Wiring, higher amp alternator, suggestions

#21

Race Director

Member Since: Apr 2007

Location: South Western Ontario

Posts: 11,061

Received 845 Likes

on

721 Posts

No they don't. Your problem was that you expected an old alternator design that was only ever engineered to produce 72A to reliably produce 200A instead.

FYI, A 140A CS144 can output about 90A using 700rpm idle speed and the typical 2.5:1 drive ratio which turns the alternator around 1750rpm.

The stock 63A 10SI can produce about 15A at the same rpm. The 10SI alternators just don't produce much output at low rpm's which is why they fail miserably when you attempt to add a bunch of extra load.

The CS130 is somewhere around 70A at the same rpm. Not as good as the CS144 but still quite respectable.

So, can we stop with this stupid "the alternator doesn't work at idle" crap? You just need the right alternator. A CS144 is quite capable of running 2 fans and high wattage headlights at idle without even breaking a sweat.

The new heavy loads do not need to be connected directly to the battery. You have a very nice heavy wire already running to the solenoid which is more than capable of powering these accessories. So, run another nice heavy wire to your power connection terminal block and you're just fine. FYI, you'd have to draw over 200A to get a 1V drop on a piece of 6awg wire 10' long.

FYI, A 140A CS144 can output about 90A using 700rpm idle speed and the typical 2.5:1 drive ratio which turns the alternator around 1750rpm.

The stock 63A 10SI can produce about 15A at the same rpm. The 10SI alternators just don't produce much output at low rpm's which is why they fail miserably when you attempt to add a bunch of extra load.

The CS130 is somewhere around 70A at the same rpm. Not as good as the CS144 but still quite respectable.

So, can we stop with this stupid "the alternator doesn't work at idle" crap? You just need the right alternator. A CS144 is quite capable of running 2 fans and high wattage headlights at idle without even breaking a sweat.

The new heavy loads do not need to be connected directly to the battery. You have a very nice heavy wire already running to the solenoid which is more than capable of powering these accessories. So, run another nice heavy wire to your power connection terminal block and you're just fine. FYI, you'd have to draw over 200A to get a 1V drop on a piece of 6awg wire 10' long.

#22

Race Director

Member Since: Apr 2007

Location: South Western Ontario

Posts: 11,061

Received 845 Likes

on

721 Posts

You must be joking. If the 10SI basic overall design was capable of supporting 200A then Delco would have done that instead of engineering the whole new CS130 and CS144 alternators.

Where I'm gettting alternators built? I consider it stupid to use a 10SI alternator case to "build" a 200A alternator (or even a 140A alternator), so I would never go anywhere to buy or get one of those built. I use a factory type CS144 and it maintains 14V with the cooling fan, 380W of high beam lights and the fuel injection in my car running, even at idle.

Have you ever even looked at the stock main power wiring? The wire runs from the alternator to the horn relay which is the main power distribution and then from there it branches off to the fuse panel, HVAC fan high speed relay and battery. Exactly the same layout as what I describe but updated to heavier wires and a bigger/better alternator to support more load.

Where I'm gettting alternators built? I consider it stupid to use a 10SI alternator case to "build" a 200A alternator (or even a 140A alternator), so I would never go anywhere to buy or get one of those built. I use a factory type CS144 and it maintains 14V with the cooling fan, 380W of high beam lights and the fuel injection in my car running, even at idle.

Have you ever even looked at the stock main power wiring? The wire runs from the alternator to the horn relay which is the main power distribution and then from there it branches off to the fuse panel, HVAC fan high speed relay and battery. Exactly the same layout as what I describe but updated to heavier wires and a bigger/better alternator to support more load.

Last edited by lionelhutz; 03-30-2014 at 04:05 PM.

#23

Team Owner

In the above 2 posts Lionel and AW are both rong, but I not going to get into it, as it is pointless at this point......so to speak.....

I"m not saying TOTALY rong in either case, but I just have to grin about some of the wiring suggestions......

70 year old ET here, worked with engineers who were PHD level and even a CIA Physicist ..... I rebuilt a motor home from ground up, and so used a CS144 because I"m dragging a 1200 watt inverter to run a fridge while on the road....call it a water/beer/mustard/cola cooler.....

then became a contractor remodeling houses......and have been working on cars nearly 60 years now.....I bet you all never even rebuilt an automotive generator now, HAVE you??? much less an alternator.....or a starter....

someone here in this thread dunno much about chassis/frame shark grounding either....with 6 bolts that hold the birdcage to the chassis frame, there is about zero chance the birdcage will lose contact with the frame....the other two in the rear are riding in fiberglass.....

does anyone even know how the battery negative gets to the engine???

the ONLY thing stock about my '72 vette is the front lighting and rear lighting harness, not the lights, just the harness and some interconnects.....ALL the rest of the harness has been redone, as I alluded to above....OH, and by by Ralph the beeper NADER too.....

I"m not saying TOTALY rong in either case, but I just have to grin about some of the wiring suggestions......

70 year old ET here, worked with engineers who were PHD level and even a CIA Physicist ..... I rebuilt a motor home from ground up, and so used a CS144 because I"m dragging a 1200 watt inverter to run a fridge while on the road....call it a water/beer/mustard/cola cooler.....

then became a contractor remodeling houses......and have been working on cars nearly 60 years now.....I bet you all never even rebuilt an automotive generator now, HAVE you??? much less an alternator.....or a starter....

someone here in this thread dunno much about chassis/frame shark grounding either....with 6 bolts that hold the birdcage to the chassis frame, there is about zero chance the birdcage will lose contact with the frame....the other two in the rear are riding in fiberglass.....

does anyone even know how the battery negative gets to the engine???

the ONLY thing stock about my '72 vette is the front lighting and rear lighting harness, not the lights, just the harness and some interconnects.....ALL the rest of the harness has been redone, as I alluded to above....OH, and by by Ralph the beeper NADER too.....

#24

Race Director

Member Since: Apr 2007

Location: South Western Ontario

Posts: 11,061

Received 845 Likes

on

721 Posts

The way I'm suggesting follows the same methodology of the factory wiring and has a rather well proven track record in the 10's of millions of GM cars and trucks which were wired that way.

I've completely 100% re-wired one of the cars I own too. Not 1 piece of stock wire left. Rebuilt generators, starters, alternators, fixed bricked PCM's, make my own EFI harnesses, etc, etc. So, what's the point with your claims?

Apparently, you also don't know about the 74 having rubber body mounts between the body and frame. Rather hard to get a good connection through rubber, isn't it?

Last edited by lionelhutz; 03-30-2014 at 04:41 PM.

#25

Race Director

Member Since: Apr 2007

Location: South Western Ontario

Posts: 11,061

Received 845 Likes

on

721 Posts

The alternator runs at 14.4V. Take away the alternator and the battery runs at 12.5V. If you believe the battery can supply any current before the alternator is loaded down so it's output is also around 12.5V then you're the one that needs to go to school and learn something.

#26

Le Mans Master

Member Since: May 2003

Location: Fernandina Beach FL

Posts: 8,483

Received 3,222 Likes

on

1,733 Posts

2023 Restomod of the Year finalist

2020 C3 of the Year Winner - Modified

Have you ever even looked at the stock main power wiring? The wire runs from the alternator to the horn relay which is the main power distribution and then from there it branches off to the fuse panel, HVAC fan high speed relay and battery. Exactly the same layout as what I describe but updated to heavier wires and a bigger/better alternator to support more load.

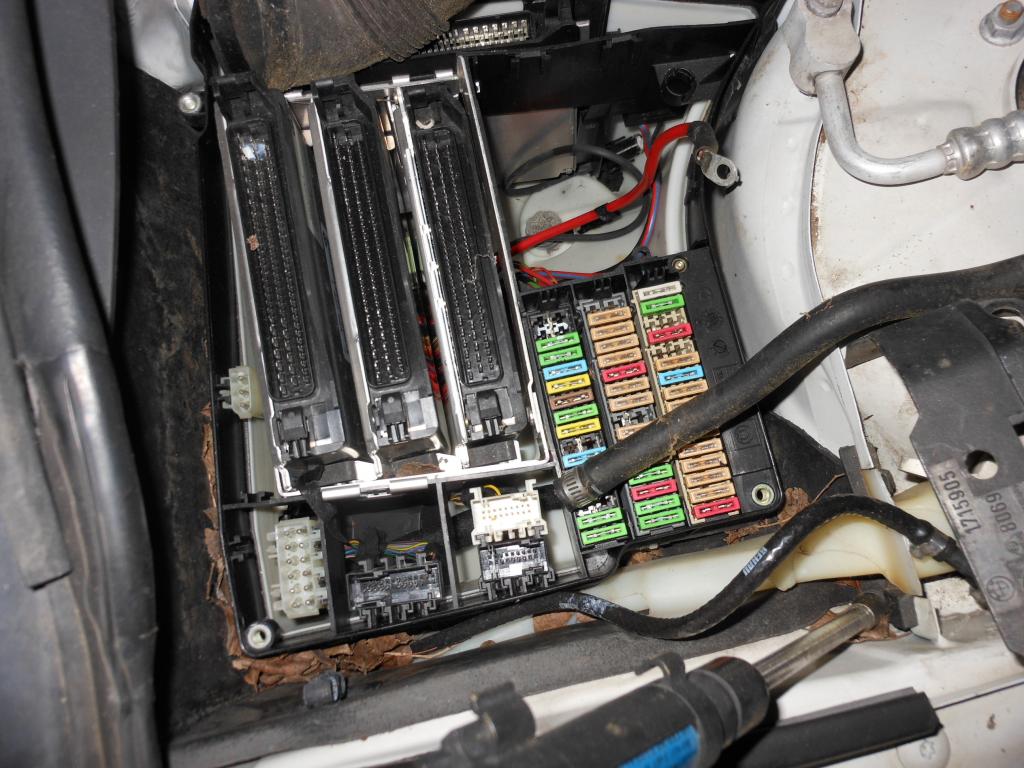

EVER look at a new car? Like one where the beancounters had NO influence on the design? Lets use a BMW 750IL- I just happen to have one laying around-$100k new...LOTs of electronics.... The engineers - I'm guessing a TEAM of them- decided the BEST way to do it was- RUN a LARGE gauge wire DIRECTLY from the alternator to the battery AND run everything OFF the battery.

I didn't sleep at a Holiday Inn last night (actually it was a Marriott but I digress...)-so here's how THEY did it-

Notice the 3 wires running back to the trunk- one to the starter- one to a forward fusebox and the third to the alternator. Oh BTW- the alt is NOT fused- the wire runs in it's own metal conduit in the engine compartment.

Please explain why this is not a good idea? It's not my idea- I just can't imagine of the engineers going to all this trouble to do it wrong...

#27

Race Director

Member Since: Apr 2007

Location: South Western Ontario

Posts: 11,061

Received 845 Likes

on

721 Posts

I could really care less how a new BMW is wired. The C3 in question doesn't have dozen of different computers in it and 1000's of feet of wiring like the BWM will have. The stock C3 wiring at 10awg could support around 40A or so of load and everything worked just fine. So, change to 6awg and it will support 100A of load just fine. You can waste time going overkill and running wires back to the battery but it's not necessary for everything to work fine in a C3.

#28

Race Director

Member Since: Apr 2007

Location: South Western Ontario

Posts: 11,061

Received 845 Likes

on

721 Posts

But the charging circuit doesn't run through an ammeter. It runs through a piece of wire and the small leads of what's really a voltmeter are connected at each end of that wire. The meter then measures the voltage drop in the wire and displays it as a current. So, this "ammeter" loses it's ability to display the proper current as soon as you upgrade the charging wire.

#29

Le Mans Master

Member Since: May 2003

Location: Fernandina Beach FL

Posts: 8,483

Received 3,222 Likes

on

1,733 Posts

2023 Restomod of the Year finalist

2020 C3 of the Year Winner - Modified

I could really care less how a new BMW is wired. The C3 in question doesn't have dozen of different computers in it and 1000's of feet of wiring like the BMW will have. The stock C3 wiring at 10awg could support around 40A or so of load and everything worked just fine. So, change to 6awg and it will support 100A of load just fine. You can waste time going overkill and running wires back to the battery but it's not necessary for everything to work fine in a C3.

Why not? You might learn something.

“Wisdom is not a product of schooling but of the lifelong attempt to acquire it.”

Albert Einstein

#30

Race Director

Member Since: Apr 2007

Location: South Western Ontario

Posts: 11,061

Received 845 Likes

on

721 Posts

with a 1969 as a reference vehicle and the first diagram i pulled up, the alternator is connected to the horn relay. the starter solenoid is connected to one side of the ammeter, and the horn relay is connected to the other side of the ammeter, forcing all charging current and vehicle loads through an ammeter that only registers 30amps in either direction. voltage meters can connect parallel, but ammeters get spliced in line to see the amount of current passing through them. connected in the manner i previously stated, the new loads and charging capacity would simply be invisible to the factory ammeter, and it would still read correct to the factory electrical loads.

There is simply no way you can upgrade the charging wires and still have the meter read correctly like it did before. If you install a whole new charging wire by removing the old alternator to horn relay wire and running a new wire directly to the battery or solenoid then the ammeter reads a discharge all the time due to the car loads. If you replace the charging wire with a heavier gauge then the voltage drop in the new wire will be less and the ammeter will read a lower current than what is really flowing. It would still indicate charging and discharging but the current level would be wrong.

Spending $60 for the replacement voltmeter linked earlier in this thread should be the easiest decision to make since it allows the wiring to be upgraded without having to worry about splicing that ammeter back into the circuit and then having it read the wrong current.

#31

Team Owner

but the charging circuit runs through an ammeter that cannot support 100 amps. but if a charging cable is run to the battery, and loads are connected at the starter lug, the ammeter and vehicles electrical system can stay original and ammeter will still work correctly and read accurately. and since ammeter is only a guage showing current flow and direction, and the alternator is internally regulated, the charging system will still work exactly like its supposed to. without any vehicle modification or sacrafices of guages

NO, what you dunno would fill a bucket.....RONG, flat out RONG@@@@!@!!!!

been there done that......

#32

Team Owner

I could really care less how a new BMW is wired. The C3 in question doesn't have dozen of different computers in it and 1000's of feet of wiring like the BWM will have. The stock C3 wiring at 10awg could support around 40A or so of load and everything worked just fine. So, change to 6awg and it will support 100A of load just fine. You can waste time going overkill and running wires back to the battery but it's not necessary for everything to work fine in a C3.

I dunno why, they run some decent machine shops....but show them an electron and they go ape......

#34

Instructor

Thread Starter

Lots of opinions and to each they could certainly be right and work. That's why I come here, see all the different options and learn I am learning a lot that's for sure.

The connect it to the battery part leaves me with a question and please don't take it wrong I am going from a different perspective, I work on computers so this is just a question to learn more or just unconfuse myself a little.

The battery cable goes from the starter to the battery sort of like a buss bar in a house fuse panel where lights etc tap off of it any place along its length, computers are kind of the same they run a buss that you tap off of so if you think of the battery cable as a bus bar what difference does it make which end (or even in the middle some place) I connect to tap power other than some resistance in the wire because of length.

Am I way out in left field there or would both ends yield the same result (of course I am leaving out a lot about how to connect, etc but just wondered.

IT is funny in a way, here we are talking about 100, 140, 200 amps and I just had a new house built and with all the modern appliances, wiring for lights, outlets, everything it is 200amp???

The connect it to the battery part leaves me with a question and please don't take it wrong I am going from a different perspective, I work on computers so this is just a question to learn more or just unconfuse myself a little.

The battery cable goes from the starter to the battery sort of like a buss bar in a house fuse panel where lights etc tap off of it any place along its length, computers are kind of the same they run a buss that you tap off of so if you think of the battery cable as a bus bar what difference does it make which end (or even in the middle some place) I connect to tap power other than some resistance in the wire because of length.

Am I way out in left field there or would both ends yield the same result (of course I am leaving out a lot about how to connect, etc but just wondered.

IT is funny in a way, here we are talking about 100, 140, 200 amps and I just had a new house built and with all the modern appliances, wiring for lights, outlets, everything it is 200amp???

#35

Team Owner

But an aircraft mechanic friend says Lucas is pretty good at aircraft 'tronics......I have never worked on an aircraft, probably much to the relief of the world......

AND SO, the bottom line case in my position IS, you expect a charge voltage of 14.8 upon startup.....so to make the battery happy, it will decline to ~13.4 after a while, and if you are running the a/c the electric fans will be pulling current IF wired from the battery lug, at starter or battery...no difference.....BUT that ~30 amp running voltage for the Spals will drop some voltage from alt. to bat. NOW if you run a few trip to the store in typical use....yes even a vette has to maintain THAT standard....with the a/c on, the current drain from the fan wire will drop voltage at the battery, reducing the charge available...

SO to ASSume those electric FANS care about a 700 mv ripple on the alt output stud is just silly.....

how do I know this??? Tektronics scope...and Fluke DVM and monitor several cars/builds over some years/decades now.....

Forgive me if maybe I don't type everything so clearly, but my overall theory and practice stands......

the way I read some of the above posts.....well, lets just say I know more.....

I will assume some of the above posts are just a misunderstanding due to expression of thoughts.....to assume otherwise is beyond BEYONDO!!!!

I will assume some of the above posts are just a misunderstanding due to expression of thoughts.....to assume otherwise is beyond BEYONDO!!!!

#36

Instructor

Thread Starter

irelandr that is awesome, I build and repair pc's too. gaming pc's. and host small scale lan parties at my home since like 05-06. awesome thing about computers is while ac and dc voltages are a different animal, everything inside a pc runs on dc 12v or less. how cool is that? it's almost like a computer just begs to be built into a car, no? you must see what built. here is my build thread- http://www.mp3car.com/show-off-your-...me-tuning.html this car does things most cars will never dream of doing.

#37

Team Owner

Lots of opinions and to each they could certainly be right and work. That's why I come here, see all the different options and learn I am learning a lot that's for sure.

The connect it to the battery part leaves me with a question and please don't take it wrong I am going from a different perspective, I work on computers so this is just a question to learn more or just unconfuse myself a little.

The battery cable goes from the starter to the battery sort of like a buss bar in a house fuse panel where lights etc tap off of it any place along its length, computers are kind of the same they run a buss that you tap off of so if you think of the battery cable as a bus bar what difference does it make which end (or even in the middle some place) I connect to tap power other than some resistance in the wire because of length.

Am I way out in left field there or would both ends yield the same result (of course I am leaving out a lot about how to connect, etc but just wondered.

IT is funny in a way, here we are talking about 100, 140, 200 amps and I just had a new house built and with all the modern appliances, wiring for lights, outlets, everything it is 200amp???

The connect it to the battery part leaves me with a question and please don't take it wrong I am going from a different perspective, I work on computers so this is just a question to learn more or just unconfuse myself a little.

The battery cable goes from the starter to the battery sort of like a buss bar in a house fuse panel where lights etc tap off of it any place along its length, computers are kind of the same they run a buss that you tap off of so if you think of the battery cable as a bus bar what difference does it make which end (or even in the middle some place) I connect to tap power other than some resistance in the wire because of length.

Am I way out in left field there or would both ends yield the same result (of course I am leaving out a lot about how to connect, etc but just wondered.

IT is funny in a way, here we are talking about 100, 140, 200 amps and I just had a new house built and with all the modern appliances, wiring for lights, outlets, everything it is 200amp???

take that same volt drop across a car battery trying to be charged....because you are running 30 amp, and the battery is not so happy in daily/city use.....

Look at the schematics....the source of the power is from the alt.....why loop all this load around the world???.....take the supid fans off the alt. directly, like I have for over 15 years now.....not to mention earlier car projects.....just to keep this related to my '72 vette.....

#38

Instructor

Thread Starter

On my list, don't think I have a ground problem but was going to run several grounds (radiator shell for fans, frame to block, transmission to cross member, etc just to be sure I had good ground everywhere and for anything I may do i the future.

#39

Instructor

Thread Starter

aircraft mechanics are less than auto mechanics. any honest aircraft mechanic will admit that. I know it might sound like the opposite would be true, but aviation mechanics is all about red tape. one person will tighten a blot, then another person will come behind him and verify tq on that bolt while a third will write down on paper that he whitnessed the whole ordeal. because of what happens if an aircraft breaks down mid-flight, this is how that industry is geared, leaving most aircraft mechanics feeling like their job is mindless labor. I go back and forth with my friend, Rob, in the airforce about who has the cooler job. I only work on vettes, but he works on f-16's and he is jelous of my job, while I am jelous of his.

#40

Team Owner

been a while.......