Another '79 tach problem

#1

Racer

Thread Starter

I had a bad tach board on my '79 so I replaced it with a new board and new filter from Corvette America. I removed and replaced the needle to zero with the ignition on, started the car and tach seemed to work fine. Drove the car today for first time after installing new board and the tach reads maybe 800 or 900 rpm to high. Still reads zero with engine off and ignition on. Any ideas on what the problem could be besides bad new board.I bought the board and filter a couple months ago so I don't know if Corvette America will replace it.

#2

I had a bad tach board on my '79 so I replaced it with a new board and new filter from Corvette America. I removed and replaced the needle to zero with the ignition on, started the car and tach seemed to work fine. Drove the car today for first time after installing new board and the tach reads maybe 800 or 900 rpm to high. Still reads zero with engine off and ignition on. Any ideas on what the problem could be besides bad new board.I bought the board and filter a couple months ago so I don't know if Corvette America will replace it.

This video shows how to do it.

#3

Racer

Thread Starter

Soooo how do you calibrate the board if you don't have a generator. As I said, I already set the needle to zero with engine off and ignition on. Is there an adjustment on the board that changes the needle position at higher rpm's to match the rpm of a know good aftermarket tach.

#4

Soooo how do you calibrate the board if you don't have a generator. As I said, I already set the needle to zero with engine off and ignition on. Is there an adjustment on the board that changes the needle position at higher rpm's to match the rpm of a know good aftermarket tach.

#5

Racer

Thread Starter

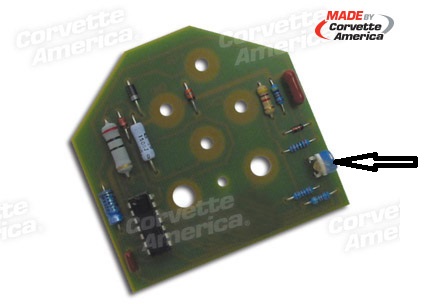

Great, that's what I will do. Does anyone have a picture of the circuit board showing where the adjustment screw or whatever it is to adjust the rpm is located.

#8

Just showing my age, but don't you have an old Dwell Meter? Mine also displays engine RPM.....

NOTE: Yes, I still have the old Dwell Meter. Haven't used it in ages, but now I know it could serve a purpose.

Well.... except my EZ-EFI also displays RPM.

Soooo how do you calibrate the board if you don't have a generator. As I said, I already set the needle to zero with engine off and ignition on. Is there an adjustment on the board that changes the needle position at higher rpm's to match the rpm of a know good aftermarket tach.

Well.... except my EZ-EFI also displays RPM.

Last edited by carriljc; 06-11-2017 at 09:42 PM.

#9

Racer

Thread Starter

OK, I removed the tach and circuit board from my car, connected jumper wires from the three sockets on the gauge cluster to the three screws on the circuit board that mate to those three sockets. I then hooked up my dial back timing light that has a built in tach to compare rpm's with the car's tach. I turned on the ignition switch and the needle on the car's tach registered at zero. I started the car and the car's tach registered 500 rpm higher at idle than the timing light tach. Revved the car to progressively higher rpm's to 3000 rpm on the timing light tach and the car tach was 1400 rpm higher. NOT GOOD I then slightly turned the calibration screw on the circuit board but the car tach's rpm did not change. Turned the screw a little more with no change, moved it back to original position and the turned it the other way still with no results. Never could get the calibration adjustment screw to make any change in the tach's behavior at all. RATS So I called the good people at Corvette America, where I bought the circuit board and explained the situation and they volunteered to send me a new circuit board at no charge. GREAT CUSTOMER SERVICE. When the replacement arrives I will post with the results.

#10

Former Vendor

Member Since: Aug 2006

Location: Jeffersonville Indiana 812-288-7103

Posts: 76,656

Received 1,813 Likes

on

1,458 Posts

St. Jude Donor '08-'09-'10-'11-'12-'13-'14-'15

It's the imported board and doesn't have a very high success rate without tweaking. The reason I know is I used to sell that board and fix them before we sold them. It also has a 1 turn pot on it and you can usually tap the pot and make the reading change.

But... I'm not here to put down that board, for years before I made my own it was all I could get and use and fixing the issue was not a huge deal for us.

So lets visit why you didn't see any change... ( Antz81, I think we put a note up on that video warning people of this but if not I'll get one added). The pot makes micro changes at the lower RPM's... it makes huge changes at the top end. So adjusting the needle at say 500-700 rpms... you'll hardly see anything different.

When we pre-calibrate the boards we do them at 4000 rpms. Once we adjust the board to 4k then all the other readings usually fall in place. What issues this causes... most people don't want to hold their car at 4k to calibrate the circuit board and even doing it at 3000 rpms is an issue. So turning the pot at say 500 should have made the needle move, but only so slightly and with the pot on your board being a 1 turn pot it probably made all kinds of changes at the higher end that you didn't see...

There may not have been anything wrong with the board aside from just not being calibrated properly and I hope the new one you get works fine. If not, we'll you know where to find one that will.

Willcox

But... I'm not here to put down that board, for years before I made my own it was all I could get and use and fixing the issue was not a huge deal for us.

So lets visit why you didn't see any change... ( Antz81, I think we put a note up on that video warning people of this but if not I'll get one added). The pot makes micro changes at the lower RPM's... it makes huge changes at the top end. So adjusting the needle at say 500-700 rpms... you'll hardly see anything different.

When we pre-calibrate the boards we do them at 4000 rpms. Once we adjust the board to 4k then all the other readings usually fall in place. What issues this causes... most people don't want to hold their car at 4k to calibrate the circuit board and even doing it at 3000 rpms is an issue. So turning the pot at say 500 should have made the needle move, but only so slightly and with the pot on your board being a 1 turn pot it probably made all kinds of changes at the higher end that you didn't see...

There may not have been anything wrong with the board aside from just not being calibrated properly and I hope the new one you get works fine. If not, we'll you know where to find one that will.

Willcox

#11

It's the imported board and doesn't have a very high success rate without tweaking. The reason I know is I used to sell that board and fix them before we sold them. It also has a 1 turn pot on it and you can usually tap the pot and make the reading change.

But... I'm not here to put down that board, for years before I made my own it was all I could get and use and fixing the issue was not a huge deal for us.

So lets visit why you didn't see any change... ( Antz81, I think we put a note up on that video warning people of this but if not I'll get one added). The pot makes micro changes at the lower RPM's... it makes huge changes at the top end. So adjusting the needle at say 500-700 rpms... you'll hardly see anything different.

When we pre-calibrate the boards we do them at 4000 rpms. Once we adjust the board to 4k then all the other readings usually fall in place. What issues this causes... most people don't want to hold their car at 4k to calibrate the circuit board and even doing it at 3000 rpms is an issue. So turning the pot at say 500 should have made the needle move, but only so slightly and with the pot on your board being a 1 turn pot it probably made all kinds of changes at the higher end that you didn't see...

There may not have been anything wrong with the board aside from just not being calibrated properly and I hope the new one you get works fine. If not, we'll you know where to find one that will.

Willcox

But... I'm not here to put down that board, for years before I made my own it was all I could get and use and fixing the issue was not a huge deal for us.

So lets visit why you didn't see any change... ( Antz81, I think we put a note up on that video warning people of this but if not I'll get one added). The pot makes micro changes at the lower RPM's... it makes huge changes at the top end. So adjusting the needle at say 500-700 rpms... you'll hardly see anything different.

When we pre-calibrate the boards we do them at 4000 rpms. Once we adjust the board to 4k then all the other readings usually fall in place. What issues this causes... most people don't want to hold their car at 4k to calibrate the circuit board and even doing it at 3000 rpms is an issue. So turning the pot at say 500 should have made the needle move, but only so slightly and with the pot on your board being a 1 turn pot it probably made all kinds of changes at the higher end that you didn't see...

There may not have been anything wrong with the board aside from just not being calibrated properly and I hope the new one you get works fine. If not, we'll you know where to find one that will.

Willcox

when i did mine (also a board from corvette america) i first adjusted it at idle to get it close (was about 300 out) then took it up to 4000 to fine tune it.

even at idle there should have been a change. But you are right it would be a greater error at high rpm if not correctly calibrated.

#12

Racer

Thread Starter

well, the new replacement tach circuit board from Corvette America arrived today. I removed the defective circuit board from my tach and installed the new replacement board that I just received. I then pluged it into my gauge cluster turned the ignition switch to run and set the pointer to zero. Moment of truth, I started the car, the tach worked but it seemed the engine was running at a lower rpm than what the tach was indicating. So I removed the tach, hooked three jumper wires from the dash sockets and to the three mating studs on the tach. Hooked up my timing light and started the engine. Sure enough the tach was reading 1100 rpm faster than the timing light tach. Just like the previous circuit board had indicated. I revved the engine to 4000 rpm and held it steady as I turned the calibration screw until the car tach matched the timing light tach. The reading of the car tach was then consistant with the timing light tach through out the entire rpm range just as Wilcox said it would. Another problem fixed thanks to the Corvette forum  This makes me wonder how many tach circuit boards have been installed in C3's over the years that have not been calibrated and are giving false reading that the owners who are not even aware of it. And why do companies continue to sell circuit boards without information stating that they need to be calibrated and provide instructions for such. Wilcox excluded !! Thanks for the help

This makes me wonder how many tach circuit boards have been installed in C3's over the years that have not been calibrated and are giving false reading that the owners who are not even aware of it. And why do companies continue to sell circuit boards without information stating that they need to be calibrated and provide instructions for such. Wilcox excluded !! Thanks for the help

This makes me wonder how many tach circuit boards have been installed in C3's over the years that have not been calibrated and are giving false reading that the owners who are not even aware of it. And why do companies continue to sell circuit boards without information stating that they need to be calibrated and provide instructions for such. Wilcox excluded !! Thanks for the help

This makes me wonder how many tach circuit boards have been installed in C3's over the years that have not been calibrated and are giving false reading that the owners who are not even aware of it. And why do companies continue to sell circuit boards without information stating that they need to be calibrated and provide instructions for such. Wilcox excluded !! Thanks for the help

#13

Former Vendor

Member Since: Aug 2006

Location: Jeffersonville Indiana 812-288-7103

Posts: 76,656

Received 1,813 Likes

on

1,458 Posts

St. Jude Donor '08-'09-'10-'11-'12-'13-'14-'15

good deal... most don't want to take the car to 4K... I'm glad you're fixed.

Willcox

Willcox