My purpose built track car

#21

Burning Brakes

I was wondering what the length is from the front of the engine to the half shafts? My GT40 kit is running a 327 mated to a Corvair trans axle. The 4 speed is strong enough but the spider gears don't last long if you get on it a lot and would never make it as a track setup. I was thinking of going with the Audi 5000 but I'm not sure it's all that much stronger than the Corvair. Your set up look like a good way to go.

Building the car will be as much if not more fun than driving it. Just take your time and don't let any one talk you into taking any short cuts to save time or money. When your done you will have a car that you can be proud to say, I did not buy it I built it.

Dave

Building the car will be as much if not more fun than driving it. Just take your time and don't let any one talk you into taking any short cuts to save time or money. When your done you will have a car that you can be proud to say, I did not buy it I built it.

Dave

Last edited by opel; 11-23-2007 at 02:30 AM.

#22

Drifting

Thread Starter

Holly smokes! You got some ***** (Big Block/*****) to start from scratch. Your setup is very similar to the Mongoose GTP kit car. Aaron Quinne has one built and I wondered why he went with the slush box, now I know.

Your reference to the cost of the Porsche transaxle makes me believe you've explored the factoryfive GTM alternative.

What body do you plan to use, target weight?

You will find hundreds of questions popping up should you decide to post your build progress. You my friend started out on a true life experience. I hope you'll have enough patience and persistance to see this remarkable project to its completion.

Both the FF GTM and the GTP are great alternatives, but their cost is nearing a full race car cost. They make you consider Randy's (DRM) race car build offer.

Please keep posting about your progress!

Your reference to the cost of the Porsche transaxle makes me believe you've explored the factoryfive GTM alternative.

What body do you plan to use, target weight?

You will find hundreds of questions popping up should you decide to post your build progress. You my friend started out on a true life experience. I hope you'll have enough patience and persistance to see this remarkable project to its completion.

Both the FF GTM and the GTP are great alternatives, but their cost is nearing a full race car cost. They make you consider Randy's (DRM) race car build offer.

Please keep posting about your progress!

This car is something I have been thinking about building for many years. We designed something very similar during college and I vowed I would build it someday. Finding cars like the GTP and GTM have given me a lot of ideas. Reading through the GT40 forums is where I found most of the information about transaxles. I spend many days searching through their archives trying to find an alternative to the Porsche box. At one point I decided I would just have to spend the money. More internet searching and I found a guy that mated the Vette engine and transaxle combo in a Corvair. That was a large part of making up my mind.

I don't plan on any body; just enough sheetmetal to enclose the cockpit. That may change over time, but my goal right now it to get the car on the track.

My buddies have been kidding me about finishing the project. However, they also come over to help. Seeing responses to my posts is a good way to keep me motivated.

Thanks

Ken

#23

Drifting

Thread Starter

Opel,

The length from the front of the engine to the axle centerline is between 47-48". Probably more importantly, the distance from the rear of the block/front of trans is 26-27". Most of the guys at the GT40 forum that talked about the combo said it was too long for their kits. The overall length is 54".

If you could use it, the combo is a lot more reliable than the Corvair. It might be close to the same weight because all the cases are aluminum.

I looked at the Audi box, and everyone I talked to said they were good for about 350-400HP at the most. This is after you add the steel mid plate; custome side plate; etc. By the time it's all said and done, it was getting close to the cost of a Porsche box. The Audi's aren't as common as they once were, and that is also driving up the cost. Lots of guys use them, but I didn't feel it would live in constant track use.

I noticed the large diameter tubing in your car. Do you have more pics of the frame? How long have you been driving your car? Also, it looks like the alternator is mounted on the rear of the engine. Do you have pics of that? The car looks good. I assume you have a great time driving it.

Ken

The length from the front of the engine to the axle centerline is between 47-48". Probably more importantly, the distance from the rear of the block/front of trans is 26-27". Most of the guys at the GT40 forum that talked about the combo said it was too long for their kits. The overall length is 54".

If you could use it, the combo is a lot more reliable than the Corvair. It might be close to the same weight because all the cases are aluminum.

I looked at the Audi box, and everyone I talked to said they were good for about 350-400HP at the most. This is after you add the steel mid plate; custome side plate; etc. By the time it's all said and done, it was getting close to the cost of a Porsche box. The Audi's aren't as common as they once were, and that is also driving up the cost. Lots of guys use them, but I didn't feel it would live in constant track use.

I noticed the large diameter tubing in your car. Do you have more pics of the frame? How long have you been driving your car? Also, it looks like the alternator is mounted on the rear of the engine. Do you have pics of that? The car looks good. I assume you have a great time driving it.

Ken

#24

Le Mans Master

The project is big, and it quickly teaches you that you don't know as

much as you thought. I had originally planned on modeling the whole

thing in CAD, and then simply building to the plan. It didn't take very

long to realize I can't model for beans, and it's hard to figure out the "soft" stuff.

much as you thought. I had originally planned on modeling the whole

thing in CAD, and then simply building to the plan. It didn't take very

long to realize I can't model for beans, and it's hard to figure out the "soft" stuff.

Each section has a menu (reverse chronological order) along the top

right of the page. Start at the '?' and read forward in time. Be aware

- there is a lot of material.

DESIGN LOG: (05/26/02 to 02/08/05)

for the full story of the three-year long dp1 design process

PROTOTYPE BUILD LOG: (02/13/05 to 09/18/06)

for details of the year and a half that it took to get it built.

PROTOTYPE TEST LOG: (09/24/06 to present)

Thanks for posting. All the best as you move towards completion.for the full story of the three-year long dp1 design process

PROTOTYPE BUILD LOG: (02/13/05 to 09/18/06)

for details of the year and a half that it took to get it built.

PROTOTYPE TEST LOG: (09/24/06 to present)

Ken R.

.

#27

Tech Contributor

Member Since: Jun 2004

Location: I tend to be leery of any guy who doesn't own a chainsaw or a handgun.

Posts: 18,367

Received 771 Likes

on

553 Posts

I now understand what you were saying about the manual box shifter linkage. I was at a swap meet today, and someone was selling a C5 roller with a manual trans. That is a long gearbox setup, along with the inconvenient location of the linkage. Even if the linkage could be rectified with a housing change/modification, the length of the transaxle when a bellhousing is added would probably still be unacceptable. Oh well, if it was easy, it wouldn't be as much fun.

Keep us posted!

Keep us posted!

#28

Drifting

Thread Starter

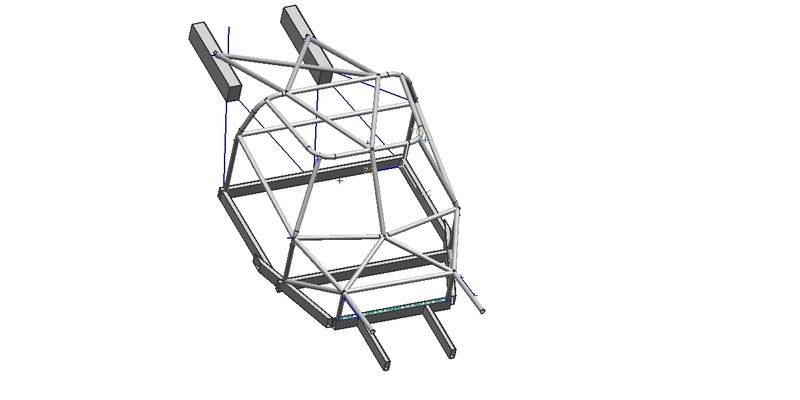

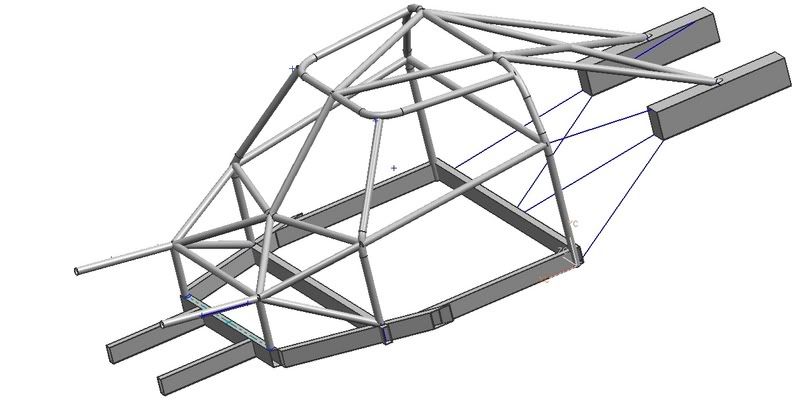

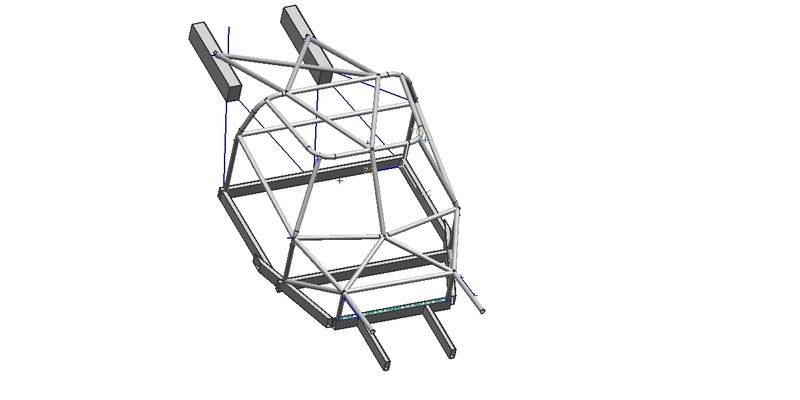

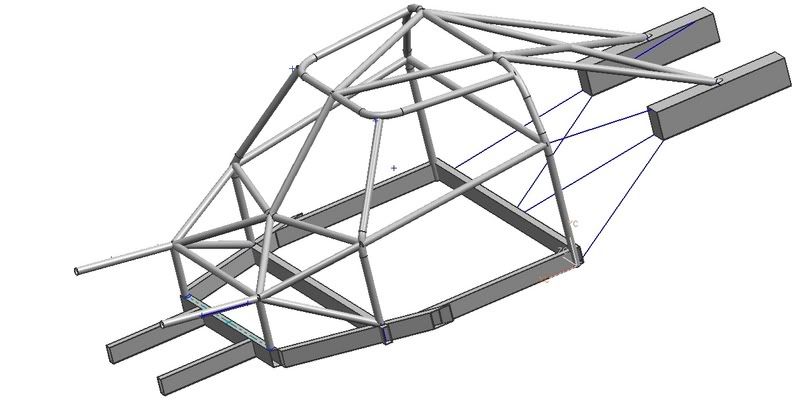

I finally have some more CAD pics of the chassis. Right now, I am doing some research trying to figure out the most efficient use of tubing. When I say efficient, I want the chassis to be as stiff as possible, especially in torsion, for the lightest weight. The nice thing about US is it calculates the weight of the frame so I can keep track of how much the extra tubes are adding.

I found a link to a SAE paper on increasing the torsional stiffness of a NASCAR Cup car. It was done almost 10 years ago, but it's still relevant. When I read through the article, I realized the Cup car chassis is very similar to what I am designing. The paper analyzes every change they make for added stiffness and weight. It is serving as a great guide for me. Here is the link for anyone interested: http://www.ces.clemson.edu/%7Elonny/.../sae983053.pdf

And, here are some pics of where I stand right now:

In this configuration, the chassis weighs 173 lbs. I still need to add all the tubes connecting the main cockpit to the rear subframe; the side impact protection tubing; bracing for the front suspension area; cross-bracing for the lower frame rails in the cockpit; and the sheetmetal. I plan to make a single piece sheetmetal floor as well as front and rear firewalls. In addition to this, I am planning on bonding/welding sheetmetal between key tubes to make some vertical shear panels. From my research, these should add a fair amount of stiffness. I will try and get some pics of that this weekend. All that extra bracing and sheetmetal should get the chassis at about 275 lbs.

On the side, I started making a balsa wood model of the chassis. I did this because I don't know how to use the FEA package on UG. It didn't take long to realize it will probably be easier to learn to use the FEA. So, that's what I am doing. It might take a while, but it will allow me to try a lot more ideas. The wife will be happy too, because there won't be balsa wood and glue all over the kitchen table.

I found a link to a SAE paper on increasing the torsional stiffness of a NASCAR Cup car. It was done almost 10 years ago, but it's still relevant. When I read through the article, I realized the Cup car chassis is very similar to what I am designing. The paper analyzes every change they make for added stiffness and weight. It is serving as a great guide for me. Here is the link for anyone interested: http://www.ces.clemson.edu/%7Elonny/.../sae983053.pdf

And, here are some pics of where I stand right now:

In this configuration, the chassis weighs 173 lbs. I still need to add all the tubes connecting the main cockpit to the rear subframe; the side impact protection tubing; bracing for the front suspension area; cross-bracing for the lower frame rails in the cockpit; and the sheetmetal. I plan to make a single piece sheetmetal floor as well as front and rear firewalls. In addition to this, I am planning on bonding/welding sheetmetal between key tubes to make some vertical shear panels. From my research, these should add a fair amount of stiffness. I will try and get some pics of that this weekend. All that extra bracing and sheetmetal should get the chassis at about 275 lbs.

On the side, I started making a balsa wood model of the chassis. I did this because I don't know how to use the FEA package on UG. It didn't take long to realize it will probably be easier to learn to use the FEA. So, that's what I am doing. It might take a while, but it will allow me to try a lot more ideas. The wife will be happy too, because there won't be balsa wood and glue all over the kitchen table.

#29

Megasquirt are currently testing a 4L60E transmission controller. By the time my car is ready, I expect the code and hardware will be available and fully tested. I plan to combine this with paddle shifters to have complete control over the auto.

I've learned a lot in going from a stock '99 a4 trans, to a rebuilt RPM unit with a shift kit and a torque converter with a slightly higher stall. The behavior is quite different. I would love to transmission talk with you some day...

There is still a ton of stuff that I don't have figured out with the transmission yet... but I'm learning.

#30

Drifting

Thread Starter

To be honest, my knowledge of automatic transmissions is not that great. We make a lot of parts for automatics here at work, so that has helped me understand how they work internally. However, I am not even close to being an expert. I am going with the automatic because I chose not to spend the big bucks on a Porsche transaxle.

As for the Megasquirt, here are some quotes of what the trans controller will be able to do:

"The code has two shift modes and a manual mode, full shift speed programmability, full line pressure control, manual shifts via 'paddle' shifters, TCC control, a speedo (tested 0-250 mph), trip odometer (to 0.001 mile resolution), and a user-specified pulse/mile speedo output. Four LEDs indicate the current gear."

This information comes from here: http://www.msefi.com/viewtopic.php?t=29423

Megasquirt refers to a DIY fuel injection system. Over the years, it has grown substantially to include complete engine management. Over the last year or so, the group has been developing a separate piece of hardware that can communicate with the Megasquirt ECU. This piece of hardware, the GPIO (for general purpose inputs and outputs) simply takes extra inputs, talks with the ECU, and sends outputs based on the software installed. One of the main pieces of software being developed is a transmission controller. The 4L60E and 4L80E are the first transmissions to be controlled. The testing is just now heating up.

The system will be able to take inputs from electric switches to signal a gear change. I plan to use this product: http://www.twistmachine.com/products/shrifter.html as the inputs to the trans controller while on track.

I figure I will start with a stock trans and see how it works with the MS controller. I will then update as necessary.

Ken

As for the Megasquirt, here are some quotes of what the trans controller will be able to do:

"The code has two shift modes and a manual mode, full shift speed programmability, full line pressure control, manual shifts via 'paddle' shifters, TCC control, a speedo (tested 0-250 mph), trip odometer (to 0.001 mile resolution), and a user-specified pulse/mile speedo output. Four LEDs indicate the current gear."

This information comes from here: http://www.msefi.com/viewtopic.php?t=29423

Megasquirt refers to a DIY fuel injection system. Over the years, it has grown substantially to include complete engine management. Over the last year or so, the group has been developing a separate piece of hardware that can communicate with the Megasquirt ECU. This piece of hardware, the GPIO (for general purpose inputs and outputs) simply takes extra inputs, talks with the ECU, and sends outputs based on the software installed. One of the main pieces of software being developed is a transmission controller. The 4L60E and 4L80E are the first transmissions to be controlled. The testing is just now heating up.

The system will be able to take inputs from electric switches to signal a gear change. I plan to use this product: http://www.twistmachine.com/products/shrifter.html as the inputs to the trans controller while on track.

I figure I will start with a stock trans and see how it works with the MS controller. I will then update as necessary.

Ken

#32

Former Vendor

To be honest, my knowledge of automatic transmissions is not that great. We make a lot of parts for automatics here at work, so that has helped me understand how they work internally. However, I am not even close to being an expert. I am going with the automatic because I chose not to spend the big bucks on a Porsche transaxle.

As for the Megasquirt, here are some quotes of what the trans controller will be able to do:

"The code has two shift modes and a manual mode, full shift speed programmability, full line pressure control, manual shifts via 'paddle' shifters, TCC control, a speedo (tested 0-250 mph), trip odometer (to 0.001 mile resolution), and a user-specified pulse/mile speedo output. Four LEDs indicate the current gear."

This information comes from here: http://www.msefi.com/viewtopic.php?t=29423

Megasquirt refers to a DIY fuel injection system. Over the years, it has grown substantially to include complete engine management. Over the last year or so, the group has been developing a separate piece of hardware that can communicate with the Megasquirt ECU. This piece of hardware, the GPIO (for general purpose inputs and outputs) simply takes extra inputs, talks with the ECU, and sends outputs based on the software installed. One of the main pieces of software being developed is a transmission controller. The 4L60E and 4L80E are the first transmissions to be controlled. The testing is just now heating up.

The system will be able to take inputs from electric switches to signal a gear change. I plan to use this product: http://www.twistmachine.com/products/shrifter.html as the inputs to the trans controller while on track.

I figure I will start with a stock trans and see how it works with the MS controller. I will then update as necessary.

Ken

As for the Megasquirt, here are some quotes of what the trans controller will be able to do:

"The code has two shift modes and a manual mode, full shift speed programmability, full line pressure control, manual shifts via 'paddle' shifters, TCC control, a speedo (tested 0-250 mph), trip odometer (to 0.001 mile resolution), and a user-specified pulse/mile speedo output. Four LEDs indicate the current gear."

This information comes from here: http://www.msefi.com/viewtopic.php?t=29423

Megasquirt refers to a DIY fuel injection system. Over the years, it has grown substantially to include complete engine management. Over the last year or so, the group has been developing a separate piece of hardware that can communicate with the Megasquirt ECU. This piece of hardware, the GPIO (for general purpose inputs and outputs) simply takes extra inputs, talks with the ECU, and sends outputs based on the software installed. One of the main pieces of software being developed is a transmission controller. The 4L60E and 4L80E are the first transmissions to be controlled. The testing is just now heating up.

The system will be able to take inputs from electric switches to signal a gear change. I plan to use this product: http://www.twistmachine.com/products/shrifter.html as the inputs to the trans controller while on track.

I figure I will start with a stock trans and see how it works with the MS controller. I will then update as necessary.

Ken

Hey Ken,

Your project looks like it may take a long time to build and get figured out. Why use Megasquirt? I know about 5 people running the Megasquirt and about half of them are happy with the results.

I can have a engine like yours running in a afternoon using a aftermarket harness, and factory ECU. Just a idea!

Randy

#33

Drifting

Thread Starter

Randy,

Thanks for the offer. I am actually running a Megasquirt on my 69 right now. It is controlling the fuel, as well as distributorless ignition and the electric fans. I have been very happy with Megasquirt. I must say that figuring out how to use it and tune it is part of the enjoyment for me as well. The biggest reason I like the MS is that it's always growing. People are always coming out with new applications; everything from boost control, traction control, data logging, electronic gages, etc. The transmission controller is another huge plus for me. The MS computer and trans controller will cost me less than $500. An aftermarker trans controller alone will cost close to $700.

I know some people have had issues with MS. On the other hand, my dad is what I consider to be a fuel injection expert. I say that, because he designed and built his own system from scratch. I don't mean he bought someone else's computer and assembled a system. He designed the computer, built it, and wrote all the lanquage. After years of running that, he has finally switched to the MS because he has installed several of them and seen how well they can work.

I also have a friend that tunes professionally who will probably help me get the maps dialed in. Don't take it the wrong way, from everything I've seen, you guys do great work. I am just trying to explain why I am going the way I am.

Thanks again for the offer.

Ken

Thanks for the offer. I am actually running a Megasquirt on my 69 right now. It is controlling the fuel, as well as distributorless ignition and the electric fans. I have been very happy with Megasquirt. I must say that figuring out how to use it and tune it is part of the enjoyment for me as well. The biggest reason I like the MS is that it's always growing. People are always coming out with new applications; everything from boost control, traction control, data logging, electronic gages, etc. The transmission controller is another huge plus for me. The MS computer and trans controller will cost me less than $500. An aftermarker trans controller alone will cost close to $700.

I know some people have had issues with MS. On the other hand, my dad is what I consider to be a fuel injection expert. I say that, because he designed and built his own system from scratch. I don't mean he bought someone else's computer and assembled a system. He designed the computer, built it, and wrote all the lanquage. After years of running that, he has finally switched to the MS because he has installed several of them and seen how well they can work.

I also have a friend that tunes professionally who will probably help me get the maps dialed in. Don't take it the wrong way, from everything I've seen, you guys do great work. I am just trying to explain why I am going the way I am.

Thanks again for the offer.

Ken

Last edited by bb69; 12-05-2007 at 08:40 PM.

#34

Tech Contributor

Member Since: Jun 2004

Location: I tend to be leery of any guy who doesn't own a chainsaw or a handgun.

Posts: 18,367

Received 771 Likes

on

553 Posts

Ken,

I'm enjoying your project updates. Custom projects have always been my favorites. If I may ask a favor, I'd be interested in details about your '69 and the injection system also. Prior to retirement a couple years ago I designed ECMs and PCMs (for a company you've probably heard of ). I spend most of my free time these days on mechanical projects, but I'm still interested in what other enthusiasts are doing on the electronics side.

). I spend most of my free time these days on mechanical projects, but I'm still interested in what other enthusiasts are doing on the electronics side.

thanks,

Mike

I'm enjoying your project updates. Custom projects have always been my favorites. If I may ask a favor, I'd be interested in details about your '69 and the injection system also. Prior to retirement a couple years ago I designed ECMs and PCMs (for a company you've probably heard of

). I spend most of my free time these days on mechanical projects, but I'm still interested in what other enthusiasts are doing on the electronics side.

). I spend most of my free time these days on mechanical projects, but I'm still interested in what other enthusiasts are doing on the electronics side.

thanks,

Mike

#36

Drifting

Thread Starter

Ken,

I'm enjoying your project updates. Custom projects have always been my favorites. If I may ask a favor, I'd be interested in details about your '69 and the injection system also. Prior to retirement a couple years ago I designed ECMs and PCMs (for a company you've probably heard of ). I spend most of my free time these days on mechanical projects, but I'm still interested in what other enthusiasts are doing on the electronics side.

). I spend most of my free time these days on mechanical projects, but I'm still interested in what other enthusiasts are doing on the electronics side.

thanks,

Mike

I'm enjoying your project updates. Custom projects have always been my favorites. If I may ask a favor, I'd be interested in details about your '69 and the injection system also. Prior to retirement a couple years ago I designed ECMs and PCMs (for a company you've probably heard of

). I spend most of my free time these days on mechanical projects, but I'm still interested in what other enthusiasts are doing on the electronics side.

). I spend most of my free time these days on mechanical projects, but I'm still interested in what other enthusiasts are doing on the electronics side.

thanks,

Mike

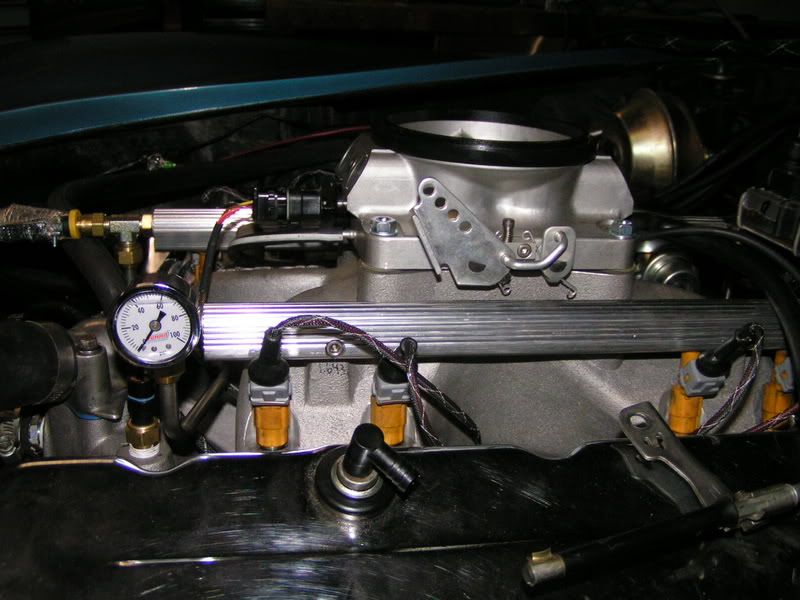

Here are some pics from the 69. I used the intake and fuel rails from the Holley kit. The throttle body came from an older system, called Air Sensors. They are sold by a small company called Auto-Nomics. I bought my fuel pump and wiring harness from them as well. The ignition is all Ford EDIS parts. A friend made a tooth wheel that I bolted to the front crank pulley. It has the same tooth count as the original Ford wheel. The MS computer gets the engine position information from the tooth wheel via the EDIS module. The EDIS module controls the charging of the coils, and the MS computer simply sends the EDIS module a signal telling it when to fire. I have 12x12 tables for VE, A/F ratio, and spark advance. With the use of a wideband, the system has the ability to self tune the VE table to match the values you have put in for the A/F table. I got the system installed at the beginning of this year. It took me a while to realize my injectors were too small. I have just recently put in larger injectors and starting the tuning process over. I've learned a lot during the process, and anyone that does it will appreciate the skill professional tuners have.

Here is a thread from the C3 tech session I created when I got it installed:

http://forums.corvetteforum.com/show...egasquirt+edis

Thanks for the interest guys.

Ken

#37

Drifting

Thread Starter

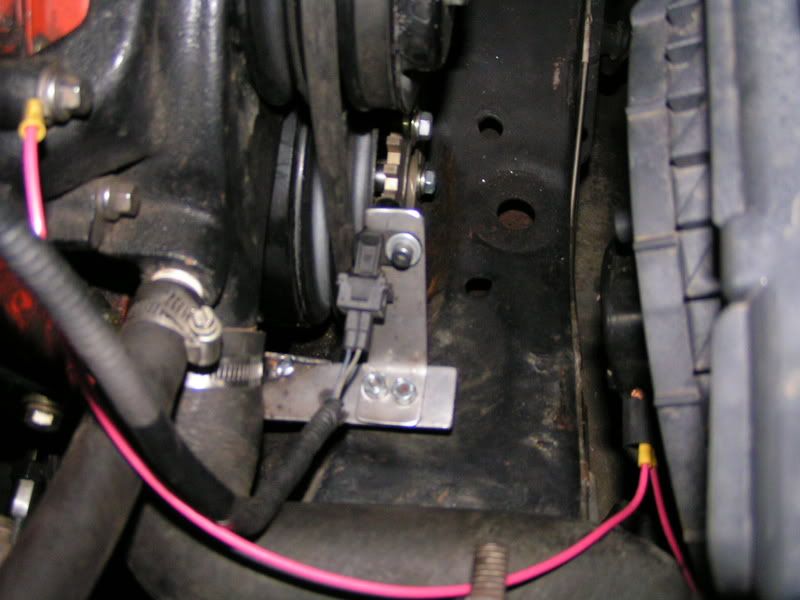

Happy New Year to everyone. I used the new year as motivation to make some progress on the car. The two weeks previous to that were spent relaxing with family and friends. Now, it’s time to get back on track. Yesterday, I got two big things done. First, I moved the engine back about an inch on the motor mounts. The engine was just too close to the seat. I could have simply moved the seat further forward, but every time I move the seat forward, I reduce the legroom and the amount of room available to climb into the seat. Below, you can see the revised mounts. It wasn’t that much work, but I tossed the idea around in my head for a long time.

The other major accomplishment was connecting the rear frame rail sections with the rest of the car. Once I made the decision to move the engine back, I figured I was all set to start connecting the pieces. I had a lot of plans to tie down the rear suspension and make sure it was all square to within millimeters. Then, I realized that GM doesn’t get it that close, and the main goal of this project is to actually get something on the track. So, I checked the rear frame rails to make sure they were straight and level, and started welding. I still have to attach the frame rails in a few more places, but at least now they don’t move too much. I will continue to check the position of the rear suspension as I add the other connections.

A problem I was facing was how to attach the rear down bars to the frame rails. My chop saw would not cut the sharp angle easily. I had some cutoff pieces of rectangular tubing available, so I used them to mount the down bars. I still need to add some reinforcement, but I think it came out well.

The Harbor Freight tubing notcher continues to do good work.

With this done, I am now out of tubing. It’s time to head for the store and order some more so I can finish the rear section and start working on mounting the front suspension. While I am waiting on the tubing, I will try to get some more work done on the CAD model and FEA. I need to update the CAD model to reflect these down tubes as they are in a slightly different position.

The other major accomplishment was connecting the rear frame rail sections with the rest of the car. Once I made the decision to move the engine back, I figured I was all set to start connecting the pieces. I had a lot of plans to tie down the rear suspension and make sure it was all square to within millimeters. Then, I realized that GM doesn’t get it that close, and the main goal of this project is to actually get something on the track. So, I checked the rear frame rails to make sure they were straight and level, and started welding. I still have to attach the frame rails in a few more places, but at least now they don’t move too much. I will continue to check the position of the rear suspension as I add the other connections.

A problem I was facing was how to attach the rear down bars to the frame rails. My chop saw would not cut the sharp angle easily. I had some cutoff pieces of rectangular tubing available, so I used them to mount the down bars. I still need to add some reinforcement, but I think it came out well.

The Harbor Freight tubing notcher continues to do good work.

With this done, I am now out of tubing. It’s time to head for the store and order some more so I can finish the rear section and start working on mounting the front suspension. While I am waiting on the tubing, I will try to get some more work done on the CAD model and FEA. I need to update the CAD model to reflect these down tubes as they are in a slightly different position.

Last edited by bb69; 01-02-2008 at 09:41 AM.

#38

Tech Contributor

Member Since: Jun 2004

Location: I tend to be leery of any guy who doesn't own a chainsaw or a handgun.

Posts: 18,367

Received 771 Likes

on

553 Posts

Keep us updated.

#40

Drifting

Thread Starter

69427,

That's a good point about the tolerances on the frame drawings. My guess is that there are some pretty big stackups by the time the frame is assembled and welded. All the holes and mounting points in the rails and body mounts were probably punched before the frame was welded together. Today's cars are a lot better in most areas (many cars have no built in adjustment for the suspension), but the C5 rear suspension crossmember bolts in with 4 bolts. There are 2 locating pins, but I was surprised at the clearance between those pins and their mating holes. I could easily shift the crossmember a few millimeters just by loosening the bolts. I guess I will find out how good/bad my fab skills are when I take the car to be aligned the first time.

Ken