How much will a '80 Diff Handle?

#1

Racer

Thread Starter

Beginning resto mod of my 1980 Corvette. Hope to have the body off by Christmas.

The car is a 305 California car. Replacing the 305/automatic will be a Bill Mitchell Hardcore 454 SBC and a Richmond ROD 6 speed. The 454 was dyno'd at 590 flywheel HP. I will be detuning it somewhat by using a lower rise intake and a 4150 style carb.

I am very concerned about the rear end of this car. The car will probably never see the drag strip, and will more than likely have regular BF Goodrich Radial T/A's. No tires stickier than these. ( I thought these tires might be the 'fuse', and will spin before any ring and pinion breakage might occur) Nonetheless, there will be'testing' of the power output that's for sure. But, for the most part, it'll be just a cruiser. Is this rear end going to hold up? From what I've read, this may be the weakest rear of all the C3's.

I've read of the conversions to earlier C3 cast iron units, the 12 bolt center section conversion, or the live axle 12 bolt/Ford 9 Inch setups. The live axle swap is of interest, but wondering, if used, does this mandate a side pipe exhaust? Anyway, thanks for any thoughts you have. With the body off, that'll be the perfect time for any rear end mods. Once the whole deal is done, I'll be stuck.

The car is a 305 California car. Replacing the 305/automatic will be a Bill Mitchell Hardcore 454 SBC and a Richmond ROD 6 speed. The 454 was dyno'd at 590 flywheel HP. I will be detuning it somewhat by using a lower rise intake and a 4150 style carb.

I am very concerned about the rear end of this car. The car will probably never see the drag strip, and will more than likely have regular BF Goodrich Radial T/A's. No tires stickier than these. ( I thought these tires might be the 'fuse', and will spin before any ring and pinion breakage might occur) Nonetheless, there will be'testing' of the power output that's for sure. But, for the most part, it'll be just a cruiser. Is this rear end going to hold up? From what I've read, this may be the weakest rear of all the C3's.

I've read of the conversions to earlier C3 cast iron units, the 12 bolt center section conversion, or the live axle 12 bolt/Ford 9 Inch setups. The live axle swap is of interest, but wondering, if used, does this mandate a side pipe exhaust? Anyway, thanks for any thoughts you have. With the body off, that'll be the perfect time for any rear end mods. Once the whole deal is done, I'll be stuck.

Popular Reply

11-05-2015, 11:51 AM

Drifting

Let me point out first that the C4 Dana 44 and the C3 Dana 44 have absolutely nothing in common. Except for shim position, the C4 D44 is very similar to the iron C3 diff.

The C3 D44 is unique in the fact that the outer case does not support the side loading of the carrier. The bearing caps support the load. Nearly all diffs use the case for support. The exceptions are the Ford 9 inch, Mopar 8 3/4, and the C1/early chevy. But they have a different cap design. One of the major changes to the C4 D44 was they reverted back to the case supporting the side load.

The good points of the C3 D44:

The clutches use a Belleville spring which keeps the 4 spider gears in constant mesh. No backlash. No hammering effect.

30 spline stub axles. Even the very soft factory axles are almost impossible to twist.

Oversize stub axle bearings.

Bad points:

Lack of machining. I'll cover this later.

Weak support of the carrier.

Posi carrier. The right side clutches are not fully supported. The top 3 discs rely on a sheet metal retainer to hold them in place which it never does. They always strip the retainer and stack up the discs.

Rear pinion bearing very small. This was changed on the C4 D44.

The good and the bad:

Aluminium housing. Weight savings. Weak bearing caps.

Pinion bearing preload shims. Although they eliminate the use of a crush sleeve, having to stack .100-.110 in shims is too much. Very hard to set the preload.

The most unique design of Dana diffs are the placement of the shims. To set the pinion gear depth the shims are stacked behind the race, not the pinion bearing. Opposite of most diffs. This is not much of a problem on the iron Dana's but on the aluminum ones it can be. Every time you remove the race from the housing it gets looser. Improper removal of the race can ruin the housing.

The shims on the carrier are stacked behind the bearings, also opposite of most diffs. A pair of set up bearings are almost vital to have.

Here's the big question. How can someone with 400+hp beat on a C3 D44 with no problems yet 200 hp motors with autos blow them up? Because C3 D44's are not all them same. I mentioned earlier about the lack of machining. On every differential from any manufacturer the bearing caps sit on machined pads. Not the C3 D44. These caps sit on as-cast metal. And it is not smooth or flat. But that is not the big problem. The height of the casting determines the amount of metal removed from the cap during the boring process. A housing with a thick boss will have less metal removed from the cap. A housing with a low boss will have more metal removed from the cap. Now add to it the fact that the cap bolt holes are slotted which require the bolts to have a large washer made into the head. The cap is then notched to clear the bolt head. This notch is the thinnest part of the cap. It is also where all the caps crack. The thickness at the notch can be as thick as .340 to as little as .200. This thickness determines the strength of the diff.

I've mentioned before in other threads about cap stretch. 200 hp iron diffs don't have anything to worry about. But 500 hp and hard launches make it an issue. Even with the iron differentials. The average thickness of a C3 C44 cap (above the bearing) is less than .450. About equal to an iron diff cap. The C4 D44 caps were changed and have a full inch of metal above the bearing. Gm knew of the problem of cap stretch and added a bump stop in the C4 batwing. Even at 1 inch thickness they still develop cracks.

Mike

The C3 D44 is unique in the fact that the outer case does not support the side loading of the carrier. The bearing caps support the load. Nearly all diffs use the case for support. The exceptions are the Ford 9 inch, Mopar 8 3/4, and the C1/early chevy. But they have a different cap design. One of the major changes to the C4 D44 was they reverted back to the case supporting the side load.

The good points of the C3 D44:

The clutches use a Belleville spring which keeps the 4 spider gears in constant mesh. No backlash. No hammering effect.

30 spline stub axles. Even the very soft factory axles are almost impossible to twist.

Oversize stub axle bearings.

Bad points:

Lack of machining. I'll cover this later.

Weak support of the carrier.

Posi carrier. The right side clutches are not fully supported. The top 3 discs rely on a sheet metal retainer to hold them in place which it never does. They always strip the retainer and stack up the discs.

Rear pinion bearing very small. This was changed on the C4 D44.

The good and the bad:

Aluminium housing. Weight savings. Weak bearing caps.

Pinion bearing preload shims. Although they eliminate the use of a crush sleeve, having to stack .100-.110 in shims is too much. Very hard to set the preload.

The most unique design of Dana diffs are the placement of the shims. To set the pinion gear depth the shims are stacked behind the race, not the pinion bearing. Opposite of most diffs. This is not much of a problem on the iron Dana's but on the aluminum ones it can be. Every time you remove the race from the housing it gets looser. Improper removal of the race can ruin the housing.

The shims on the carrier are stacked behind the bearings, also opposite of most diffs. A pair of set up bearings are almost vital to have.

Here's the big question. How can someone with 400+hp beat on a C3 D44 with no problems yet 200 hp motors with autos blow them up? Because C3 D44's are not all them same. I mentioned earlier about the lack of machining. On every differential from any manufacturer the bearing caps sit on machined pads. Not the C3 D44. These caps sit on as-cast metal. And it is not smooth or flat. But that is not the big problem. The height of the casting determines the amount of metal removed from the cap during the boring process. A housing with a thick boss will have less metal removed from the cap. A housing with a low boss will have more metal removed from the cap. Now add to it the fact that the cap bolt holes are slotted which require the bolts to have a large washer made into the head. The cap is then notched to clear the bolt head. This notch is the thinnest part of the cap. It is also where all the caps crack. The thickness at the notch can be as thick as .340 to as little as .200. This thickness determines the strength of the diff.

I've mentioned before in other threads about cap stretch. 200 hp iron diffs don't have anything to worry about. But 500 hp and hard launches make it an issue. Even with the iron differentials. The average thickness of a C3 C44 cap (above the bearing) is less than .450. About equal to an iron diff cap. The C4 D44 caps were changed and have a full inch of metal above the bearing. Gm knew of the problem of cap stretch and added a bump stop in the C4 batwing. Even at 1 inch thickness they still develop cracks.

Mike

#2

Melting Slicks

Mike Dyer (tracdogg2 on the forum) is the guru on 80-82 Corvette Dana 44 diffs. He rebuilt the Dana 44 that went in my '73. He said it would be good up to 400 HP. Sounds like you are way over that. You might want to give him a call.

#3

Melting Slicks

Yes the Tires will be the Fuse. The Ring and Pinion is not the weak point generally the u-joints, stub shafts and Yokes are. The Carrier and its Posi have a short life as well. Is You Car a 4 Speed ? If so it should have the more desirable 1350 U-Joints. Pull a strap off a 1/2 shaft and check the bolts if its 5/16" you have the 1350 and if its 1/4" You have the smaller 1330 U-joints. Checking the end play on the Yokes will give you an idea of the condition of the rear it self. If the Oil is Black the Posi Clutch's are probably gone.

#4

Safety Car

Lower ratios are better and tires that spin are better , That said dead hook , sticky tire and you will have BOOM ................

#5

Melting Slicks

I have around 540 hp with my 406, and have been running the aluminum rear with 3.70 gears for years. Of course my automatic helps cushion some shock, but I have blasted 7000 rpm shifts many times, ...even with the MT 295 55 drag radials. Mine is a toy,...never raced, but mostly back road driven with an occasional burst of fun.

If you drive it like you claim,...."just a cruiser",...I think it'll last a long time for you.

If you drive it like you claim,...."just a cruiser",...I think it'll last a long time for you.

#6

I just put a new/used rear differential in my 81, the previous owner had it for around 3000-4000 miles and someone totaled his 81 in the front. He gave me the receipts and I called where he had it rebuilt, they rated it for 500HP. It has new hardened steel shafts and 3.07 gears, REM coating new gears, bearings, seals etc. The place that built it is called Duntov Motors and has free shipping and will buy back you old core parts.

I am not advertising for them, but just passing along what I came across in deciding whether to rebuild my original, or get one built.

I am not advertising for them, but just passing along what I came across in deciding whether to rebuild my original, or get one built.

#7

Drifting

Beginning resto mod of my 1980 Corvette. Hope to have the body off by Christmas.

The car is a 305 California car. Replacing the 305/automatic will be a Bill Mitchell Hardcore 454 SBC and a Richmond ROD 6 speed. The 454 was dyno'd at 590 flywheel HP. I will be detuning it somewhat by using a lower rise intake and a 4150 style carb.

I am very concerned about the rear end of this car. The car will probably never see the drag strip, and will more than likely have regular BF Goodrich Radial T/A's. No tires stickier than these. ( I thought these tires might be the 'fuse', and will spin before any ring and pinion breakage might occur) Nonetheless, there will be'testing' of the power output that's for sure. But, for the most part, it'll be just a cruiser. Is this rear end going to hold up? From what I've read, this may be the weakest rear of all the C3's.

I've read of the conversions to earlier C3 cast iron units, the 12 bolt center section conversion, or the live axle 12 bolt/Ford 9 Inch setups. The live axle swap is of interest, but wondering, if used, does this mandate a side pipe exhaust? Anyway, thanks for any thoughts you have. With the body off, that'll be the perfect time for any rear end mods. Once the whole deal is done, I'll be stuck.

The car is a 305 California car. Replacing the 305/automatic will be a Bill Mitchell Hardcore 454 SBC and a Richmond ROD 6 speed. The 454 was dyno'd at 590 flywheel HP. I will be detuning it somewhat by using a lower rise intake and a 4150 style carb.

I am very concerned about the rear end of this car. The car will probably never see the drag strip, and will more than likely have regular BF Goodrich Radial T/A's. No tires stickier than these. ( I thought these tires might be the 'fuse', and will spin before any ring and pinion breakage might occur) Nonetheless, there will be'testing' of the power output that's for sure. But, for the most part, it'll be just a cruiser. Is this rear end going to hold up? From what I've read, this may be the weakest rear of all the C3's.

I've read of the conversions to earlier C3 cast iron units, the 12 bolt center section conversion, or the live axle 12 bolt/Ford 9 Inch setups. The live axle swap is of interest, but wondering, if used, does this mandate a side pipe exhaust? Anyway, thanks for any thoughts you have. With the body off, that'll be the perfect time for any rear end mods. Once the whole deal is done, I'll be stuck.

#8

Le Mans Master

I just shucked the left rear half shaft and rear end on my '81. Less than 400 HP on automatic parts. The culprit was the small 1/4 " bolts that hold the straps for the u-joint. I sheared one off and BOOM. Very costly.

Use the manual transmission yokes and u-joints if you plan to stick with the Dana 44. The bolts and u-joints are larger.

#10

Le Mans Master

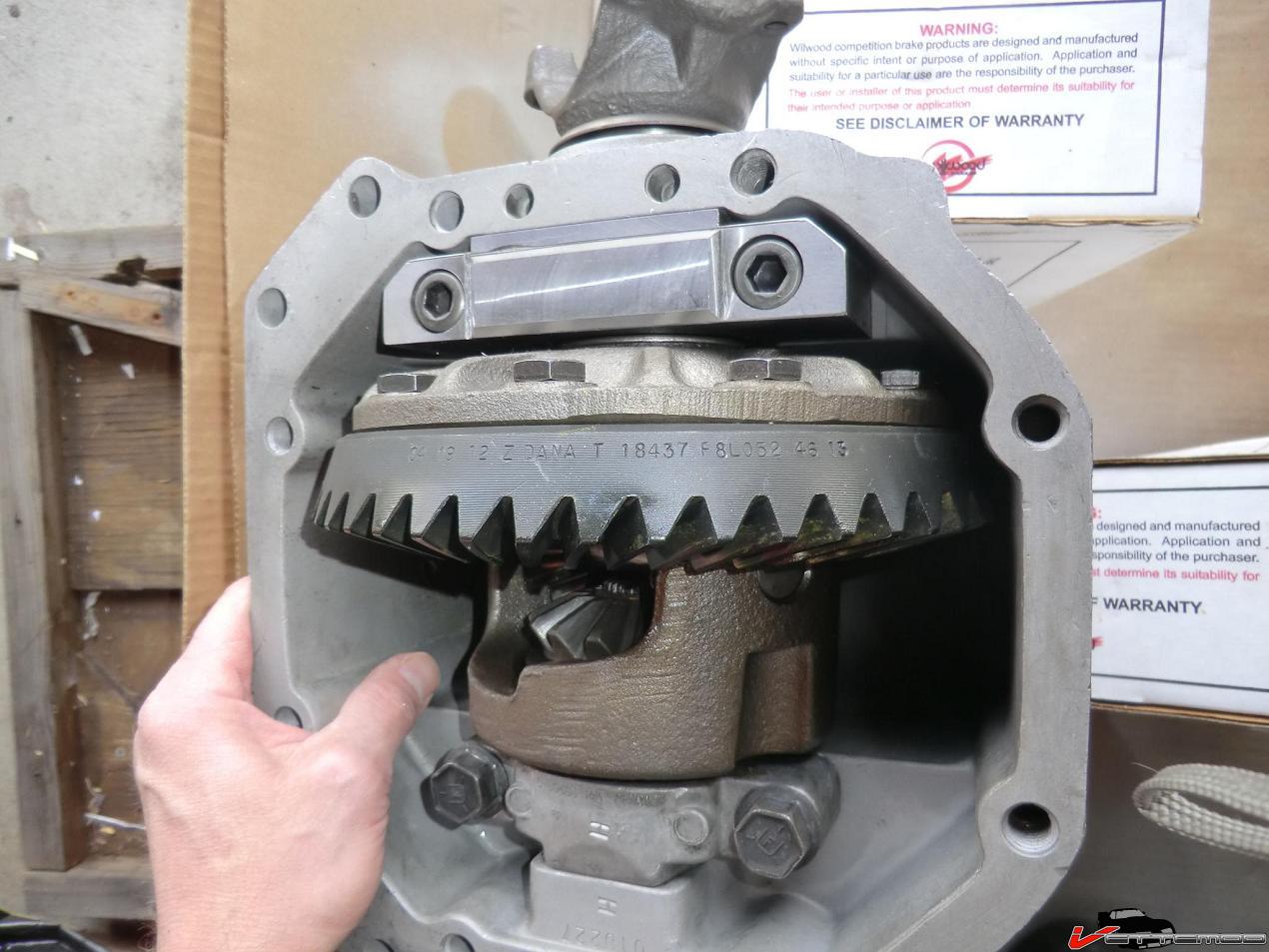

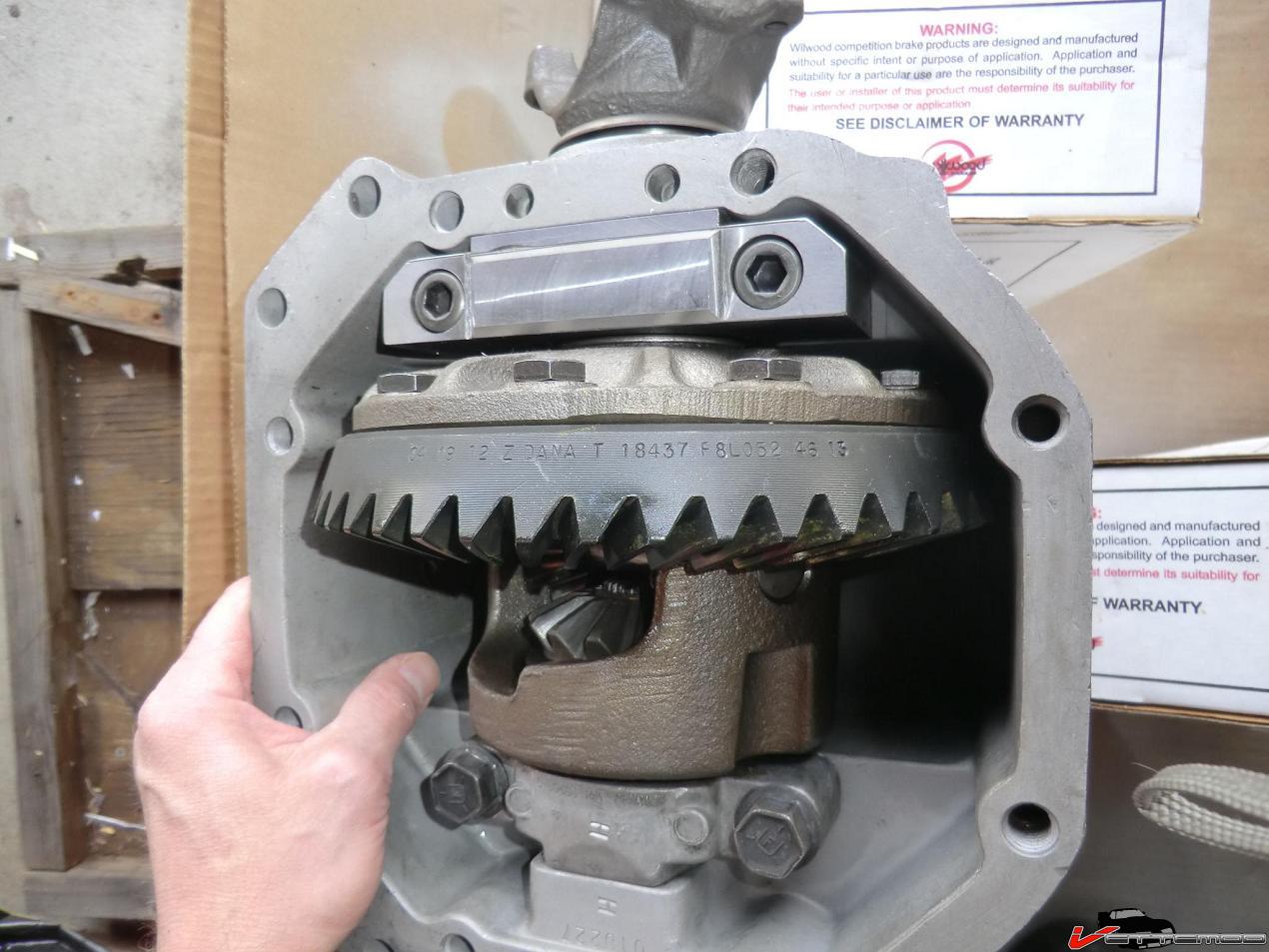

Since drag racing isn't your priority, you've all the more reason to stick with the IRS, but based IMOE one doesn't necessarily have to be on slicks or dumping the clutch at ridiculous revs to grenade a diff. Apply enough torque with sufficient bite very often and you WILL break something. That said, while you may not need to go as far as this, FYI here's what I have in my non-strip, AX/RR oriented shark...

Eaton 12-bolt posi IRS diff conversion with 31-spline Hy-Tuff yokes, 3" half-shafts with solid u-joints, high-nickel HD stub axles with 1/2" x 3" lug studs, solid diff x-member locating kit (3-point) and heim-jointed camber struts with lock plates (no eccentrics). I also have a late C3 batwing on hand, to which I plan on mating my 12-bolt IRS diff, tho I'm undecided whether to fab a mid-plate adapter or simply use pins in lieu of the two omitted cover bolts, as I'm not sure if or how much of a possible risk is housing distortion.

FWIW, my diff was done by Henry's Machine Works w/Pepe Estrada (the original "Taxing the IRS" guru) way back when, so you'll need to enlist someone else such as Mike D or Gary R if you want a HD 10-bolt or 12-bolt IRS unit built. A word of caution: I'd be seated when you inquire about the cost involved, as this level of work doesn't come cheap. Except for what I've spent on engines, my IRS setup is most probably worth more than the rest of my car.

TSW

edit - Mike, I for one never get tired of reading your driveline related material.

Eaton 12-bolt posi IRS diff conversion with 31-spline Hy-Tuff yokes, 3" half-shafts with solid u-joints, high-nickel HD stub axles with 1/2" x 3" lug studs, solid diff x-member locating kit (3-point) and heim-jointed camber struts with lock plates (no eccentrics). I also have a late C3 batwing on hand, to which I plan on mating my 12-bolt IRS diff, tho I'm undecided whether to fab a mid-plate adapter or simply use pins in lieu of the two omitted cover bolts, as I'm not sure if or how much of a possible risk is housing distortion.

FWIW, my diff was done by Henry's Machine Works w/Pepe Estrada (the original "Taxing the IRS" guru) way back when, so you'll need to enlist someone else such as Mike D or Gary R if you want a HD 10-bolt or 12-bolt IRS unit built. A word of caution: I'd be seated when you inquire about the cost involved, as this level of work doesn't come cheap. Except for what I've spent on engines, my IRS setup is most probably worth more than the rest of my car.

TSW

edit - Mike, I for one never get tired of reading your driveline related material.

Last edited by TheSkunkWorks; 11-04-2015 at 10:50 AM.

#11

Drifting

Thanks.

It looks like the mid-plate needs to be a minimum of 1/4 inch thick. Haven't figured out a solution for the two missing bolts. But I'm still working on it.

Mike

It looks like the mid-plate needs to be a minimum of 1/4 inch thick. Haven't figured out a solution for the two missing bolts. But I'm still working on it.

Mike

#12

#13

Drifting

#14

Drifting

I would also like to see you're right up. I have a 1980 with 383/436hp and a 700r4 transmission with factory Dana 44.

Last edited by havesometo; 11-04-2015 at 02:13 PM.

#15

Racer

Thread Starter

Thanks for the great replies. Love to hear the long version of the 80-82 diff story. My car has an automatic, so I'll, at the very least, look into the 4 speed parts when I get into the diff.

#17

#18

Drifting

Let me point out first that the C4 Dana 44 and the C3 Dana 44 have absolutely nothing in common. Except for shim position, the C4 D44 is very similar to the iron C3 diff.

The C3 D44 is unique in the fact that the outer case does not support the side loading of the carrier. The bearing caps support the load. Nearly all diffs use the case for support. The exceptions are the Ford 9 inch, Mopar 8 3/4, and the C1/early chevy. But they have a different cap design. One of the major changes to the C4 D44 was they reverted back to the case supporting the side load.

The good points of the C3 D44:

The clutches use a Belleville spring which keeps the 4 spider gears in constant mesh. No backlash. No hammering effect.

30 spline stub axles. Even the very soft factory axles are almost impossible to twist.

Oversize stub axle bearings.

Bad points:

Lack of machining. I'll cover this later.

Weak support of the carrier.

Posi carrier. The right side clutches are not fully supported. The top 3 discs rely on a sheet metal retainer to hold them in place which it never does. They always strip the retainer and stack up the discs.

Rear pinion bearing very small. This was changed on the C4 D44.

The good and the bad:

Aluminium housing. Weight savings. Weak bearing caps.

Pinion bearing preload shims. Although they eliminate the use of a crush sleeve, having to stack .100-.110 in shims is too much. Very hard to set the preload.

The most unique design of Dana diffs are the placement of the shims. To set the pinion gear depth the shims are stacked behind the race, not the pinion bearing. Opposite of most diffs. This is not much of a problem on the iron Dana's but on the aluminum ones it can be. Every time you remove the race from the housing it gets looser. Improper removal of the race can ruin the housing.

The shims on the carrier are stacked behind the bearings, also opposite of most diffs. A pair of set up bearings are almost vital to have.

Here's the big question. How can someone with 400+hp beat on a C3 D44 with no problems yet 200 hp motors with autos blow them up? Because C3 D44's are not all them same. I mentioned earlier about the lack of machining. On every differential from any manufacturer the bearing caps sit on machined pads. Not the C3 D44. These caps sit on as-cast metal. And it is not smooth or flat. But that is not the big problem. The height of the casting determines the amount of metal removed from the cap during the boring process. A housing with a thick boss will have less metal removed from the cap. A housing with a low boss will have more metal removed from the cap. Now add to it the fact that the cap bolt holes are slotted which require the bolts to have a large washer made into the head. The cap is then notched to clear the bolt head. This notch is the thinnest part of the cap. It is also where all the caps crack. The thickness at the notch can be as thick as .340 to as little as .200. This thickness determines the strength of the diff.

I've mentioned before in other threads about cap stretch. 200 hp iron diffs don't have anything to worry about. But 500 hp and hard launches make it an issue. Even with the iron differentials. The average thickness of a C3 C44 cap (above the bearing) is less than .450. About equal to an iron diff cap. The C4 D44 caps were changed and have a full inch of metal above the bearing. Gm knew of the problem of cap stretch and added a bump stop in the C4 batwing. Even at 1 inch thickness they still develop cracks.

Mike

The C3 D44 is unique in the fact that the outer case does not support the side loading of the carrier. The bearing caps support the load. Nearly all diffs use the case for support. The exceptions are the Ford 9 inch, Mopar 8 3/4, and the C1/early chevy. But they have a different cap design. One of the major changes to the C4 D44 was they reverted back to the case supporting the side load.

The good points of the C3 D44:

The clutches use a Belleville spring which keeps the 4 spider gears in constant mesh. No backlash. No hammering effect.

30 spline stub axles. Even the very soft factory axles are almost impossible to twist.

Oversize stub axle bearings.

Bad points:

Lack of machining. I'll cover this later.

Weak support of the carrier.

Posi carrier. The right side clutches are not fully supported. The top 3 discs rely on a sheet metal retainer to hold them in place which it never does. They always strip the retainer and stack up the discs.

Rear pinion bearing very small. This was changed on the C4 D44.

The good and the bad:

Aluminium housing. Weight savings. Weak bearing caps.

Pinion bearing preload shims. Although they eliminate the use of a crush sleeve, having to stack .100-.110 in shims is too much. Very hard to set the preload.

The most unique design of Dana diffs are the placement of the shims. To set the pinion gear depth the shims are stacked behind the race, not the pinion bearing. Opposite of most diffs. This is not much of a problem on the iron Dana's but on the aluminum ones it can be. Every time you remove the race from the housing it gets looser. Improper removal of the race can ruin the housing.

The shims on the carrier are stacked behind the bearings, also opposite of most diffs. A pair of set up bearings are almost vital to have.

Here's the big question. How can someone with 400+hp beat on a C3 D44 with no problems yet 200 hp motors with autos blow them up? Because C3 D44's are not all them same. I mentioned earlier about the lack of machining. On every differential from any manufacturer the bearing caps sit on machined pads. Not the C3 D44. These caps sit on as-cast metal. And it is not smooth or flat. But that is not the big problem. The height of the casting determines the amount of metal removed from the cap during the boring process. A housing with a thick boss will have less metal removed from the cap. A housing with a low boss will have more metal removed from the cap. Now add to it the fact that the cap bolt holes are slotted which require the bolts to have a large washer made into the head. The cap is then notched to clear the bolt head. This notch is the thinnest part of the cap. It is also where all the caps crack. The thickness at the notch can be as thick as .340 to as little as .200. This thickness determines the strength of the diff.

I've mentioned before in other threads about cap stretch. 200 hp iron diffs don't have anything to worry about. But 500 hp and hard launches make it an issue. Even with the iron differentials. The average thickness of a C3 C44 cap (above the bearing) is less than .450. About equal to an iron diff cap. The C4 D44 caps were changed and have a full inch of metal above the bearing. Gm knew of the problem of cap stretch and added a bump stop in the C4 batwing. Even at 1 inch thickness they still develop cracks.

Mike

The following 7 users liked this post by tracdogg2:

76custompaint (11-05-2015),

BlackC3vette (11-05-2015),

Illegal Vette (11-06-2015),

Jeffs82c3 (11-30-2015),

mbhnm (11-11-2015),

and 2 others liked this post.

#19

Racer

Thread Starter

Thanks so much for the detailed info. Seems the best thing to do is to see what my diff looks like once removed and make some decisions based on what I find.

And thanks also to TheSkunkWorks for the info on costs involved with a 12 bolt setup. I just finished a 509BBC major redo on my Nova, which went over budget. Costs on this project will be of consideration, as I'm doing the whole car i.e. new interior, paint, and installation of a '82 CE openable rear hatch.

And thanks also to TheSkunkWorks for the info on costs involved with a 12 bolt setup. I just finished a 509BBC major redo on my Nova, which went over budget. Costs on this project will be of consideration, as I'm doing the whole car i.e. new interior, paint, and installation of a '82 CE openable rear hatch.

#20

Melting Slicks

Ok Mike, now tell the people how you make the D44 all better.