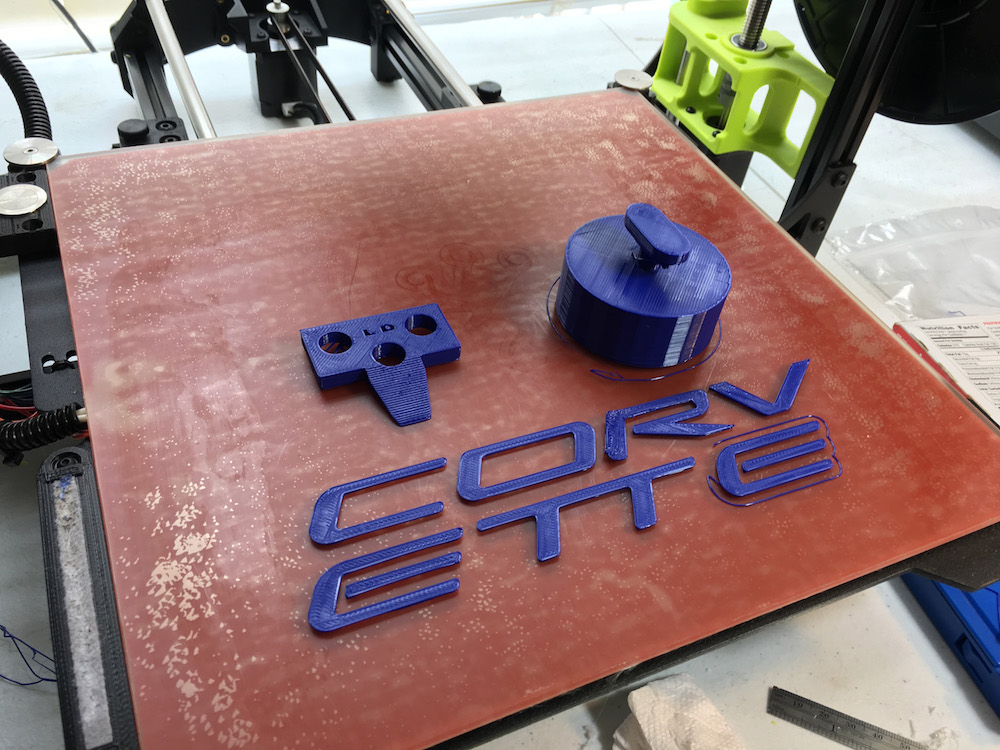

Would You 3D-Print Parts for Your Corvette?

With most carmakers looking into 3D printers for parts manufacturing, we wondered just how difficult it could be.

Remember the first time you heard the words “3D printer?” We do, and we certainly had no idea what the heck it meant. Fast-forward about five years, and the manufacturing world has basically been turned upside down by this nifty creation. Heck, even car- and truck-makers are now beginning to use 3D printers for parts manufacturing.

If you’re not familiar with what an actual 3D printer is, don’t worry because we’ve got you covered. According to this in-depth breakdown of the 3D-printing process, it’s not all that different from a regular ink-and-paper printer. But, instead of ink, it uses a printer head that releases different kinds of plastics while following a preset pattern designated by the user.

CHECK OUT: What Forum Members Are Saying About This Impressive Tech

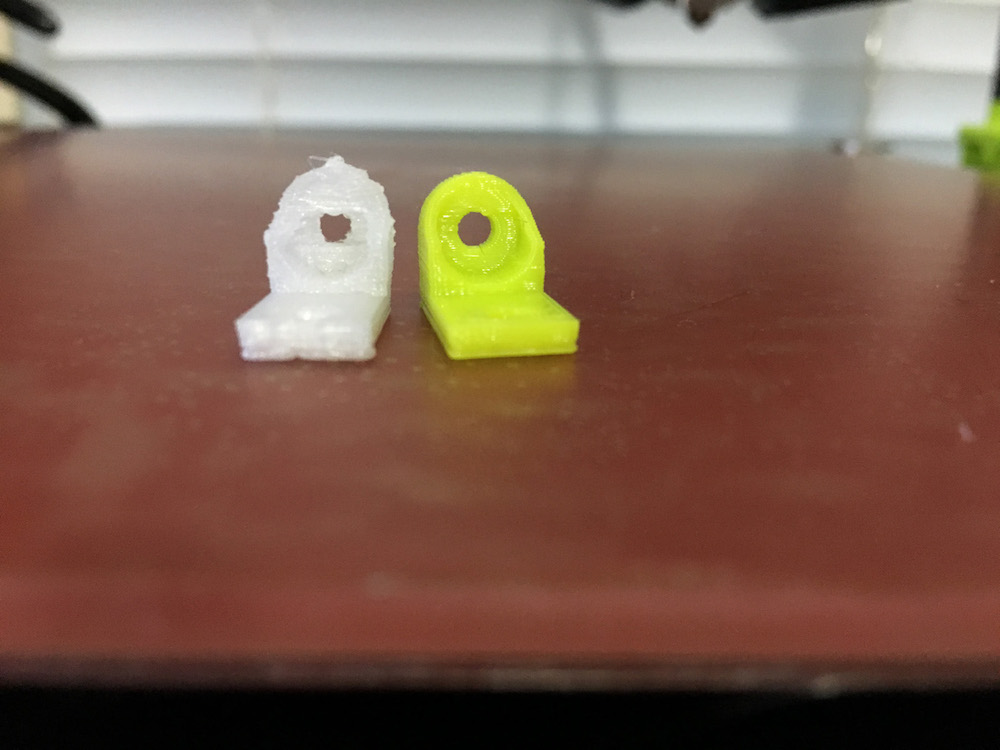

Like all investments, you get what you pay for. A cheap 3D printer with cheap plastic will create mediocre three-dimensional parts. Conversely, a high-end printer with high-quality plastic can create brake ducts worthy of your Corvette Z06. Cool, huh? Another huge benefit of 3D-printing is the cost to manufacture parts. As you can see in these photos, it’s easy to create badges, brake ducts, and even mounting brackets.

Need a part for your vintage ‘Vette? No problem! Don’t pay $300 for that glove box bracket or radio knob, simply turn on your trusty 3D printer and make one yourself!

The future is here, folks.

Via [Ford-Trucks] | Video and photos: [Christian Moe]