Serious Oil Leaks in a 383

#1

Melting Slicks

Thread Starter

I doubt I'd proceed with this 383 build had I known of the oil leak problems it bestowed on me.

Splash oil was still being sucked into the carburetor by way of the PCV Valve and it's tubing to the carb base. So, I replaced the PCV Valve with a new breather, which fit tight onto the gasket of the valve cover.

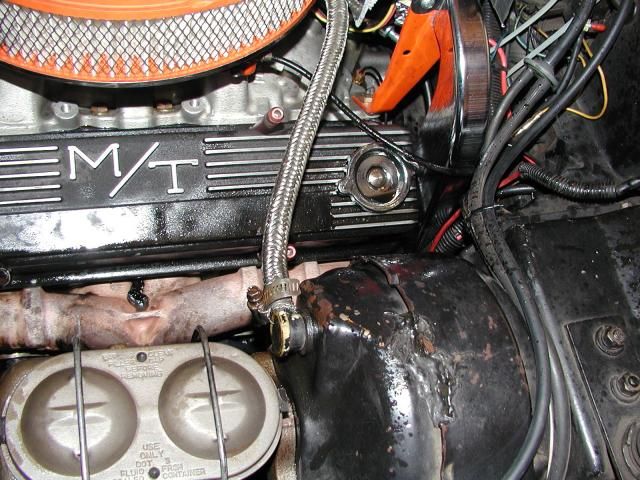

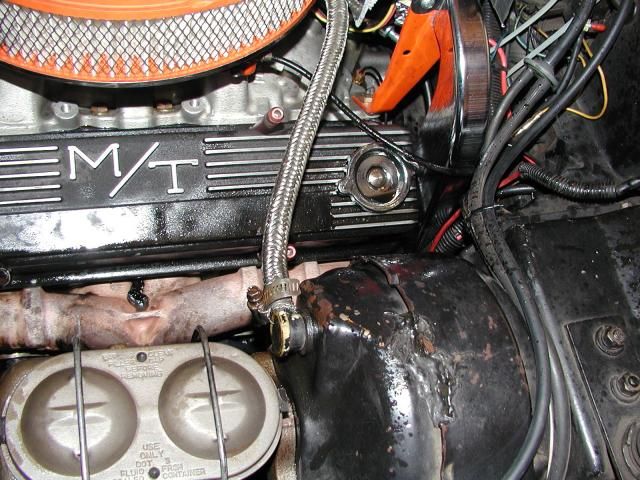

Drove 4 miles, and the engine starts smokin'! Smoke even spewed from the steering column into the interior! Scary Crap! Got home and found this:

Oil breather was dripping oil, and the filler cap showed pooled oil as well. Valve covers are tightly down on the cylinder head with new valve cover gaskets, so the leaks aren't from there.

My question is: Could the High Volume Oil Pump I installed 500 miles ago be causing all these oil leak problems? Would they go away with a standard volume Oil Pump? Anyone else have a similar problem?

Thanks,

Steve

My question

Splash oil was still being sucked into the carburetor by way of the PCV Valve and it's tubing to the carb base. So, I replaced the PCV Valve with a new breather, which fit tight onto the gasket of the valve cover.

Drove 4 miles, and the engine starts smokin'! Smoke even spewed from the steering column into the interior! Scary Crap! Got home and found this:

Oil breather was dripping oil, and the filler cap showed pooled oil as well. Valve covers are tightly down on the cylinder head with new valve cover gaskets, so the leaks aren't from there.

My question is: Could the High Volume Oil Pump I installed 500 miles ago be causing all these oil leak problems? Would they go away with a standard volume Oil Pump? Anyone else have a similar problem?

Thanks,

Steve

My question

#3

Race Director

Looks like the dipstick is backed out some in one picture. Could be some of the cause of the oil on brake booster area. Could something be causing the oil pan/crankcase to be pressurized pushing oil back up the dipstick?

#4

Race Director

I am betting severe blowby, excessive crankcase pressure. Generally from bad rings, bad hone, improper cylinder finish, rings not seating, Rings installed upside down. Who built it?

#5

Melting Slicks

Thread Starter

WOW! Thanks for all the responses.

Yeah redvetracr, baffled covers, and the gasket is tight around the breather.

The oil is being forced out thru the breather medium and onto the engine bay.

Eddie 70, I've noted that creeping dipstick too.

63 Mako, This engine only has about 500 miles and a month and a half in-service on it. This leak/pressurization problem is steadily getting worse and worse. There were no leaks the first 250 miles; then a small weeping of oil from the breathers started it all. Strange: Right valve cover/oil breather is now just a wee bit damp. This breather is now dryer than it was a few weeks ago.

Blowby makes sense, but how? I made damn sure the rings were installed correctly; Correct side up and staggered ends. The new Pistons/Rings were .03 over, the cylinders were bored .03 over. What else is there?

Leakdown test on a new 500 mile motor. How humiliating. But it looks like it's the next logical step.

Pressure's comin' from somewhere. And it's getting worse (on the left side anyway).

Steve

Yeah redvetracr, baffled covers, and the gasket is tight around the breather.

The oil is being forced out thru the breather medium and onto the engine bay.

Eddie 70, I've noted that creeping dipstick too.

63 Mako, This engine only has about 500 miles and a month and a half in-service on it. This leak/pressurization problem is steadily getting worse and worse. There were no leaks the first 250 miles; then a small weeping of oil from the breathers started it all. Strange: Right valve cover/oil breather is now just a wee bit damp. This breather is now dryer than it was a few weeks ago.

Blowby makes sense, but how? I made damn sure the rings were installed correctly; Correct side up and staggered ends. The new Pistons/Rings were .03 over, the cylinders were bored .03 over. What else is there?

Leakdown test on a new 500 mile motor. How humiliating. But it looks like it's the next logical step.

Pressure's comin' from somewhere. And it's getting worse (on the left side anyway).

Steve

#6

Race Director

Eddie 70, I've noted that creeping dipstick too.

63 Mako, This engine only has about 500 miles and a month and a half in-service on it. This leak/pressurization problem is steadily getting worse and worse. There were no leaks the first 250 miles; then a small weeping of oil from the breathers started it all.

Blowby makes sense, but how? I made damn sure the rings were installed correctly; Correct side up and staggered ends. The new Pistons/Rings were .03 over, the cylinders were bored .03 over. What else is there?

Leakdown test on a new 500 mile motor. How humiliating. But it looks like it's the next logical step.

Pressure's comin' from somewhere. And it's getting worse (on the left side anyway).

Steve

63 Mako, This engine only has about 500 miles and a month and a half in-service on it. This leak/pressurization problem is steadily getting worse and worse. There were no leaks the first 250 miles; then a small weeping of oil from the breathers started it all.

Blowby makes sense, but how? I made damn sure the rings were installed correctly; Correct side up and staggered ends. The new Pistons/Rings were .03 over, the cylinders were bored .03 over. What else is there?

Leakdown test on a new 500 mile motor. How humiliating. But it looks like it's the next logical step.

Pressure's comin' from somewhere. And it's getting worse (on the left side anyway).

Steve

#7

Melting Slicks

Thread Starter

"Torque plate honed"? I don't follow.

Here's the kit.

http://www.ebay.com/itm/SBC-CHEVY-383-STROKER-KIT-SCAT-CRANK-RODS-030-FORGED-FLAT-TOP-PISTONS-2PC-RMS-/331231662680?pt=Motors_Car_Truck_Parts_Accessories&hash=item4d1ef21258

Here's the heads.

http://www.ebay.com/itm/327-350-CHEVY-ALUMINUM-CYLINDER-HEADS-SBC-2-02-STRAIGHT-PLUG-190CC-/361005673556?pt=Motors_Car_Truck_Parts_Accessories&hash=item540d9d6c54

Block is from a '78 C-10, surfaced head area, bored to .030, and cleaned.

Steve

#8

Burning Brakes

Member Since: Feb 2014

Location: Cape Neddick Maine

Posts: 1,042

Received 226 Likes

on

148 Posts

2020 C3 of the Year Finalist - Modified

how much end gap is on the rings? dumb question/comment but you are using a conventional oil right? rings don't like to seat using synthetics or other friction modifiers

#9

Team Owner

Member Since: Oct 2004

Location: altered state

Posts: 81,242

Received 3,043 Likes

on

2,602 Posts

St. Jude Donor '05

Assuming theres no oil drainback issue Id get the motor warm then do your leakdown youl have your answer.

Oil pump has nothing to do with it rule that out of the equation

Hope its not a cranckcase issue

Oil pump has nothing to do with it rule that out of the equation

Hope its not a cranckcase issue

#10

Melting Slicks

Thread Starter

I never checked the gap. I assumed them well within specification since pistons & rings were a matched set and new.

This is what the oil is:

http://www.royalpurpleconsumer.com/p...-break-in-oil/

Steve

#11

Melting Slicks

Thread Starter

Steve

#12

Race Director

You bore the engine leaving it a few thousandths undersize then bolt a torque plate to the block and hone the cylinder to finish size. The torque plate makes the cylinder round after honing mimicking what you have when the head is bolted on. You use a specific grit stone and speed to get the correct finish for your type of rings. If it was just bored .030 over and not torque plate honed to specific finish odds of seating the rings is slim to none.

#13

Melting Slicks

Thread Starter

You bore the engine leaving it a few thousandths undersize then bolt a torque plate to the block and hone the cylinder to finish size. The torque plate makes the cylinder round after honing mimicking what you have when the head is bolted on. You use a specific grit stone and speed to get the correct finish for your type of rings. If it was just bored .030 over and not torque plate honed to specific finish odds of seating the rings is slim to none.

That's a very interesting procedure. Very effective, I can see.

Seems odd that after hundreds of kits the stroker company has sold, this procedure has never been out there and in print for use by them.

I'll due the leakdown test when my new fistula scar heals up well enough, and I'll post the results.

Steve

#14

Melting Slicks

Thread Starter

Here's a question that someone may have a different answer to:

On an engine case being abnormally pressurized, how can the problem be anything but bad piston ring sealing or damaged piston(s)?

Thanks.

Steve

On an engine case being abnormally pressurized, how can the problem be anything but bad piston ring sealing or damaged piston(s)?

Thanks.

Steve

#15

Burning Brakes

Member Since: Feb 2014

Location: Cape Neddick Maine

Posts: 1,042

Received 226 Likes

on

148 Posts

2020 C3 of the Year Finalist - Modified

If the oil is too high ion the pan it will wrap around the crank cause cavitation and windage.

I don't believe this is your problem though.

I have seen rings mismarked before. Even pre fit rings should still be checked. I file mine for each cylinder so I can custom set mine for the intended application.

#16

Burning Brakes

Member Since: Feb 2014

Location: Cape Neddick Maine

Posts: 1,042

Received 226 Likes

on

148 Posts

2020 C3 of the Year Finalist - Modified

at idle pull the breathers out and start the engine do you have puffs of smoke vapor coming out of the holes? jazz the throttle quickly any smoke/vapor?

That should tell you the problem.

That should tell you the problem.

#17

Melting Slicks

Thread Starter

funny you should asked I was pondering the same thing. Digging deeper do you have the correct oil pan and dipstick? and do how about a windage tray depending on how hard you turn it

And it's funny you bring that up jkippen. The donor block ('78 C-10) came to me without an oil pan and without the dipstick/tube(s). Thinking they were all the same (ads touted "For SBC's"), I skimped and bought a cheap chrome pan and a single tube dipstick. I can't remember for sure, but I think the pan had no windage tray in it.

If the oil is too high ion the pan it will wrap around the crank cause cavitation and windage.

I don't believe this is your problem though.

I have seen rings mismarked before. Even pre fit rings should still be checked. I file mine for each cylinder so I can custom set mine for the intended application.

The rings were marked pretty well, and I took a lot of time assembling the pistons. I had never seen the "corkscrew" type wristpin holders before. They were a bitch to fit in at first, but after about 10(!), I got the hang of it. Geez....I wonder....

And it's funny you bring that up jkippen. The donor block ('78 C-10) came to me without an oil pan and without the dipstick/tube(s). Thinking they were all the same (ads touted "For SBC's"), I skimped and bought a cheap chrome pan and a single tube dipstick. I can't remember for sure, but I think the pan had no windage tray in it.

If the oil is too high ion the pan it will wrap around the crank cause cavitation and windage.

I don't believe this is your problem though.

I have seen rings mismarked before. Even pre fit rings should still be checked. I file mine for each cylinder so I can custom set mine for the intended application.

The rings were marked pretty well, and I took a lot of time assembling the pistons. I had never seen the "corkscrew" type wristpin holders before. They were a bitch to fit in at first, but after about 10(!), I got the hang of it. Geez....I wonder....

#18

Race Director

#19

Burning Brakes

Member Since: Feb 2014

Location: Cape Neddick Maine

Posts: 1,042

Received 226 Likes

on

148 Posts

2020 C3 of the Year Finalist - Modified

Steve,

how did you stager the end gaps? did you stager them to the piston pin as a manual would state or did you just make sure the gaps didn't line up? Also are they done different for the left and right side banks?

I am not trying to insult you. I don't know your skill level so please don't take it as an insult.

Are you certain the rings didn't move as you installed them?

The rings should break in fairly quick after start up I say one guy one time that put Slick 50 in an engine during break in LOL Thing is it coated the walls and wouldn't let the rings seat.

Another funny one was bored an engine .030 guy did his own assembly and used std rings on it. didn't realize they came miss marked.

how did you stager the end gaps? did you stager them to the piston pin as a manual would state or did you just make sure the gaps didn't line up? Also are they done different for the left and right side banks?

I am not trying to insult you. I don't know your skill level so please don't take it as an insult.

Are you certain the rings didn't move as you installed them?

The rings should break in fairly quick after start up I say one guy one time that put Slick 50 in an engine during break in LOL Thing is it coated the walls and wouldn't let the rings seat.

Another funny one was bored an engine .030 guy did his own assembly and used std rings on it. didn't realize they came miss marked.

#20

Melting Slicks

Thread Starter

Steve,

how did you stager the end gaps? did you stager them to the piston pin as a manual would state or did you just make sure the gaps didn't line up? Also are they done different for the left and right side banks?

Gaps 120 degrees out from each other, with the oil gap aligned with the upper edge of it's conrod.

I am not trying to insult you. I don't know your skill level so please don't take it as an insult.

Don't worry about that! Plenty of mistakes in a 28 year Naval career tend to thicken one's skin my friend.

Don't worry about that! Plenty of mistakes in a 28 year Naval career tend to thicken one's skin my friend.

Are you certain the rings didn't move as you installed them?

Used a standard Ring Compressor Sleeve, with the Allen handle. I'd suppose they could move a little. Flooded with engine oil, covered the rod's studs with rubber hose, aligned the block in the stand for a straight down shot to the crank, tapped into place, that's about it.

The rings should break in fairly quick after start up I say one guy one time that put Slick 50 in an engine during break in LOL Thing is it coated the walls and wouldn't let the rings seat.

Nothin' but Break-in Oil.

Another funny one was bored an engine .030 guy did his own assembly and used std rings on it. didn't realize they came miss marked.

Truthfully, I checked only one ring's end gap: the first one I took out of the package.

how did you stager the end gaps? did you stager them to the piston pin as a manual would state or did you just make sure the gaps didn't line up? Also are they done different for the left and right side banks?

Gaps 120 degrees out from each other, with the oil gap aligned with the upper edge of it's conrod.

I am not trying to insult you. I don't know your skill level so please don't take it as an insult.

Don't worry about that! Plenty of mistakes in a 28 year Naval career tend to thicken one's skin my friend.

Don't worry about that! Plenty of mistakes in a 28 year Naval career tend to thicken one's skin my friend.Are you certain the rings didn't move as you installed them?

Used a standard Ring Compressor Sleeve, with the Allen handle. I'd suppose they could move a little. Flooded with engine oil, covered the rod's studs with rubber hose, aligned the block in the stand for a straight down shot to the crank, tapped into place, that's about it.

The rings should break in fairly quick after start up I say one guy one time that put Slick 50 in an engine during break in LOL Thing is it coated the walls and wouldn't let the rings seat.

Nothin' but Break-in Oil.

Another funny one was bored an engine .030 guy did his own assembly and used std rings on it. didn't realize they came miss marked.

Truthfully, I checked only one ring's end gap: the first one I took out of the package.

Thanks for your time and help. Much appreciated.

Steve