58 - Top Fender molding speed self-thread nuts suck

#1

Melting Slicks

Thread Starter

I bought some reproduction top fender molding from Corvette Central (CC) a while back ago which came with speed nuts. While putting them on, none of the speed nuts snugged up tight to the molding...they all would freely spin when bottoming out.

I'm assuming I'm not the only one having this problem and was wondering if anyone else has some solutions.

I personally think their nuts are really cheap thin metal that doesn't bite/cut into the stud and just ends up deforming the hole.

They do hold the stainless down, but it's not snug and I can slightly move the top molding.

Suggestions?

I'm assuming I'm not the only one having this problem and was wondering if anyone else has some solutions.

I personally think their nuts are really cheap thin metal that doesn't bite/cut into the stud and just ends up deforming the hole.

They do hold the stainless down, but it's not snug and I can slightly move the top molding.

Suggestions?

#3

Melting Slicks

Thread Starter

They should be threaded in my opinion. The studs are tapered so I wouldn't think threading them would be simple.

#4

Team Owner

For all those over-chromed trim studs (e.g. side spears and top fender windsplits) a good shot of W-40 followed by threading the speed nuts slowly, carefully and straight ALL the way down the stud while the part is OFF the car will make your life easy when you finally install the piece. No more loose nuts or broken off studs.

#6

Melting Slicks

Thread Starter

I think the reason is that they are made of thin metal and easily get distorted. Explains why Frank puts them on so delicately. You should have to be treating them like they are so fragile and I would be willing to bet the originals were made from a much thicker material instead of this China soda can crap.

#7

Safety Car

I think the reason is that they are made of thin metal and easily get distorted. Explains why Frank puts them on so delicately. You should have to be treating them like they are so fragile and I would be willing to bet the originals were made from a much thicker material instead of this China soda can crap.

A lot of the "pal" nuts do not properly fit the studs on much of the trim items being reproduced today. the problem is almost always in the stud, not the nut. A trick is to take the "pal" nut and put it over a steel rod that fills the inside of the nut. Then take a small hammer and tap lightly on the top of the nut, until it closes up the opening. This will usually make them grab the chrome shaft and start cutting threads. Just go slowly, as it is real easy to get the hole closed up so small that it will not start at all! It is kind of a finesse thing getting the hole to close down enough to grab the stud, without closing it down too much.

Regards, John McGraw

#8

Melting Slicks

Thread Starter

take a small hammer and tap lightly on the top of the nut, until it closes up the opening.

#9

Team Owner

Don't know. I've put a set of repro windsplits on my car and another on a pal's. Using WD-40 as 'cutting oil' and bearing straight down on those pal nuts (with the piece off the car) gets them threaded every time for me. If you close up the nuts' holes excessively then you will definitely have a problem.

Wacky - did you put the '58 steel fender reinforcement bars under the fenders ? If so, then those speed nuts don't have to all the way down anyway and they should tighten up nicely...

Wacky - did you put the '58 steel fender reinforcement bars under the fenders ? If so, then those speed nuts don't have to all the way down anyway and they should tighten up nicely...

#10

Melting Slicks

Thread Starter

No...I don't have the reinforcement. My reproduction front end is a hand-laid front and pretty thick.

#11

Team Owner

Ok - yes, I remember now...

The following users liked this post:

Plasticman (09-14-2015)

#13

Melting Slicks

Thread Starter

Interesting stuff. Didn't know that. I have a 58 and I wish mine were threaded. I thought the ones I took off the car were original, but they are studded also.

#15

Safety Car

In fact, on '58-'59, the rear threaded stud didn't use nuts. There was a special retainer nut(View E in AIM pic) pushed into the body. The last 2 studs pushed in and locked that last one. Reason is no clearance for nuts under the dash as the horizontal reinforcement was in the way.

I recall I had a pic of the special retainer somewhere from a '59 I did but can't find it. Mashinter has one, if he see's this he'll post it.

Later cars, '60 up IIRC, had big holes drilled in the reinforcement to allow a nut placed there.

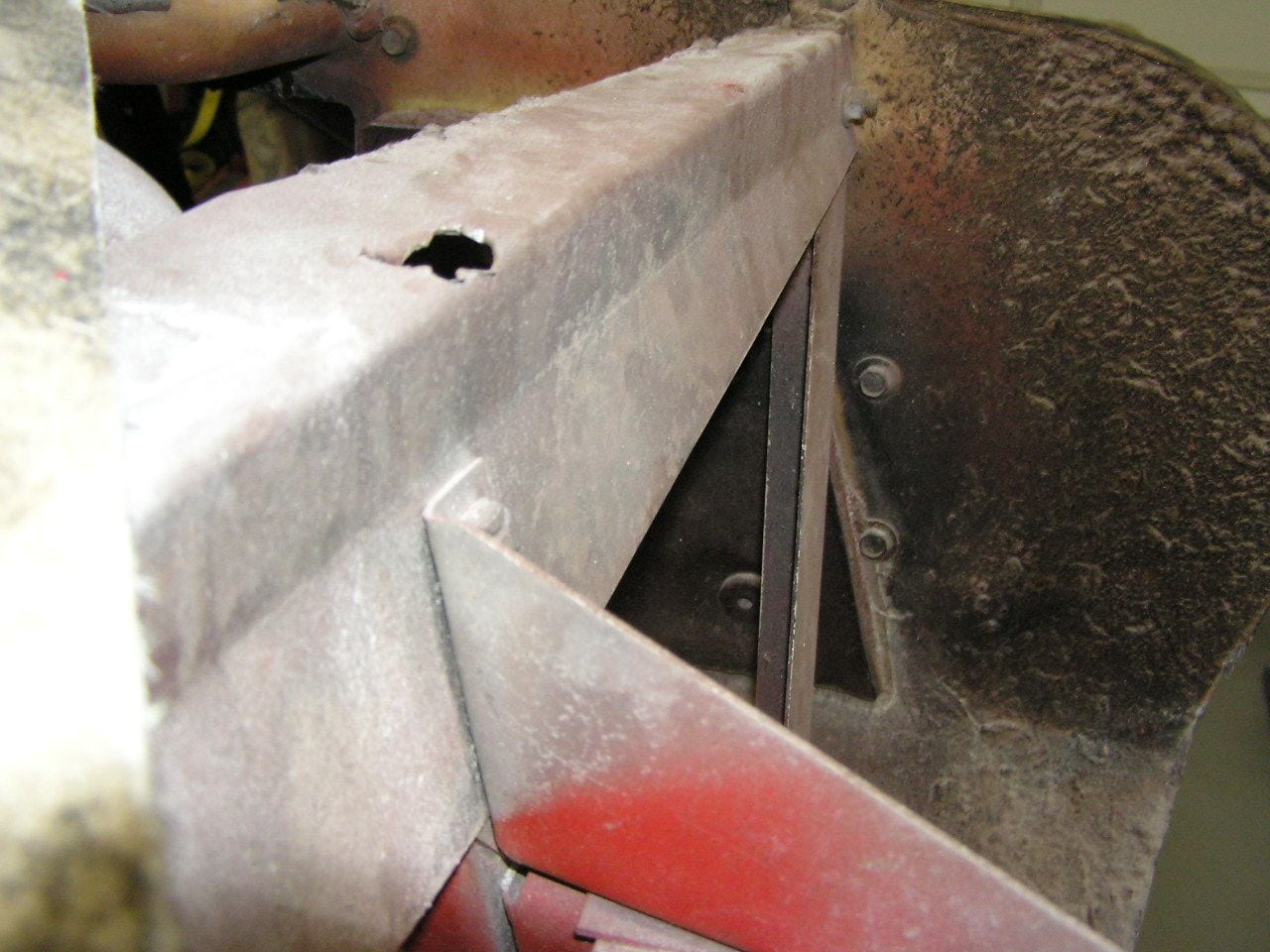

Here's a '59 where someone replaced the top trims over 40 years ago and cut up the aluminum to get the nut on.

I opened the holes on each side with a hole saw for ease of assembly later.

#16

Drifting

Here ya go:

The retainer has wings on top to keep it from pushing through the fender and barbs to hold it in the fender. This will only work on threaded studs because it grabs the threads. This retainer did not hold the back of the trim very well. I will use nuts on the 2 rear positions when I reinstall the trim.

The retainer has wings on top to keep it from pushing through the fender and barbs to hold it in the fender. This will only work on threaded studs because it grabs the threads. This retainer did not hold the back of the trim very well. I will use nuts on the 2 rear positions when I reinstall the trim.

The following users liked this post:

rich5962 (09-15-2015)

#17

Team Owner

And if you don't put some dum-dum on those two rearmost nuts on the windsplits you get a nice leak in the cockpit.