C1 dual master cylinder

#41

Race Director

Member Since: Jun 2006

Location: Inverness FL

Posts: 17,891

Received 727 Likes

on

621 Posts

St. Jude Donor '07

Charles

as there is no boot boss/large boot on the end on the Mopar MC to center the MC in the firewall hole like the OEM, do you think that it might be possible to raise the mounting holes on the flange (and thereby lower the centerline of the piston a bit), and thereby making the mounting nuts a bit more accessible.

i realize the pushrod needs a 'fairly straight' shot at the back of the piston, but by the nature of the pedal movement, there has to be a bit of misalignment due to the eccentric arc of the pedal swing where the pushrod attaches to the pedal linkage; maybe a little more or less wouldn't matter...

Bill

BTW, if i had to remove the MC mounting studs from the pedal assembly and bolt the MC on from behind, i would be tempted to thread the holes on the MC flange rather than use nuts (yep, the benefit of hindsight on seeing your problem.. lol)

as there is no boot boss/large boot on the end on the Mopar MC to center the MC in the firewall hole like the OEM, do you think that it might be possible to raise the mounting holes on the flange (and thereby lower the centerline of the piston a bit), and thereby making the mounting nuts a bit more accessible.

i realize the pushrod needs a 'fairly straight' shot at the back of the piston, but by the nature of the pedal movement, there has to be a bit of misalignment due to the eccentric arc of the pedal swing where the pushrod attaches to the pedal linkage; maybe a little more or less wouldn't matter...

Bill

BTW, if i had to remove the MC mounting studs from the pedal assembly and bolt the MC on from behind, i would be tempted to thread the holes on the MC flange rather than use nuts (yep, the benefit of hindsight on seeing your problem.. lol)

Last edited by wmf62; 11-14-2008 at 02:39 PM.

#42

Safety Car

Charles

as there is no boot boss/large boot on the end on the Mopar MC to center the MC in the firewall hole like the OEM, do you think that it might be possible to raise the mounting holes on the flange (and thereby lower the centerline of the piston a bit), and thereby making the mounting nuts a bit more accessible.

as there is no boot boss/large boot on the end on the Mopar MC to center the MC in the firewall hole like the OEM, do you think that it might be possible to raise the mounting holes on the flange (and thereby lower the centerline of the piston a bit), and thereby making the mounting nuts a bit more accessible.

Charles

#43

Race Director

Member Since: Jun 2006

Location: Inverness FL

Posts: 17,891

Received 727 Likes

on

621 Posts

St. Jude Donor '07

I made a new pushrod

You could raise the mounting holes some, but then you can't get to the bottom one. Besides, if you move it up/down too much you might have a problem with the pushrod binding on the inside of the MC piston, unless you angled the body of the MC to make it line up, but that might cause other problems.

I'm not sure what material my MC is cast from, but I don't think I would trust threaded holes. The material seems rather soft (compared with cast iron) and I would be afraid of stripping a threaded hole.

Charles

You could raise the mounting holes some, but then you can't get to the bottom one. Besides, if you move it up/down too much you might have a problem with the pushrod binding on the inside of the MC piston, unless you angled the body of the MC to make it line up, but that might cause other problems.

I'm not sure what material my MC is cast from, but I don't think I would trust threaded holes. The material seems rather soft (compared with cast iron) and I would be afraid of stripping a threaded hole.

Charles

thank you VERY much.. do you have a sketch of the part(s) you had to make for your new push rod, or could you dimension your picture with those dimensions like you annotated your other pix? it would help prevent reinventing the wheel... please...

as to the threads.. the line connects are threaded, so the material is capable of being threaded; and the threads could always be drilled out and a nut/bolt substituted.

thanks again...

Bill

Last edited by wmf62; 11-14-2008 at 08:55 PM.

#45

Race Director

Member Since: Jun 2006

Location: Inverness FL

Posts: 17,891

Received 727 Likes

on

621 Posts

St. Jude Donor '07

. the first one i got wasn't right, and i finally ordered one that is part # 101323M (the 'M' one is different from the 101323 NAPA # that Charles listed) and it looks like the one in Charles' last pix. cost me a discounted price of approx $23 plus a $10 core charge...

. the first one i got wasn't right, and i finally ordered one that is part # 101323M (the 'M' one is different from the 101323 NAPA # that Charles listed) and it looks like the one in Charles' last pix. cost me a discounted price of approx $23 plus a $10 core charge...and, i just found out that i had to get adapter fittings to match the brake lines to the MC... another $12

Bill

Last edited by wmf62; 11-15-2008 at 10:43 AM.

#46

Race Director

Member Since: Nov 2000

Location: Beverly Hills (Pine Ridge) Florida

Posts: 10,152

Received 525 Likes

on

374 Posts

FWIW, when i bought mine there were about 4 different interchangeable MCs listed for the same application (1967 Satellite) and all of them looked different...  . the first one i got wasn't right, and i finally ordered one that is part # 101323M (the 'M' one is different from the 101323) and it looks like the one in Charles' pix. cost me a discounted price of approx $23 plus a $10 core charge...

. the first one i got wasn't right, and i finally ordered one that is part # 101323M (the 'M' one is different from the 101323) and it looks like the one in Charles' pix. cost me a discounted price of approx $23 plus a $10 core charge...

and, i just found out that i had to get adapter fittings to match the brake lines to the MC... another $12

Bill

. the first one i got wasn't right, and i finally ordered one that is part # 101323M (the 'M' one is different from the 101323) and it looks like the one in Charles' pix. cost me a discounted price of approx $23 plus a $10 core charge...

. the first one i got wasn't right, and i finally ordered one that is part # 101323M (the 'M' one is different from the 101323) and it looks like the one in Charles' pix. cost me a discounted price of approx $23 plus a $10 core charge...and, i just found out that i had to get adapter fittings to match the brake lines to the MC... another $12

Bill

Plasticman

#48

Race Director

Member Since: Jun 2006

Location: Inverness FL

Posts: 17,891

Received 727 Likes

on

621 Posts

St. Jude Donor '07

Charles

one more question to add to the others i've asked...

are the MC mounting studs that project through the firewall from the pedal frame welded or press-fit into the pedal frame?

Bill

one more question to add to the others i've asked...

are the MC mounting studs that project through the firewall from the pedal frame welded or press-fit into the pedal frame?

Bill

#49

Safety Car

Charles

thank you VERY much.. do you have a sketch of the part(s) you had to make for your new push rod, or could you dimension your picture with those dimensions like you annotated your other pix? it would help prevent reinventing the wheel... please...

as to the threads.. the line connects are threaded, so the material is capable of being threaded; and the threads could always be drilled out and a nut/bolt substituted.

thanks again...

Bill

thank you VERY much.. do you have a sketch of the part(s) you had to make for your new push rod, or could you dimension your picture with those dimensions like you annotated your other pix? it would help prevent reinventing the wheel... please...

as to the threads.. the line connects are threaded, so the material is capable of being threaded; and the threads could always be drilled out and a nut/bolt substituted.

thanks again...

Bill

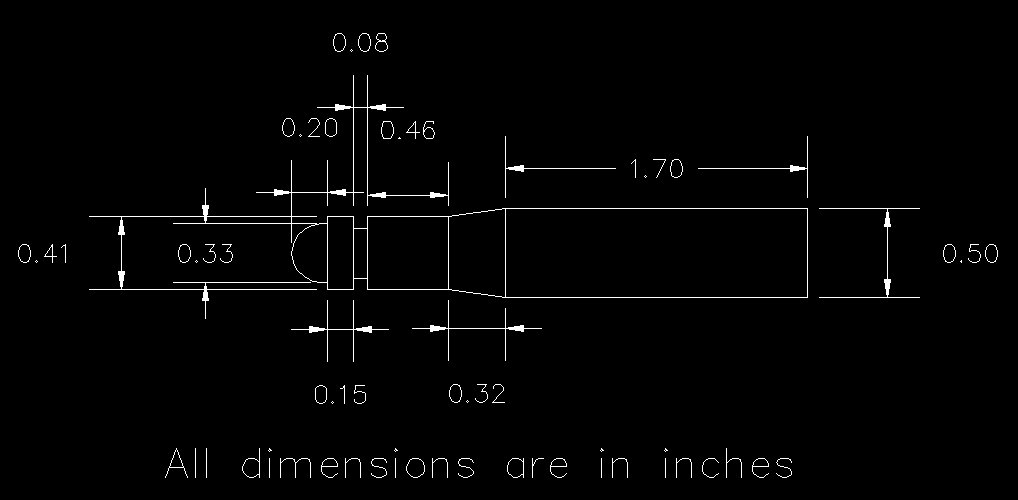

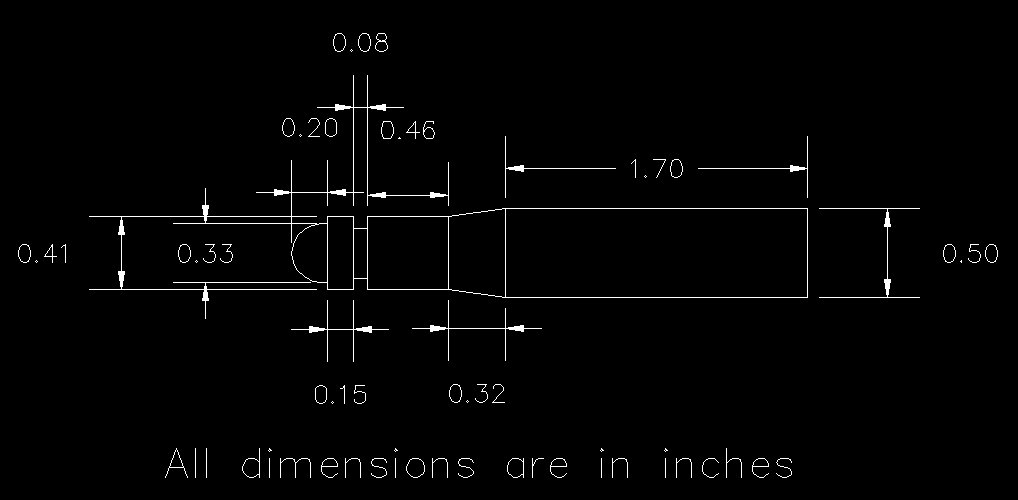

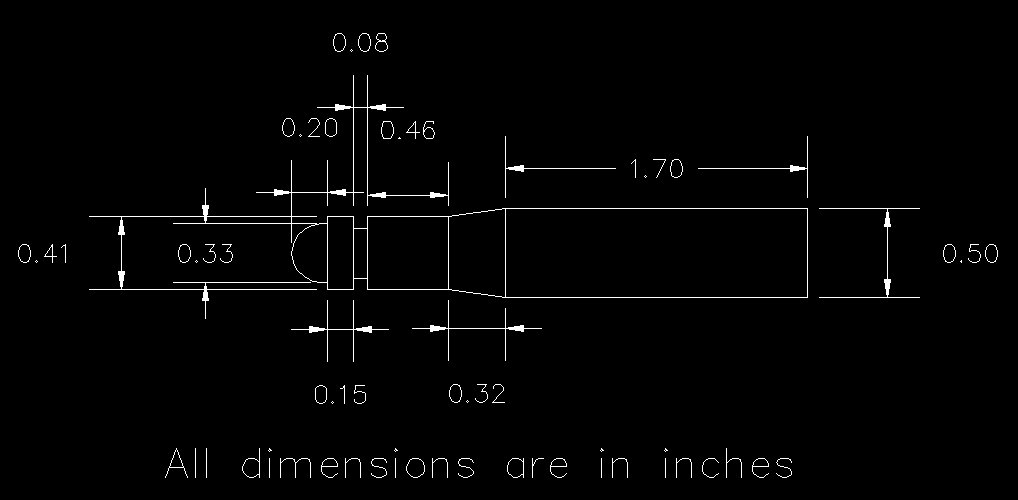

Here is a sketch. I just "eyeballed" the thing when I was machining it, really didn't measure anything as I was turning it down. I got my MC from NAPA, part number 10-1323M, cost was $28.49 + $17 core. I tried to give the NAPA guy an old VW master cylinder for a core, but unfortunately he opened the box to check it.

Last edited by cbernhardt; 11-15-2008 at 11:59 AM.

#50

Safety Car

Charles

#51

Race Director

Member Since: Jun 2006

Location: Inverness FL

Posts: 17,891

Received 727 Likes

on

621 Posts

St. Jude Donor '07

You are probably correct, the threaded hole should not be a problem.

Here is a sketch. I just "eyeballed" the thing when I was machining it, really didn't measure anything as I was turning it down. I got my MC from NAPA, part number 10-1323M, cost was $28.49 + $17 core. I tried to give the NAPA guy an old VW master cylinder for a core, but unfortunately he opened the box to check it.

Here is a sketch. I just "eyeballed" the thing when I was machining it, really didn't measure anything as I was turning it down. I got my MC from NAPA, part number 10-1323M, cost was $28.49 + $17 core. I tried to give the NAPA guy an old VW master cylinder for a core, but unfortunately he opened the box to check it.

again, THANKS...

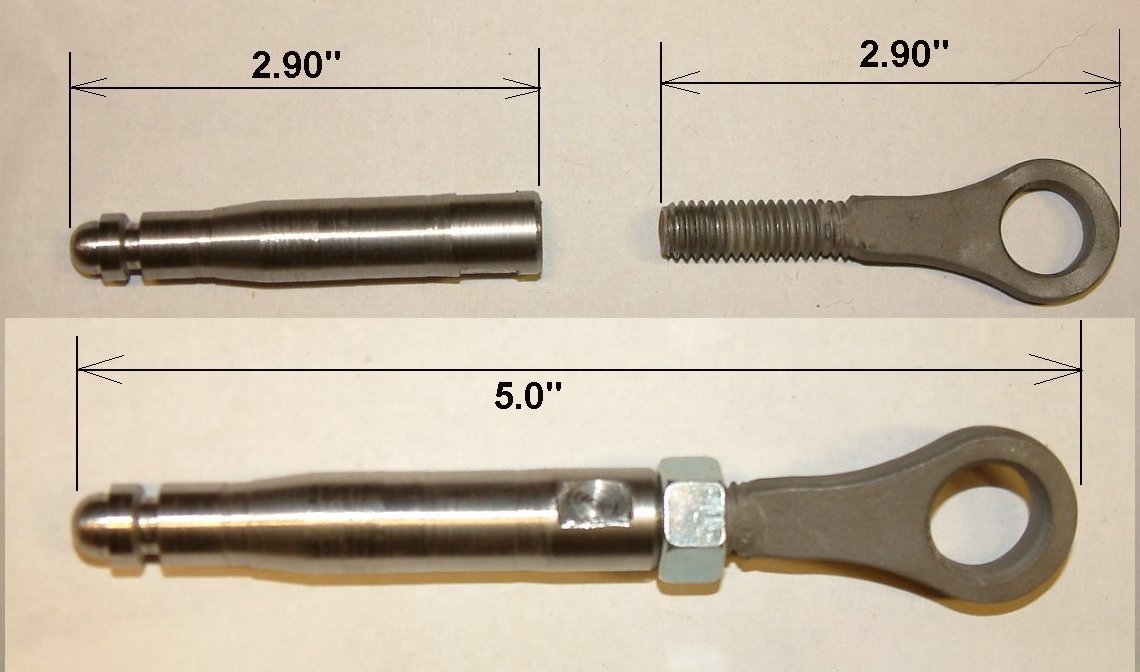

i presume you had to drill and tap the new pushrod piece you fabbed and had to cut and thread the original pushrod so that the 2 pieces can be connected and adjusted for length.

can you give me an idea of the overall length of the assembled new pushrod assembly; AND the overall length of the modified original pushrod?

Bill

BTW, i was able to sneak a different junk MC into the core box, so i saved the core charge... lol

#52

Race Director

Member Since: Jun 2006

Location: Inverness FL

Posts: 17,891

Received 727 Likes

on

621 Posts

St. Jude Donor '07

Jim

did you measure to see if it would fit in the space between the firewall and the aircleaner box? the MC measures an overall flange face-to-end of approx 7-1/2" and it might be a VERY tight fit on my 62.

but i see 2 possible alternatives: 1) move the air cleaner box slightly forward on the fender, or 2) it MIGHT be possible to remove some of the material from the nose of the MC casting as it looks like there is extra material for a provision for putting a line fitting on the nose end. depending on how the MV bore looks on the inside, it MIGHT be possible to remove some of this extra nose material and gain a 1/4" to 1/2".

Charles

what do you think?

Bill

did you measure to see if it would fit in the space between the firewall and the aircleaner box? the MC measures an overall flange face-to-end of approx 7-1/2" and it might be a VERY tight fit on my 62.

but i see 2 possible alternatives: 1) move the air cleaner box slightly forward on the fender, or 2) it MIGHT be possible to remove some of the material from the nose of the MC casting as it looks like there is extra material for a provision for putting a line fitting on the nose end. depending on how the MV bore looks on the inside, it MIGHT be possible to remove some of this extra nose material and gain a 1/4" to 1/2".

Charles

what do you think?

Bill

#53

Safety Car

Jim

did you measure to see if it would fit in the space between the firewall and the aircleaner box? the MC measures an overall flange face-to-end of approx 7-1/2" and it might be a VERY tight fit on my 62.

but i see 2 possible alternatives: 1) move the air cleaner box slightly forward on the fender, or 2) it MIGHT be possible to remove some of the material from the nose of the MC casting as it looks like there is extra material for a provision for putting a line fitting on the nose end. depending on how the MV bore looks on the inside, it MIGHT be possible to remove some of this extra nose material and gain a 1/4" to 1/2".

Charles

what do you think?Bill

did you measure to see if it would fit in the space between the firewall and the aircleaner box? the MC measures an overall flange face-to-end of approx 7-1/2" and it might be a VERY tight fit on my 62.

but i see 2 possible alternatives: 1) move the air cleaner box slightly forward on the fender, or 2) it MIGHT be possible to remove some of the material from the nose of the MC casting as it looks like there is extra material for a provision for putting a line fitting on the nose end. depending on how the MV bore looks on the inside, it MIGHT be possible to remove some of this extra nose material and gain a 1/4" to 1/2".

Charles

what do you think?Bill

Charles

again, THANKS...

i presume you had to drill and tap the new pushrod piece you fabbed and had to cut and thread the original pushrod so that the 2 pieces can be connected and adjusted for length.

can you give me an idea of the overall length of the assembled new pushrod assembly; AND the overall length of the modified original pushrod?

Bill

again, THANKS...

i presume you had to drill and tap the new pushrod piece you fabbed and had to cut and thread the original pushrod so that the 2 pieces can be connected and adjusted for length.

can you give me an idea of the overall length of the assembled new pushrod assembly; AND the overall length of the modified original pushrod?

Bill

#54

Race Director

Member Since: Jun 2006

Location: Inverness FL

Posts: 17,891

Received 727 Likes

on

621 Posts

St. Jude Donor '07

Charles

to paraphrase Charles Schultz... 'You're a Good Man, Charles Bernhardt'. thanks..

now it will be interesting to see what Jim Lockwood has to say about his fit

Bill

#56

Race Director

Member Since: Feb 2007

Location: northern california

Posts: 13,613

Received 6,530 Likes

on

3,004 Posts

C2 of Year Finalist (track prepared) 2019

My car's air cleaner is located by the original, factory, molded in nut-plate, so I'm not real excited about drilling new holes.

Anyway, here's what I found:

Compare the less-than-four-inch clearance here to the 4.25" minimum needed, as shown in one of Charles' earlier postings.

Jim

Last edited by jim lockwood; 11-16-2008 at 03:11 PM.

#57

Race Director

Member Since: Jun 2006

Location: Inverness FL

Posts: 17,891

Received 727 Likes

on

621 Posts

St. Jude Donor '07

Bill, it's not encouraging. To fit the Mopar master cylinder on a fuelie, you would have to relocate the air cleaner forward an inch or more, preferably more. However, about an inch is all the additional room available due to the contour of the fender in the vicinity of the lower air cleaner mount.

My car's air cleaner is located by the original, factory, molded in nut-plate, so I'm not real excited about drilling new holes.

Anyway, here's what I found:

Compare the less-than-four-inch clearance here to the 4.25" minimum needed, as shown in one of Charles' earlier postings.

Jim

My car's air cleaner is located by the original, factory, molded in nut-plate, so I'm not real excited about drilling new holes.

Anyway, here's what I found:

Compare the less-than-four-inch clearance here to the 4.25" minimum needed, as shown in one of Charles' earlier postings.

Jim

it's hard to really tell for sure with the MC still in place because the centerline of the end curve of the filter box is a bit lower than the bottom centerline of the MC; so, the actual interference point might be higher (and therefore longer) than what is seen by sighting down from the ruler. BUT, it is close.... VERY close....

i cut a piece of paint paddle approx 7-1/2" long and placed it as low as i could alongside the MC, between the firewall mounting point of the orig MC and the filter box:

as you can see, it is a tight fit, BUT i may be able to trim a portion off the nose end of the Mopar MC and make it clear, and/or i could still move the filter box forward a bit (which i really don't want to do either). AND/OR, using Charles' idea of a shim between the MC and the firewall, make the shim a bit wedge-shaped and tip the forward end of the MC up a bit if the liquid level in the MC reservoir would permit it (there is a bit of a rake to these cars and the fluid may not be level in the MC now).... AND/OR raise the whole MC a bit at its mounting point at the firewall and thereby raise the end of the MC higher on the filter box end curve

Bill

Last edited by wmf62; 11-16-2008 at 03:54 PM.

#58

Safety Car

Also, I have a 1/8" spacer between the fiberglass and the MC flange. You could eliminate this spacer and gain an additional 1/8", but you would have to cut a hole in the fiberglass so that the retaining screw/tab would have some place to fit.

Charles

Charles

#59

Race Director

Member Since: Jun 2006

Location: Inverness FL

Posts: 17,891

Received 727 Likes

on

621 Posts

St. Jude Donor '07

yes, i realized you had a spacer in your installation for the purpose of leveling out the back of the MC flange. i got my 7-1/2" overall length by standing the flange end of the MC on the table top and just measured end-to-nose from the table top.

i think there are ways of making this fit a FI car (there is no problem that i can foresee in making it work on a non-FI car); maybe there are ways beyond the ideas i outlined above..... is it worth the effort, i don't know; but the challenge of finding an answer certainly makes it fun.... and if you've seen some of the things i've done, you know that John and I relish a challenge... and from i've seen of your projects, you do too...

Bill

Last edited by wmf62; 11-16-2008 at 04:58 PM.

#60

Instructor

Member Since: Apr 2007

Location: Maurertown Virginia

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

SSBC brakes offer a universal master cylinder push rod, (part#A1726) that adapts to 10 different applications for $58. This should help those of us who don't have a metal lathe.