Desktop Dyno request thread

#21

Burning Brakes

Wow, This is a great offer. I'm in the middle of building my motor and would really appreciatte the DD run. Here are my Specs....

L82 Bottom End

5.7" connecting rod

4.000 bore x 3.48 stroke

flat top pistons (believe the valve reliefs are in the 5-6cc range)

Pistons sit .0027" down from the deck

Head gasket thickness (compressed) is .039

Heads are GM casting ending in 041 (fuelies w/accessory holes, straight plug)

valves are 1.6 exhaust and 2.05 intake

after unshrouding and milling to make them straight, the combustion chamber measure 62cc

Heads have been ported (full) to improve flow

Springs are matched to cam (came in set)

Cam is Competition Cams XE268H

Here are the specs:

http://www.compcams.com/information/...68H-10_001.asp

Intake Manifold is a second generation Edelbrock Performer (supposed to be equivalent to ZZ4 manifold or bow-tie manifold)

Carb will be 750cfm quadrajet

No headers. I will be using 65 fuelie rams horn manifolds, ported to match the exhaust port sizes. These are rams horns which have true 2.5" exhaust outlets

There's a bunch that's not quite stock here, so it might be a challenge.

Thanks for your offer.

-Fred

L82 Bottom End

5.7" connecting rod

4.000 bore x 3.48 stroke

flat top pistons (believe the valve reliefs are in the 5-6cc range)

Pistons sit .0027" down from the deck

Head gasket thickness (compressed) is .039

Heads are GM casting ending in 041 (fuelies w/accessory holes, straight plug)

valves are 1.6 exhaust and 2.05 intake

after unshrouding and milling to make them straight, the combustion chamber measure 62cc

Heads have been ported (full) to improve flow

Springs are matched to cam (came in set)

Cam is Competition Cams XE268H

Here are the specs:

http://www.compcams.com/information/...68H-10_001.asp

Intake Manifold is a second generation Edelbrock Performer (supposed to be equivalent to ZZ4 manifold or bow-tie manifold)

Carb will be 750cfm quadrajet

No headers. I will be using 65 fuelie rams horn manifolds, ported to match the exhaust port sizes. These are rams horns which have true 2.5" exhaust outlets

There's a bunch that's not quite stock here, so it might be a challenge.

Thanks for your offer.

-Fred

#22

Burning Brakes

Ok, I got my numbers,,

327 sbc

333ci (.040overbore)

3.25 stroke

5.7 rods

3917291 iron heads, 64cc, 1.94x1.5 valves

comp ratio 9.6

750 cfm edelbrock carb #1411

1.6 rockers

power plus dual plane 180deg style intake, 1500-6500 rpm

Comp cam #12-211-2 link-http://www.compcams.com/Technical/Search/CamDetails.asp?PartNumber=12-211-2

1,5/8 headers to 2-1/2inch dual exhaust,,,

Thanks !!

327 sbc

333ci (.040overbore)

3.25 stroke

5.7 rods

3917291 iron heads, 64cc, 1.94x1.5 valves

comp ratio 9.6

750 cfm edelbrock carb #1411

1.6 rockers

power plus dual plane 180deg style intake, 1500-6500 rpm

Comp cam #12-211-2 link-http://www.compcams.com/Technical/Search/CamDetails.asp?PartNumber=12-211-2

1,5/8 headers to 2-1/2inch dual exhaust,,,

Thanks !!

Last edited by Michel B; 08-27-2007 at 09:12 PM.

#24

Le Mans Master

Thread Starter

Hey Billa, I been debating over actually getting it dynoed. Pretty mild setup and this one will be easy for ya. Thanks in advance.

350 .060 over stock bottom end with dish pistons.

stock vortec heads (excpet a little bigger springs to accept bigger then stock cam). the modified ones from SDPC.

Edelbrock Performer with 600 Holley.

1 5/8" ceramic Flowtech headers to sidepipes.

Comp XE262 cam http://store.summitracing.com/partde...2&autoview=sku

that work for ya ?

350 .060 over stock bottom end with dish pistons.

stock vortec heads (excpet a little bigger springs to accept bigger then stock cam). the modified ones from SDPC.

Edelbrock Performer with 600 Holley.

1 5/8" ceramic Flowtech headers to sidepipes.

Comp XE262 cam http://store.summitracing.com/partde...2&autoview=sku

that work for ya ?

#25

Le Mans Master

Thread Starter

Need the CR or the volume of the reliefs in the pistons. Sorry

Billa,

Thanks for the offer, exactly what I need to give the sanity check to my planned '69 motor. I've got the rotating assembly, just picking the rest of the components. I'm looking for big power in the 2500-5500 range, to go with my TKO-600, 3.70 gears and 28" tires. I'm running sidepipes, so I've got to have some cam duration to make it sound right and I hope to keep it around 10:1 compression. Here's my plan, not written in stone.

Block 4.060

Crank 3.75" Stroke

Pistons TRW Forged Flat Top 2 valve relief

Rods 5.7"

Head Gasket .049"

Heads AFR 195 76cc chamber

2.050 intake flow 274 cfm @.500 lift

1.60 exhaust flow 207 cfm @.500 lift

Intake Edlebrock Performer RPM Air Gap

Carb Holley 4779 750cfm mechanical secondary

Exhaust 1 7/8" Sidepipe headers into 4" pipes

Cam Lunati Voodoo LUN-60103LK http://store.summitracing.com/partde...K&autoview=sku

227/233 Duration at .050

.489/.504 Lift with 1.5 rockers

Any verification or alternate suggestions would be appreciated. Thanks.

Jimbo

Thanks for the offer, exactly what I need to give the sanity check to my planned '69 motor. I've got the rotating assembly, just picking the rest of the components. I'm looking for big power in the 2500-5500 range, to go with my TKO-600, 3.70 gears and 28" tires. I'm running sidepipes, so I've got to have some cam duration to make it sound right and I hope to keep it around 10:1 compression. Here's my plan, not written in stone.

Block 4.060

Crank 3.75" Stroke

Pistons TRW Forged Flat Top 2 valve relief

Rods 5.7"

Head Gasket .049"

Heads AFR 195 76cc chamber

2.050 intake flow 274 cfm @.500 lift

1.60 exhaust flow 207 cfm @.500 lift

Intake Edlebrock Performer RPM Air Gap

Carb Holley 4779 750cfm mechanical secondary

Exhaust 1 7/8" Sidepipe headers into 4" pipes

Cam Lunati Voodoo LUN-60103LK http://store.summitracing.com/partde...K&autoview=sku

227/233 Duration at .050

.489/.504 Lift with 1.5 rockers

Any verification or alternate suggestions would be appreciated. Thanks.

Jimbo

#26

Le Mans Master

Thread Starter

They're "typical" dyno numbers - so they represent no accessories. DD is always 5+ % optimistic on torque; the HP numbers are decent (not "accurate") given full cam information and head flow data.

#27

Le Mans Master

Thread Starter

OzzyTom, here's my take - pretty close to what your builder is spec'ing. The sign of a great engine builder - plan the build, build to the plan and deliver the numbers. I'm kinda 1/2 between an "assembler" and a "builder" myself.

Question - why .015 deck vs. zero deck?

Sweet torque power curve...and a very nice 'Vette!

Question - why .015 deck vs. zero deck?

Sweet torque power curve...and a very nice 'Vette!

#28

Racer

Billla,

Sorry. My pistons are flat top 2 valve relief or -6cc. Block is 0 deck as well. I haven't figured the CR, but hoping for right at 10:1. Thanks again.

Jimbo

Sorry. My pistons are flat top 2 valve relief or -6cc. Block is 0 deck as well. I haven't figured the CR, but hoping for right at 10:1. Thanks again.

Jimbo

#29

Instructor

I built my engine about 15 years ago and have often thought about putting it on a dyno, just never did. Actually for ten of those years it sat in my garage with a cam that had too much duration and made no power. A few years ago I swapped it out with the one described below. I'd be very interested to see what your software thinks I've built.

The block is a .030 over 350 small block old style (circa 74). With a bore of 4.030 and a standard stroke of 3.48, it displaces 355 cubic inches. Rod length is a standard 5.7 inches for that era.

I used the old style AFR 190 cc heads. Flow numbers are as follows:

Lift Int Ext (2.02 / 1.60 68 cc)

.100 ? ?

.200 129 108

.300 195 156

.400 240 178

.500 260 190

.600 262 194

I could give you all the dimensions, but the static compression ratio is 10.1 to 1. Flat top pistions, small valve relief (3 cc I believe), and block decked to 0.00. Not that it changes the HP, but I used standard rods that were shot peened bushed for full floating pistons. The entire assembly was balanced.

I use an old Holley dual plane high rise manifold. I don't recall the number, but presumably it's very similar to the Z-28 manifolds of 1969. My first engine rebuild was a Z-28 302 and much of this engine mimics it. For example I used the Z-28 oil pan, oil pump, baffle, etc. The carb is a Holley 700 cubic feet per minute mechanical secondary.

I haven't done much with the exhaust. I prefer to keep it looking pretty stock. I have the original rams horn exhaust manifolds attached to true dual 2.5 inch pipes. This is on a '74 so there's no catalytic converter, just flow master mufflers. Some day I'll port match the mainfold to the heads but that a future. (I have lots of futures!)

The camshaft is a Crane HMV-278-2. Numbers are as follows:

Duration 278 Intake 222 @ .050

290 Exhaust 234 @ .050

Lift Intake .3115 at the cam .475 at the valve (1.5)

Exhaust .3294 at the cam .494 at the valve (1.5)

Lobe Separation is 114 degrees.

I mentioned my earlier cam had too much duration. It was fun to run it up to 7000 RPM, but the car was a dog (i.e. 15.7 in the quarter). I chose the current cam based on an attempt to optimize dynamic compression ratio. I've copied some of my old notes below for anyone who might be interested.

Would you mind using your program to see what improvement might be made with 1.6 rockers? (I use Crower stainless roller rockers at 1.5 but I've considered trying the same rockers in a 1.6 ratio.)

Thanks for your time doing this evaluation. When I finally get the bodywork done, I'll post pictures for forum members.

--------------------------------------------------------------------

Dynamic Compression Notes for my car:

Dynamic Compression Ratio

It appears that most gas engines make the best power with a DCR between 7.5 and 8.5 on 91 or better octane. Race engines, using high octane race gas, can tolerate higher DCR's with 8.8:1 to 9:1 a good DCR to shoot for.

My ratio: 9.12 to 9.22 depending on altitude.

See: http://www.wallaceracing.com/dynamic-cr.php

Cam closes at 72 ABDC on intake at .004.

Cam closes at 40 ABDC on intake at .050

Discussion: http://www.empirenet.com/pkelley2/DynamicCR.html

Your engine summary is as follows:

Bore - 4.030 inches

Stroke - 3.48 inches

Rod c-c length - 5.7 inches

With a static compression ratio of 10.1:1.

Your camshaft specifications call for an inlet valve closing of 40 degrees ABDC (after bottom dead center).

Your chamber volume is 79.94 cc's. With this camshaft your dynamic, or effective stroke is 3.18 inches.

Your dynamic compression ratio is 9.22 :1 corrected for cam timing, altitude, and rod length.

Your dynamic cranking pressure, corrected for cam timing, rod length and altitude is 190.86 PSI.

Your dynamic boost compression ratio, reflecting static c.r., cam timing, altitude, and boost of 0 PSI is 9.22 :1.

The block is a .030 over 350 small block old style (circa 74). With a bore of 4.030 and a standard stroke of 3.48, it displaces 355 cubic inches. Rod length is a standard 5.7 inches for that era.

I used the old style AFR 190 cc heads. Flow numbers are as follows:

Lift Int Ext (2.02 / 1.60 68 cc)

.100 ? ?

.200 129 108

.300 195 156

.400 240 178

.500 260 190

.600 262 194

I could give you all the dimensions, but the static compression ratio is 10.1 to 1. Flat top pistions, small valve relief (3 cc I believe), and block decked to 0.00. Not that it changes the HP, but I used standard rods that were shot peened bushed for full floating pistons. The entire assembly was balanced.

I use an old Holley dual plane high rise manifold. I don't recall the number, but presumably it's very similar to the Z-28 manifolds of 1969. My first engine rebuild was a Z-28 302 and much of this engine mimics it. For example I used the Z-28 oil pan, oil pump, baffle, etc. The carb is a Holley 700 cubic feet per minute mechanical secondary.

I haven't done much with the exhaust. I prefer to keep it looking pretty stock. I have the original rams horn exhaust manifolds attached to true dual 2.5 inch pipes. This is on a '74 so there's no catalytic converter, just flow master mufflers. Some day I'll port match the mainfold to the heads but that a future. (I have lots of futures!)

The camshaft is a Crane HMV-278-2. Numbers are as follows:

Duration 278 Intake 222 @ .050

290 Exhaust 234 @ .050

Lift Intake .3115 at the cam .475 at the valve (1.5)

Exhaust .3294 at the cam .494 at the valve (1.5)

Lobe Separation is 114 degrees.

I mentioned my earlier cam had too much duration. It was fun to run it up to 7000 RPM, but the car was a dog (i.e. 15.7 in the quarter). I chose the current cam based on an attempt to optimize dynamic compression ratio. I've copied some of my old notes below for anyone who might be interested.

Would you mind using your program to see what improvement might be made with 1.6 rockers? (I use Crower stainless roller rockers at 1.5 but I've considered trying the same rockers in a 1.6 ratio.)

Thanks for your time doing this evaluation. When I finally get the bodywork done, I'll post pictures for forum members.

--------------------------------------------------------------------

Dynamic Compression Notes for my car:

Dynamic Compression Ratio

It appears that most gas engines make the best power with a DCR between 7.5 and 8.5 on 91 or better octane. Race engines, using high octane race gas, can tolerate higher DCR's with 8.8:1 to 9:1 a good DCR to shoot for.

My ratio: 9.12 to 9.22 depending on altitude.

See: http://www.wallaceracing.com/dynamic-cr.php

Cam closes at 72 ABDC on intake at .004.

Cam closes at 40 ABDC on intake at .050

Discussion: http://www.empirenet.com/pkelley2/DynamicCR.html

Your engine summary is as follows:

Bore - 4.030 inches

Stroke - 3.48 inches

Rod c-c length - 5.7 inches

With a static compression ratio of 10.1:1.

Your camshaft specifications call for an inlet valve closing of 40 degrees ABDC (after bottom dead center).

Your chamber volume is 79.94 cc's. With this camshaft your dynamic, or effective stroke is 3.18 inches.

Your dynamic compression ratio is 9.22 :1 corrected for cam timing, altitude, and rod length.

Your dynamic cranking pressure, corrected for cam timing, rod length and altitude is 190.86 PSI.

Your dynamic boost compression ratio, reflecting static c.r., cam timing, altitude, and boost of 0 PSI is 9.22 :1.

Last edited by Gearhead74; 08-28-2007 at 09:06 AM.

#30

Burning Brakes

OzzyTom, here's my take - pretty close to what your builder is spec'ing. The sign of a great engine builder - plan the build, build to the plan and deliver the numbers. I'm kinda 1/2 between an "assembler" and a "builder" myself.

Question - why .015 deck vs. zero deck?

Sweet torque power curve...and a very nice 'Vette!

Question - why .015 deck vs. zero deck?

Sweet torque power curve...and a very nice 'Vette!

Thanks Billa, for running the numbers through....

I'm excited!

I wanted big block type power from a small block, and if my motor manages to pull close to those numbers, I'll be absolutely stoked.

That torque curve is indeed awesome.

It will be interesting to see what I actually get at the rear wheels once installed.

As to the 9.015" deck height ... No idea ???

It's the spec they list on their web site.

Thanks again for taking the time... you're a champ.

tom

Last edited by OzzyTom; 08-28-2007 at 08:07 AM.

#31

Le Mans Master

Thread Starter

Interesting on the .015 - so what do you run for a head gasket? I'm interested in what the final quench is.

#32

Le Mans Master

Thread Starter

Billa,

Thanks for the offer, exactly what I need to give the sanity check to my planned '69 motor. I've got the rotating assembly, just picking the rest of the components. I'm looking for big power in the 2500-5500 range, to go with my TKO-600, 3.70 gears and 28" tires. I'm running sidepipes, so I've got to have some cam duration to make it sound right and I hope to keep it around 10:1 compression. Here's my plan, not written in stone.

Block 4.060

Crank 3.75" Stroke

Pistons TRW Forged Flat Top 2 valve relief

Rods 5.7"

Head Gasket .049"

Heads AFR 195 76cc chamber

2.050 intake flow 274 cfm @.500 lift

1.60 exhaust flow 207 cfm @.500 lift

Intake Edlebrock Performer RPM Air Gap

Carb Holley 4779 750cfm mechanical secondary

Exhaust 1 7/8" Sidepipe headers into 4" pipes

Cam Lunati Voodoo LUN-60103LK http://store.summitracing.com/partde...K&autoview=sku

227/233 Duration at .050

.489/.504 Lift with 1.5 rockers

Any verification or alternate suggestions would be appreciated. Thanks.

Jimbo

Thanks for the offer, exactly what I need to give the sanity check to my planned '69 motor. I've got the rotating assembly, just picking the rest of the components. I'm looking for big power in the 2500-5500 range, to go with my TKO-600, 3.70 gears and 28" tires. I'm running sidepipes, so I've got to have some cam duration to make it sound right and I hope to keep it around 10:1 compression. Here's my plan, not written in stone.

Block 4.060

Crank 3.75" Stroke

Pistons TRW Forged Flat Top 2 valve relief

Rods 5.7"

Head Gasket .049"

Heads AFR 195 76cc chamber

2.050 intake flow 274 cfm @.500 lift

1.60 exhaust flow 207 cfm @.500 lift

Intake Edlebrock Performer RPM Air Gap

Carb Holley 4779 750cfm mechanical secondary

Exhaust 1 7/8" Sidepipe headers into 4" pipes

Cam Lunati Voodoo LUN-60103LK http://store.summitracing.com/partde...K&autoview=sku

227/233 Duration at .050

.489/.504 Lift with 1.5 rockers

Any verification or alternate suggestions would be appreciated. Thanks.

Jimbo

Here's what I came up with - no obvious suggestions here and it seems to be a great match for your gearing.

#33

Le Mans Master

Thread Starter

Heres mine when you have the time

Bore x stroke SBC

4.03 x 3.48 5.7in rods head gasket compressed thickness .040

Speed Pro forged aluminum +6.1 dish flat tops/4 valve reliefs generating 9.72:1 with 64cc heads

Pro topline 180cc aluminum 64cc heads with 2.02/1.60 valves

.100 .200 .300 .400 .500 .600 .700

Intake 72 154 208 254 271 274 276

Exhaust 60 121 159 184 193 199 202

Comp Cams XS282S-10 http://www.compcams.com/Technical/Se...umber=12-678-4

1.5 rockers, here are the springs http://store.summitracing.com/partde...5&autoview=sku

Demon 725 vac. sec. w/electric choke, Edlebrock Performer EPS intake, HVH Super Sucker carb spacer.

Hooker side exit exhaust with no inserts, 1 7/8 tubes

Bore x stroke SBC

4.03 x 3.48 5.7in rods head gasket compressed thickness .040

Speed Pro forged aluminum +6.1 dish flat tops/4 valve reliefs generating 9.72:1 with 64cc heads

Pro topline 180cc aluminum 64cc heads with 2.02/1.60 valves

.100 .200 .300 .400 .500 .600 .700

Intake 72 154 208 254 271 274 276

Exhaust 60 121 159 184 193 199 202

Comp Cams XS282S-10 http://www.compcams.com/Technical/Se...umber=12-678-4

1.5 rockers, here are the springs http://store.summitracing.com/partde...5&autoview=sku

Demon 725 vac. sec. w/electric choke, Edlebrock Performer EPS intake, HVH Super Sucker carb spacer.

Hooker side exit exhaust with no inserts, 1 7/8 tubes

Hope you've got some solid gears there

Hope you've got some solid gears there

#34

Le Mans Master

Thread Starter

Wow, This is a great offer. I'm in the middle of building my motor and would really appreciatte the DD run. Here are my Specs....

L82 Bottom End

5.7" connecting rod

4.000 bore x 3.48 stroke

flat top pistons (believe the valve reliefs are in the 5-6cc range)

Pistons sit .0027" down from the deck

Head gasket thickness (compressed) is .039

Heads are GM casting ending in 041 (fuelies w/accessory holes, straight plug)

valves are 1.6 exhaust and 2.05 intake

after unshrouding and milling to make them straight, the combustion chamber measure 62cc

Heads have been ported (full) to improve flow

Springs are matched to cam (came in set)

Cam is Competition Cams XE268H

Here are the specs:

http://www.compcams.com/information/...68H-10_001.asp

Intake Manifold is a second generation Edelbrock Performer (supposed to be equivalent to ZZ4 manifold or bow-tie manifold)

Carb will be 750cfm quadrajet

No headers. I will be using 65 fuelie rams horn manifolds, ported to match the exhaust port sizes. These are rams horns which have true 2.5" exhaust outlets

L82 Bottom End

5.7" connecting rod

4.000 bore x 3.48 stroke

flat top pistons (believe the valve reliefs are in the 5-6cc range)

Pistons sit .0027" down from the deck

Head gasket thickness (compressed) is .039

Heads are GM casting ending in 041 (fuelies w/accessory holes, straight plug)

valves are 1.6 exhaust and 2.05 intake

after unshrouding and milling to make them straight, the combustion chamber measure 62cc

Heads have been ported (full) to improve flow

Springs are matched to cam (came in set)

Cam is Competition Cams XE268H

Here are the specs:

http://www.compcams.com/information/...68H-10_001.asp

Intake Manifold is a second generation Edelbrock Performer (supposed to be equivalent to ZZ4 manifold or bow-tie manifold)

Carb will be 750cfm quadrajet

No headers. I will be using 65 fuelie rams horn manifolds, ported to match the exhaust port sizes. These are rams horns which have true 2.5" exhaust outlets

The only comment I had was regarding quench - .064 (if my math is right) is terrible

If the block and heads are flat, I'd consider using a steel gasket to drop it to .042 - better. Not an immediate thing...but something to consider especially if you've had problems getting a full 36 degrees of total advance. Probably a nit, but it crossed my mind.

If the block and heads are flat, I'd consider using a steel gasket to drop it to .042 - better. Not an immediate thing...but something to consider especially if you've had problems getting a full 36 degrees of total advance. Probably a nit, but it crossed my mind.

#35

Le Mans Master

Thread Starter

Ok, I got my numbers,,

327 sbc

333ci (.040overbore)

3.25 stroke

5.7 rods

3917291 iron heads, 64cc, 1.94x1.5 valves

comp ratio 9.6

750 cfm edelbrock carb #1411

1.6 rockers

power plus dual plane 180deg style intake, 1500-6500 rpm

Comp cam #12-211-2 link-http://www.compcams.com/Technical/Search/CamDetails.asp?PartNumber=12-211-2

1,5/8 headers to 2-1/2inch dual exhaust,,,

Thanks !!

327 sbc

333ci (.040overbore)

3.25 stroke

5.7 rods

3917291 iron heads, 64cc, 1.94x1.5 valves

comp ratio 9.6

750 cfm edelbrock carb #1411

1.6 rockers

power plus dual plane 180deg style intake, 1500-6500 rpm

Comp cam #12-211-2 link-http://www.compcams.com/Technical/Search/CamDetails.asp?PartNumber=12-211-2

1,5/8 headers to 2-1/2inch dual exhaust,,,

Thanks !!

Peaky little beast

#36

Le Mans Master

For fun, try this s/c application for me please: TIA, Gary

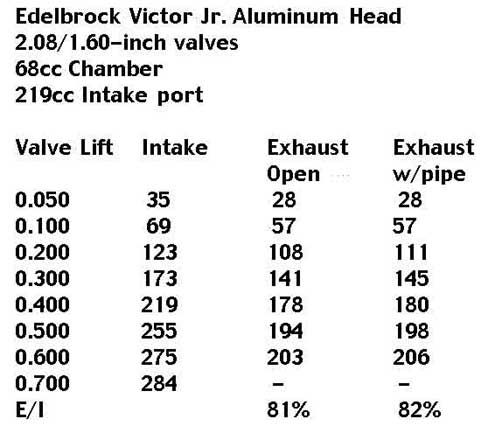

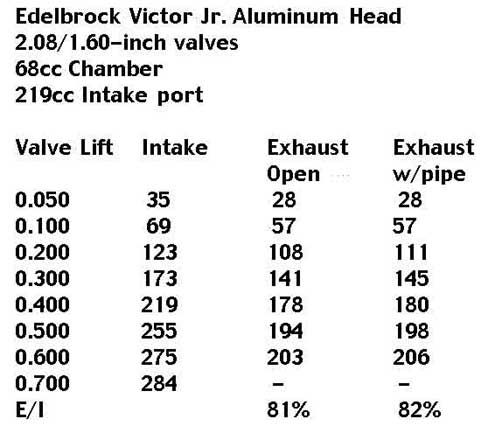

383, 6 inch rods, 8.3 scr, vic. jr. intake, vic. jr. heads (chart attached)

Comp cams cam, XR280R (solid roller 242/248, 110 lsa), installed straight up, 1-3/4 inch headers, Holley 750 dp, inter-cooled supercharger running 16 lbs. boost at 6,500 rpm (engine).

Cam chart:http://www.compcams.com/Technical/Se...umber=11-771-8

383, 6 inch rods, 8.3 scr, vic. jr. intake, vic. jr. heads (chart attached)

Comp cams cam, XR280R (solid roller 242/248, 110 lsa), installed straight up, 1-3/4 inch headers, Holley 750 dp, inter-cooled supercharger running 16 lbs. boost at 6,500 rpm (engine).

Cam chart:http://www.compcams.com/Technical/Se...umber=11-771-8

#37

Le Mans Master

Thread Starter

The block is a .030 over 350 small block old style (circa 74). With a bore of 4.030 and a standard stroke of 3.48, it displaces 355 cubic inches. Rod length is a standard 5.7 inches for that era.

I used the old style AFR 190 cc heads. Flow numbers are as follows:

Lift Int Ext (2.02 / 1.60 68 cc)

.100 ? ?

.200 129 108

.300 195 156

.400 240 178

.500 260 190

.600 262 194

I could give you all the dimensions, but the static compression ratio is 10.1 to 1. Flat top pistions, small valve relief (3 cc I believe), and block decked to 0.00. Not that it changes the HP, but I used standard rods that were shot peened bushed for full floating pistons. The entire assembly was balanced.

I use an old Holley dual plane high rise manifold. I don't recall the number, but presumably it's very similar to the Z-28 manifolds of 1969. My first engine rebuild was a Z-28 302 and much of this engine mimics it. For example I used the Z-28 oil pan, oil pump, baffle, etc. The carb is a Holley 700 cubic feet per minute mechanical secondary.

I haven't done much with the exhaust. I prefer to keep it looking pretty stock. I have the original rams horn exhaust manifolds attached to true dual 2.5 inch pipes. This is on a '74 so there's no catalytic converter, just flow master mufflers. Some day I'll port match the mainfold to the heads but that a future. (I have lots of futures!)

The camshaft is a Crane HMV-278-2. Numbers are as follows:

Duration 278 Intake 222 @ .050

290 Exhaust 234 @ .050

Lift Intake .3115 at the cam .475 at the valve (1.5)

Exhaust .3294 at the cam .494 at the valve (1.5)

Lobe Separation is 114 degrees.

I mentioned my earlier cam had too much duration. It was fun to run it up to 7000 RPM, but the car was a dog (i.e. 15.7 in the quarter). I chose the current cam based on an attempt to optimize dynamic compression ratio. I've copied some of my old notes below for anyone who might be interested.

Would you mind using your program to see what improvement might be made with 1.6 rockers? (I use Crower stainless roller rockers at 1.5 but I've considered trying the same rockers in a 1.6 ratio.)

I used the old style AFR 190 cc heads. Flow numbers are as follows:

Lift Int Ext (2.02 / 1.60 68 cc)

.100 ? ?

.200 129 108

.300 195 156

.400 240 178

.500 260 190

.600 262 194

I could give you all the dimensions, but the static compression ratio is 10.1 to 1. Flat top pistions, small valve relief (3 cc I believe), and block decked to 0.00. Not that it changes the HP, but I used standard rods that were shot peened bushed for full floating pistons. The entire assembly was balanced.

I use an old Holley dual plane high rise manifold. I don't recall the number, but presumably it's very similar to the Z-28 manifolds of 1969. My first engine rebuild was a Z-28 302 and much of this engine mimics it. For example I used the Z-28 oil pan, oil pump, baffle, etc. The carb is a Holley 700 cubic feet per minute mechanical secondary.

I haven't done much with the exhaust. I prefer to keep it looking pretty stock. I have the original rams horn exhaust manifolds attached to true dual 2.5 inch pipes. This is on a '74 so there's no catalytic converter, just flow master mufflers. Some day I'll port match the mainfold to the heads but that a future. (I have lots of futures!)

The camshaft is a Crane HMV-278-2. Numbers are as follows:

Duration 278 Intake 222 @ .050

290 Exhaust 234 @ .050

Lift Intake .3115 at the cam .475 at the valve (1.5)

Exhaust .3294 at the cam .494 at the valve (1.5)

Lobe Separation is 114 degrees.

I mentioned my earlier cam had too much duration. It was fun to run it up to 7000 RPM, but the car was a dog (i.e. 15.7 in the quarter). I chose the current cam based on an attempt to optimize dynamic compression ratio. I've copied some of my old notes below for anyone who might be interested.

Would you mind using your program to see what improvement might be made with 1.6 rockers? (I use Crower stainless roller rockers at 1.5 but I've considered trying the same rockers in a 1.6 ratio.)

http://www.cranecams.com/?show=brows...tType=camshaft

This is my best shot. I saw virtually no change with the 1.6 rocker ratio, which isn't too surprising given the flat flow numbers in that lift range for the heads. IMHO, dual-pattern cams aren't a great choice for the SBC unless you've got very deep gears and live in high RPM ranges. I can see both why she loved to rev - but also why it wasn't a quarter mile beast. I'd consider a cam swap; might be worth a call to Crane or CompCams (or fill out the online form) and see what they recommend. I think there's another 30 HP or so waiting in a swap, and definitely the option to move the power down in the RPM range.

#38

Le Mans Master

Thread Starter

For forced induction, there's additional information required. I don't have a lot of experience with DD here - so we may get complete

DD wants either the specific blower model (Vortech, Paxton, etc.) or:

Island flow cfm

Impeller speed rpm

Peak efficiency %

Belt ratio

Boost limit psi

Pressure ratio

Internal ratio

Intercooler %

Here's a sample screen:

DD wants either the specific blower model (Vortech, Paxton, etc.) or:

Island flow cfm

Impeller speed rpm

Peak efficiency %

Belt ratio

Boost limit psi

Pressure ratio

Internal ratio

Intercooler %

Here's a sample screen:

#39

Le Mans Master

Thread Starter

Folks, I want to thank everybody for their very complete information and patience. Generally, I'll get the runs done within a week or so after posting subject to the impact of Real Life  I think I'm caught up except for a couple of folks where I'm waiting for information.

I think I'm caught up except for a couple of folks where I'm waiting for information.

If there are any other DD users that want to get in on the action out there - please don't hesitate to dive in If you're going to do a run, just post that you've got it so we don't duplicate efforts.

If you're going to do a run, just post that you've got it so we don't duplicate efforts.

Hope this is a useful thread!

I think I'm caught up except for a couple of folks where I'm waiting for information.

I think I'm caught up except for a couple of folks where I'm waiting for information.If there are any other DD users that want to get in on the action out there - please don't hesitate to dive in

If you're going to do a run, just post that you've got it so we don't duplicate efforts.

If you're going to do a run, just post that you've got it so we don't duplicate efforts.Hope this is a useful thread!

Last edited by billla; 08-29-2007 at 12:59 PM.

#40

Instructor

Member Since: Mar 2006

Location: Miami FL

Posts: 127

Likes: 0

Received 0 Likes

on

0 Posts

well would be great to know what my dads combo is making, and if you wouldn't mind doing a second one just to see what these heads EDL-60909 with no other changes would do to the combo that would be great!!!! trying to talk the old man into them  thanks alot!!!

thanks alot!!!

1976 L82

350 SBC bored .30 over

stock rods and stroke

Speed pro forged flat tops, 9.7.1 CR part # L2256

stock heads and valves, not milled, comp 981-16 springs

crane 1.5 ratio RR CRN-11744-16

Edelbrock performer intake EDL-3701

Edelborck 600CFM carb EDL-1405

Hooker 1-5/8 headers into 4" baffled sidepipes

Comp cams gross valve lift .462 int./ .469 exh, advertised duration 262 int/ 270 exh, lobe separation 110 CCA-CL12-238-2

thanks alot!!!

thanks alot!!!1976 L82

350 SBC bored .30 over

stock rods and stroke

Speed pro forged flat tops, 9.7.1 CR part # L2256

stock heads and valves, not milled, comp 981-16 springs

crane 1.5 ratio RR CRN-11744-16

Edelbrock performer intake EDL-3701

Edelborck 600CFM carb EDL-1405

Hooker 1-5/8 headers into 4" baffled sidepipes

Comp cams gross valve lift .462 int./ .469 exh, advertised duration 262 int/ 270 exh, lobe separation 110 CCA-CL12-238-2