first class. Of course, the real test will be when I take it out to the drag strip.

I have included some pics:

Once I get the motor completed, my plan is to make a few DynoJet runs with the factory 3.70 rearend and then switch to this new 4.11 rearend and make a few more runs to see what the differences are.

Steve

#2

Melting Slicks

Nice build. Any idea how much cutting of the fiberglass is needed for the 1480 kit?

Whats the benefit of the HY-TUFF axles? are they heat cycled/treated? How much extra for the TUFF treatment?

Whats the benefit of the HY-TUFF axles? are they heat cycled/treated? How much extra for the TUFF treatment?

Last edited by 68 NJConv 454; 07-05-2011 at 03:42 PM.

#4

Drifting

#6

Drifting

Thread Starter

Steve

#7

Drifting

Thread Starter

Steve

#10

Race Director

Member Since: Jan 2000

Location: Corsicana, Tx

Posts: 12,617

Received 1,878 Likes

on

916 Posts

2020 C2 of the Year - Modified Winner

2020 Corvette of the Year (performance mods)

C2 of Year Winner (performance mods) 2019

2017 C2 of Year Finalist

Sweeettt!!!

Another killer Mikey build!

Steve...I haven't called in a while...I'm almost scared to ask what's in store for the convertible!!

But it's going to be a fun ride I bet! I mean it ran 11's with that little *stock* smalblock using cast iron manifolds!

JIM

Another killer Mikey build!

Steve...I haven't called in a while...I'm almost scared to ask what's in store for the convertible!!

But it's going to be a fun ride I bet! I mean it ran 11's with that little *stock* smalblock using cast iron manifolds!

JIM

#11

Drifting

Thread Starter

#12

Drifting

Thread Starter

I'm hoping that it will all be worth it when it is finished!

Steve

#13

Le Mans Master

Very nice eye candy there Steve. I never met Mike Dyer but he seems like one hell of a guy, helped me set up my posi over the phone. Yeah, that little 383 was a good running motor, can't wait to see the big block conversion.

I like the billet flanges for the half shafts too, does Mike have those?

I like the billet flanges for the half shafts too, does Mike have those?

#14

Drifting

Thread Starter

Very nice eye candy there Steve. I never met Mike Dyer but he seems like one hell of a guy, helped me set up my posi over the phone. Yeah, that little 383 was a good running motor, can't wait to see the big block conversion.

I like the billet flanges for the half shafts too, does Mike have those?

I like the billet flanges for the half shafts too, does Mike have those?

Mike is indeed one hell of a nice guy. Very helpful and an honest individual. There are not many people you can say that about now days.

Mike got those billet flanges from Tom's.

Steve

#15

Le Mans Master

Can't go wrong on a Tracdogg IRS.....

I pound on mine every time I drive it on, drag radials stay on the car 100% of the time....Its still quiet as can be...... I have atleast 20 mid to high 6 sec 1/8 passes on (low 1.50 60's) and she's still kickin.... and mine is still a 10 bolt....

I also aligned my rear end using Tracdogg's "string" method..... my car hooks hard and goes straight as an arrow....

That ole boy knows his ****!

I pound on mine every time I drive it on, drag radials stay on the car 100% of the time....Its still quiet as can be...... I have atleast 20 mid to high 6 sec 1/8 passes on (low 1.50 60's) and she's still kickin.... and mine is still a 10 bolt....

I also aligned my rear end using Tracdogg's "string" method..... my car hooks hard and goes straight as an arrow....

That ole boy knows his ****!

#17

Drifting

Thread Starter

Can't go wrong on a Tracdogg IRS.....

I pound on mine every time I drive it on, drag radials stay on the car 100% of the time....Its still quiet as can be...... I have atleast 20 mid to high 6 sec 1/8 passes on (low 1.50 60's) and she's still kickin.... and mine is still a 10 bolt....

I also aligned my rear end using Tracdogg's "string" method..... my car hooks hard and goes straight as an arrow....

That ole boy knows his ****!

I pound on mine every time I drive it on, drag radials stay on the car 100% of the time....Its still quiet as can be...... I have atleast 20 mid to high 6 sec 1/8 passes on (low 1.50 60's) and she's still kickin.... and mine is still a 10 bolt....

I also aligned my rear end using Tracdogg's "string" method..... my car hooks hard and goes straight as an arrow....

That ole boy knows his ****!

Steve

#18

Drifting

Thread Starter

My goal is simply to make the engine compartment look as close to 100% stock as possible (when viewed from standing next to the car). I even want it to sound stock. I'm hoping the cam I selected will allow this.

As far as 10's through stock manifolds, that is indeed the goal. Based on your experience what kind of rwhp numbers will I need to attain this? The trans is a TKO-600. I have a set of M/T 255/60x15 DOT Street Radials for the car. I believe that is what you are using.

Steve

#19

Le Mans Master

I am not sure how much RWHP you would need since it is a stick car....I am normally only saavy on auto tranny with good converter stats but..... Typically stick cars run better MPH and show more RWHP yet ET considerably worse then a good auto tranny and converter...

Shooting off of the cuff, I would say you would need 500rwhp at a minimum with a stick and thats gonna have to be leaving real well.....

Not a good comparison but.... my 99 Trans Am M6 that weighed 3800lbs with me in it ran 11.30s@125 at 545rwhp...BUT that was only with 1.75 60's and crappy 5.00 330's.... I feel it would have ran 10.90s on 6k clutch dumps IF it didnt bog or blow up but....I never tried it... That same car with an auto and a good converter would have ran 11.30s on motor and probably 10.30s on spray...

Seeing as how you were running 11.80s with 400 rwhp on the small block, add another 100hp and you "should" be in the high 10s....

Shooting off of the cuff, I would say you would need 500rwhp at a minimum with a stick and thats gonna have to be leaving real well.....

Not a good comparison but.... my 99 Trans Am M6 that weighed 3800lbs with me in it ran 11.30s@125 at 545rwhp...BUT that was only with 1.75 60's and crappy 5.00 330's.... I feel it would have ran 10.90s on 6k clutch dumps IF it didnt bog or blow up but....I never tried it... That same car with an auto and a good converter would have ran 11.30s on motor and probably 10.30s on spray...

Seeing as how you were running 11.80s with 400 rwhp on the small block, add another 100hp and you "should" be in the high 10s....

Thanks! You do very nice work.

Thanks! You do very nice work.