1958 clutch pedal adjustment

#1

Pro

Thread Starter

Sometime in the early 60's my 58 was converted to manual transmission. The clutch setup was a little funky, but I have since fixed everything using factory pieces. I used the 58 rod from the pedal to z bar. I am now having difficulty because there is not enough adjustment at the rod that pushes the clutch fork. I have it adjusted as short as it will go and it is not enough to get the TO bearing released from the pressure plate.

I know the 58 and 59 push rod from the pedal is different, but is the length different? Any ideas? Thanks

The trans is T10 with stock bell.

I know the 58 and 59 push rod from the pedal is different, but is the length different? Any ideas? Thanks

The trans is T10 with stock bell.

Last edited by 68L71; 02-14-2013 at 03:05 PM.

#2

Team Owner

I don't know which rod might be longer but the later rod ('59-'62) has a slight bow in it where the earlier rod is straight. Corvette Central pictures clearly show this.

#5

Pro

Thread Starter

#6

Team Owner

I would call CC and ask about the lengths it appears to me if you had a shorter pedal rod then the clutch fork rod would yield more adjustment for shortening...

Another alternative (unless you are hung up on originality) is to talk to these guys about an adjustable rod: http://speeddirect.com/index.aspx?nodeID=65 I had to user their system on my '67 Chevelle that was converted from auto tranny to 4-speed.

I would also check out the clutch fork carefully and make sure the riveted on metal 'leaf' on the back is still properly attached and it is riding on the ball stud correctly.

Another alternative (unless you are hung up on originality) is to talk to these guys about an adjustable rod: http://speeddirect.com/index.aspx?nodeID=65 I had to user their system on my '67 Chevelle that was converted from auto tranny to 4-speed.

I would also check out the clutch fork carefully and make sure the riveted on metal 'leaf' on the back is still properly attached and it is riding on the ball stud correctly.

Last edited by Frankie the Fink; 02-15-2013 at 09:29 AM.

#8

Team Owner

That would definitely factor in

#9

I am going through the same problem. Someone converted my 59 to a stick a long time ago. They welded Micky Mouse brackets & drilled holes in the frame to mount the Z bar. I ground off the brackets & welded the holes in the frame. I bought the Z bar bracket , welded it to the frame put it all together. My first problem I had I think is your problem, the rod from the clutch peddle to the Z bar was to long I had no more adjustment left. Correct rod fixed that. Next I think I welded the spring bracket in the wrong place the clutch will not come up all the way the spring is hitting the Z bracket I welded the the frame.

Mike

Mike

Last edited by Michael 59' corvette; 02-16-2013 at 08:06 AM. Reason: Spelling

#10

Team Owner

I don't know why these conversions seem so troublesome. My Chevelle 'added in' 4 speed used a popular kit and everytime you push in the clutch the brake pedal moved sideways an inch. The brake pedal (part of the same kit) routinely destroyed the brake light switch. Took me a week to straighten out. Seems like this should be straight forward with factory parts.

#12

Pro

Thread Starter

I finally got back to this today. I pulled the inspection cover off the stock bell housing. It seems like the TO bearing is too big. When it is all the way back on the shaft it only has 1 mm of clearance. I happen to have an extra TO bearing from CC that I had previously bought before buying the clutch kit from them and it is the same thickness. The only factor here seems to be the fly wheel thickness. I am not happy to have to pull things apart yet again.

Last edited by 68L71; 03-22-2013 at 08:31 PM.

#13

Race Director

These cars use a short TO bearing and cone shaped PP diaphrgm, if you went to a diaphrgm clutch.

.

Doug

.

Doug

#14

Instructor

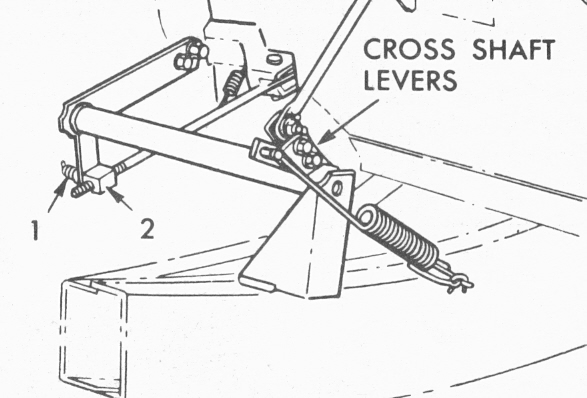

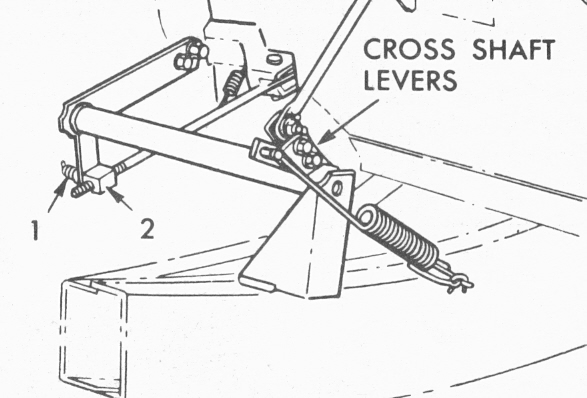

I posted these photos on the NCRS site. A member there was having problems adjusting his clutch. It turned out to be the fork was the wrong one. This might not be your issue but since you have the unfortunate task of disassembling that area anyway you can check your fork to make sure it is the right one.

Erich

sorry for the large photos, couldn't get clickable thumbnails

to work right

Erich

sorry for the large photos, couldn't get clickable thumbnails

to work right

Last edited by 62vetteman; 03-23-2013 at 01:46 PM. Reason: thumbnails didn't resize

#15

Race Director

Member Since: Nov 2000

Location: Beverly Hills (Pine Ridge) Florida

Posts: 10,159

Received 528 Likes

on

377 Posts

62 Vetteman,

Great photos, and clearly shows the difference (that I was not aware of).

Slight hi-jack, with just a couple of questions:

1. Is there any differance in length (I have a "new" C1 Corvette Central fork that is shorter than my "installed" fork, and don't know where my longer fork is from).

2. What did the 63 fork look like?

Thanks,

Plasticman

Great photos, and clearly shows the difference (that I was not aware of).

Slight hi-jack, with just a couple of questions:

1. Is there any differance in length (I have a "new" C1 Corvette Central fork that is shorter than my "installed" fork, and don't know where my longer fork is from).

2. What did the 63 fork look like?

Thanks,

Plasticman

#16

Melting Slicks

I had some of the same problems, I had to make my own rod from threaded rod and rod ends, plus it gets rid of the rubber and the metal on metal wear points. Works nice and smooth.

http://www.fototime.com/E65431406E4481F/medium.jpg

http://www.fototime.com/E65431406E4481F/medium.jpg

#17

Pro

Thread Starter

I used a screw driver to pry the TO bearing, rather than just pushing with my hand, and I could get get it to go back and get the needed 1/4" clearance between the TO and the fingers of the clutch. So it seems the ball stud pivot is too long. Any insite on this procedure?

Thanks

Thanks

#18

Race Director

Is your TO bearing properly installed on the clutch fork properly?

There is a right way, and wrong way to install it. Unfortunately, i don't have pics of either way available.

Ball stud length is about the last thing I would consider. It isn't normally something that one adjusts, but it has been so long since I had a factory bell, that i don't recall if there is an adjustment.

Doug

There is a right way, and wrong way to install it. Unfortunately, i don't have pics of either way available.

Ball stud length is about the last thing I would consider. It isn't normally something that one adjusts, but it has been so long since I had a factory bell, that i don't recall if there is an adjustment.

Doug

#20

Team Owner

Member Since: Oct 2000

Location: Washington Michigan

Posts: 38,899

Received 1,860 Likes

on

1,103 Posts

Last edited by JohnZ; 03-23-2013 at 08:21 PM.